Professional Documents

Culture Documents

RA Bowtie Methodology

Uploaded by

pankajbhatt376Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA Bowtie Methodology

Uploaded by

pankajbhatt376Copyright:

Available Formats

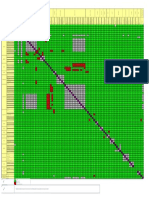

Case study – Incident at Yashashvi Rasayan Pvt Ltd.

, Dahej

Risk Assessment by the bowtie methodology www.sudakshaconsulting.com

Analysis models for risk management and incident analysis explained here is limited to the information available in public domain. The illustration is an example to demonstrate the

Ambient Environment

conditions

Continuous weather Provide shelter to Provide observation

monitoring in the sensitve booths/ towers for

location instrumentation monitoring

Sudaksha Management Solutions LLP or its personnel do not claim to have first hand information and are not liable for the accuracy of the incident information considered for the discussion.

Storage site

conditions

siting & construction - Implementation of Restrict storage of Colour coding of Implement additional

Used on 1 Incident Installation of flame Display signages for

MoEF, PESO & PCB storage license authorised materials pipelines for controls as and when

proof electrical fittings adherence

approvals conditions only identification - IS 2379 facility is expanded

Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident

Fail 100% Fail 100% Fail 100% Fail 100% Fail 0% Fail 100% Fail 100%

(1 of 1) (1 of 1) (1 of 1) (1 of 1) (0 of 1) (1 of 1) (1 of 1)

Storage of chemcals

for manufacturing

operations

comprehensiveness of bowtie methodology and is based on the EHS, technical and process expertise of our available with Sudaksha Management Solutions LLP.

Working conditions

in the site Used on 1 Incident

Unloading material Deployment of Adherence to SoP & Deployment of Use of approved &

from tankers Restrict entry only to Round the clock adequate stand-by to

qualified & trained checklist for operation certified tools and

complying with CMVR authorised persons supervision by experts man during rest

personnel steps - SDS extract tackles

rule 9, 129 - 134 intervals

Operations

monitoring Loss of control

Unloading material Installation of gas in chemical

seamless monitoring 24/7 manned Shut down systems for

Used on 1 Incident from tankers Implementation of detection systems to containment

from central control operations with stand- controlled shut down

complying with CMVR work permit system detect spillages /

room by support during abnormalities

rule 9, 129 - 134 leakages

Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident

Used on 1 Incident Used on 1 Incident

Fail 100% Fail 100% Fail 100% Fail 100%

Fail 100% Fail 100%

(1 of 1) (1 of 1) (1 of 1) (1 of 1)

(1 of 1) (1 of 1)

Piping and

instrumentation

integrity

use materials for Routing of pipelines to Colour coding of Pressure testing of Pressure control Carry out periodical

pipelines compatible Earthing and bonding devices (valves,

prevent vehicle cross pipelines for piplines & vessels for maintenance as per

transmission fluid (E.g, to maintain continuity rupture discs) to

over identification - IS 2379 mechincal integrity established plans

glass lining for Nitric monitor safe working

acid) pressure

This effort is in academic interest to enhance approach to safety for a stronger risk management in industrial operations.

Tanker truck

operations

Limit entry to vehicles Deployment of wheel Routing of pipelines

Movement of vehicles facilitating vehicle

complying with CMVR chokes for TT before

in defined paths cross over and prevent

rule 9, 129 - 134 filling operations

damages

Seamless power

supply for operations

Install dedicated Operation of AMF DG

UPS backup for critical

power supply line from sets in case of load

operations

ESCOM shedding

Awareness in the

local community

Conduct periodical Knowledge sharing on Conduct periodical Involvement in

training and Do's donts through table top exercises periodical On-site and

awareness campaigns leaflets and local with stake holders & off-site mock drills

media MARG

Run away reactions /

gas release to

atmosphere

Stop operations and Neutralisation of the Stop all activities Activate reponse Make annoucements

Storage of chemcals Dyke wall to contain involving use of energy measures as per informing community

Shut down the plant in spill as per SDS B0 B0 C0 B1

for manufacturing the spill to prevent ignition in onsite / offsite in the vicinity and

a controlled sequence recommendations

operations the location emergency response evacuate them to safe

plans locations

Used on 1 Incident

Fire / explosions

Stop all activities Evacuation of Neutralisation of the Activation of automatic Fire mitigation using Cordon the site for

involving use of energy personnel from the spill as per SDS fire fighting systems to equipment, personnel investigation & related Used on 1 Incident

to prevent ignition affected area to safe recommendations contain the damage & MARG resources process

zones C2 C1 B2 C1

Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident Used on 1 Incident

Loss of control Used on 1 Incident

in chemical Fail 100% Fail 100% Fail 100% Fail 100% Fail 0%

Fail 100%

containment (1 of 1) (1 of 1) (1 of 1) (1 of 1) (0 of 1)

(1 of 1)

Injuries / fatalities

Evacuation of Provide first aid Operate relief camps Shift personnel with Inform families of

personnel from the treatment for minor through doctors from major injuries to injured persons & take Used on 1 Incident

affected area to safe injuries in the site OHC nearby hospitals & hospital for treatment necessary measures to

zones MARG fufill legal formalities

Used on 1 Incident Used on 1 Incident

Used on 1 Incident Used on 1 Incident Used on 1 Incident

Fail 100% Fail 100%

Fail 100% Fail 100% Fail 0%

(1 of 1) (1 of 1)

(1 of 1) (1 of 1) (0 of 1)

Loss of reputation

Cordon the site for Issue public statement Provide relief Conduct and Comply with legal

investigation & related in local media to measures to all participate in requirements for

process inform the incident affected to ensure investigation by restoration of

their safety and well experts to identify normalcy

being failure causes

Incident Analysis by - Barrier failure Analysis Technique

Operations

Fire / explosions

monitoring

Unloading material seamless monitoring 24/7 manned Installation of gas Shut down systems for Stop all activities Evacuation of Neutralisation of the Activation of automatic Fire mitigation using Cordon the site for

from tankers Implementation of detection systems to personnel from the

from central control operations with stand- controlled shut down involving use of energy spill as per SDS fire fighting systems to equipment, personnel investigation & related

complying with CMVR work permit system detect spillages / affected area to safe

room by support during abnormalities to prevent ignition recommendations contain the damage & MARG resources process

rule 9, 129 - 134 leakages zones

Storage of chemcals

for manufacturing

operations / Loss of

control in chemical

containment

Storage site

Injuries / fatalities

conditions

siting & construction Implementation of Restrict storage of Colour coding of Implement additional Evacuation of Provide first aid Shift personnel with Operate relief camps Inform families of

Display signages for personnel from the through doctors from injured persons & take

of facility - MoEF & storage license authorised materials pipelines for controls as and when treatment for minor major injuries to

adherence affected area to safe nearby hospitals & necessary measures to

PCB approvals conditions only identification - IS 2379 facility is expanded injuries in the site OHC hospital for treatment

zones MARG fufill legal formalities

ST1 New chemicals PL1 Pipeline colour

Chemical storages Pipeline color had

were added without faded

approvals

Legends - Barrier failure modes

PL2 Exposure to

ST 2 Temporary extreme weather

storage Pipelines were exposed

Temporary storage due to extreme weathers

to urgent customer leading to erosion of

requirements colours

MOC Management of PL3 Paint selection

change Cheap paints selected

No management due to budget and cost

intervention to review constraints

chages in site

operation

You might also like

- If I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)From EverandIf I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)No ratings yet

- ) Dvflfxohg H (Huflfhvfruuljpv: Filière de Sciences Économiques Et de GestionDocument133 pages) Dvflfxohg H (Huflfhvfruuljpv: Filière de Sciences Économiques Et de GestionHamid BassourNo ratings yet

- Load, N Male, 10watt: Product Data Sheet N-TER-10Document1 pageLoad, N Male, 10watt: Product Data Sheet N-TER-10Mani_3ipNo ratings yet

- Formula Sheet Introduction To ElectrodynamicsDocument3 pagesFormula Sheet Introduction To ElectrodynamicsHemang ChopraNo ratings yet

- Rdehradun DistfDocument1 pageRdehradun DistfSagarNo ratings yet

- Les CascadesDocument3 pagesLes Cascadeshs77grtm79No ratings yet

- HULTO MBZH: Omvlochten Halogeenvrije InstallatiekabelDocument3 pagesHULTO MBZH: Omvlochten Halogeenvrije InstallatiekabelRamses De LeeuwNo ratings yet

- CascadesDocument3 pagesCascadesapi-3740041No ratings yet

- En-Route ChartsDocument1 pageEn-Route ChartsSamphan TreepisanNo ratings yet

- 31122018HE0QRKXJChaptersFinalEIAsingalPdf PDFDocument272 pages31122018HE0QRKXJChaptersFinalEIAsingalPdf PDFChitti NenavathNo ratings yet

- CompatibilityMatrix FINEMarineDocument1 pageCompatibilityMatrix FINEMarineICMG ConsultancyNo ratings yet

- Plan Model2Document1 pagePlan Model2Moch Sauma Ridho PangersaNo ratings yet

- Panorama To Promote Safety (Arabic)Document21 pagesPanorama To Promote Safety (Arabic)Ali MarhoonNo ratings yet

- Interpreting Cointegrated ModelsDocument34 pagesInterpreting Cointegrated ModelsrunawayyyNo ratings yet

- Entsog Gie Sysdev 2020-2021Document1 pageEntsog Gie Sysdev 2020-2021Arief MujiyantoNo ratings yet

- Worksheet - Decision-Making and Problem-SolvingDocument4 pagesWorksheet - Decision-Making and Problem-SolvingYasir Butt100% (1)

- 01 - Large NetworksDocument38 pages01 - Large Networksasim zamanNo ratings yet

- Brahma Township Revised LayoutDocument1 pageBrahma Township Revised LayoutIkhlaaque AlamNo ratings yet

- Kontur: Produced by An Autodesk Student VersionDocument1 pageKontur: Produced by An Autodesk Student VersionDiphda IlhamNo ratings yet

- A4 Hazardous Areas Site Map Final AW 2Document1 pageA4 Hazardous Areas Site Map Final AW 2Joylyn ManioNo ratings yet

- Matsama Abil Hasan 2021 Form BedaharaDocument1 pageMatsama Abil Hasan 2021 Form Bedaharaelsa diadorapambayunNo ratings yet

- Pet Suites Building SF 13,900 : BelowDocument1 pagePet Suites Building SF 13,900 : BelowchrisNo ratings yet

- Enrout ChartDocument1 pageEnrout Chartชายไทย ไร้ชื่อNo ratings yet

- حافلات الرياضDocument1 pageحافلات الرياضluaysudanNo ratings yet

- 00 Conjunto Mayakaan 14092019Document1 page00 Conjunto Mayakaan 14092019Mallely PerezNo ratings yet

- Satellite Image Map of Greater Tehran: LegendDocument1 pageSatellite Image Map of Greater Tehran: Legendamir.hajirassouliha6445No ratings yet

- Passing: Andrew Toovey (2020)Document3 pagesPassing: Andrew Toovey (2020)LaTonya Hutchison 101No ratings yet

- Plan Showing 'F/N' Ward of Municipal Corporation of Greater MumbaiDocument1 pagePlan Showing 'F/N' Ward of Municipal Corporation of Greater MumbaiRational NationalNo ratings yet

- Cancontrol List 2022-07-27 enDocument115 pagesCancontrol List 2022-07-27 enAndrés Felipe Matamala QuezadaNo ratings yet

- Vehicle W - Vocals - Trumpet in BB 2Document2 pagesVehicle W - Vocals - Trumpet in BB 2avrstrtNo ratings yet

- Vehicle W - Vocals - Trumpet in BB 2Document2 pagesVehicle W - Vocals - Trumpet in BB 2avrstrtNo ratings yet

- Cedar Creek Fire Soil Burn SeverityDocument1 pageCedar Creek Fire Soil Burn SeverityStatesman JournalNo ratings yet

- PT - Adiprima - KPR - MB - 250tpd OCC - Line Rebuild - FYI - R0 - 20230112 To Customer-1Document1 pagePT - Adiprima - KPR - MB - 250tpd OCC - Line Rebuild - FYI - R0 - 20230112 To Customer-1Yudhi HalimNo ratings yet

- Hyundai r140w 9a Electric CircuitDocument2 pagesHyundai r140w 9a Electric Circuitjason100% (51)

- Makateeb e Sadrul Afazil by Zulfaqar Khan NaimiDocument251 pagesMakateeb e Sadrul Afazil by Zulfaqar Khan Naimisunnivoice100% (2)

- Atf Estimation Part1Document41 pagesAtf Estimation Part1mujtabaiftikhar156No ratings yet

- My Family 4 Sep 2020Document1 pageMy Family 4 Sep 2020hatem bellaajNo ratings yet

- Case Yr/Ct Issue Rule/Standard Used Facts Holding Reasoning Policy?Document1 pageCase Yr/Ct Issue Rule/Standard Used Facts Holding Reasoning Policy?Bella KayNo ratings yet

- Projeto - 2006 - 02.134.02-001-6Document15 pagesProjeto - 2006 - 02.134.02-001-6andre.shiotaniNo ratings yet

- Economic Corridor Khasra Map 11jan2022Document1 pageEconomic Corridor Khasra Map 11jan2022singh2406ssNo ratings yet

- M E D D: Ovimiento N OS ImensionesDocument8 pagesM E D D: Ovimiento N OS ImensionesBeckham Chaparro SolanoNo ratings yet

- Airport Map 03-10-2015 PDFDocument1 pageAirport Map 03-10-2015 PDFPamarthi RadhakrishnaNo ratings yet

- Airport Map 03-10-2015Document1 pageAirport Map 03-10-2015lrkstNo ratings yet

- Asset-V1 MITx+6.86x+3T2020+typeasset+blockslides Lecture6 CompressedDocument22 pagesAsset-V1 MITx+6.86x+3T2020+typeasset+blockslides Lecture6 CompressedRahul VasanthNo ratings yet

- Rainwater DrainageDocument3 pagesRainwater DrainageTuan-Anh NguyenNo ratings yet

- Why Do Companies Pay Dividends?: (Article Begins On Next Page)Document51 pagesWhy Do Companies Pay Dividends?: (Article Begins On Next Page)abu141No ratings yet

- EP12cR1362: District Court Western District ELDocument5 pagesEP12cR1362: District Court Western District ELjimhtolbert434No ratings yet

- Week 2: Introduction To Discrete-Time Stochastic Processes: 15.455x Mathematical Methods of Quantitative FinanceDocument58 pagesWeek 2: Introduction To Discrete-Time Stochastic Processes: 15.455x Mathematical Methods of Quantitative FinanceBruné100% (1)

- Dist 2 Zoning 2016Document1 pageDist 2 Zoning 2016Alteina CoradoNo ratings yet

- تسميع أبدأ صحDocument11 pagesتسميع أبدأ صحEslam FekryNo ratings yet

- KrishnaDocument1 pageKrishnarsshivanandNo ratings yet

- Elementary School Attendance Area Map: Park ForestDocument1 pageElementary School Attendance Area Map: Park ForestIlseNo ratings yet

- Teaching Model For Integrating CreativityDocument1 pageTeaching Model For Integrating CreativitySPONo ratings yet

- Plan D'urgenceDocument1 pagePlan D'urgencekarla.adamesNo ratings yet

- Regras de Derivação Parte 1Document5 pagesRegras de Derivação Parte 1Liliane GonçalvesNo ratings yet

- Gershwin Rhapsody in Blue Piano SoloDocument27 pagesGershwin Rhapsody in Blue Piano SoloAlejandro Pajuelo García75% (4)

- جيرةDocument1 pageجيرةالمصرية للاعمال الكهربيةNo ratings yet

- Pure Imagination: Willy Wonka & The Chocolate Factory Piano CoverDocument3 pagesPure Imagination: Willy Wonka & The Chocolate Factory Piano CoverMusicPPPNo ratings yet

- HirarcDocument34 pagesHirarcBungsu HiperkesNo ratings yet

- Organization ChartDocument1 pageOrganization Chartpankajbhatt376No ratings yet

- Jsa For Pest Control ManagmentDocument7 pagesJsa For Pest Control Managmentpankajbhatt376100% (2)

- Sprinkler Hydraulic Calculation (Manual Worksheet)Document5 pagesSprinkler Hydraulic Calculation (Manual Worksheet)pankajbhatt3760% (1)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- SOP Material InstructionsDocument1 pageSOP Material Instructionspankajbhatt376100% (1)

- Pankaj BhattDocument4 pagesPankaj Bhattpankajbhatt376No ratings yet

- Electrical Rubber Mat SpecificationDocument1 pageElectrical Rubber Mat Specificationpankajbhatt376No ratings yet

- Development Modification Phase(s) : Unit/Train: Discipline: HSE System No.: Subsystem No.Document10 pagesDevelopment Modification Phase(s) : Unit/Train: Discipline: HSE System No.: Subsystem No.pankajbhatt376No ratings yet

- Chunking Chunking Chunking: Stator Service IssuesDocument1 pageChunking Chunking Chunking: Stator Service IssuesGina Vanessa Quintero CruzNo ratings yet

- Strategic Audit of VodafoneDocument35 pagesStrategic Audit of VodafoneArun Guleria89% (9)

- Nyambe African Adventures An Introduction To African AdventuresDocument5 pagesNyambe African Adventures An Introduction To African AdventuresKaren LeongNo ratings yet

- San Mateo Daily Journal 01-28-19 EditionDocument28 pagesSan Mateo Daily Journal 01-28-19 EditionSan Mateo Daily JournalNo ratings yet

- Beer Pilkhani DistilleryDocument44 pagesBeer Pilkhani DistillerySunil Vicky VohraNo ratings yet

- Medabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink ForumsDocument5 pagesMedabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink Forumsdegraded 4resterNo ratings yet

- University Fees Structure (Himalayan Garhwal University) - UttarakhandDocument1 pageUniversity Fees Structure (Himalayan Garhwal University) - UttarakhandabhaybaranwalNo ratings yet

- EDB Postgres Failover Manager Guide v2.1Document86 pagesEDB Postgres Failover Manager Guide v2.1Anggia MauritianaNo ratings yet

- CUET 2022 General Test 6th October Shift 1Document23 pagesCUET 2022 General Test 6th October Shift 1Dhruv BhardwajNo ratings yet

- Watch One Piece English SubDub Online Free On Zoro - ToDocument1 pageWatch One Piece English SubDub Online Free On Zoro - ToSadeusuNo ratings yet

- APA Citation Method For ERLACS: Reference Citations in TextDocument8 pagesAPA Citation Method For ERLACS: Reference Citations in Textdanny_alfaro_8No ratings yet

- Cpar ReviewerDocument6 pagesCpar ReviewerHana YeppeodaNo ratings yet

- Flowrox Valve Solutions Catalogue E-VersionDocument16 pagesFlowrox Valve Solutions Catalogue E-Versionjavier alvarezNo ratings yet

- Biscotti: Notes: The Sugar I Use in France, Is CalledDocument2 pagesBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaNo ratings yet

- Antifraud PlaybookDocument60 pagesAntifraud PlaybookDani UsmarNo ratings yet

- Risk Analysis and Assessment Methodologies in Work SitesDocument49 pagesRisk Analysis and Assessment Methodologies in Work SitesNhut NguyenNo ratings yet

- R15 Understanding Business CyclesDocument33 pagesR15 Understanding Business CyclesUmar FarooqNo ratings yet

- Rubber Band Arrangements - Concert BandDocument25 pagesRubber Band Arrangements - Concert BandJonatas Souza100% (1)

- Roland Fantom s88Document51 pagesRoland Fantom s88harryoliff2672100% (1)

- Nature of Science-Worksheet - The Amoeba Sisters HWDocument2 pagesNature of Science-Worksheet - The Amoeba Sisters HWTiara Daniel25% (4)

- 2.1 DRH Literary Translation-An IntroductionDocument21 pages2.1 DRH Literary Translation-An IntroductionHassane DarirNo ratings yet

- List of Modern Equipment and Farm ToolsDocument15 pagesList of Modern Equipment and Farm ToolsCarl Johnrich Quitain100% (2)

- Household: Ucsp11/12Hsoiii-20Document2 pagesHousehold: Ucsp11/12Hsoiii-20Igorota SheanneNo ratings yet

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDocument75 pagesDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1No ratings yet

- Sodexo GermanyDocument13 pagesSodexo GermanySandeep Kumar AgrawalNo ratings yet

- Heart Rate Variability Threshold As An Alternative.25Document6 pagesHeart Rate Variability Threshold As An Alternative.25Wasly SilvaNo ratings yet

- Lakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoDocument2 pagesLakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoShivam MishraNo ratings yet

- User ManualDocument96 pagesUser ManualSherifNo ratings yet

- Junos ErrorsDocument2 pagesJunos ErrorsrashidsharafatNo ratings yet

- Principles To Action (Short)Document6 pagesPrinciples To Action (Short)nsadie34276No ratings yet