Professional Documents

Culture Documents

Jedec Standard: Coretronic

Uploaded by

彭以和Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jedec Standard: Coretronic

Uploaded by

彭以和Copyright:

Available Formats

JEDEC

STANDARD

Accelerated Moisture Resistance -

Unbiased HAST

ic

on

tr

re

co

JESD22-A118A

(Revision of JESD22-A118, December 2000, Reaffirmed June 2008)

MARCH 2011

JEDEC SOLID STATE TECHNOLOGY ASSOCIATION

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

NOTICE

JEDEC standards and publications contain material that has been prepared, reviewed, and

approved through the JEDEC Board of Directors level and subsequently reviewed and approved

by the JEDEC legal counsel.

JEDEC standards and publications are designed to serve the public interest through eliminating

misunderstandings between manufacturers and purchasers, facilitating interchangeability and

improvement of products, and assisting the purchaser in selecting and obtaining with minimum

delay the proper product for use by those other than JEDEC members, whether the standard is to

be used either domestically or internationally.

JEDEC standards and publications are adopted without regard to whether or not their adoption

may involve patents or articles, materials, or processes. By such action JEDEC does not assume

any liability to any patent owner, nor does it assume any obligation whatever to parties adopting

the JEDEC standards or publications.

The information included in JEDEC standards and publications represents a sound approach to

product specification and application, principally from the solid state device manufacturer

viewpoint. Within the JEDEC organization there are procedures whereby a JEDEC standard or

ic

publication may be further processed and ultimately become an ANSI standard.

on

No claims to be in conformance with this standard may be made unless all requirements stated in

tr

the standard are met.

re

Inquiries, comments, and suggestions relative to the content of this JEDEC standard or

co

publication should be addressed to JEDEC at the address below, or refer to www.jedec.org under

Standards and Documents for alternative contact information.

Published by

©JEDEC Solid State Technology Association 2011

3103 North 10th Street

Suite 240 South

Arlington, VA 22201-2107

This document may be downloaded free of charge; however JEDEC retains the

copyright on this material. By downloading this file the individual agrees not to

charge for or resell the resulting material.

PRICE: Contact JEDEC

Printed in the U.S.A.

All rights reserved

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

PLEASE!

DON’T VIOLATE

THE

LAW!

This document is copyrighted by JEDEC and may not be

reproduced without permission.

ic

on

Organizations may obtain permission to reproduce a limited number of copies

through entering into a license agreement. For information, contact:

tr

re

co

JEDEC Solid State Technology Association

3103 North 10th Street

Suite 240 South

Arlington, VA 22201-2107

or refer to www.jedec.org under Standards and Documents

for alternative contact information.

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

ic

on

tr

re

co

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 1

ACCELERATED MOISTURE RESISTANCE - UNBIASED HAST

(From JEDEC Board Ballot JCB-00-56 and JCB-11-17, formulated under the cognizance of the

JC-14.1 Subcommittee on Reliability Test Methods for Packaged Devices.)

1 Scope

This test method applies primarily to moisture resistance evaluations and robustness testing, and

may be used as an alternative to unbiased autoclave. Samples are subjected to a non-condensing,

humid atmosphere, similar to the JESD-22-A101, "Steady State Temperature, Humidity and Bias

Life Test", but with a higher temperature. For the temperature limits defined by this procedure,

the test will typically generate the same failure mechanisms as those in an unbiased

"85 °C/85% RH" Steady State Humidity Life Test, but caution must be used if higher

temperatures are considered since non-realistic failure modes can be generated. The use of a

non-condensing environment avoids many irrelevant external failures, e.g., pin-to-pin leakage or

lead corrosion. However, because absorbed moisture typically decreases glass transition

ic

temperature for most polymeric materials, the combination of high humidity and high

temperature (> Tg) may produce unrealistic material failures. Thus, caution is needed if and

on

when Unbiased HAST is required for reliability or qualification purposes.

tr

The Unbiased HAST is performed for the purpose of evaluating the reliability of non-hermetic

re

packaged solid-state devices in humid environments. It is a highly accelerated test which

employs temperature and humidity under non-condensing conditions to accelerate the

co

penetration of moisture through the external protective material (encapsulant or seal) or along

the interface between the external protective material and the metallic conductors which pass

through it. Bias is not applied in this test to ensure the failure mechanisms potentially

overshadowed by bias can be uncovered (e.g., galvanic corrosion). This test is is used to identify

failure mechanisms internal to the package and is destructive.

2 Apparatus

The test requires a pressure chamber capable of maintaining a specified temperature and relative

humidity during ramp-up to, and ramp-down from, the specified test conditions.

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 2

2 Apparatus (cont’d)

2.1 Records

A permanent record of the temperature profile for each test cycle is recommended, so the stress

conditions can be verified. Calibration records shall verify that the equipment avoids

condensation on devices under test (DUTs) hotter than 50 °C during ramp-up and ramp-down for

conditions of maximum thermal mass loading. Calibration records shall verify that, for steady

state conditions and maximum thermal mass loading, test conditions are maintained within the

tolerances specified in Table 1.

2.2 Devices under stress

Devices under stress must be placed in the chamber to minimize temperature gradients. Devices

under stress shall be no closer than 3 cm from internal chamber surfaces, and must not be

subjected to direct radiant heat from heaters. If devices are mounted on boards, the boards

should be oriented to minimize interference with vapor circulation.

2.3 Ionic contamination ic

on

Care must be exercised in the choice of any materials introduced into the chamber in order to

minimize release of contamination, and minimize degradation due to corrosion and other

tr

mechanisms. Ionic contamination of the test apparatus shall be controlled to avoid test artifacts.

re

2.4 Distilled or deionized water

co

Distilled or deionized water with a minimum resistivity of 1 megohm-cm at room temperature

shall be used.

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 3

3 Test conditions

Test conditions consist of a temperature, relative humidity, and duration.

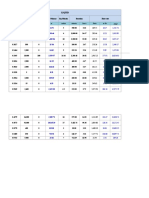

Table 1 — Temperature, relative humidity and pressure

Test Temperature1 Relative Temperature2 Vapor pressure2

condition3,4 1

(dry bulb °C) humidity (%) (wet bulb, °C) (psia/kPa)

A 130 ± 2 85± 5 124.7 33.3/230

B 110 ± 2 85± 5 105.2 17.7/122

NOTE 1 Tolerances apply to the entire usable test area.

NOTE 2 For information only.

NOTE 3 The test conditions are to be applied continuously except during any interim readouts. For

interim readouts, devices should be returned to stress within the time specified in 4.4

ic

NOTE 4 The unbiased HAST duration is intended to meet or exceed an equivalent field lifetime under use

conditions. The duration is established based on the acceleration of the stress (see JEP122). The stress

on

duration is specified by internal qualification requirements, JESD47 or the applicable procurement

document. Typical test durations are:

tr

re

Condition Duration

A 96 hours (-0,+2)

co

B 264 hours (-0, +2).

CAUTION: For plastic-encapsulated microcircuits, it is known that moisture reduces the effective glass

transition temperature of the molding compound. Stress temperatures above the effective glass transition

temperature may lead to failure mechanisms unrelated to operational use.

4 Procedure

The test devices shall be mounted in a manner that exposes them to a specified condition of

temperature and humidity. Exposure of devices to conditions that result in condensation on

them, particularly during ramp-up and ramp-down, shall be avoided. While devices are above

30 oC, R.H. must be ≥ 40% to ensure their moisture content is not reduced, i.e., inadvertant

moisture bake out.

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 4

4 Procedure (cont’d)

4.1 Ramp-up

4.1.1 The time to reach stable temperature and relative humidity conditions shall be less than 3

hours.

4.1.2 Condensation shall be avoided by ensuring that the test chamber (dry bulb) temperature

exceeds the wet-bulb temperature at all times, and that the rate of ramp up shall not be

faster than a rate which ensures that the temperature of any DUT does not lag below the

wet bulb temperature.

4.1.3 The dry- and wet-bulb temperature set points shall be maintained so that the relative

humidity is not less than 50 % after significant heating begins. In a dry laboratory, the

chamber ambient may initially be drier than this.

4.2 Ramp-down

4.2.1 The first part of ramp-down to a slightly positive gauge pressure (a wet bulb temperature

ic

of about 104 °C) shall be long enough to avoid test artifacts due to rapid

on

depressurization, but shall not exceed 3 hours.

tr

4.2.2 The second part of ramp-down from a wet bulb temperature of 104 °C to room

temperature shall occur with the chamber vented. There is no time restriction, and forced

re

cooling of the vessel is permitted.

co

4.2.3 Condensation on devices shall be avoided in both parts of the ramp down by ensuring

that the test chamber (dry bulb) temperature exceeds the wet-bulb temperature at all

times.

4.2.4 Ramp-down should maintain the moisture content of the molding compound

encapsulating the die. Therefore, the relative humidity shall not be less than 50 % during

the first part of the ramp-down, see 4.2.1.

4.3 Test Clock

The test clock starts when the temperature and relative humidity reach the set points, and stops at

the beginning of ramp-down.

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 5

4 Procedure (cont’d)

4.4 Readout

Electrical test shall be performed not later than 48 hours after the end of ramp-down. Note, for

intermediate readouts, devices shall be returned to stress within 96 hours of the end of ramp-

down. The rate of moisture loss from devices after removal from the chamber can be reduced by

placing the devices in sealed moisture barrier bags, the bags should be non-vacuum sealed

without a N2 purge and without dessicant. When devices are placed in sealed bags, the "test

window clock" runs at 1/3 of the rate of devices exposed to the laboratory ambient. Thus the test

window can be extended to as much as 144 hours, and the time to return to stress to as much as

288 hours by enclosing the devices in sealed moisture barrier bags.

NOTE 1 The electrical test parameters should be chosen to preserve any defect (i.e., by limiting the

applied test current).

NOTE 2 Additional time-to-test delay or return-to-stress delay time may be allowed if justified by

technical data

4.5 Handling ic

on

Suitable hand-covering shall be used to handle devices, boards and fixtures. Contamination

control is important in any highly accelerated moisture stress test.

tr

re

5 Failure criteria

co

A device will be considered to have failed if parametric limits are exceeded, or if functionality

cannot be demonstrated under nominal and worst-case conditions as specified in the applicable

procurement document or data sheet.

6 Safety

Follow equipment manufacturer's recommendations and local safety regulations.

7 Summary

The following details shall be specified in the applicable procurement document:

(a) Test duration

(b) Test conditions

(c) Measurements after test.

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

JEDEC Standand No. 22-A118A

Page 6

Annex A (informative) Differences between JESD22-A118A and JESD22-A118

This table briefly describes most of the changes made to entries that appear in this standard,

JESD22-A118A, compared to its predecessor, JESD22-A118 (December 2000, Reaffirmed June

2008). If the change to a concept involves any words added or deleted (excluding deletion of

accidentally repeated words), it is included. Some punctuation changes are not included.

Clause Description of change

1, 2 Combined to align with JEDEC Sytle Manual, JM7

All Renumbered accordingly

4.4 Readout: Added two notes

ic

on

tr

re

co

Test Method A118A

(Revision of Test Method A118)

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

Standard Improvement Form JEDEC JESD22-A118A

The purpose of this form is to provide the Technical Committees of JEDEC with input from the

industry regarding usage of the subject standard. Individuals or companies are invited to submit

comments to JEDEC. All comments will be collected and dispersed to the appropriate

committee(s).

If you can provide input, please complete this form and return to:

JEDEC Fax: 703.907.7583

Attn: Publications Department

3103 North 10th Street

Suite 240 South

Arlington, VA 22201-2107

1. I recommend changes to the following:

Requirement, clause number

Test method number Clause number

The referenced clause number has proven to be: ic

on

Unclear Too Rigid In Error

Other

tr

re

2. Recommendations for correction:

co

3. Other suggestions for document improvement:

Submitted by

Name: Phone:

Company: E-mail:

Address:

City/State/Zip: Date:

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

ic

on

tr

re

co

Downloaded by peng Michael (peng7@ms11.hinet.net) on May 11, 2021, 12:19 pm CST

You might also like

- Edec Standard: CoretronicDocument14 pagesEdec Standard: Coretronic彭以和No ratings yet

- Accelerated Moisture ResistanceDocument12 pagesAccelerated Moisture ResistanceMirnaNo ratings yet

- Temperature CyclingDocument18 pagesTemperature CyclingMirnaNo ratings yet

- Jedec Standard: Els ServiçosDocument18 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- JEDEC JESD22a101cDocument12 pagesJEDEC JESD22a101cAglieglie BrazorNo ratings yet

- Jesd51 13Document14 pagesJesd51 13truva_kissNo ratings yet

- High Temperature Storage LifeDocument12 pagesHigh Temperature Storage LifeMirnaNo ratings yet

- Steady State Temperature HumidityDocument12 pagesSteady State Temperature HumidityMirnaNo ratings yet

- HERMETICITYDocument8 pagesHERMETICITYMirnaNo ratings yet

- Temperature, Bias, and Operating LifeDocument14 pagesTemperature, Bias, and Operating LifeMirnaNo ratings yet

- Jedec 22a111Document18 pagesJedec 22a111Rafael Palhas DomingosNo ratings yet

- Low Temperature Storage LifeDocument10 pagesLow Temperature Storage LifeMirna0% (1)

- Cycled Temperature Humidity BiasDocument12 pagesCycled Temperature Humidity BiasMirnaNo ratings yet

- Jesd51 12Document24 pagesJesd51 12liuxc111No ratings yet

- Jedec Standard: Information Requirements For The Qualification of Silicon DevicesDocument7 pagesJedec Standard: Information Requirements For The Qualification of Silicon DevicesMy HomeNo ratings yet

- Jedec Standard: Smart Modular TechnologiesDocument18 pagesJedec Standard: Smart Modular TechnologiesCamilo SouzaNo ratings yet

- Eia/Jedec Standard: Test Method A110-B Highly-Accelerated Temperature and Humidity Stress Test (HAST)Document11 pagesEia/Jedec Standard: Test Method A110-B Highly-Accelerated Temperature and Humidity Stress Test (HAST)Bruno SotoNo ratings yet

- Jedec Standard: Els ServiçosDocument38 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- Test Method For The Measurement ofDocument16 pagesTest Method For The Measurement ofMirnaNo ratings yet

- Jedec Permanent MarkingDocument14 pagesJedec Permanent Markingbeach_lover_1970No ratings yet

- Jedec Standard: Thermal Modeling OverviewDocument10 pagesJedec Standard: Thermal Modeling Overviewtruva_kissNo ratings yet

- Mechanical Shock - Component andDocument14 pagesMechanical Shock - Component andMirna100% (1)

- JEP154Document34 pagesJEP154yangNo ratings yet

- JEP144ADocument36 pagesJEP144AMahboobeh ShokrollahiNo ratings yet

- Jedec Standard: Els ServiçosDocument32 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- Jedec StandardDocument22 pagesJedec StandardFrank ChenNo ratings yet

- Jedec Standard: N-Channel MOSFET Hot Carrier Data AnalysisDocument15 pagesJedec Standard: N-Channel MOSFET Hot Carrier Data AnalysisBenchNo ratings yet

- Jedec Standard: N-Channel MOSFET Hot Carrier Data AnalysisDocument15 pagesJedec Standard: N-Channel MOSFET Hot Carrier Data AnalysisBenchNo ratings yet

- Jedec Standard: Els ServiçosDocument30 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- JEP157Document128 pagesJEP157Mahboobeh ShokrollahiNo ratings yet

- JESD22-B103B Vibration, Variable FrequencyDocument16 pagesJESD22-B103B Vibration, Variable Frequencyyangmingliu0709No ratings yet

- Jedec 22B112A 1Document30 pagesJedec 22B112A 1Shih Chien ChenNo ratings yet

- JEP155Document56 pagesJEP155istailerNo ratings yet

- JESD22 B110A Sub Assembly ShockDocument16 pagesJESD22 B110A Sub Assembly ShockTan Long BinNo ratings yet

- Gate Charge Test MethodDocument14 pagesGate Charge Test MethodMirnaNo ratings yet

- JEDEC Autoclave - 22a102dDocument12 pagesJEDEC Autoclave - 22a102dDaus Villa Jr.No ratings yet

- Jesd209 2FDocument284 pagesJesd209 2Fhuan nguyenNo ratings yet

- JESD22B113A Board Level Cyclic Bend Test Method For Interconnect ReliabilityDocument22 pagesJESD22B113A Board Level Cyclic Bend Test Method For Interconnect Reliabilityyangmingliu0709No ratings yet

- Jedec Standard: Integrated Circuit Thermal Test Method Environmental Conditions - Junction-to-BoardDocument17 pagesJedec Standard: Integrated Circuit Thermal Test Method Environmental Conditions - Junction-to-BoardMarcio SilvaNo ratings yet

- JESD22-A100C Cycled Temp Humid Bias TestDocument12 pagesJESD22-A100C Cycled Temp Humid Bias Testtehky63No ratings yet

- JSTD 033Document20 pagesJSTD 033Paul GuyNo ratings yet

- Jedec Standard: Customer Notification of Product/Process Changes by Solid-State SuppliersDocument12 pagesJedec Standard: Customer Notification of Product/Process Changes by Solid-State SuppliersMohamed KhalifaNo ratings yet

- Jedec Standard: Embedded Multi-Media Card (E - MMC) Electrical Standard (5.1)Document352 pagesJedec Standard: Embedded Multi-Media Card (E - MMC) Electrical Standard (5.1)Mee PlaguyNo ratings yet

- Short Circuit Withstand Time TestDocument12 pagesShort Circuit Withstand Time TestMirnaNo ratings yet

- 22 Field Induced Charged Device ModelDocument18 pages22 Field Induced Charged Device ModelMirnaNo ratings yet

- Jedec Standard: Electrically Erasable Programmable ROM (EEPROM) Program/Erase Endurance and Data Retention Stress TestDocument23 pagesJedec Standard: Electrically Erasable Programmable ROM (EEPROM) Program/Erase Endurance and Data Retention Stress TestsupNo ratings yet

- Previews 2505383 PreDocument7 pagesPreviews 2505383 PreRaghuNo ratings yet

- JEP160Document26 pagesJEP160ReAdPTNo ratings yet

- Solid-State Drive (SSD) Requirements and Endurance Test Method JESD218ADocument34 pagesSolid-State Drive (SSD) Requirements and Endurance Test Method JESD218AСергей КаменевNo ratings yet

- JEP140Document14 pagesJEP140beach_lover_1970No ratings yet

- Jedec Standard: Western DigitalDocument34 pagesJedec Standard: Western DigitalNiharica Sohal100% (3)

- Iec Pas 62307-2002Document5 pagesIec Pas 62307-2002Sergio LungrinNo ratings yet

- 22A105CDocument12 pages22A105CDuram_Han_2546No ratings yet

- Thermal Impedance Measurement ForDocument16 pagesThermal Impedance Measurement ForMirnaNo ratings yet

- JEDEC Power Mosfet StandardDocument56 pagesJEDEC Power Mosfet StandarddanielzanNo ratings yet

- Jedec Standard: Arrowhead QADocument32 pagesJedec Standard: Arrowhead QAdaveNo ratings yet

- Jedec Standard: DELPHI Compact Thermal Model GuidelineDocument24 pagesJedec Standard: DELPHI Compact Thermal Model GuidelineAniketKulkarniNo ratings yet

- Jesd84 B51Document352 pagesJesd84 B51Mee Plaguy100% (1)

- J-STD-046 Notification For Product ChangesDocument14 pagesJ-STD-046 Notification For Product ChangesPiotr MarjakNo ratings yet

- PG Series - Pressure Gauge: Product FeaturesDocument1 pagePG Series - Pressure Gauge: Product Features彭以和No ratings yet

- Solder Test Nicolloy Battery TermDocument5 pagesSolder Test Nicolloy Battery Term彭以和No ratings yet

- Mil STD 883kDocument765 pagesMil STD 883kTom DruryNo ratings yet

- Rhesca: About SAT-5100Document48 pagesRhesca: About SAT-5100彭以和No ratings yet

- SPECIFICATIONS For Constant Temperature and Humidity ChamberDocument5 pagesSPECIFICATIONS For Constant Temperature and Humidity Chamber彭以和No ratings yet

- Solder Test Nicolloy Battery TermDocument5 pagesSolder Test Nicolloy Battery Term彭以和No ratings yet

- Aim m8 Solder Paste Rev 8Document4 pagesAim m8 Solder Paste Rev 8彭以和No ratings yet

- Data Sheet: Agilent 10-Element Bar Graph ArrayDocument7 pagesData Sheet: Agilent 10-Element Bar Graph Array彭以和No ratings yet

- Agilent-4339b ManualDocument286 pagesAgilent-4339b Manual彭以和No ratings yet

- Agilent 4339B/4349B High Resistance Meters: Technical OverviewDocument8 pagesAgilent 4339B/4349B High Resistance Meters: Technical Overview彭以和No ratings yet

- Mil STD 202hDocument305 pagesMil STD 202hfunson123100% (1)

- En 50155 (2017)Document110 pagesEn 50155 (2017)彭以和100% (1)

- Jedec Standard: CoretronicDocument12 pagesJedec Standard: Coretronic彭以和No ratings yet

- Temperature POD 050504Document4 pagesTemperature POD 050504彭以和No ratings yet

- M10 94400 1 PDFDocument271 pagesM10 94400 1 PDFdiegomilitojNo ratings yet

- Arduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreyDocument26 pagesArduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreysabteleNo ratings yet

- Internship ReportDocument9 pagesInternship ReportSyrah MichaelNo ratings yet

- 0116 Mass and Dimension Limits Truck VehiclesDocument10 pages0116 Mass and Dimension Limits Truck VehicleskejspmNo ratings yet

- Jacoby TarboxDocument7 pagesJacoby TarboxBayu Permana RydhaNo ratings yet

- Beep CodesDocument6 pagesBeep Codeslrac_adazolNo ratings yet

- Field Work No 8 SurveyingDocument18 pagesField Work No 8 SurveyingRalph GalvezNo ratings yet

- ELCB ExperimentDocument4 pagesELCB ExperimentShubham Singh RathoreNo ratings yet

- Astm A234Document8 pagesAstm A234Joffre ValladaresNo ratings yet

- Conference Paper TemplateDocument3 pagesConference Paper TemplateDeden MSNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan AranyawatNo ratings yet

- For My Website CookieDocument445 pagesFor My Website CookieShantonu SarkerNo ratings yet

- Aero TownDocument6 pagesAero TownPhilippine Bus Enthusiasts SocietyNo ratings yet

- Consort ChecklistDocument2 pagesConsort ChecklistAyuAnatrieraNo ratings yet

- DIN EN ISO 2409-2020英文Document22 pagesDIN EN ISO 2409-2020英文김종원No ratings yet

- Guia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Document11 pagesGuia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Kelly de Souza SilvaNo ratings yet

- Keeline Operation & Maintenance Manual: Safety at The Highest LevelDocument24 pagesKeeline Operation & Maintenance Manual: Safety at The Highest LevelEddy Cuellar MartinezNo ratings yet

- Flow Meter ManualDocument70 pagesFlow Meter Manualrommel duranNo ratings yet

- MobileComm Corporate ProfileDocument28 pagesMobileComm Corporate ProfileArshadullah KhanNo ratings yet

- Iso 11623 - 2015 - PDFDocument36 pagesIso 11623 - 2015 - PDFandres jaramilloNo ratings yet

- BUDGIT Electric Hoists and Trolley BrochureDocument16 pagesBUDGIT Electric Hoists and Trolley BrochureJogi Oscar SinagaNo ratings yet

- Ac500 Web Server Lvd-eotn121u-En - RevaDocument5 pagesAc500 Web Server Lvd-eotn121u-En - RevaBui Xuan DuongNo ratings yet

- Metasol MS - UL - #24 - 2023.08.16Document4 pagesMetasol MS - UL - #24 - 2023.08.16Karloff AutencioNo ratings yet

- Canon FB1210U Service ManualDocument102 pagesCanon FB1210U Service ManualDuplessisNo ratings yet

- Anexo 05 - Process Planning and Audit v2 1Document33 pagesAnexo 05 - Process Planning and Audit v2 1QMS : Aswin Cold ForgeNo ratings yet

- A Study On State Bank of India's Doorstep Banking ServiceDocument3 pagesA Study On State Bank of India's Doorstep Banking ServiceEditor IJTSRDNo ratings yet

- GH TXu Yyfls 73 IDumDocument15 pagesGH TXu Yyfls 73 IDumdabu choudharyNo ratings yet

- 4.8 Inspection and Maintenance PhilosophyDocument10 pages4.8 Inspection and Maintenance PhilosophyMohamed KenawyNo ratings yet

- Multisens Picture Error in Rlink 2: Ddt4AllDocument16 pagesMultisens Picture Error in Rlink 2: Ddt4AllAriana ScheiderNo ratings yet

- IoT in Electronics Manufacturing (White Paper)Document17 pagesIoT in Electronics Manufacturing (White Paper)John JalaniNo ratings yet

- En 10219-1 PDFDocument39 pagesEn 10219-1 PDFASHISH100% (1)