Professional Documents

Culture Documents

Calibration Certi DFT Gauge - Paint Report Lot 02

Uploaded by

sanket0 ratings0% found this document useful (0 votes)

339 views6 pagesrytg

Original Title

Calibration Certi DFT Gauge _ Paint Report Lot 02

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrytg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

339 views6 pagesCalibration Certi DFT Gauge - Paint Report Lot 02

Uploaded by

sanketrytg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

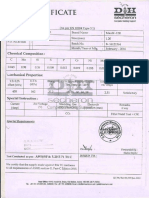

Hi-Tech Laboratory & Services

(A House of Measurement & Calibration)

Shivani Complex, C-4, Vidya Vihar, Opp. Barkatullah University,

Hi-Tech Bhopal. 462.026 MP, India

‘Tol: 0755 - 2410094, 4235738 Telefax. : 0755 - 2410004

Seer Sf eames

CL: CALIBRATION CERTIFICATE

Form Ne HILSIOFIOS) (aendnert No 2 Ded 308 2010)

HILSTISMEWE3815 | 29.05.2015 ‘working 29.05.2015 29.05.2016 1 of 2

‘1a. Calibrated For: ’b._ Name of Equipment instrument

‘Mist Heavy Engineering Work Shop Foile of Digital Coating Thickness Gauge

(A Unit of Jai Prakash Associates Ltd),

Jaypee Nagar - Rewa - 486 450 (M.P.) c. Calibration Location: AtLab

2) Description & Identification of Equipment Instrument Under Calibrations (EUC):

Detail of Coating Thickness Foil

c _= ene aa 22%

Detail of Coating Thickness Gau;

Fischer 2 AA SS ae

3) Standard / Calibrator & Measuri

[Exeral gta

Micrometer

[The Standards used for calibration were calibrated by using reference standard traceable to National Standard

4) Principle / Methodology of Calibration & Procedure :

“Methodology adopted for Calibration Is as per HTLS Procedure NO HTLS/CP/DM-1 (Coating Thickness) which has been

compared with the standard Fol. Using through calibrated Digital Micrometer.

5) Calibration Results : Foil ma

THOZZOI6

eum

2 um 1031 2

. b. ym 248205 25

«. um 281 a

4 um sist 22

° ym 12581 126

1 fa 001% 04

The valves have Been rounded Tas per IS72-TOBD wherever appteable)

Expended uncertainty reported is et epprox 95% confidence level with K=2.

[Calibrated by : (Authorized Signatory :

IREMANT OFA i [SANIAY BAIS

[Caktraion Enginaer laualty Manager

NaBL

‘ACCREDITED LABORATORY

-Tech Laboratory & Services

(A House of Measureme:

& Calibration)

Shivani Complex, C-4, Vidya

Hi-Tech Bhopal. 462 026 MP.. india

Tel.: 0755 - 2410094, 4235738 Telefax. : 0755 - 2410094

Mobile: 094250 09513 web: www his.co in

e-mail: htIsbpl@hotmail.com / mfo@htls.co.in

CALIBRATION CERTIFICATE

(Form Wo. TLS/OF/5)(Amondnet No. 02 Daied 30.08.2070

f, Opp. Barkatullah University

HTLSISHEWA38.15 | 29.05.2015 ‘working 2018 29.05.2016 1 of2

(Aap eas

a un 10 8 re

b. am 248 2

a ye a 25

3. i 61 se

e am 125 120

1 yn 980, 999

The values have bean rounded OY as por IS TB6Ojwherovar applicable?

Expended uncertainty reported is at aporox 95% confisence level wth K=2.

6) Environmental Conditions: a) Temperature 2082S b) Humidity: 50210%

7) Calibration Status & Remark :

8. ACalbration Sticker has been affixed on EUC™.

The Foil of Digital Coating Thickness Gauge has been calibrated and slatus report has been given,

& The Resuits certified here are valid at tho time and under stated conditions of measurements.

4. The re-production of report without prior permission in writing is strictly prohibited.

© This cortiiate relates ony to the calibrated iter,

1. Refer to report before use. Under NAB cop ny Fak

[Calibrated by: 2 [Authorized Signatory = 7

IHEMANT On [SANJAY BAIS

[Geitraion Engine ualiy Mananer

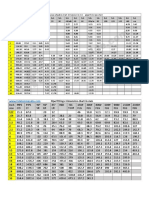

HEAVY ENGINEERING WORKSHOP

A unit of Jaiprakash Associates Ltd.

CONTROL AND INSPECTION REPORT

FOR SHOT BLASTING AND PAINTING

; REPORT NO.=

CUSTOMER :. JSW Stoo! Ltd. HEWIJSW /02

PROJECT - DHARAMTAR PORT Ltd eee ee one

No. 30003230

libration No, HTLS/1S/HEW/338.16

ITEM DESCRIPTION : AS PER ATTECHED ANNEXURE HEWNSWIDP/O2 eee Validity 29.05.2018 to 29.65.2016

MARK NOJ/QTY ~ AS PER ATTECHED ANNEXURE HEW/JSW/DP/02

DRAWING NO. AS PER ATTECHED ANNEXURE HEW/JSWIDP/02

ACCEPTANCE CRITERIA: AS PER APPROVED TECHANICAL SPECIFICATION /QAP

PROCESS FOR SURFACE PREPARATION : SHOT BLASTING

fees FINISH: SA2 172

PAINTING : ONE COAT OF ZINC RICH EPOXY(65 TO 75MICRONS ) AND ONECOAT OF EPOXY MIO PAINT (100)

[TO 125MICRONS) AND TWO COAT OF ALIPHATIC ACRYLIC POLYURETHANE (100 TO 120MICRON) ON SURFACE

Total DFT Required Micron) Mi

ACTIVITIES DATE AMBIENT TEMP (‘C)| appep pet

MINI | MAXI WG

SURFACE PREPRATION 09.03.2016 r

Fe ingle 28°C TO 36°C oK | ok ok

INECOAT OF ZINC RICH

10.03.2016 . :

= ecee 28°C TO.35°C 76 86 81

INE COAT OF MIO 11,03 2076 2

eps zectossec | 176 | 106 188

|TWO COAT OF ALIPHATIC.

12.03.2016

JACRYLIC POLYURETHANE 1025.03.2016 zercTosssc | 22 | 322 a0

2

a * oY

ons:

TON ENGINEER CLIENT/TPI

y Raye ele oz

HEAVY ENGINEEING WORKSHOP

(A Unit of Jai Prakash Associates Ltd.)

[Castonen- JSW DHARAMTAR FORT Da

PANTING ANNETURE HEWSATOPG2 ae ROSE

3 x | Marine tm Darin mare awa

Fransier Tower DFT

7 Sie Stair ‘ALIS MOI OF 825, R1 7 3oa08

Grid-2

2 ma Cokumn ‘Alls MOi OF 909, Ra i 360.22

3 Ba Column ALIS MOL OF 18, RI 1 402.80

4 ca Column ANISMO1 OF 810, Rt T 1292.81

: Bo Beam ‘ALIS MOL CP 309, Ret r 142.01

e Bas Beam ‘ATIS MOL OF 928, Rt 1 388.71

7 Bs Beam ALISMOLC F831, RA T 1510.88

= Bot Bean ‘ALIS MOI F330, R1 F 298.17

> S05 Shub Cohumn ‘ALIS MOL CP 922, Ret r 076

10 BAIA Beem ‘ALIS MOI CF 309, Rei r 134.68

i Baa Beam TALIS MOL CF 009, RA H 190.42

2 26 Beam ‘ALIS MOI CF909, RA H Va.14

3 Baio rs ‘ALIS MOI CF 509, 1 T 176.98

1 Bas = ‘ALIS MOI C F309, RL 1 149.72

5 Bat Beam ‘ALIS MOL CF.309, Rot 1 189.21

16 BSA Beam ‘ALIS MOI CF 09, Ret r 62.08

7 Bas Pea ‘ALIS MOI OF 321, RO H 454.25

8 Bas Beam ALIS MO1CF.2i, RO H 309.37

9 B80 Beem ‘ALIS MOI.C F323, RO ri 259.69

ai la pa Anis Moi oF 323.0 3 Tran

a Be = ‘ALIS MO1 CF 326, RA H 129.52

2 Bot Bean ALIS MOI C F326, RI 1 129.14

2 B63 Beam ‘ALIS MOI OF 926, 1 z 169.09

a | _aB.3s Horizontal Bracing ‘ALIS MOL CP 927, RL 1 25.57

25 | _HB-26 Horizontal Bracing ‘ALIS MOL CF 927, Ret 1 7180

26_| _ne-27 Horizontal Bracing AIS MOL OF 27, @1 T 2056

ae Horizontal Bracing AI1S MOL OF 827, Ret r 26.40

2 | _HB.99 Horizontal Bracing ‘ALISMOI OF 827, Rt z 2640

2» | _#B-40 Horizontal racing ALIS MOI CF 927, Ra r 20.74

30 | rear Horizontal Bracing ALIS MOLCF27, R1 1 23.74

3 7 Horiontal Bracing ANISMOI CF 27, Ri H 22.65

2 | _np-a3 Horizontal Bracing ‘ALIS MOL C327, Rei H 2.77

[ups Horizontal Bracing ‘ALISMOI OF 827, 1 1 2057

| nBas Horizontal Bracing (ALIS MOL CF 327, RA F 25.59

35 | Bae Horizontal Bracing ‘ALIS MOI CP 27, RA T 32.0

36 Bae Beam ‘ALIS MO1 OF 928, 1 1 317.85

7 B26 Beam ALIS MO1CF 928, Ret H 295.77

38 Bae Beam ANS M01 CF 328, RT H 290.85

8 Baz Beam ‘ALIS MO1CP 928, Rt H 193.48

2 B38 Beam ‘ALIS MO1 CF 928, RA Hi 254.12

a Ba Bem ‘ANIS M01 CF 928, Ro 1 151.70

Die} @ cE

CREL io

one

7

| a aa misworeRSa RTT roe

3 | oa = Als More 329,R1[ 7 73552

‘ade Beam Anis MOLE F929, [ 7 va89

“ina aa mis wore a26. 1 [7 16m

a a) aa ‘As Ore F390, RT] 7 7H06

7] 56 Dan ANS Mole F390, [7 om

a] esr a Aus MoI GF 90,1] 1 2557

@ | B99 = ausworeraso.Ra 1 2776

0 | B00 Beam AUS More 30.R1 | —T 20459

a = ALIS MOLE F 90,1] 1 WaT

| B02 Bea ALIS MOI CF 390.R1 | 1 m7

ar ooeas 2 mus MOLE FSsI.Rr | 7 36547

ail aaea a AUS MoLeFSsi.RI [1 25631

3 | ban ian ‘AIS MOTE 509, RL | a 7

sx fae oa AUIS MOr CF 909.1 [a 204

7 oaey a ALS MOT C309. | a i140

| es ia ‘Aig MOLE F505, RT| a 1327

| ane om AIS MOTE F909, RT| 3 1284

oxlcer aa ‘AUIS MOT eFaa1, RO [I 72555

a | 520 a AUS MOTE Fz. RO [T 15.5

| pao = Aus wore FSa1.RO | 1680

[ee a Aus wore rsatRo | 1 1629

fica ee Sea Aus More aai.Ro | 1 1367

[eas 2am TANS MOT 26 Re 1 2805

| Bar ea ‘AUS Moor S2RI [a 7.08

[ones eae AusNoLePa2 RT| a 7.08

a | 529 = AUS MorcR26R [a 430

@ | 3a0 eas ALIS MOTE 326 1 1 632

| eat Ds aus MOL er a9¢ RA [1 Te

rie Alina = Ais MOT F996 i 3065

a | ea8 a TALIS MOL CF 996 Rt 1 28

an oo aa AUS MoI CF as1.RI [7 a1158

Bar = AUIS More 326,R1| 2 28352

73) ee ra Ais wore P26, RI [ om)

ic pa TAS More F 926.1 [ aia02

aes soa ALIS More 326-1] 7 36255

nes = ALIS MO EF 326, | 365.07

| ss som Anis wore F926; [7 Tea

a = AUIS More 326-R1 | 1 35615

fio = ALIS MOI €F 326-R:1 | 21

2] eee = AUIS MOL S26,R1 | 7 ry

a = Ais MOL OF 996, [ 127

“| Bsr Ba AISMOL CF 36,1 [7 2m

| Bes a AUIS MorCF996,R1 [1 107

EES Beam ‘AIS WOT OF36, RI [1 Ta

| Be as TALIS MOL CF926,R1 | 7 1467

i [eons Teron Brag AUIS MoT oFSz7, RA] 2555

ge ae

= [es Teron Bracing isworoFaar RT [1 wa

co | a. Bea ‘Aris wor era, R1 [1 18

o1_[ Bus Bea ANS MOL Crea. R1 [1 wa

[Baia Bean Aris MoI cPaat, 0 7 1578

=p Beam [Anis Wore 36,1 1 157.34

| ae = IANS Mou CF 6, 1 21293

95 [em Bam iS Mor CP aa6, Rt 1 6898

95 [pee Beam [Anis Mor 6 90,1 7 7679

1 | @kaaxan Spice pate #96 ALIS Mor eRa0s, RO | 9 1088

jor | or-2axan Splint #27 As More a0s.R0 | 3 142

ws [aaa Slice plate #28 ‘ANISWOF F206, RO [3 a1

nos | aRa.axan Splice plate #29 ‘Ais wor cFa0s, RO | 3 waz

to? | aRaaKan Slice pine #30 Aus Mor cra0s, RO | 3 wea

is Spe plate #3 ALis More Fa0s.R-0 | 3 un

| oRaaxan Slice pate #22 ‘TIS MOL C F205, RO [3 v7

Tio | GRaaKan Splice plat 39 ‘AUIS Mol C205, RO [3 350

mi [ oRaaxaa | Biotin Bracing #18 8) ‘ALIS Mor cas, RO | a ei

Tia | oR-2ax20 | Blvaton Bracing #21 (Mae Als Mor Pa0s, 0 | 6 2386

ATSMOH CFPOT RD

anf spur Son Pat ta GPa 2 1088

ATSWOTCFa07 RS

mp mm Soe Pate 427 mors 2 1m

a ;

mm | mn Sen Pate 28 mines a 6

ATEUOT CF 27 A

| me Spee Pate 20 ten cra a oa

ATeWOTC FOF RT

a | un Spee Pate #0 aes 2 ea

ASOT CaO RT

me | oe Sea Pao 1 uot Cr a 3 mes

ATBWOI CFTR

mf mr SplcaPa 2 mor ora 2 vow

am or Seen Pa 8 ATOMIC RS 2 o20

m= [er veion Brag (Sie #78 Ai Mon aR @ e808

280 EBR Elevation Bracing (Middle) #21 At EA ee 6 231.65

ie

[wear ovsntal racing musworeraiaRa [1 eT

| aBarA Horzntal Bracing ‘AnsMo1GFais. Ra | 1 1668

2 | 8 Horconial Brig ANS MocRaN. Rt [a 154.18

21 [wean Horna Bracing Ausworerais.R1 [1 1s8

16800 Ta083 55

Howac!

(CuENT/TPI

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- BTC Welding Cons JSWDocument6 pagesBTC Welding Cons JSWsanketNo ratings yet

- AR NED - Offer List - 18.11.201500138Document1 pageAR NED - Offer List - 18.11.201500138sanketNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DsanketNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeKhalilahmad KhatriNo ratings yet

- 1 SS MT 006Document44 pages1 SS MT 006sanketNo ratings yet

- Witness Inspection and Test PlanDocument5 pagesWitness Inspection and Test PlansanketNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- Document Inspection and Test PlanDocument5 pagesDocument Inspection and Test PlansanketNo ratings yet

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- Asmesection Viii-Div-1& 2Document7 pagesAsmesection Viii-Div-1& 2sanketNo ratings yet

- DFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- API 650 Tank Design ReviewDocument1 pageAPI 650 Tank Design ReviewjasminneeNo ratings yet

- 575 ReviewDocument4 pages575 ReviewjasminneeNo ratings yet

- DFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- AWS D1.1-D1.1M (R) - 2015 RT PDFDocument5 pagesAWS D1.1-D1.1M (R) - 2015 RT PDFsanketNo ratings yet

- Muscles Anatomy: Singleg GlutebridgDocument1 pageMuscles Anatomy: Singleg GlutebridgsanketNo ratings yet

- Pipe Fitting Dimantion and ScheduleDocument1 pagePipe Fitting Dimantion and SchedulesanketNo ratings yet

- Ultrasound VelocityDocument1 pageUltrasound VelocitymmNo ratings yet

- Aws D1.1-D1.1M (R) - 2015 2Document1 pageAws D1.1-D1.1M (R) - 2015 2sanketNo ratings yet

- 350 Master CanDocument113 pages350 Master CanSangeeth.KpNo ratings yet

- 32 Samss 007Document38 pages32 Samss 007sanketNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- Ultrasonic Inspection Velocity TableDocument2 pagesUltrasonic Inspection Velocity TableCesar Tochukwu NwokoNo ratings yet