Professional Documents

Culture Documents

Asmesection Viii-Div-1& 2

Uploaded by

sanket0 ratings0% found this document useful (0 votes)

28 views7 pagessection viii

Original Title

ASMESECTION VIII-DIV-1& 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsection viii

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views7 pagesAsmesection Viii-Div-1& 2

Uploaded by

sanketsection viii

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 7

This division contains mandatory

requirements, specific prohibitions, and non

mandatory guidance for pressure vessel

materials, design, fabrication, examination,

inspection, testing, certification and

pressure relief.

This division is divides into three subsections:

Mandatory and non mandatory appendices

Subsection A: consists of part UG – Covering

the general requirements applicable to all

pressure vessels.

Subsection B: covers specific requirements that

are applicable to the various methods used in

the fabrication of pressure vessels

UW – Requirements for pressure vessels

fabricated by welding

UF - Requirements for pressure vessels

fabricated by forging

UB – Requirements for pressure vessels

fabricated by brazing

Subsection C:

UCS- Requirements for Pressure vessels

constructed of carbon & low alloy steels

UNF- Requirements for pressure vessels

constructed of Non-ferrous materials

UHA- Requirements for pressure vessels

constructed of High alloy steel

UCI- Requirements for pressure vessels

constructed of cast iron

UCL- Requirements for welded pressure vessels

constructed of Material with Corrosion

Resistant Integral Cladding, Weld Metal Overlay

Cladding, or Applied Linings

UCD- Requirements for pressure vessels

constructed of Cast Ductile Iron

UHT- Requirements for pressure vessels

constructed of Ferritic Steels with Tensile

Properties Enhanced by Heat Treatment

ULW- Requirements for pressure vessels

Fabricated by Layered Construction

ULT- Alternative Rules for Pressure Vessels

Constructed of Materials Having Allowable

Stresses at low Temperature

UHX- Rules for Shell and Tube Heat Exchangers

UIG- Requirements for pressure vessels

constructed of Impregnated Graphite

Based on the Committee’s consideration,

the following classes of vessels are not

included in the scope of this Division;

Those within the scope of other sections

Fired process tubular heaters

Pressure containers which are integral parts or

components of rotating or reciprocating

mechanical devices, such as pumps,

compressors, turbines, generators, engines, and

hydraulic or pneumatic cylinders where the

primary design consideration and/or stresses

are derived from the functional requirements of

the device.

Structures whose primary function is the

transport of fluids from one location to another

within a system of which it is an integral part,

that is, piping system:

Piping components, such as pipe, flanges,

bolting, gaskets, valves, expansion joints, and

fittings and the pressure containing parts of

other components, such as strainers and

devices which serve such purpose as mixing,

separating, snubbing, distributing, and metering

or controlling flow, provided that pressure

containing parts of such components are

generally recognized as piping components or

accessories;

A vessel for containing air the compression of

which serves only as a cushion, when none of

the following limitations are exceeded:

1.A design pressure of 300 psi (2 Mpa)

2.A design temperature of 210 ºF (99 ºC)

A hot water supply storage tank heated by

steam or any other indirect means when none

of the following limitations is exceeded:

1.A heat input of 200000 Btu/hr (58. kW)

2.A water temperature of 210 ºF (99 ºC)

3.A nominal water containing capacity of 120

gal(450 L)

Vessels not exceeding the design pressure, at

the top of the vessel, limitations below, with no

limitation on size (see UG-28(f), 9-1(c)).

1.Vessels having an internal or external

pressure not exceeding 15 psi (100 kPa)

2.Combination units having an internal or

external pressure in each chamber not

exceeding 15 psi and differential pressure

on the common elements not exceeding 15

psi (see UG-19(a))

Vessels having an inside diameter, width,

height, or cross section diagonal not exceeding

6 in.(1522 mm), with no limitation on length or

vessel or pressure;

Pressure vessels for human occupancy.

Any pressure vessel which meets all the

applicable requirements of this division may

be stamped with the certification mark with

the U designator.

In relation to the geometry of pressure

containing parts, the scope of this division

shall include the following:

1) Where external piping; other pressure vessels

including heat exchangers: or mechanical device,

such as pumps, mixers, or compressors, are to be

connected to the vessel:

1.) the welding end connection for the

first circumferential joint for welded

connections (see UW- 13 (i))

2.)the 1st threaded joint for screwed

connections

3.)the face of the first flange for bolted,

flanged connections

4.)the 1st sealing surface for proprietary

connections or fittings

2) Where non pressure parts are welded

directly to either the internal or external

pressure- retaining surface of a pressure vessel,

this scope shall include the design, fabrication,

testing, and material requirements established for

non pressure part attachments by the applicable

paragraph of this division.

3) Pressure retaining covers for vessel

openings, such as manhole or handhole covers,

and bolted covers with their attaching bolting and

nuts:

You might also like

- ASME U-1 Classificação de VasosDocument3 pagesASME U-1 Classificação de VasosJose FaustinoNo ratings yet

- Extracto de Seccion 8 Div 1Document22 pagesExtracto de Seccion 8 Div 1Jorge DiazNo ratings yet

- ASME Boiler and Pressure Vessel Code Section VIII excerptDocument19 pagesASME Boiler and Pressure Vessel Code Section VIII excerptAgniva DuttaNo ratings yet

- ASME SECTION VIII DIVISION-1 CODES, STANDARDS & SPECIFICATIONSDocument73 pagesASME SECTION VIII DIVISION-1 CODES, STANDARDS & SPECIFICATIONSShafqat Afridi100% (5)

- TSG 21-2016 Supervision Regulation On Safety Technology For Stationary Pressure VesselsDocument174 pagesTSG 21-2016 Supervision Regulation On Safety Technology For Stationary Pressure VesselsBalusamyNo ratings yet

- Asme Section Viii Div-1,2,3Document73 pagesAsme Section Viii Div-1,2,3me2437090% (39)

- Asme Standards Specifications-1Document72 pagesAsme Standards Specifications-1DHAVAL PANCHAL100% (1)

- Asme Sect. Viii Div-I Codes, Standards & SpecificationsDocument72 pagesAsme Sect. Viii Div-I Codes, Standards & SpecificationsrodrigoperezsimoneNo ratings yet

- PV Newsletter - Volume 2012 Issue 8Document8 pagesPV Newsletter - Volume 2012 Issue 8SachinNo ratings yet

- Asme Section Viii Div 1 2 3Document73 pagesAsme Section Viii Div 1 2 3Sakthi Pk100% (3)

- Part I-Section II-Chapter 2Document3 pagesPart I-Section II-Chapter 2nayan vyasNo ratings yet

- Standards and Codes: Asme Section ViiiDocument44 pagesStandards and Codes: Asme Section ViiiNitin LuhadiyaNo ratings yet

- Chapter No 3Document5 pagesChapter No 3MuhammadAwaisNo ratings yet

- Stress Analysis Traning-VarunDocument50 pagesStress Analysis Traning-Varunanurag7878100% (3)

- 1.hydrostatic Test and Flushing (R2)Document19 pages1.hydrostatic Test and Flushing (R2)sethu1091100% (8)

- Pressure VesselsDocument31 pagesPressure VesselsRho Natta MatahariNo ratings yet

- ASME BPV Code Section VIII Divisions: Requirements for Pressure Vessel Design and ConstructionDocument5 pagesASME BPV Code Section VIII Divisions: Requirements for Pressure Vessel Design and ConstructionDiana CarolinaNo ratings yet

- Pipe Stress Basics DTD 23oct2006Document9 pagesPipe Stress Basics DTD 23oct2006Javier García100% (1)

- ME Laws WK 12Document110 pagesME Laws WK 12Charle CandelarioNo ratings yet

- 23 21 13 Hydronic Piping Systems QA QCDocument5 pages23 21 13 Hydronic Piping Systems QA QCAsmara KanthiNo ratings yet

- ASME SEC VIII DIV I Welding RequirementsDocument25 pagesASME SEC VIII DIV I Welding RequirementsshankerNo ratings yet

- Pressure TestingDocument14 pagesPressure TestingWeld Bro Sandeep100% (2)

- ASME Sec VIII the most common code for oil & gas pressure vesselsDocument13 pagesASME Sec VIII the most common code for oil & gas pressure vesselsShieeplNo ratings yet

- ASME Sec VIII the most common code for oil & gas pressure vesselsDocument14 pagesASME Sec VIII the most common code for oil & gas pressure vesselsShieeplNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument9 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument11 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- Asme Sec Viii Div-2Document31 pagesAsme Sec Viii Div-2Yash Rami100% (3)

- ASME VIII Div 1 ReportDocument12 pagesASME VIII Div 1 ReportAmir Zamri100% (2)

- ASME Pressure VesselsDocument25 pagesASME Pressure Vesselspenjualgas100% (2)

- Pressure Vessel Proj. ExecDocument58 pagesPressure Vessel Proj. ExecashwinsudaNo ratings yet

- Plate Heat ExchangerDocument2 pagesPlate Heat Exchangerprashant_dc_inNo ratings yet

- Inspection of The SystemsDocument12 pagesInspection of The SystemsTulen CabuldinNo ratings yet

- Selection and Sizing of Pressure Relief ValvesDocument21 pagesSelection and Sizing of Pressure Relief ValvesjoesuhreNo ratings yet

- Load CasesDocument15 pagesLoad CasesVishnu Menon100% (1)

- PEDDay2 - 2 - SS-EN 13445Document65 pagesPEDDay2 - 2 - SS-EN 13445Srujana KandagatlaNo ratings yet

- FEM Analysis For Pipeline ExpansionDocument12 pagesFEM Analysis For Pipeline ExpansionMahesh SinalkarNo ratings yet

- Project Standards and Specifications Piping Design Criteria Rev1.0Document15 pagesProject Standards and Specifications Piping Design Criteria Rev1.0Alejandro AguanteNo ratings yet

- Heat Exchangers: Technical Manual Mt064Document17 pagesHeat Exchangers: Technical Manual Mt064abessiNo ratings yet

- Pipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsDocument4 pagesPipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsUmesh TiwariNo ratings yet

- Chapter 5 Code Design - Pressure VesselDocument11 pagesChapter 5 Code Design - Pressure VesselEDWARD T CHENJERAINo ratings yet

- Vessels For High Pressure Dust CollectorsDocument4 pagesVessels For High Pressure Dust CollectorsWade ColemanNo ratings yet

- Dot 49CFR 178.71Document10 pagesDot 49CFR 178.71Juan Alejandro Jurado de la RosaNo ratings yet

- The Safe Operation of Pressure Vessels and BoilersDocument11 pagesThe Safe Operation of Pressure Vessels and BoilersTrainer 01No ratings yet

- Piping Stress Analysis Specification for PTTEP Arthit Field DevelopmentDocument23 pagesPiping Stress Analysis Specification for PTTEP Arthit Field Developmentsamprof4vw83% (6)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

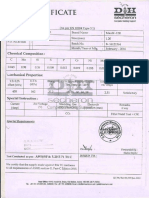

- Calibration Certi DFT Gauge - Paint Report Lot 02Document6 pagesCalibration Certi DFT Gauge - Paint Report Lot 02sanketNo ratings yet

- AR NED - Offer List - 18.11.201500138Document1 pageAR NED - Offer List - 18.11.201500138sanketNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DsanketNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- 575 ReviewDocument4 pages575 ReviewjasminneeNo ratings yet

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- BTC Welding Cons JSWDocument6 pagesBTC Welding Cons JSWsanketNo ratings yet

- Witness Inspection and Test PlanDocument5 pagesWitness Inspection and Test PlansanketNo ratings yet

- 1 SS MT 006Document44 pages1 SS MT 006sanketNo ratings yet

- Document Inspection and Test PlanDocument5 pagesDocument Inspection and Test PlansanketNo ratings yet

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- DFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeKhalilahmad KhatriNo ratings yet

- API 650 Tank Design ReviewDocument1 pageAPI 650 Tank Design ReviewjasminneeNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- DFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- AWS D1.1-D1.1M (R) - 2015 RT PDFDocument5 pagesAWS D1.1-D1.1M (R) - 2015 RT PDFsanketNo ratings yet

- Muscles Anatomy: Singleg GlutebridgDocument1 pageMuscles Anatomy: Singleg GlutebridgsanketNo ratings yet

- Pipe Fitting Dimantion and ScheduleDocument1 pagePipe Fitting Dimantion and SchedulesanketNo ratings yet

- Ultrasound VelocityDocument1 pageUltrasound VelocitymmNo ratings yet

- Aws D1.1-D1.1M (R) - 2015 2Document1 pageAws D1.1-D1.1M (R) - 2015 2sanketNo ratings yet

- 350 Master CanDocument113 pages350 Master CanSangeeth.KpNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- 32 Samss 007Document38 pages32 Samss 007sanketNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- Ultrasonic Inspection Velocity TableDocument2 pagesUltrasonic Inspection Velocity TableCesar Tochukwu NwokoNo ratings yet

- Tutorial Sheet 4Document2 pagesTutorial Sheet 4Syed YousufuddinNo ratings yet

- Envl 4300 Lab3Document9 pagesEnvl 4300 Lab3api-662867343No ratings yet

- Physics Investigatory Project Class 12Document12 pagesPhysics Investigatory Project Class 12shivanginirai7No ratings yet

- Impact of Excessive Mobile Phone Usage On Human JCSB 1000235Document5 pagesImpact of Excessive Mobile Phone Usage On Human JCSB 1000235nidNo ratings yet

- F.E. Campbell - Sweet Slavery - HIT 139Document115 pagesF.E. Campbell - Sweet Slavery - HIT 139HokusLocus67% (3)

- Importance and Uses of Medicinal Plants - An Overview: December 2016Document8 pagesImportance and Uses of Medicinal Plants - An Overview: December 2016safamanz001 safaNo ratings yet

- Smoke Stratification - Understanding the DynamicsDocument3 pagesSmoke Stratification - Understanding the DynamicsGagan UpadhyayNo ratings yet

- InfraTapp - Infra Tapp - Manual ENGDocument64 pagesInfraTapp - Infra Tapp - Manual ENGEliaNo ratings yet

- Land Tenure SystemsDocument140 pagesLand Tenure SystemsjoeclintNo ratings yet

- Past PapaersDocument515 pagesPast PapaersShariq ShaNo ratings yet

- Chemistry Units 8 12Document29 pagesChemistry Units 8 12reg speckNo ratings yet

- The Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Document9 pagesThe Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Md. Abdul KarimNo ratings yet

- Earth First! Climbers Guild Vol. 2Document16 pagesEarth First! Climbers Guild Vol. 2CascadiaDefenders100% (2)

- EXU EN 2017-12 Manual Web PDFDocument126 pagesEXU EN 2017-12 Manual Web PDFИльнур ТагировNo ratings yet

- Cat Helimax 2016 Esp 1Document74 pagesCat Helimax 2016 Esp 1HKM IngenierosNo ratings yet

- Work Permit Renewal Application FormDocument2 pagesWork Permit Renewal Application FormyamojodnabNo ratings yet

- Pharmaceutical Microbiology - B.pharmDocument383 pagesPharmaceutical Microbiology - B.pharmkeyurNo ratings yet

- GRADES 1 To 12 Daily Lesson LogDocument5 pagesGRADES 1 To 12 Daily Lesson LogFlordeliza Manaois RamosNo ratings yet

- ANPATH1 ReviewerDocument17 pagesANPATH1 ReviewerRashid DayaoNo ratings yet

- Music and Therapy Bun2Document17 pagesMusic and Therapy Bun2PanteaAlisaNo ratings yet

- Public Health EngineeringDocument10 pagesPublic Health EngineeringOmkar DeshpandeNo ratings yet

- Concrete's enormous role in world's longest sea bridgeDocument3 pagesConcrete's enormous role in world's longest sea bridgeRafiath SiraNo ratings yet

- Starbucks BSC Project Analyzes Store PerformanceDocument8 pagesStarbucks BSC Project Analyzes Store Performanceandrea100% (1)

- BW Mc2 XWHM y Na ManualDocument23 pagesBW Mc2 XWHM y Na ManualSatyasrinivas PulavarthiNo ratings yet

- Mbenson hw410 1602c - Unit-9-AssignmentDocument46 pagesMbenson hw410 1602c - Unit-9-Assignmentapi-355858071No ratings yet

- C612Document5 pagesC612dinhtung2210100% (1)

- Herbal MedicineDocument38 pagesHerbal MedicineBurei KouNo ratings yet

- Yoga & Diet To Prevent DepressionDocument5 pagesYoga & Diet To Prevent DepressionDietician Mrunmayee DixitNo ratings yet

- 2020 End Year 6 PenulisanDocument8 pages2020 End Year 6 PenulisanZulhillmi ZainuddinNo ratings yet

- Comparing Food with Comparative AdjectivesDocument4 pagesComparing Food with Comparative AdjectivesLuisito GonzalezNo ratings yet