Professional Documents

Culture Documents

Risk Assessment & Safe Working Practice

Uploaded by

kamranshamoo1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment & Safe Working Practice

Uploaded by

kamranshamoo1Copyright:

Available Formats

Risk Assessment & Safe Working Practice

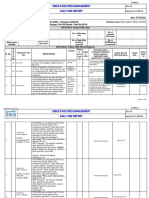

RA Ref Number: 33b Revision: 3 Project/Job Number Reference Insert Job Number Approval Date: 30/03/2018

RA Description: Splicing of fibre optic cabling Next Review Date: 01/04/2019

Notes: Please refer to Safe Working Practices 33b for definitions of items in this assessment. Created by: Lee Davies

Risk Assessment The summary risk assessment is calculated as “Likelihood” x “Consequence” Issued by: Insert Name

Method & Scoring and categorised as follows; 1 to 6 = Low Risk – 7 to 16 = Medium Risk – 17 to 25 = High Risk Issue Date: Insert Date

TASK HAZARDS PERSONS INITIAL CONTROL MEASURES REVISED

AFFECTED RISK RISK LEVEL

LEVEL

Stripping of fibre Cuts from knives. Engineer Likelihood 4 • A self-retracting knife must be used to reduce the risk of injuries. Likelihood 1

optic cable Strains from bending / Severity 4 • Engineers move to stretch legs as they feel the need to. Severity 4

stooping to reach Total 16 • Engineers wear trousers with built in knee protection pads. Total 4

cables, Medium Risk • Engineers report all work related injuries, including aches and pains from Low Risk

Knee injuries from termination work, CDI operate a Health Management Programme to

kneeling on floor. constantly monitor engineers health.

Termination of Eye Injury from flying Engineer / Likelihood 4 • Engineers are trained to cut / strip fibre-optic cabling to reduce the risks of Likelihood 1

fibre-optic cabling glass particles passers by Severity 4 flying particles. Severity 4

Total 16 • Engineers are supplied with suitable PPE for the task / Gloves to EN 388 Eye Total 4

Medium Risk Goggle EN 166 Low Risk

• Engineers are provided with, and use a ‘sharps’ container into which to place

stripped cable ends.

• Engineers are trained to dispose of off cuts and sharps in line with CDI

environmental policy (Ref EMSP 2/1-01)

RA Number: 33b - Issue Revision: 3 Page 1 of 4

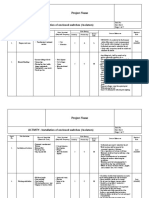

Risk Assessment & Safe Working Practice

TASK HAZARDS PERSONS INITIAL CONTROL MEASURES REVISED

AFFECTED RISK RISK LEVEL

LEVEL

Termination of Isopropanol alcohol Engineer / Likelihood 4 • Only trained fibre optic termination engineers use Isopropanol alcohol also in Likelihood 1

fibre-optic cabling used for cleaning Passers-by. Severity 4 impregnated wipes Severity 4

Total 16 • Seek medical attention on excessive exposure to these levels. Call 999 and tell Total 4

Inhalation: Exposure to Medium Risk the operator that exposure to this substance has occurred. Low Risk

400ppm causes • Very small amounts of IA are used to clean fibre optic elements.

headaches, irritation, • PPE fingerless gloves to EN 388 will be used.

dizziness, weakness, • Must be used only in open well ventilated areas.

nausea and asphyxiation. • A wiping cloth is required to use/dispense IA.

• Always ensure that adequate ventilation is available in the areas where IA is to

Eye contact: Causes

be used.

irritation, redness,

• Use vent fans if required to increase ventilation through flow.

blurred sight.

Skin Contact: Causes

irritation, defeating of

skin, dermatitis

Termination of Eye injury from flying Engineer Likelihood 4 • Follow set-up and operating instructions for Splicer/Oven unit/ Likelihood 1

fibre- optic glass, burns from arc, Severity 4 • Only trained fibre optic termination engineers are to use a splicer. Severity 4

cabling with a temporary blindness Total 16 • Engineers are supplied with suitable PPE for the task / Gloves EN388 / Eye Total 4

splicer from arc. Burns from Medium Risk Goggle EN166 Low Risk

oven • Burns from arc are reduced due to the fact that the arc will only function once

the safety cover is in place.

• Burns from oven are reduced due to the fact that the oven will only function

once the safety catches are in place

Temporary blindness is greatly reduced to the fact that the arc will not function

until the safety cover is in place.

RA Number: 33b - Issue Revision: 3 Page 2 of 4

Risk Assessment & Safe Working Practice

Safe Working Practice: 33b – Splicing of fibre optic cabling

1 PURPOSE: The purpose of this guide is to highlight safe working practices for: Splicing of fibre

optic cabling.

THIS MUST NOT BE TREATED AS A SUBSTITUTE FOR TRAINING.

2 PROTECTIVE CLOTHING AND EQUIPMENT

Operators must wear

➢ PPE as directed by the Task Specific Risk Assessment.

➢ CDI issued work wear

3 BEFORE WORK.

➢ Follow the individual manufacturers instructions for termination.

➢ Follow Manufacturers operating instructions for Splicing & Curing

➢ Be aware of different manufacturers guidelines for termination practices.

➢ Manufacturers cabling systems installed by CDI include;

➢ Systimax

➢ AMP/TYCO

➢ ADC Krone / TE Connectivity

➢ Brand-Rex

➢ BICC

➢ HT Data

➢ Molex

➢ Connectix.

➢ Each system uses different types of individual component; all engineers should be familiar

with the system being installed. If in doubt….ASK.

4. DURING WORK

➢ The individual fibre optic elements are terminated in the cabinet and in some cases can be

terminated at the local end.

Patch Panel.

➢ The fibre optic cable will be installed into the appropriate fibre optic patch panel via the pre-

drilled entrance on the reverse of the patch panel. The fibre will be secured in place with a

compression gland for the purpose of the task.

➢ The fibre optic cable sheath will be stripped back in line with the relevant RA/SWP, a splice

sleeve will be installed to either the main fibre or the pigtail. Each individual element of fibre

will be stripped back and cleaned with Isopropanol Alcohol. Once the cleaning has took

place the bare fibres will be inserted into the cleave tool to allow it to be cut to the precise

length ready for splicing, again the fibres will be cleaned prior to being placed in the splicing

machine.

➢ Insert both fibres into the splicing machine (one from either end) and line them up as best as

the human eye can do. Once your happy with the alignment of the fibres close the fibre

holders and press the button that aligns the fibres.

RA Number: 33b - Issue Revision: 3 Page 3 of 4

Risk Assessment & Safe Working Practice

4. DURING WORK continued

➢ Once your happy with the alignment and the cleaves, close the safety cover and press the

button to initiate the electrodes into performing the splice. This process takes no longer than

12 seconds, once 5 seconds has passed open the cover and slide the splice sleeve over the join

and place it into the oven. The oven can only be initiated once the lid has been closed and the

button pressed. This will take 1 minute to cook and 1 minute to cool.

➢ Once the oven has finished and cooled down remove the fibre from the oven and place it

carefully into the patch panel. The excess fibre will be coiled neatly into the cable

management within the patch panel. The splice sleeve will be place into the splice bridge.

➢ The process will be repeated until all fibres are complete. Once all fibres are completed the

patch panel will be rack mounted in the cabinet.

5 AFTER WORK

➢ Clear away all scrap materials, and ensure all patch panels are tightly fitted.

➢ Clean out the cabinet, and remove all waste etc.

CDI GROUP LTD PLACES GREAT IMPORTANCE ON EVERYONE'S SAFETY:

FAILURE TO COMPLY WITH ANY OF THE ABOVE MAY RESULT IN DISCIPLINARY

ACTION

RA Number: 33b - Issue Revision: 3 Page 4 of 4

You might also like

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Adverse Weather Condition HIRADocument5 pagesAdverse Weather Condition HIRAVenkadesh PeriathambiNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Hirac 1Document1 pageHirac 1Agape PrintshopNo ratings yet

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerNo ratings yet

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- 1-Demolation Risk Assessment ReportDocument8 pages1-Demolation Risk Assessment ReportSyed Ali HassanNo ratings yet

- SEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingDocument3 pagesSEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingSn AhsanNo ratings yet

- Manual Rubbish Handling SafetyDocument1 pageManual Rubbish Handling SafetyScribder0% (1)

- Fire Risk Assessment For Site Office and SiteDocument11 pagesFire Risk Assessment For Site Office and SiteSajid Shah100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Lifting Operations Planning Risk Assessment PDFDocument1 pageLifting Operations Planning Risk Assessment PDFulisses costaNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Risk Assessment For Installation of Enclosed Switches IsolatorsDocument7 pagesRisk Assessment For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- FIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSADocument2 pagesFIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSAJohnNo ratings yet

- Non-Routine Hazards and Risk Assessment SummaryDocument42 pagesNon-Routine Hazards and Risk Assessment SummaryGanesh Murugesan0% (1)

- Personal Protective Equipment ProceduresDocument3 pagesPersonal Protective Equipment ProceduresLwandziso DlaminiNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- JHA for Unloading Product from Ship at Port of SalalahDocument4 pagesJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- RA Excavation For Trial TrenchDocument9 pagesRA Excavation For Trial TrenchSasi KumarNo ratings yet

- Fire Prevention PolicyDocument4 pagesFire Prevention PolicymuhammadkashikNo ratings yet

- F006B CoSHH Inventory FormDocument1 pageF006B CoSHH Inventory FormShahlaNo ratings yet

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNo ratings yet

- Incidents By Root Causes Tools Equipment TrainingDocument5 pagesIncidents By Root Causes Tools Equipment TrainingvictorNo ratings yet

- Ra1 - General Risk Assessment Form 2015Document3 pagesRa1 - General Risk Assessment Form 2015api-349297013No ratings yet

- Nebosh Igc 3 Observation Sheet 00218445 Ajit Kumar 1 PDFDocument12 pagesNebosh Igc 3 Observation Sheet 00218445 Ajit Kumar 1 PDFAbdelkader Fattouche100% (1)

- 6 Methods of Confined Space RescueDocument26 pages6 Methods of Confined Space RescueSARFARAZ KHANNo ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- Operating in Confined SpacesDocument4 pagesOperating in Confined SpacesFaiqoh NahareyNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- 4 WK No. 05 (Month) 2022 Sepdc-Central - Weekly Kpi - (Project Name) - Rev. 02 (Individual)Document5 pages4 WK No. 05 (Month) 2022 Sepdc-Central - Weekly Kpi - (Project Name) - Rev. 02 (Individual)Shafie ZubierNo ratings yet

- Confined Space Rescue PlanDocument4 pagesConfined Space Rescue PlanbalasubramaniamNo ratings yet

- SCP109 - Risk Assessment For Glass Partition EditedDocument4 pagesSCP109 - Risk Assessment For Glass Partition EditedamenmohdNo ratings yet

- Risk Assessment ScaffoldingDocument4 pagesRisk Assessment ScaffoldingisaacbombayNo ratings yet

- Hazard Identification and Risk Control-TemplateDocument2 pagesHazard Identification and Risk Control-TemplateShristika Pradhan100% (1)

- Sharjah Waterfront City-Sector 2 & Sun IslandDocument2 pagesSharjah Waterfront City-Sector 2 & Sun IslandCaptainNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Stop Work AuthortyDocument8 pagesStop Work AuthortyRonald Sarillana100% (1)

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Safety Observation Formate - 01Document3 pagesSafety Observation Formate - 01Peter LuvisNo ratings yet

- Safe excavation SOPDocument6 pagesSafe excavation SOPHana Seiadi100% (1)

- SBOI Chklist PDFDocument1 pageSBOI Chklist PDFRajanNo ratings yet

- Confined Space Entry Rescue Plan 1Document11 pagesConfined Space Entry Rescue Plan 1patrick ruwonaNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- Work at Heigh at Night SafetyDocument49 pagesWork at Heigh at Night SafetyKhuda BukshNo ratings yet

- Fire Prevention Plan: Provided As A Public Service byDocument16 pagesFire Prevention Plan: Provided As A Public Service byAnonymous ycFeyuLAtNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet

- Behavior Based Safety (BBS) : Emco QatarDocument29 pagesBehavior Based Safety (BBS) : Emco QatarparthaNo ratings yet

- JOB SAFETY ANALYSIS FOR VEHICLE REPAIR AND MAINTENANCEDocument4 pagesJOB SAFETY ANALYSIS FOR VEHICLE REPAIR AND MAINTENANCEba ratnaparkheNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Bar Bending Checklist: Contractor NameDocument1 pageBar Bending Checklist: Contractor NameAfroz AlamNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- SDS Alcad BDX en Aug10Document4 pagesSDS Alcad BDX en Aug10Suthep LairusameeNo ratings yet

- Ohs PR 09 19 f10 (A) Chain Block InspectionDocument2 pagesOhs PR 09 19 f10 (A) Chain Block InspectionShafie ZubierNo ratings yet

- Risk Assessment AnalysisDocument7 pagesRisk Assessment Analysiskamranshamoo1No ratings yet

- Study Guide: Course: IOSH Managing Safely Recommended Study Hours: 18 HoursDocument2 pagesStudy Guide: Course: IOSH Managing Safely Recommended Study Hours: 18 HoursRiyaz Ur Rahaman CiNo ratings yet

- Risk Assessment AnalysisDocument7 pagesRisk Assessment Analysiskamranshamoo1No ratings yet

- Disinfection SurfacesDocument1 pageDisinfection Surfaceskamranshamoo1No ratings yet

- F06-Appointment OHS RepresenativeDocument1 pageF06-Appointment OHS Represenativekamranshamoo1No ratings yet

- Permission LetterDocument1 pagePermission Letterkamranshamoo1No ratings yet

- Disinfection SurfacesDocument1 pageDisinfection Surfaceskamranshamoo1No ratings yet

- F06-Appointment OHS RepresenativeDocument1 pageF06-Appointment OHS Represenativekamranshamoo1No ratings yet

- HSE Committee Meeting Minutes 0001Document8 pagesHSE Committee Meeting Minutes 0001Mohd Zulhaidy100% (2)

- Surfaces Disinfection: Location Month April DateDocument1 pageSurfaces Disinfection: Location Month April Datekamranshamoo1No ratings yet

- HSE Committee Meeting Minutes 0001Document8 pagesHSE Committee Meeting Minutes 0001Mohd Zulhaidy100% (2)

- Yes I Am A Khan I Will KKKZHNDocument1 pageYes I Am A Khan I Will KKKZHNkamranshamoo1No ratings yet

- Booking Reference: TYL2GA Booking Status: Con Rmed: PrintDocument3 pagesBooking Reference: TYL2GA Booking Status: Con Rmed: Printkamranshamoo1No ratings yet

- Corrective Action LogDocument30 pagesCorrective Action Logkamranshamoo1No ratings yet

- 5 Star Safety Filing SystemDocument1 page5 Star Safety Filing Systemkamranshamoo1No ratings yet

- GGG SGSGDocument1 pageGGG SGSGkamranshamoo1No ratings yet

- NasirDocument1 pageNasirkamranshamoo1No ratings yet

- Ali KhanDocument1 pageAli Khankamranshamoo1No ratings yet

- NEBOSH GC Course SummaryDocument14 pagesNEBOSH GC Course Summarykamranshamoo1No ratings yet

- Effective Safety Committees: Success FactorsDocument3 pagesEffective Safety Committees: Success Factorskamranshamoo1No ratings yet

- First Aid KitDocument1 pageFirst Aid Kitkamranshamoo1No ratings yet

- Osha 2226Document28 pagesOsha 2226Touil HoussemNo ratings yet

- IGC1 Updated Question Bank-1Document23 pagesIGC1 Updated Question Bank-1kamranshamoo1No ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word Documentkamranshamoo1No ratings yet

- Advance MoneyDocument1 pageAdvance Moneykamranshamoo1No ratings yet

- First AidDocument1 pageFirst Aidkamranshamoo1No ratings yet

- GC3 Candidate Report Template1952016261156Document1 pageGC3 Candidate Report Template1952016261156kamranshamoo1No ratings yet

- Survey ActivityDocument1 pageSurvey Activitykamranshamoo1No ratings yet

- First Aid KitDocument1 pageFirst Aid Kitkamranshamoo1No ratings yet

- Course Is 344 Fall 2018 v2Document6 pagesCourse Is 344 Fall 2018 v2kimkimNo ratings yet

- ACA2028: Apparent Cause Analysis TechniquesDocument21 pagesACA2028: Apparent Cause Analysis TechniquesMaureen Janelle RemaneaNo ratings yet

- Project Kick Off MeetingDocument11 pagesProject Kick Off Meetingpradeep100% (1)

- EPCM TheMisunderstoodContractDocument6 pagesEPCM TheMisunderstoodContractmonikatickoo4412100% (2)

- Security AnalysisDocument21 pagesSecurity AnalysisCharishma KarumanchiNo ratings yet

- Luna Pen NegotiationDocument9 pagesLuna Pen NegotiationJoanne Ferrer100% (1)

- Importance of Governance, Risk, and Compliance Principles: ChaptertwoDocument10 pagesImportance of Governance, Risk, and Compliance Principles: ChaptertwoYuris ZegaNo ratings yet

- Insurance Law-DisclosureDocument34 pagesInsurance Law-DisclosureDavid Fong100% (1)

- DLL 4th Week HazardsDocument16 pagesDLL 4th Week HazardsmjcNo ratings yet

- VicRoads 2019-Road Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign Supports-DoneDocument19 pagesVicRoads 2019-Road Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign Supports-DoneMineaNo ratings yet

- Practice Exam: Updated 01/09/21Document159 pagesPractice Exam: Updated 01/09/21Florian D0% (1)

- FAHM 2018 Programme v4Document16 pagesFAHM 2018 Programme v4Aviation Events InternationalNo ratings yet

- Management Oversight and Risk Tree (MORT)Document60 pagesManagement Oversight and Risk Tree (MORT)m2z.marksmanNo ratings yet

- Biocompatibility in Eu MDRDocument11 pagesBiocompatibility in Eu MDRsachinNo ratings yet

- RCMDocument2 pagesRCMMohd Idris MohiuddinNo ratings yet

- Engineering As Social ExperimentationDocument18 pagesEngineering As Social ExperimentationHarshan ArumugamNo ratings yet

- Analysis of Credit Risk, Liquidity and Profitability of The Trade Bank of Iraq For The Period (2012-2021)Document25 pagesAnalysis of Credit Risk, Liquidity and Profitability of The Trade Bank of Iraq For The Period (2012-2021)Ali Abdulhassan AbbasNo ratings yet

- ENGLISH TEST FOR 9 TH FORM - MAY Week 2Document7 pagesENGLISH TEST FOR 9 TH FORM - MAY Week 2Bụng Bự BôngNo ratings yet

- Student Support Material: Class XI Business StudiesDocument111 pagesStudent Support Material: Class XI Business StudiesPushpinder KumarNo ratings yet

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentBasky0% (1)

- Training - Training Manual On Community Based Early Warning System On Landslide PDFDocument39 pagesTraining - Training Manual On Community Based Early Warning System On Landslide PDFCDMP Bangladesh100% (1)

- Gilman Et Al 2017 Ecological Data From Observer Programmes Underpin Ecosystem-Based Fisheries ManagementDocument15 pagesGilman Et Al 2017 Ecological Data From Observer Programmes Underpin Ecosystem-Based Fisheries ManagementHothon TrioniNo ratings yet

- How Health and Safety Management Systems Work and What They Look LikeDocument8 pagesHow Health and Safety Management Systems Work and What They Look LikeQue EnaNo ratings yet

- Business Environment and Concepts - Version 1 NotesDocument27 pagesBusiness Environment and Concepts - Version 1 Notesaffy714No ratings yet

- Safeuse of Concrete Pump PDFDocument47 pagesSafeuse of Concrete Pump PDFAdegboyega Adeyemi100% (1)

- Chapter 05 AnsDocument42 pagesChapter 05 AnsLuisLoNo ratings yet

- PETRONAS Canada 2020 04 Policy HSSEDocument11 pagesPETRONAS Canada 2020 04 Policy HSSELearning的生活No ratings yet

- Pinnacle Case Chapter 11Document4 pagesPinnacle Case Chapter 11Albertha PalmaNo ratings yet

- Finmar - Chapter 12 - 14Document24 pagesFinmar - Chapter 12 - 14AlexanNo ratings yet

- Z 016 6566424.PDF Norsok SandardDocument43 pagesZ 016 6566424.PDF Norsok Sandardlumagbas100% (1)