Professional Documents

Culture Documents

V7I2 Complete Paper 2 Ajay

Uploaded by

ajay kunduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V7I2 Complete Paper 2 Ajay

Uploaded by

ajay kunduCopyright:

Available Formats

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

Study of designing pavements for light aircraft

1

Ajay Kundu, Research Scholar, 2Ranadip Mandal CBS group of Institution

Introduction : According to the Federal Aviation

Administration, airport pavements are primarily constructed

to provide adequate support for the loads imposed by aircraft

using an airport. The Federal Aviation Administration states

that an adequate pavement design produces a firm and stable,

all-year, all-weather surface. In order to effectively fulfill these requirements, the pavement must be of

such quality and thickness that it will not fail under the loads imposed by the various aircrafts using the

airport. It is also vital for the pavement throughout the airport to be durable and long-lasting in order to

control operating costs. The pavement chosen must possess sufficient inherent stability to withstand the

constant traffic, adverse weather conditions, and other deteriorating influences to a degree that it does not

constantly have to be attended to.

Key words : pavements, aircraft, runway etc

Although aircraft landing gears are involved in the design of airport pavement, the Federal Aviation

Administration does not specifically prescribe any component of landing gear design. In 1958, the

Federal Aviation Administration adopted a policy of limiting maximum Federal participation in airport

pavements to a pavement section designed to serve a 350,000 pound aircraft with a DC-S-50 series

landing gear configuration. The main intent of this policy was to insure that future aircraft were equipped

with landing gears that would not stress the pavements more than the referenced 350,000 pound aircraft.

Since, aircraft manufacturers have accepted and followed the 1958 policy. Even though aircraft gross

weights have substantially exceeded 350,000 pounds they still have designed all aircraft landing gear to

conform to the policy. This feat has been accomplished by increasing the number and spacing of landing

gear wheels. Therefore, even though the policy of 1958 is not exactly the same as it was the year it was

adopted, the landing gear stills falls to the responsibility of the aircraft designers and manufactures.

Steps in the pavement design process :

1. Existing Soil Investigation and Evaluation

The first step in the pavement design process is to inspect the existing soil present throughout the site.

According to the Federal Aviation Administration, the Unified Soil Classification system should be used

in all matters concerning civil airport pavements. Soil conditions include factors such as the elevation of

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

the water table, the presence of water bearing strata, and the field properties of the soil. Some examples

of field properties of the soil include the soil’s density, moisture content, and frost penetration.

The standard method for classifying soils for engineering purposes is ASTM D 2487, or more commonly

known as the Unified System. One of the primary purposes in determining the soil classifications is to

have some idea of how the soil will behave under different scenarios. The Unified System classifies soil

first by grain size and then further subgroups that particular soil based upon its plasticity index.

2. Overall Pavement Thickness

Now that the engineering properties

of the soil are known, the overall

thickness of the pavement needed

throughout the airport can be

determined.

The strength of the sub grade is the

main factor in determining the

thickness of the pavement needed for

a particular application. The value of

the stiffness of the sub grade is

required if the stresses and strains in

the pavement and the sub grade are to

be calculated. Sub grade strength is

expressed in terms of its California bearing ratio (CBR) value. The CBR value is measured by

an empirical test devised by the California State Highway Association and is simply the

resistance to a penetration of 2.45nn of a standard cylindrical plunger to various penetrations in

crushed aggregate, notably 13.24kN at 2.5mm penetration and 19.96kN at 5.0mm penetration.

The CBR value can be determined by conducting various tests on collected soil samples, or it

can be obtained from a standard table provided by the Federal Aviation Administration. In the

case of the Lake Mathews Airport, the CBR value and the soil characteristics for the site was

found through a provided table. Table illustrates how the Field CBR value was found for the soil

around the Lake Mathews Airport site.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

If the worst case scenario were considered, a CBR value of 3 to 5 would be selected. In order to

be conservative, a CBR value of 4 was selected. In addition, a Field CBR value of 4 was

selected due to the fact that the CBR values range from 3 to 40 in the location of the runway and

taxiway.

Once the Field CBR value is determined, the total pavement thickness can then be found. The

overall pavement thickness is a function of both the CBR value and the maximum aircraft gross

weight. Figure 4.3 illustrates the design curve that was used to determine the pavement

thickness. With a Field CBR value of 4 and a maximum aircraft gross weight of 12,500 pounds,

the thickness of the pavement was found to be 14 inches.

3. Typical Pavement Layers

There are various types of pavement that the Federal Aviation Administration deems acceptable.

These include flexible, ridged, hot mix asphalt overlays, and ridged overlays. A pavement does

not have to consist of just one of these specific types, but rather, there can be a combination

which would result in a complex pavement ranging somewhere between flexible and ridged.

A typical pavement design consists of four distinct layers: surface, base, subbase, and subgrade.

The first layer in the pavement is the surface. The surface courses include portland cement

concrete, hot mix asphalt, sand-bituminous mixture, and sprayed bituminous surface treatments.

The subsequent layer is the base. The base courses consist of a variety of different materials

which generally fall into two main classes: treated and untreated. The untreated bases consist of

crushed or uncrushed aggregates, where as the treated bases normally consist of a crushed or

uncrushed aggregate that has been mixed with a stabilizer such as cement or bitumen. The

subbase course is the next in the pavement design layer. The subbase courses consist of a

granular material, a stabilized granular material, or a stabilized soil. The final layer consists of

the subgrade. The subgrade is the natural soil or a fill, which is compacted to a specified percent

of compaction based on the depth of compacted soil.

4. Flexible Pavement for Light Aircraft

Pavement for light aircraft is deemed by the Federal Aviation Administration as pavement

intended to serve aircraft with gross weights of less than 30,000 pounds. With the Lake

Mathews Airport being an AII-BII category airport, the maximum gross weight that the airport

can serve is 12,500 pounds. This gross aircraft weight would put the Lake Mathews Airport in

the light aircraft category.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

Flexible pavement for light aircraft is composed of hot mix asphalt surfacing, base course,

subbase, and prepared subgrade. The hot mix asphalt surface is responsible for preventing water

to seep into the base course. In addition, the hot mix asphalt must provide a smooth, well-

bonded surface free from loose particles that pose a potential threat to aircraft or persons using

the airport. The base course is the primary load carrying component of the flexible pavement.

The subbase course is usually required for flexible pavement, except for those with a CBR value

of 20 or greater. However, with a CBR value of 4 for the Lake Mathews site, a subbase course is

needed.

5. Overall Pavement Thickness

The pavement thickness of 14 inches, which was determined previously, must be used upon all

areas of airport pavement according to the Federal Aviation Administration. No reduction in

thickness should be made for “noncritical” areas of pavement. With the total pavement thickness

already determined, the next step in the pavement design process is to find the thickness of the

surfacing and the base.

Surfacing and Base Thickness

According to the Federal Aviation Administration, to find the surfacing and base thickness, the

CBR 20-line is used. Using the chart provided by the Federal Aviation Administration, the

thickness of the surfacing and base can be found. Using a CBR value of 20, as instructed by the

Federal Aviation Administration, and a maximum aircraft gross weight of 12,500 pounds, a

value of four and a half inches is obtained for the thickness of the surfacing and base. This

thickness value is rounded up to five inches in order to be conservative and also because this

base is, in essence, the structural element of the pavement. Figure 4.5 represents how the

thickness for the surfacing and base was generated.

The Federal Aviation Administration states that the minimum thickness of the hot mix asphalt

surfacing over a granular base is two inches. The reason for the minimum surfacing thickness is

that layers thinner than two inches are difficult to place and compact on granular bases. Hot mix

asphalt surfacing thickness of less than two inches is permissible on stabilized base materials if

proper lay down and compaction can be achieved. However, for the Lake Mathews Airport, a

hot mix asphalt surface of two inches will be used. This will have a corresponding base

thickness of three inches.

Subbase Thickness

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

The difference between the total pavement thickness required and the CBR 20-line thickness

yields the thickness of the subbase. With a total pavement thickness of 14 inches and a surfacing

and base thickness of five inches, the total subbase thickness is required to be nine inches. Using

engineering judgment a surface thickness of four inches will be used, and a base thickness of

three inches will be used. Therefore the final thickness of the flexible pavement is 16 inches.

Subgrade

The subgrade materials need to be compacted to a specific percentage depending upon whether

the soil is noncohesive or cohesive and the design aircraft gross weight. For the Lake Mathews

Airport, with cohesive soil and a maximum gross aircraft weight of 12,500 pounds, it was

determined that the subgrade needs to be compacted to 85 percent for eight to twelve inches or

90 percent for four to eight inches in depth. If the above compaction requirements cannot be

met, then the base will need to be increased in order to accommodate the aircraft. Table 4.3

depicts how the subgrade compaction requirements for the Lake Mathews Airport were obtained.

Table 4.3. Subgrade compaction requirements for light load flexible pavement per AC 150/5320-6D.

Rigid Pavement for Light Aircraft

Rigid pavements for light aircraft are composed of Portland cement concrete surfacing, subbase,

and prepared subgrade.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

Portland Cement Surfacing : When determining the required thickness for the various rigid

pavement layers, design curves provided by the Federal Aviation Administration prove to be

exceptionally helpful. However, there are no design curves for light aircraft ridged pavement.

There are only two thickness requirements for the Portland cement surfacing; that for pavement

designed to serve aircraft weight 12,500 pounds or less and that for aircraft weighing between

12,501 pounds and 30,000 pounds. For ridged pavements designed to serve aircraft weighing

12,500 pounds or less, a Portland cement surfacing thickness of five inches is required. Rigid

pavement designed to serve aircraft weighing between 12,501 pounds and 30,000 pounds should

be six inches thick. With the Lake Mathews Airport serving aircraft with a gross weight less

than 12,500 pounds, the Portland cement surfacing thickness for rigid pavement needs to be five

inches.

Subbase: No subbase is required for rigid pavement designs intended to serve aircraft weighing

12,500 pounds or less, except when soil types OL, MH, CH, or OH is encountered. If a subbase

is needed, the Federal Aviation Administration specifies when any of the above soil types are

present, a minimum four inch subbase should be provided. Due to the fact that CH soil type was

discovered at the Lake Mathews Airport site, a subbase of four inches for the rigid pavement

design is required.

Subgrade : The Federal Aviation Administration stipulates that a subgrade comprised of

cohesive soils used in fill sections, the entire fill shall be compacted to 90 percent of the

maximum density. For cohesive soils in cut sections, the top six inches of the subgrade shall be

compacted to 90 percent of the maximum density. The Federal Aviation Administration

specifies different standards for noncohesive soils, however due to the fact that the Lake

Mathews Airport consists only of cohesive soils, these standards do not apply. For the Lake

Mathews Airport, entire fill section and the top six inches of the cut section needs to be

compacted to 90 percent.

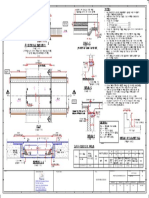

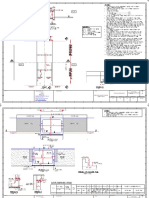

Jointing of Light Load Rigid Pavements : The maximum spacing of joints for light load rigid

pavements should be 12.5 feet for longitudinal joints and 15 feet for transverse joints. Jointing

details for expansion joints, contraction joints, and construction joints are illustrated in Figure

4.6, Figure 4.7, and Figure 4.8 respectively.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

Fig 4.7 Expansion joint details for light load rigid pavement per AC 150/5320-6D.

Fig 4.8. Contraction joint details for light load rigid pavement per AC 150/5320-6D.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

Fig 4.9. Construction joint details for light load rigid pavement per AC 150/5320-6D.

The Federal Aviation Administration notes that several differences exist between light load and

heavy load rigid pavement joints. For example, butt-type construction and expansion joints are

permitted when an asphalt or cement stabilized subbase is provided. Also, half round-keyed

joints are permitted even though the slab thick nesses are less than nine inches. Odd-shaped slabs

should be reinforced with 0.05% steel in both directions. The Federal Aviation Administration

defines odd-shaped slabs as slabs that are not rectangular in shape, or rectangular slabs which

length-to-width ratios exceed 1.25.

For the Lake Mathews Airport, longitudinal joints are going to be placed every 12.5 feet, for a

total of six sections. In the transverse direction, joints will be placed every 15 feet. These

transverse joints will extend for the entire length of the runway.

References :

1. Prasad, Bageshwar (2007), “Life Cycle Cost Analysis of Cement Concrete Roads Vs.

Bituminous Roads”, Indian Highways, Vol.35, No.9, 19-26.

2. Haider, S. W. and Harichandran, R. S. (2008), “Relating Axle Load Spectra to Truck Gross

Vehicle Weights and Volumes”, J. Transp. Eng., 133(12), 696-705

3. Huang, W.H., Sung, Y. L. and Lin, J. D. (2002), “Development of Axle Load Distribution

for Heavy Vehicles”, Pre-Prints, 81 Annual Meeting, Transportation Research Board,

Washington, D. C.

Paper is available at www.jrps.in | Email : info@jrps.in

© INTERNATIONAL JOURNAL FOR RESEARCH PUBLICATION & SEMINAR

ISSN: 2278-6848 | Volume: 07 Issue: 02 | April – June 2016

4. IRC:37-2001, “Guidelines for the Design of Flexible Pavements”, The Indian Roads

Congress, New Delhi.

5. IRC:58-2002, “Guidelines for the Design of Plain Jointed Rigid Pavements for Highways”

(Second Revision), Indian Roads Congress, 2002, New Delhi.

6. Liu, W. D., Cornell, C. A. and Imbsen, R.A. (1988),“Analysis of Bridge Truck Overloads”,

Probabilistic Methods in Civil Engineering, P. D. Spanos, ed., ASCE, New York, 221-224

7. Mintsis, G., Taxiltaris, C., Babas, S., Patonis, P. and Filaktakis, A. (2002), “Analyzing

Heavy Goods Vehicle Data Collected on Main Road Network in Greece”, Transportation

Research Record, 1809, Transportation Research Board, Washington, D.C.

Paper is available at www.jrps.in | Email : info@jrps.in

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 15.MNB Gad 2X5.0X3 - 01-1Document1 page15.MNB Gad 2X5.0X3 - 01-1ajay kunduNo ratings yet

- Design Note of Box MNB of Size 7 M X 3 M: TitleDocument94 pagesDesign Note of Box MNB of Size 7 M X 3 M: Titleajay kunduNo ratings yet

- Wing Wall - Height Up To 3.5mDocument51 pagesWing Wall - Height Up To 3.5majay kunduNo ratings yet

- Ogl at RhsDocument5 pagesOgl at Rhsajay kunduNo ratings yet

- Plan Sign BoardDocument3 pagesPlan Sign Boardajay kunduNo ratings yet

- Box Culvert 1.5X1.5Document3 pagesBox Culvert 1.5X1.5ajay kundu100% (2)

- Analysis of Rates For C.C. Block M-30 Size 450x300x150m Minimum Cement 360 Kg. Per CumDocument13 pagesAnalysis of Rates For C.C. Block M-30 Size 450x300x150m Minimum Cement 360 Kg. Per Cumajay kunduNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Itr Project Report AmolDocument58 pagesItr Project Report Amolrajnish patilNo ratings yet

- SSL - Cold Planer MB - 26feb2020Document13 pagesSSL - Cold Planer MB - 26feb2020potenzaengenhariaNo ratings yet

- Yanmar SV100 2PB Portugal Peixoto e PeixotoDocument8 pagesYanmar SV100 2PB Portugal Peixoto e PeixotoLima PereiraNo ratings yet

- Road Safety-Basic Rules of The RoadDocument14 pagesRoad Safety-Basic Rules of The RoadGlobal EHSNo ratings yet

- Howo Maintenance InstructionsDocument7 pagesHowo Maintenance InstructionsSimon EllyNo ratings yet

- AU2288Document19 pagesAU2288Chandler MinhNo ratings yet

- FLIX Booking 3006412160Document1 pageFLIX Booking 3006412160Şahin AkınNo ratings yet

- History of MercedesDocument8 pagesHistory of MercedesAli ZnibarNo ratings yet

- BTK - A318 - A319 - A320 - A321 - IPC - 01-Aug-2019 - FIG. 79-00-00-09 - TUBES SCAVENGE INSTL-CFM56 Zone(s) 400 (Aug 01 - 19)Document2 pagesBTK - A318 - A319 - A320 - A321 - IPC - 01-Aug-2019 - FIG. 79-00-00-09 - TUBES SCAVENGE INSTL-CFM56 Zone(s) 400 (Aug 01 - 19)Irfan05No ratings yet

- Ranjith K.P Vs Principal Secretary To Govt TransportDocument8 pagesRanjith K.P Vs Principal Secretary To Govt TransportSrishti JainNo ratings yet

- Modification of Simple Car To Hybrid CarDocument1 pageModification of Simple Car To Hybrid CarUsama AnsariNo ratings yet

- Konecranes SMV 10-600 B - SMV 60-1200 B Driver's Instruction BookDocument48 pagesKonecranes SMV 10-600 B - SMV 60-1200 B Driver's Instruction BookApri YandriNo ratings yet

- SRDM 4-0 Projektni Elementi Puta (120511-Eng-Konačna)Document122 pagesSRDM 4-0 Projektni Elementi Puta (120511-Eng-Konačna)Milutin StrbicNo ratings yet

- 150 5300 13B Airport DesignDocument434 pages150 5300 13B Airport DesignEllen Divina MenorNo ratings yet

- CRS in MitsubishiDocument46 pagesCRS in MitsubishiDidiq 47No ratings yet

- Route 20 Updated 9.5.23Document2 pagesRoute 20 Updated 9.5.23Priscila Garcia gonzaleZNo ratings yet

- Book 1Document1 pageBook 1Henny Komala Sari SibaraniNo ratings yet

- Volume I Cts For mmr-0909Document569 pagesVolume I Cts For mmr-0909api-270998557100% (1)

- Unit 7 - Grammar FocusDocument8 pagesUnit 7 - Grammar FocustrinhmbNo ratings yet

- 003 Cambio AutomaticoDocument3 pages003 Cambio Automaticotaoufik159No ratings yet

- Region Company Name Permit No Validity Equipment/ Classification (Radio/Wdn/Rfid/B Roadcast) Address RemarksDocument54 pagesRegion Company Name Permit No Validity Equipment/ Classification (Radio/Wdn/Rfid/B Roadcast) Address RemarksGerald TiocsonNo ratings yet

- Ferrari: Chassis Electrical System InstrumentsDocument4 pagesFerrari: Chassis Electrical System InstrumentsJose LiraNo ratings yet

- Mazda 3 Despiece 2004Document19 pagesMazda 3 Despiece 2004Krlos GomezNo ratings yet

- 1.8T 5V (Aeb & Atw)Document374 pages1.8T 5V (Aeb & Atw)Vladimir Socin ShakhbazyanNo ratings yet

- Technical Specification Sandvik TH320-03Document6 pagesTechnical Specification Sandvik TH320-03abadNo ratings yet

- Summative Assignment 1: ECON1012 Principles of Economics Semester 1 2023Document3 pagesSummative Assignment 1: ECON1012 Principles of Economics Semester 1 2023bhageerath janiNo ratings yet

- KYMCODocument4 pagesKYMCOGabriel ChiavettoNo ratings yet

- Short Functional Text (Complete Edition) : 1. NoticesDocument24 pagesShort Functional Text (Complete Edition) : 1. NoticesMTSN 1 CianjurNo ratings yet

- 2015 Scion XB User Warranty Maintenance ManualDocument62 pages2015 Scion XB User Warranty Maintenance ManualDanno NNo ratings yet

- Design and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanDocument21 pagesDesign and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanAlexei MorozovNo ratings yet