Professional Documents

Culture Documents

Payzone Ne 600: Non-Emulsifiers

Uploaded by

smithyry2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Payzone Ne 600: Non-Emulsifiers

Uploaded by

smithyry2014Copyright:

Available Formats

Completion Fluids & Additives | Formation Protection

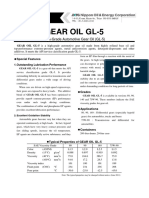

PayZone® NE 600

NON-EMULSIFIERS

Overview

Physical Properties

PayZone® NE-600 is a high-performance non-emulsifier

especially effective in monovalent completion fluids such Appearance Clear, amber solution

as standard halide brines and TETRA CS Neptune® fluids.

Odor Slight solvent

It shows exceptional performance at breaking oil/brine

emulsions. Specific Gravity 1.085 g/mL

Water Solubility Soluble

Features and Benefits

• Compatible with all divalent brine systems, including

zinc-based and TETRA CS Neptune Recommended Treatment

• Provides exceptional oil/brine emulsion breakup across

multiple crude oil and oil/brine ratios, especially in The recommended treatment of PayZone NE 600 non-

monovalent brines, standard halide brines, and TETRA emulsifier is 0.5% by volume. Consult with a TETRA

CS Neptune fluids representative for specific recommendations.

• Reduces safety concerns as it is formulated without

isopropyl alcohol

Safety and Handling

Applicable Information

Ensure good ventilation of the work station. Keep away

PayZone® NE-600 non-emulsifier is designed for treating from heat, hot surfaces, sparks, open flames and other

zinc-based brines to break up any oil/brine emulsions that ignition sources. Wear personal protective equipment.

can form during the life cycle of a well. Do not breathe dust/fume/gas/mist/vapors/spray. Avoid

contact with skin and eyes. Wash contaminated clothing

before reuse. Do not eat, drink or smoke when using this

product. Always wash hands after handling the product.

Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether

products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in

compliance with applicable laws and other governmental enactments. Seller assumes no obligation or liability for the information in this document. NO WARRANTIES

ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. Further, nothing contained

herein shall be taken as a recommendation to manufacture or use any of the herein described materials or processes in violation of existing or future patents.

01/21/2021 Contact us to learn more at: tetratec.com

Copyright © 2021 TETRA Technologies, Inc. All Rights Reserved.

Follow Us:

You might also like

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Advanced Post-Combustion CO2 CaptureDocument39 pagesAdvanced Post-Combustion CO2 CaptureMuhammad Faiz Fudzaili100% (1)

- (107.1) Experiment 2 - Milk of MagnesiaDocument5 pages(107.1) Experiment 2 - Milk of MagnesiaReysterCastroNo ratings yet

- Brochure Antifoams Defoamers Tego AntifoamDocument8 pagesBrochure Antifoams Defoamers Tego AntifoamJuan CubasNo ratings yet

- SRB & TCB Tests EvaluationDocument25 pagesSRB & TCB Tests EvaluationEmad BehdadNo ratings yet

- Advance Clean Short Trip BOP ToolDocument1 pageAdvance Clean Short Trip BOP Toolsmithyry2014No ratings yet

- Stereoisomerism and Optical Isomerism Concepts ExplainedDocument3 pagesStereoisomerism and Optical Isomerism Concepts ExplainedSanjay Mani Tripathi50% (2)

- Fabric Conveyor Belts Installation and Maintenance GuideDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guidejonodo89100% (2)

- Fpsne 100Document1 pageFpsne 100AliAliNo ratings yet

- ZEOCHEM Ethanol BrochureDocument8 pagesZEOCHEM Ethanol BrochureNguyễn Khánh HòaNo ratings yet

- THE BEAUTY MIX: Nourishing Skincare recipes you can make easily using your ThermomixFrom EverandTHE BEAUTY MIX: Nourishing Skincare recipes you can make easily using your ThermomixRating: 5 out of 5 stars5/5 (1)

- TDS ELOTEX ERA100 enDocument2 pagesTDS ELOTEX ERA100 enMohamed Osama AshmawyNo ratings yet

- Elotex Seal 80 PDFDocument2 pagesElotex Seal 80 PDFRajuNSanaboinaNo ratings yet

- Afe 2017 Xiameter-Afe-3168-Antifoam-EmulsDocument2 pagesAfe 2017 Xiameter-Afe-3168-Antifoam-EmulsZhan FangNo ratings yet

- (SG111) Sealxpert 111 Silicone Grease - Rev 1Document1 page(SG111) Sealxpert 111 Silicone Grease - Rev 1Khoon Fen KBNo ratings yet

- Xiameter AFE-1247 Antifoam EmulsionDocument2 pagesXiameter AFE-1247 Antifoam Emulsiongaurav chauhanNo ratings yet

- High-Grade Automotive Gear Oil (GL-5)Document3 pagesHigh-Grade Automotive Gear Oil (GL-5)muh fadliNo ratings yet

- Orange Peel Tech SheetDocument1 pageOrange Peel Tech SheetobsotamNo ratings yet

- Elementis-Bentone Ew - TDSDocument2 pagesElementis-Bentone Ew - TDSmgamal1080No ratings yet

- EZ Mulz 1475 TDS 1Document2 pagesEZ Mulz 1475 TDS 1Dinesh babuNo ratings yet

- 95 405 01 Xiameter Mem 0039 EmulsionDocument3 pages95 405 01 Xiameter Mem 0039 Emulsiong082993No ratings yet

- FILE - 20210525 - 094757 - Defom 5800F - TDS - EDocument2 pagesFILE - 20210525 - 094757 - Defom 5800F - TDS - Elee nguyenNo ratings yet

- XIAMETER™ AFE 0200 Antifoam Emulsion: Features & Benefits Composition ApplicationsDocument3 pagesXIAMETER™ AFE 0200 Antifoam Emulsion: Features & Benefits Composition ApplicationsZhan FangNo ratings yet

- Synolac 4100: Product Application DetailsDocument2 pagesSynolac 4100: Product Application DetailsmonrmNo ratings yet

- E3) Epimastic5100 4292Document2 pagesE3) Epimastic5100 4292Syed FaridNo ratings yet

- Irganox 1010: Industrial CoatingsDocument3 pagesIrganox 1010: Industrial CoatingsPrototypeNo ratings yet

- Eneos 10W40 SM PDSDocument2 pagesEneos 10W40 SM PDSCoc ZaaNo ratings yet

- Indian Head GasketDocument1 pageIndian Head GasketDavidNo ratings yet

- Deurheo 2810Document1 pageDeurheo 2810omerNo ratings yet

- Elementis-Bentone De-TdsDocument2 pagesElementis-Bentone De-Tdsmgamal1080No ratings yet

- Xiameter OFX-0193 Fluido - Ficha Tecnica - Dow - InglesDocument4 pagesXiameter OFX-0193 Fluido - Ficha Tecnica - Dow - InglesMario Andres Montero CastilloNo ratings yet

- Afe 1430Document2 pagesAfe 1430Gabriela ZubietaNo ratings yet

- Antiespumante Dow CorningDocument2 pagesAntiespumante Dow CorningJuan Carlos Vazquez RosasNo ratings yet

- 14.penecoat Stabilizer ENG PDS 19.11.2019Document2 pages14.penecoat Stabilizer ENG PDS 19.11.2019Bilal HodžićNo ratings yet

- d3) Epilux4 2763Document2 pagesd3) Epilux4 2763Salman KhanNo ratings yet

- ASTERITE® LAR Embedment Technical-Data-Sheet.1569415928Document2 pagesASTERITE® LAR Embedment Technical-Data-Sheet.1569415928Mamoon ShahidNo ratings yet

- XIAMETER® OFX-8803 Silicone Fluid PDFDocument3 pagesXIAMETER® OFX-8803 Silicone Fluid PDFPablo Manu Gomez VNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- TDS Loctite Nickel LB 771-EnDocument2 pagesTDS Loctite Nickel LB 771-EnGregory Alan Francisco IINo ratings yet

- MOLYKOTEDocument2 pagesMOLYKOTEDavid Palm PNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- MOLYKOTE 111 Compound 22-1087L-01Document2 pagesMOLYKOTE 111 Compound 22-1087L-01If ChenNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Rheolate 150Document2 pagesRheolate 150buninaNo ratings yet

- Safe-Surf OeDocument2 pagesSafe-Surf OeyfcozNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- XIAMETER™ AFE-0120 Antifoam Emulsion: Features & Benefits Composition ApplicationsDocument3 pagesXIAMETER™ AFE-0120 Antifoam Emulsion: Features & Benefits Composition ApplicationsZhan FangNo ratings yet

- Whitmore Det-900 GreaseDocument1 pageWhitmore Det-900 GreaseDon HowardNo ratings yet

- Confi-Lube Product Data SheetDocument1 pageConfi-Lube Product Data SheetpaimanNo ratings yet

- TETRA Break™ L: Polymer BreakerDocument1 pageTETRA Break™ L: Polymer Breakersmithyry2014No ratings yet

- Synolac 4103 WD 85Document2 pagesSynolac 4103 WD 85monrmNo ratings yet

- TDS Aristoflex AVC EnglishDocument3 pagesTDS Aristoflex AVC EnglishLucas Ferreira de PaulaNo ratings yet

- Release: DOW CORNING® 2-5009 EmulsionDocument2 pagesRelease: DOW CORNING® 2-5009 EmulsionFadhli KusumaNo ratings yet

- Caltex Aquatex 3180-0805Document3 pagesCaltex Aquatex 3180-0805faisiiNo ratings yet

- Permatex Industrial Strength Cleaner & Degreaser TDS 1 GallonDocument1 pagePermatex Industrial Strength Cleaner & Degreaser TDS 1 GallonAsadNo ratings yet

- Synolac 755 WD 60Document2 pagesSynolac 755 WD 60monrmNo ratings yet

- Surfynol® 440 Surfactant: Description Shelf LifeDocument2 pagesSurfynol® 440 Surfactant: Description Shelf LifeWangYunNo ratings yet

- Tds Elotex Mp2050 enDocument2 pagesTds Elotex Mp2050 end6cmc5jscfNo ratings yet

- Servicemanual Blade 1000Document301 pagesServicemanual Blade 1000Ionut ValentinNo ratings yet

- Thicken ErDocument3 pagesThicken ErAmr RagabNo ratings yet

- ThickenerDocument3 pagesThickenerErnesto Vicuña IslasNo ratings yet

- Thickener Guide for Skin and Hair CareDocument3 pagesThickener Guide for Skin and Hair CareErnesto Vicuña IslasNo ratings yet

- CT-4130 PDSDocument2 pagesCT-4130 PDSMark WuNo ratings yet

- Organic Ingredients Explained | What's Inside Your Beauty Products and Why?From EverandOrganic Ingredients Explained | What's Inside Your Beauty Products and Why?No ratings yet

- COCONUT OIL: Harness the Healing Powers of Coconut Oil for Optimal Wellness (2023 Guide for Beginners)From EverandCOCONUT OIL: Harness the Healing Powers of Coconut Oil for Optimal Wellness (2023 Guide for Beginners)No ratings yet

- Offshore Sand Control TechnologyDocument2 pagesOffshore Sand Control Technologysmithyry2014No ratings yet

- Delta STSG SHUNT TUBE SYSTEM CASED HOLEDocument1 pageDelta STSG SHUNT TUBE SYSTEM CASED HOLEsmithyry2014No ratings yet

- Nobre Opq 2005Document2 pagesNobre Opq 2005LawNo ratings yet

- SPE 58778 Pressure-Actuated Isolation Valves For Fluid Loss Control in Gravel/Frac-Pack CompletionsDocument6 pagesSPE 58778 Pressure-Actuated Isolation Valves For Fluid Loss Control in Gravel/Frac-Pack Completionssmithyry2014No ratings yet

- Sand Screen Case Study SSD Carbonate Reservoir CelumDocument2 pagesSand Screen Case Study SSD Carbonate Reservoir Celumsmithyry2014No ratings yet

- Quantum Multiport PackerDocument1 pageQuantum Multiport Packersmithyry2014No ratings yet

- Tetrasol Pipe Dope Remover Plus: Tads™ Displacement SystemDocument1 pageTetrasol Pipe Dope Remover Plus: Tads™ Displacement Systemsmithyry2014No ratings yet

- Ceramic Sand Screen System Data Sheet CelumDocument2 pagesCeramic Sand Screen System Data Sheet Celumsmithyry2014No ratings yet

- Bottom Assemblies For QL-Series Packers: Provides A Fit-For-Purpose Bottom On PackerDocument1 pageBottom Assemblies For QL-Series Packers: Provides A Fit-For-Purpose Bottom On Packersmithyry2014No ratings yet

- Clearfrac LT PsDocument2 pagesClearfrac LT Pssmithyry2014No ratings yet

- TETRA Break™ L: Polymer BreakerDocument1 pageTETRA Break™ L: Polymer Breakersmithyry2014No ratings yet

- A Feasibility Study of Using Frac-Packed Wells To Produce Natural Gas From Subsea Gas Hydrate ResourcesDocument13 pagesA Feasibility Study of Using Frac-Packed Wells To Produce Natural Gas From Subsea Gas Hydrate Resourcessmithyry2014No ratings yet

- Fiberpac: Proppant Washout Control TechnologyDocument2 pagesFiberpac: Proppant Washout Control Technologysmithyry2014No ratings yet

- Energies: Cement Placement: An Overview of Fluid Displacement Techniques and ModellingDocument33 pagesEnergies: Cement Placement: An Overview of Fluid Displacement Techniques and Modellingsmithyry2014No ratings yet

- Energies: Formation Damage Avoidance by Reducing Invasion With Sodium Silicate-Modified Water-Based Drilling FluidDocument12 pagesEnergies: Formation Damage Avoidance by Reducing Invasion With Sodium Silicate-Modified Water-Based Drilling Fluidsmithyry2014No ratings yet

- Energies 12 01519Document14 pagesEnergies 12 01519smithyry2014No ratings yet

- Clearfrac Hiperm PsDocument2 pagesClearfrac Hiperm Pssmithyry2014No ratings yet

- Operator Achieves 100% Gravel-Pack Completion Efficiency and Improves Productivity Index by 30%Document2 pagesOperator Achieves 100% Gravel-Pack Completion Efficiency and Improves Productivity Index by 30%smithyry2014No ratings yet

- Aquapac PsDocument1 pageAquapac Pssmithyry2014No ratings yet

- Aquapac Friction Reducer PsDocument1 pageAquapac Friction Reducer Pssmithyry2014No ratings yet

- Calcium Chloride Solution Product Data SheetDocument1 pageCalcium Chloride Solution Product Data Sheetsmithyry2014No ratings yet

- Cased Hole Gravelpack CsDocument2 pagesCased Hole Gravelpack Cssmithyry2014No ratings yet

- Quantifying Reservoir Inflow with RESMAN's Flush Out ModelDocument2 pagesQuantifying Reservoir Inflow with RESMAN's Flush Out Modelsmithyry2014No ratings yet

- Primopac: Invert Emulsion Gravel-Pack Carrier FluidDocument4 pagesPrimopac: Invert Emulsion Gravel-Pack Carrier Fluidsmithyry2014No ratings yet

- Zinc Calcium Bromide - Calcium Chloride SolutionDocument1 pageZinc Calcium Bromide - Calcium Chloride Solutionsmithyry2014No ratings yet

- PP - HPWS Product Line WC 2017Document16 pagesPP - HPWS Product Line WC 2017TheNourEldenNo ratings yet

- A Method of Proppant Pack Permeability AssessmentDocument10 pagesA Method of Proppant Pack Permeability Assessmentsmithyry2014No ratings yet

- Primopac: Invert Emulsion Gravel-Pack Carrier FluidDocument4 pagesPrimopac: Invert Emulsion Gravel-Pack Carrier Fluidsmithyry2014No ratings yet

- Honeywell Genetron 407C Technical SpecsDocument18 pagesHoneywell Genetron 407C Technical Specsvinoth kumarNo ratings yet

- Week 2 - General Chemistry 1 - LAS 1DDocument8 pagesWeek 2 - General Chemistry 1 - LAS 1Ddo san namNo ratings yet

- Mtds - Burst 100 RSDDocument2 pagesMtds - Burst 100 RSDDr. Ahmed Abdel-HakimNo ratings yet

- ChromiumDocument4 pagesChromiumTom SinghNo ratings yet

- Monografia MainDocument20 pagesMonografia MainWILIAM SALVADORNo ratings yet

- Imat Topic List by SectionDocument1 pageImat Topic List by Sectionlara germirNo ratings yet

- 15B Le Chateliers PrincipleDocument2 pages15B Le Chateliers PrincipleJasmine KeirouzNo ratings yet

- ACNV Test Determines Galvanizing Flux CompositionDocument1 pageACNV Test Determines Galvanizing Flux CompositionRana ThakurNo ratings yet

- Astringents & Bleaching AgentsDocument40 pagesAstringents & Bleaching AgentssujataNo ratings yet

- Topic 4 Chemical Bonding and Structure PDFDocument13 pagesTopic 4 Chemical Bonding and Structure PDFSveta StepanovaNo ratings yet

- Bioorganic & Medicinal Chemistry Letters: SciencedirectDocument5 pagesBioorganic & Medicinal Chemistry Letters: SciencedirectHaroon Ur RashidNo ratings yet

- Ionic Liquid-Assisted Refinery Processes - A Review and Industrial PerspectiveDocument23 pagesIonic Liquid-Assisted Refinery Processes - A Review and Industrial Perspectivemohsen miandehiNo ratings yet

- Assignment I-Chemistry 2021-22 (3 Sets)Document3 pagesAssignment I-Chemistry 2021-22 (3 Sets)Battleborn GamersNo ratings yet

- History and Future of Pilot Testing for High LSI ApplicationsDocument23 pagesHistory and Future of Pilot Testing for High LSI ApplicationsMike StandishNo ratings yet

- Kinetics of The Synthesis of Bisphenol A: Applied Catalysis, 37Document10 pagesKinetics of The Synthesis of Bisphenol A: Applied Catalysis, 37khalid -No ratings yet

- Stainless Steel Chemical Composition and PropertiesDocument2 pagesStainless Steel Chemical Composition and Propertiespratik bhoiteNo ratings yet

- Diagrama R 1234 YfDocument1 pageDiagrama R 1234 YfMaríaNo ratings yet

- Lesson 5 - Corpuscles To Chemical Atomic TheoryDocument21 pagesLesson 5 - Corpuscles To Chemical Atomic TheoryEji AlcorezaNo ratings yet

- The SkullDocument14 pagesThe SkullChesca VerzNo ratings yet

- Ge 2009Document3 pagesGe 2009RICHARD MACIENTE SILVINO DA SILVANo ratings yet

- TP-AATM 106b-A Moisture Karl Fischer MethodDocument2 pagesTP-AATM 106b-A Moisture Karl Fischer MethodRafael LugoNo ratings yet

- Tolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionDocument1 pageTolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionJorge OrihuelaNo ratings yet

- Animal Nutrition: Dervan D.S.L. Bryan, Dawn A. Abbott, Henry L. ClassenDocument9 pagesAnimal Nutrition: Dervan D.S.L. Bryan, Dawn A. Abbott, Henry L. ClassenmiminNo ratings yet

- Grid Power FNC Manual enDocument29 pagesGrid Power FNC Manual enNguyễn Anh DanhNo ratings yet

- Prereg Pharmacist Drug Calculations Roy Sinclair Booklet 2Document144 pagesPrereg Pharmacist Drug Calculations Roy Sinclair Booklet 2Maha tabiNo ratings yet