Professional Documents

Culture Documents

BTC Welding Cons JSW

Uploaded by

sanket0 ratings0% found this document useful (0 votes)

14 views6 pagesdd

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views6 pagesBTC Welding Cons JSW

Uploaded by

sanketdd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

“oe

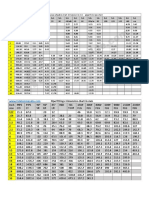

TEST CERTIFICATE DpH

sécheron

‘Complete Welding Support

(As per EN 10204 Type 3.1)

S.No. 2016/FL- 051 Brand Name : | Maxfil 12R |

Date of issue | :| 27/02/2016 Size (mm) 1.20 |

este Date ae Batch No. : | B- 16121364 i

Month/Year of Mig. _: | February - 2016

et |

Chemical Composition :

c Mn x, Js e cr Ni Mo Vv Cu

0.083 | 0.98 | 035 | 0.008 | 0.015 | oo19 | 0035 | oon | oor 007 |

\dechanical Properties:

YS:02% UTS “Diffusion | — Radiography j

offset (MPa) (MPa) eee Ga i

|

455 562 251 Satisfactory

Special Instruction : |

Current ‘Are Voltage jelding Gas |_ Remarks, 1

(Amp) ™ Co |SUBxtesion (mm) ifany \

CO: Fillet Weld Test = OK

Special Requirements |

\e |

i

i

|

Test Conducted as per: AWS/SFA:5.20E71T1C _ | ISSUED TO: |

We certify that the supply made against this TC conforms |

to all requirements of ASME section-I, Part-C Edition 2015,

QC-94/Rev:01/DTJun.2010

Head Otis: 4/46, Indust, stats, la Maidan, Indore 452008. MP) INDIA.

“Tok: 401731 241289182, 4200002, Fax +91 7314220260, Enal:dnhi@aasachoronnet /qeBdnnseceron net

‘TEST CERTIFICATE DpH

sécheron

‘Complete Welding Support

(As per EN 10204 Type 3.1)

S.No. 2016/FL- 066 Brand Name : | Maxfil -12R

Date of issue _ | :| 15/03/2016 Size (mm) : |1.20

F-O-No& Date Batch No, : | B- 16121366

Month/Year of Mig, _: | February - 2016

Chemical Composition :

Cc 7 Mn Si 5 P G Ni] Mo Vv cus

Goat | 098 | 034 | 0.007 | 0016 | oo1s | 0030 | oom | oor 0.006

\.echanical Properties: &: tg, |

YS:02% UTS Diffusion Ha Radiography

offset (M Pa) (MPa) say Dg |

448 556 2.42 Satisfactory |

1

Special Instruction : secneron \

Canat ‘Are Voltage Shielding Gas Electrode Remarks,

(Amp) @) __ CompIeee/Aekbag Susan (mm ifany

CO; Fillet Weld Test = OK

Special Requirements

be

chef Forwarded by :

Gales Dept)

Test Conducted as per: AWS/SFA:5.20E71T1C _ | SSUED TO: =a

We certify that the supply made against this TC conforms |

to all requirements of ASME section-Il, Part-C Edition 2015.

(QC-94/Rev-01/DTJun.2010

Head Otice: 4/46, Indust, stat, Kila Maidan, Indore 452 008. (MP INDIA.

‘os +91 7912612391/82 4220002, Fa: «81 731 4228260, Ema: dnhiGdnhsecheron.net/ @eOnhsecheron et

TEST CERTIFICATE

AS PER EN 10204 TYPE:3.1

Brand Name: OVERCORD Report No: SUP 2018/2448

Size (mm): a18xas0 Date of issue: 2-12-15

‘Standard-No/ AWSAS.1; £6013 19.814; ER4211K »

Classifications: *

Batch No: 26288

Date of Mfg: 21-12-15 .

| All Wold Mata Chemical Anaysis (%)

(Sement_[ 6] 8

j | Se | mie | awe ae TS a ae | [ E

Result} Gost | O21 | 04d] OT) BaF | arr | oars | coer | 5

Mechanical Properties of Al Wold Matal

Yield | — anaila | Elongation | Charpy impact | Hardness] Ferrie aa

a cueneet () | Avg. value(Joules) | (As welded) | par WRC-1962

(mime) | = (Amen) Teepe atore)

“Speci | 330 Min. | 430Min. | 17Min, | Not Specified = my

Result | 419 10 24.90 | 710,86,80,74,92 = > |

‘ Le. Avg =80 }

Diusibie ~ Conting Molsture= =

(e009 of wel mea)

Radlogepiy:- Satisfactory Filet wold Tost Satisfactory

Bend Tost: : Pwr: 2

‘We cortify that the statement in this tust report are correct and that the test welds were prepared welded and tested | |

in Accordance wit te requirement conforming to ASME See. NPar'G Law Editon SOiain aspects |

{( to

WQoo v6

Admn. Office : 15-18, Old Sewa Nagar Market,P.0. Lodhi Road, New Detni-1h0003,India,

Tel: #91-11-24647199 / 24647252. Fax: 491-11-24833847 | 24623828, E-mail: sales@superonindia com

TEST CERTIFICATE

AS PER EN 10204 TYPE:3.1

Brand Name: SUPERCITO . Report No: SUP 2015/2433

‘Size (mm): s18x450 Date of issue: 19-12-15

Standard-NoJ = AWS 6.1 6 7018 1S. 814: EB 5426H3IK

Classifications:

Batch No: 26205 a

Date of mig: fot2t5

Ali Wei ttl Chomicat Anelyet: (%)

(Ei cS ese a

‘Spec. | O48] “GIS [480] G98 G0as |~o20 [~o30 O30 | |. oe]

‘ Max. | Mex. | Max. | Max. | Max. | Max. Max, |

Reeik ood [ose v8 | oor | aner 7 ose | cazo | aos > =P aoe

Mechanical Properties of All Weld Metal

Tensile Elongation | Charpy impact Ave. | Hardness | FariwtFNat |]

(3) | valuo(outes), (As welded) | por WR-1982

e y "| Tomp. At-30(°) _|

490 Min. | 22 Min. 27 Min = S

$88 | 28.44 | 700,90.84,80,86 zg =

Avg £85.67,

« (24

‘Admn. Office : 15-18, Old Sena Nagar Market P.O. Lodhi Road, New Delni-110003,Inaia,

Tob: +01-11-24647109 / 24647262. Fax: +91-11-24659647 / 24623826, E-mail: sales@superonindia com

| | D&H SECHERON ELECTRODES PVT.LTD.

Head Orfiest4-46lndstea state Kila Mandan,

ont ing Nor STndored32006 {INDIA}

Pane 29022 4229040, 4201 Fa: O731-4229060 email: An

TEST CERTIFICATE

aie io

| 0u50 "139 ai an

[Leow =

| NbeTe AL | N I Fe

Mechanical Properties of all weld metal :

} yso2 U1S “| Elong | CVN Impact energy Goules) ae

J ofietestpa Mp | cad Test Temp at 30h

as | sa aes

Chemical composition (%) : Specification i ia per E 7018

cf 7 Me Si s a ’ Mo Tv cu

on | roo | 075 | aos | 0005 | 020 | o30 | 030 | oon |

F eomsy | gaan | enon | nang | (man) [ema | com ) | tana | (mary

4

Al

fee tie

| Mechanical Properties of all ‘weld metal:

YSO2% olfsen? WI “Elong, ~ CVN Impact energy (loules)

400 490 22.0

fain) (min) (min)

Hydrogen inl/ 10M) gens of weld metal): 2.41

Moisture: stent in coating (A): 02

rite(EN) =

(ipa) (pa) () | Test Temp at kc

lib nippy nls gale is TC eras ea

1 clea appcable or oes jeAWSeodeeniy ee

Kowal | ech

=

ments of ASME Section, Part Edison 20/3. Ui |

" D&H SECHERON ELECTRODES PVT.LTD. |

| ees Hod Ofe4-46 tdi ata Kia aan |

| Eeencren Targhee stam (NAA) |

peennei ne 422020, «29040, 429081 Fax: O73-4229260 eal: rnctine |

TEST CERTIFICATE .-

5 Ne. | 2015/Dw-114 __| Brand Name ‘Supratherme

[Date of isu [0370373015 -

WES. Now Dat | |

= nth Ye 0

| Chemical Composition of all weld metal (%) : |

z Min a sof oe pe

| usd 7 139 oat [007 |

[NeeteT AL ps pe | Ti o

Mechanical Properties of all weld metal

| YS02% U1S |" Elong | CVN impact energy Goules) | Hladiess |

[oft (Mpoy | __ (MPa) im | Test Temp at -30% |

es) 5i7 _ 2

Chemical composition (°

© [in

ass) at, | ee | os | ams | 020 | oom |

Fry | gomsy | goaey | enn) | oma) | can) | (an) | tray | mag) | > |

ninincdeice 1 L

Veta) AP ow | fe ni a

Mechanical Properties of all weld metal :_ i

YS024 cite! WTS. Elong, CVN Impact energy Goules) | Hordness

1 (pa (Mp) |) | Test Temp at 30%

400 390 20 ae iT

(in) (min) za |

PWT ot

{

test Cond E708 [As per ENGNDO Type 3a

hat the < 1C conforms 7 all uircenis of ASME Sections Pari-€ Eton 2013 this |

‘use is applicabie fo electrodes identified to AWS code only

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Calibration Certi DFT Gauge - Paint Report Lot 02Document6 pagesCalibration Certi DFT Gauge - Paint Report Lot 02sanketNo ratings yet

- AR NED - Offer List - 18.11.201500138Document1 pageAR NED - Offer List - 18.11.201500138sanketNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DsanketNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeKhalilahmad KhatriNo ratings yet

- 1 SS MT 006Document44 pages1 SS MT 006sanketNo ratings yet

- Witness Inspection and Test PlanDocument5 pagesWitness Inspection and Test PlansanketNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- Document Inspection and Test PlanDocument5 pagesDocument Inspection and Test PlansanketNo ratings yet

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- Asmesection Viii-Div-1& 2Document7 pagesAsmesection Viii-Div-1& 2sanketNo ratings yet

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- DFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- API 650 Tank Design ReviewDocument1 pageAPI 650 Tank Design ReviewjasminneeNo ratings yet

- 575 ReviewDocument4 pages575 ReviewjasminneeNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- DFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- AWS D1.1-D1.1M (R) - 2015 RT PDFDocument5 pagesAWS D1.1-D1.1M (R) - 2015 RT PDFsanketNo ratings yet

- Muscles Anatomy: Singleg GlutebridgDocument1 pageMuscles Anatomy: Singleg GlutebridgsanketNo ratings yet

- Pipe Fitting Dimantion and ScheduleDocument1 pagePipe Fitting Dimantion and SchedulesanketNo ratings yet

- Ultrasound VelocityDocument1 pageUltrasound VelocitymmNo ratings yet

- Aws D1.1-D1.1M (R) - 2015 2Document1 pageAws D1.1-D1.1M (R) - 2015 2sanketNo ratings yet

- 350 Master CanDocument113 pages350 Master CanSangeeth.KpNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- 32 Samss 007Document38 pages32 Samss 007sanketNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- Ultrasonic Inspection Velocity TableDocument2 pagesUltrasonic Inspection Velocity TableCesar Tochukwu NwokoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)