Professional Documents

Culture Documents

Entz Martens Poster

Uploaded by

soumyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Entz Martens Poster

Uploaded by

soumyaCopyright:

Available Formats

Reducing Fossil Fuel Energy Use In Agriculture

M.H. Entz, R.H. Gulden, C. Halde, K.C. Bamford, and J.R. Thiessen Martens

Department of Plant Science, University of Manitoba, Winnipeg, MB, R3T 2N2

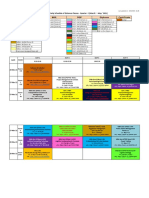

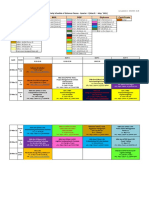

Introduction Scenario 2. Adding perennial forage hay to a Scenario 4. Organic low-till rotation at Carman

no-till grain rotation An organic rotation, featuring legume green manure crops for N supply,

An important goal in agriculture is to grazing for nutrient cycling and cash flow, and low-till green manure

reduce fossil fuel use. Canadian The rotation with a management, allows for a 65% reduction in energy use. Seed costs are

scientists have documented energy perennial forage phase increased due to use of cover crops. View crop yields for this rotation at

use coefficients for crop production allows for a 34% reduction www.umanitoba.ca/outreach/naturalagriculture/articles/fieldlab.html.

inputs (eg., Nagy, 1999; Zentner et al. in energy use, mainly less Energy budget (MJ/ha)

2004) and this knowledge has enabled fertilizer N energy. N

fertilizer needs are

Crop inputs Standard Organic* Percent change due to organic

detailed studies on fossil fuel N fertilizer 3886 0 100

reduced but hay harvest

consumption in different cropping P fertilizer 382 200** 48

operations increase

systems (eg., Hoeppner et al., 2005). energy demands. Pesticides 312 0 100

Machinery 551 450 19

Energy budget (MJ/ha) Fuel/lub. 1197 1050 12

Energy use scenarios Hayed Percent change due Seed 658 750 -13

Crop inputs Standard perennial* to perennial Total 6986 2450 65

In this project, we compare the fossil fuel energy inputs in four high N fertilizer 3886 1000 74 *Rotation: Green manure (grazed) – wheat – soybean – green manure – flax – fall rye.

yield crop production systems. In all cases, the systems are P fertilizer 382 450 -4 **Energy for compost application

compared to a conventional-till grain farm. The unit of energy used Pesticides 312 427 -36

in this study is megajoules per hectare. One megajoule is Machinery 551 870 -57

approximately equal to the energy contained in one ounce of Fuel/lub. 1197 1012 15

gasoline. The energy in these budgets includes all energy in the Seed 658 600 9

process, for example, energy to make the steel for the farm

Total 6986 4609 34

machinery and energy to manufacture fertilizer and pesticides

*Rotation: Alfalfa/grass hay (3 yr) – wheat or canola – flax – pulse – oats

(Nagy, 1999).

Scenario 1. Energy savings from no-till farming Scenario 3. Grazing the forage instead of

haying Conclusions

Two commercial farms were

compared for energy use over a

! Cropping systems that rely on mineral fertilizer N have limited

By grazing the

6 year period (Gulden and Entz, perennial forage potential for energy savings.

1996). The standard farm is phase instead of ! Conventional no-till systems provide only modest improvements in

located in the Red River Valley haying, the energy energy use.

while the no-till farm is located savings increase ! Replacing N fertilizer with legume N is the single most important

in western Manitoba. The from 34% to 43%. factor in fossil fuel energy use reduction.

rotation in both cases is: Oat – Savings are due to ! A well designed organic system uses only 35% as much fossil fuel

pea – wheat – flax. Results elimination of forage energy as conventional farming systems.

showed that no-till provided a harvest energy.

13% reduction in energy use. ! Agronomists and farmers interested in reducing fossil fuel use

should focus on legume pasture-based and organic farming

Energy budget (MJ/ha) Energy budget (MJ/ha)

systems.

Standard Percent change in energy Grazed Percent change due

Crop inputs system No-till budget due to no-till Crop inputs Standard perennial* to grazed perennial

N fertilizer 3886 1000 74 References

N fertilizer 3886 3530 9

P fertilizer 382 365 4 P fertilizer 382 200 52 Gulden, R.H. and M.H. Entz. 1996. Energy Use and Carbon Release by Manufactured

Pesticides 312 427 -36 Pesticides 312 427 -36 Inputs in Crop Production. Available on-line: http://umanitoba.ca/outreach/

naturalagriculture/articles/energy.html.

Machinery 551 370 33 Machinery 551 370 67 Hoeppner, J.W., M.H. Entz, B.G. McConkey, R.P. Zentner and C.N. Nagy. 2005.

Fuel/lub. 1197 762 36 Fuel/lub. 1197 400 33 Energy efficiency in two Canadian organic and conventional crop production systems.

Seed 658 658 0 Seed 658 600 91 Renewable Ag and Food Systems 21:60-67.

Nagy, C. N. 1999. Energy coefficients for agricultural inputs in western Canada. Centre

Total 6986 6112 13 Total 6986 2997 43 for Studies in Agriculture, Law and the Environment. University of Saskatchewan.

Rotation: Oat – pea – wheat – flax *Rotation: Birdsfoot trefoil/grass (3 yr) – wheat or canola – flax – pulse – oats Zentner et al. 2004. Soil and Tillage Research 77:125-136.

You might also like

- Energy Reports: Peeyush Soni, Rajeev Sinha, Sylvain Roger PerretDocument11 pagesEnergy Reports: Peeyush Soni, Rajeev Sinha, Sylvain Roger Perretmazinja bandaNo ratings yet

- ECG80 Energy Use in The Animal Feed SectorDocument8 pagesECG80 Energy Use in The Animal Feed SectorIppiNo ratings yet

- MoiziDocument6 pagesMoizimilanNo ratings yet

- Comparison of Energy of Tillage System in Wheat PRDocument6 pagesComparison of Energy of Tillage System in Wheat PRFedhii CaaliiNo ratings yet

- Biogas Plants in Chattisgarh (India) : A Case StudyDocument5 pagesBiogas Plants in Chattisgarh (India) : A Case StudyKHUSHBU PahwaNo ratings yet

- Biomass Pellet Firning Final - 2Document38 pagesBiomass Pellet Firning Final - 2amiyamech047858No ratings yet

- Alternative Energy SourcesDocument1 pageAlternative Energy SourcesAaron Eipe JohnNo ratings yet

- Changing Energy-Use Pattern and The Demand Projection For Indian Agriculture - GK Jha Et Al AERADocument8 pagesChanging Energy-Use Pattern and The Demand Projection For Indian Agriculture - GK Jha Et Al AERASamrat SharmaNo ratings yet

- Changing Energy-Use Pattern and The Demand Projection For Indian Agriculture - GK Jha Et Al AERADocument8 pagesChanging Energy-Use Pattern and The Demand Projection For Indian Agriculture - GK Jha Et Al AERASamrat SharmaNo ratings yet

- Biomass and Bioenergy: Research PaperDocument18 pagesBiomass and Bioenergy: Research PaperSaleha QuadsiaNo ratings yet

- Renewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The PhilippinesDocument9 pagesRenewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The PhilippinesFirman KhaerullahNo ratings yet

- Energy Paper (1) - Energy - EGY2353-2009Document6 pagesEnergy Paper (1) - Energy - EGY2353-2009rajeevkumarchoudharyNo ratings yet

- Bioenergy To PowerDocument175 pagesBioenergy To PowerH Janardan PrabhuNo ratings yet

- 10 11648 J Sjee 20150303 11Document12 pages10 11648 J Sjee 20150303 11tibiNo ratings yet

- One Paper PDFDocument8 pagesOne Paper PDFHarshal WaradeNo ratings yet

- Biomass Energy LectureDocument9 pagesBiomass Energy LectureRishant YadavNo ratings yet

- Pedrazzi ECM 2019Document9 pagesPedrazzi ECM 2019LorenzoNo ratings yet

- Organic Fertilizers ProductionDocument9 pagesOrganic Fertilizers ProductionĐặng Hiếu SángNo ratings yet

- GasificationDocument6 pagesGasificationVivek YadavNo ratings yet

- IntroductionDocument21 pagesIntroductionDAKSHINA PANDEYNo ratings yet

- A Study On The Potential of Corn Cob Enginegenerator For ElectriDocument4 pagesA Study On The Potential of Corn Cob Enginegenerator For ElectriCeddie MianoNo ratings yet

- Gunasekaran2021 Article NumericalAndExperimentalInvestDocument13 pagesGunasekaran2021 Article NumericalAndExperimentalInvestchaniefNo ratings yet

- Energy GenerationDocument11 pagesEnergy GenerationZamir ZainalNo ratings yet

- Biofuels Junction - Profile - Sept 2023Document17 pagesBiofuels Junction - Profile - Sept 2023shubhamsharma11999No ratings yet

- Nassiri2009 PDFDocument6 pagesNassiri2009 PDFrajeevkumarchoudharyNo ratings yet

- Energy Analysis of Biodiesel Production From Jojoba Seed OilDocument12 pagesEnergy Analysis of Biodiesel Production From Jojoba Seed OilSölangs QüntellaNo ratings yet

- AJEAT Vol.2 No.2 July Dec 2013 pp.6 10Document5 pagesAJEAT Vol.2 No.2 July Dec 2013 pp.6 10sumitrochakrabortiNo ratings yet

- IP UK Pine Needle Power Generation PDFDocument23 pagesIP UK Pine Needle Power Generation PDFSunny DuggalNo ratings yet

- Assignment III Paper Review 20 Feb 2022 NoUDocument13 pagesAssignment III Paper Review 20 Feb 2022 NoUKiran KhatriNo ratings yet

- Aerodynamic Analysis of RC PlaneDocument43 pagesAerodynamic Analysis of RC PlaneZahid AsifNo ratings yet

- Applied Energy 2012 - Techno-Economic Assessment of Triticale Straw For Power GenerationDocument10 pagesApplied Energy 2012 - Techno-Economic Assessment of Triticale Straw For Power GenerationNojus DekerisNo ratings yet

- Biogas From Cow ManureDocument9 pagesBiogas From Cow ManureVenu VasudevNo ratings yet

- Better Crops International 1998-2 p25Document3 pagesBetter Crops International 1998-2 p25Prachi AggarwalNo ratings yet

- Applied Energy: A.M. Blanco-Marigorta, J. Suárez-Medina, A. Vera-CastellanoDocument8 pagesApplied Energy: A.M. Blanco-Marigorta, J. Suárez-Medina, A. Vera-CastellanoMaría Fernanda MeloNo ratings yet

- Polygeneration Using Renewable Resources: Cost Optimization Using Linear ProgrammingDocument12 pagesPolygeneration Using Renewable Resources: Cost Optimization Using Linear ProgrammingSagar KumarNo ratings yet

- Energy Costs of Sugar Production: in The Philippine ContextDocument10 pagesEnergy Costs of Sugar Production: in The Philippine ContextNaeemSiddiquiNo ratings yet

- Biogas Plants MonitoringDocument12 pagesBiogas Plants MonitoringDeepak Dev BurmanNo ratings yet

- Renewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The PhilippinesDocument9 pagesRenewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The Philippinesencourage36No ratings yet

- Evaluation On Performance and Exhaust Emissions With Bio-Diesel and Ethanol Blending On A Diesel EngineDocument7 pagesEvaluation On Performance and Exhaust Emissions With Bio-Diesel and Ethanol Blending On A Diesel EngineChethan GowdaNo ratings yet

- Energy For Sustainable Development: Sophia Baumert, Asia Khamzina, Paul L.G. VlekDocument10 pagesEnergy For Sustainable Development: Sophia Baumert, Asia Khamzina, Paul L.G. VlekH.M. SALMANNo ratings yet

- Energy Consumption Pattern in Manufacturing of Different Types of Broiler FeedsDocument11 pagesEnergy Consumption Pattern in Manufacturing of Different Types of Broiler FeedsIndian Journal of Veterinary and Animal Sciences RNo ratings yet

- Biomass Energy: Group 2Document43 pagesBiomass Energy: Group 2Nur Adlina100% (1)

- Anaerobic Digesters: Operating ParametersDocument4 pagesAnaerobic Digesters: Operating ParametersRufus D SNo ratings yet

- Blower - Compressor For Biogasb1 001 02 enDocument12 pagesBlower - Compressor For Biogasb1 001 02 enMarcus NguyễnNo ratings yet

- Modeling Net Energy Balance of Ethanol Production From Native Warmseason GrassesDocument7 pagesModeling Net Energy Balance of Ethanol Production From Native Warmseason GrassesMágda CorreiaNo ratings yet

- Energy and Life Cycle Assesment of SugarcaneDocument17 pagesEnergy and Life Cycle Assesment of SugarcaneRamu RacikNo ratings yet

- Biodiesel 002Document12 pagesBiodiesel 002Nakao SakurabaNo ratings yet

- Akhtar-Lecture 11 - BioMass - StudentDocument31 pagesAkhtar-Lecture 11 - BioMass - StudentCintopanNo ratings yet

- Biomass Gasification Using Microturbines and Fuel Cells 2000Document12 pagesBiomass Gasification Using Microturbines and Fuel Cells 2000noragarcia76No ratings yet

- Content ServerDocument15 pagesContent Serversatria diinNo ratings yet

- Environmental Impacts of BiofuelsDocument17 pagesEnvironmental Impacts of BiofuelsfaridkhanNo ratings yet

- Renewable Energy: Martha Andreia Brand, Rodolfo Cardoso JacintoDocument9 pagesRenewable Energy: Martha Andreia Brand, Rodolfo Cardoso Jacintoitalo mayuber mendoza velezNo ratings yet

- Indian Energy Scenario and Energy Conservation Opportunities in Different SectorsDocument8 pagesIndian Energy Scenario and Energy Conservation Opportunities in Different SectorsSaish DalviNo ratings yet

- 8 2011-RaeDocument8 pages8 2011-RaeThomas A. MattiaNo ratings yet

- The Potential For Bioenergy Generated On Marginal La - 2024 - Renewable and SustDocument11 pagesThe Potential For Bioenergy Generated On Marginal La - 2024 - Renewable and SustDana MateiNo ratings yet

- Crops & Cropping Pattern in Relation To OrganicDocument16 pagesCrops & Cropping Pattern in Relation To OrganicJohnlouie RafaelNo ratings yet

- Energy Audit of A Wheat Processing Plant in Port Harcourt, NigeriaDocument6 pagesEnergy Audit of A Wheat Processing Plant in Port Harcourt, NigeriaAyoub EnergieNo ratings yet

- Economic Feasibilityof Briquetted FuelDocument8 pagesEconomic Feasibilityof Briquetted FuelErkan ÖZTEMELNo ratings yet

- Renewable Energy for Agriculture: Insights from Southeast AsiaFrom EverandRenewable Energy for Agriculture: Insights from Southeast AsiaNo ratings yet

- Innovation Outlook: Renewable MethanolFrom EverandInnovation Outlook: Renewable MethanolNo ratings yet

- Boron Liquid FertilizerDocument6 pagesBoron Liquid FertilizersoumyaNo ratings yet

- Head Office: Menara Great Eastern 303 Jalan Ampang 50450 Kuala LumpurDocument3 pagesHead Office: Menara Great Eastern 303 Jalan Ampang 50450 Kuala LumpursoumyaNo ratings yet

- WP 2014 132Document35 pagesWP 2014 132soumyaNo ratings yet

- Evaluation of Agricultural LimestoneDocument2 pagesEvaluation of Agricultural LimestonesoumyaNo ratings yet

- Malaka-Andaman LNG Pipeline Project-SoumyaDocument2 pagesMalaka-Andaman LNG Pipeline Project-SoumyasoumyaNo ratings yet

- Schedule Online ClassesDocument2 pagesSchedule Online ClassessoumyaNo ratings yet

- Schedule Online ClassesDocument2 pagesSchedule Online ClassessoumyaNo ratings yet

- Project Management in Product Development: Toward A Framework For Targeted FlexibilityDocument15 pagesProject Management in Product Development: Toward A Framework For Targeted FlexibilitysoumyaNo ratings yet

- Schedule Online ClassesDocument2 pagesSchedule Online ClassessoumyaNo ratings yet

- Schedule Online ClassesDocument2 pagesSchedule Online ClassessoumyaNo ratings yet

- 1.study of Technical Possibilities For Supplying Ships With LNG in The Port of Koper - VfinalDocument28 pages1.study of Technical Possibilities For Supplying Ships With LNG in The Port of Koper - VfinalsoumyaNo ratings yet

- LNG Transportation Review and COSCO-Shipping PracticesDocument20 pagesLNG Transportation Review and COSCO-Shipping PracticessoumyaNo ratings yet

- Energy Megatrends: UTP MBA - Energy Value Chain 5 September 2020Document35 pagesEnergy Megatrends: UTP MBA - Energy Value Chain 5 September 2020soumyaNo ratings yet

- Week-3-Part B - Logistic Energy Value ChainDocument33 pagesWeek-3-Part B - Logistic Energy Value ChainsoumyaNo ratings yet

- 3 Blue Corridor Strategy For LNG China v.2Document32 pages3 Blue Corridor Strategy For LNG China v.2soumyaNo ratings yet

- Value Chain Mapping For: Inbound Logistics Operations Outbound Logistics Marketing & Sales ServiceDocument2 pagesValue Chain Mapping For: Inbound Logistics Operations Outbound Logistics Marketing & Sales ServicesoumyaNo ratings yet

- Hibiscus Petroleum Berhad (5199.KL) Equity Analysis (5 Apr 2020)Document26 pagesHibiscus Petroleum Berhad (5199.KL) Equity Analysis (5 Apr 2020)soumyaNo ratings yet

- EVC - Gas LNG Ecosystem August 2020Document34 pagesEVC - Gas LNG Ecosystem August 2020soumyaNo ratings yet

- Week-3-The Business of Gas and LNG TransportationDocument31 pagesWeek-3-The Business of Gas and LNG TransportationsoumyaNo ratings yet

- Efficient Cow Comfort PDFDocument76 pagesEfficient Cow Comfort PDFkarandeep599No ratings yet

- 2005 Speth (Plains-Pueblo)Document20 pages2005 Speth (Plains-Pueblo)StevenNo ratings yet

- Effect of The Bumstead Pit On Personal WealthDocument2 pagesEffect of The Bumstead Pit On Personal WealthmassieguyNo ratings yet

- How To Make Broilers Grow Faster and BiggerDocument3 pagesHow To Make Broilers Grow Faster and Biggerchris mubiruNo ratings yet

- Indian Agriculture: Performance and Challenges - A Case StudyDocument8 pagesIndian Agriculture: Performance and Challenges - A Case StudySWETCHCHA MISKANo ratings yet

- Economic Survey 2017-18Document350 pagesEconomic Survey 2017-18Subhransu Sekhar SwainNo ratings yet

- Pringles: Invented by Fredric Baur & Alexander LiepaDocument8 pagesPringles: Invented by Fredric Baur & Alexander LiepaRăzvan FlorescuNo ratings yet

- Brotherhood of DarknessDocument16 pagesBrotherhood of DarknessHenrique Monteiro100% (2)

- CRS Agricultural Biotechnology2011Document44 pagesCRS Agricultural Biotechnology2011NathiyaNo ratings yet

- Black Beauty by Anna Sewell Retold by John Escott Book PDFDocument48 pagesBlack Beauty by Anna Sewell Retold by John Escott Book PDFNATALIANo ratings yet

- Climate Change and Agriculture in The United States: Effects and AdaptationDocument98 pagesClimate Change and Agriculture in The United States: Effects and AdaptationClimateCentralNo ratings yet

- Tuta Identification GuideDocument3 pagesTuta Identification GuideneanthesNo ratings yet

- Vol.24 - Parte 4 - Magnoliidae y HamamalidaeDocument516 pagesVol.24 - Parte 4 - Magnoliidae y HamamalidaeDana NelumboNo ratings yet

- 5 Year Business PlanDocument18 pages5 Year Business PlanNes-tValdezNo ratings yet

- A Field Trial of Infrared Thermography As A Non-Invasive Diagnostic Tool For Early Detection of Digital Dermatitis in Dairy CowsDocument5 pagesA Field Trial of Infrared Thermography As A Non-Invasive Diagnostic Tool For Early Detection of Digital Dermatitis in Dairy CowsAlfredo Rodríguez MolinaNo ratings yet

- DandelionDocument2 pagesDandelionAndre Heartless-chanNo ratings yet

- Excellent Home RemediesDocument17 pagesExcellent Home RemediesbabudevanandNo ratings yet

- Soal MID Semester Bahasa Inggris Kelas 8 SMPDocument3 pagesSoal MID Semester Bahasa Inggris Kelas 8 SMPSMKN1RAMANUTARA94% (18)

- Desmond Morris - 2009 - The Naked Man - A Study of The Male Body (Poor Quality-Double Page) (163p) (Inua)Document163 pagesDesmond Morris - 2009 - The Naked Man - A Study of The Male Body (Poor Quality-Double Page) (163p) (Inua)Dani25% (4)

- Haramaya University Sheep and Goat FatteDocument23 pagesHaramaya University Sheep and Goat FatteAbelNo ratings yet

- AFRICAN History 1Document43 pagesAFRICAN History 1Sylvia NyakujawaNo ratings yet

- Camel Farming PDFDocument31 pagesCamel Farming PDFMuhammad Farhan Ali100% (2)

- 19th Century Clothing (Art Fashion) PDFDocument38 pages19th Century Clothing (Art Fashion) PDFNenad Vitanov67% (3)

- Leafu PDFDocument362 pagesLeafu PDFWen RollandNo ratings yet

- Saddle OlogyDocument28 pagesSaddle Ologygeonenad100% (2)

- Cox - Unknown - The Limits of Lean Management Thinking Multiple Retailers and Food and Farming Supply Chains PDFDocument15 pagesCox - Unknown - The Limits of Lean Management Thinking Multiple Retailers and Food and Farming Supply Chains PDFDragan DragičevićNo ratings yet

- Pengaruh Lama Penyimpanan Terhadap Ferti 9b71ef3fDocument6 pagesPengaruh Lama Penyimpanan Terhadap Ferti 9b71ef3fSatria YudhaNo ratings yet

- Restaurant Dante - New MenuDocument2 pagesRestaurant Dante - New MenuZagatBlogNo ratings yet

- The COOK NOT MAD or Rational Cookery - Kingston, Canada 1831Document156 pagesThe COOK NOT MAD or Rational Cookery - Kingston, Canada 1831Sandra MianNo ratings yet

- Fisa ArticolDocument4 pagesFisa ArticolRuru RoxNo ratings yet