Professional Documents

Culture Documents

Design of Machine Elements Ii Assignment

Uploaded by

Tasisa Kuma0 ratings0% found this document useful (0 votes)

154 views2 pagesOriginal Title

Assignment_-DME_I

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

154 views2 pagesDesign of Machine Elements Ii Assignment

Uploaded by

Tasisa KumaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

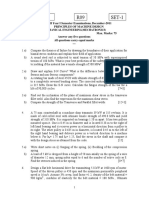

DESIGN OF MACHINE ELEMENTS II

Assignment

1. Design a bushed-pin type flexible coupling for connecting a motor

shaft to a pump shaft for the following service conditions : Power to

be transmitted = 40 kW ; speed of the motor shaft = 1000 r.p.m. ;

diameter of the motor shaft = 50 mm ; diameter of the pump shaft

= 45 mm. The bearing pressure in the rubber bush and allowable

stress in the pins are to be limited to 0.45 N/mm2 and 25 MPa

respectively

2. A bracket in the form of a plate is fitted to a column by means of

four rivets of the same size, as shown in Fig. 9.39. A load of 100

kN is applied to the bracket at an angle of 60° to the horizontal and

the line of action of the load passes through the centre of the bottom

rivet. If the maximum shear stress for the material of the rivet

is 70 MPa, find the diameter of rivets. What will be the thickness

of the plate if the crushing stress is 100 MPa?

3. Fig. shows a welded joint subjected to an eccentric load of 20 kN.

The welding is only on one side. Determine the uniform size of the

weld on the entire length of two legs. Take permissible shear

stress for the weld material as 80 MPa.

4. The bumper springs of a railway carriage are to be made of

square section wire. The ratio of mean diameter of spring to the side

of wire is nearly equal to 6. Two such springs are required to bring to

rest

a carriage weighing 20 kN moving with a velocity of 1.5 m/s with a

maximum deflection of 200 mm. Design the spring if the allowable

shear stress is not to exced 300 MPa and G = 84 kN/mm2.

You might also like

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- Me 6503 Design of Machine Elements QBDocument3 pagesMe 6503 Design of Machine Elements QBDeepak SNo ratings yet

- Assignment PC-ME 503Document5 pagesAssignment PC-ME 503039 Md Faizan AhmedNo ratings yet

- DME 1 Question BankDocument5 pagesDME 1 Question BankRahul YedduNo ratings yet

- Machine Design QsDocument5 pagesMachine Design Qskeyredin selmanNo ratings yet

- DME Unit 2 33Document35 pagesDME Unit 2 33Chandrasekhar PrabhakaranNo ratings yet

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- DMM-1 MID-2 Assignment QuestionsDocument3 pagesDMM-1 MID-2 Assignment Questionsuppada AnilNo ratings yet

- Final Design Work SheetDocument7 pagesFinal Design Work SheetKINDUNo ratings yet

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- DMM I Assignment - 4Document2 pagesDMM I Assignment - 4Konduru Vinay Kumar ReddyNo ratings yet

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- ShaftsDocument1 pageShaftsNhlaka ZuluNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- Question Bank 2 DME 1Document4 pagesQuestion Bank 2 DME 1Ayush KothariNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- Dme - Ii (17me64) : Assignement 01Document3 pagesDme - Ii (17me64) : Assignement 01NAVEEN H ENo ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Assignment 1Document4 pagesAssignment 1sonawanepmsNo ratings yet

- MDDocument4 pagesMDਲਖਵੀਰ ਸਿੰਘ ਖਾਨਾNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- LabManual MDID2016 2016 02 24 16 29 36Document23 pagesLabManual MDID2016 2016 02 24 16 29 36Rajat MehtaNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Projects For Lab BDocument91 pagesProjects For Lab BPeter AshrafNo ratings yet

- DME - 1 Assignment - II Problem Sheet (2019-20)Document2 pagesDME - 1 Assignment - II Problem Sheet (2019-20)VenkateshNo ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Assignment 01Document2 pagesAssignment 01Ratan Sadanandan O MNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- Assignment 2Document3 pagesAssignment 2sonawanepmsNo ratings yet

- Sheet2 MachineDesign1Document2 pagesSheet2 MachineDesign1محمد معوضNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- Static LoadDocument20 pagesStatic LoadTrường Hà Lạc NhậtNo ratings yet

- D MDocument9 pagesD MMuthu KumarNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- DMM I Assignment - 5Document1 pageDMM I Assignment - 5Konduru Vinay Kumar ReddyNo ratings yet

- MD1 M3 Compiled Ot 1Document67 pagesMD1 M3 Compiled Ot 1Jiuan AndradaNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Dme 2Document6 pagesDme 2NITHISH KUMAR M SNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- FALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 22-Oct-2020 Module 6 Couplings New 12Document40 pagesFALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 22-Oct-2020 Module 6 Couplings New 12AK PRODUCTIONSNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- 12me52 MQP-1Document3 pages12me52 MQP-1SumitKumarNo ratings yet

- Cat 2 Ear 306Document4 pagesCat 2 Ear 306Mercy MerryNo ratings yet

- Mugher Cement EnterpriseDocument27 pagesMugher Cement EnterpriseTasisa Kuma100% (7)

- Chapter One: 1.1 Objectives of InternshipDocument23 pagesChapter One: 1.1 Objectives of InternshipTasisa Kuma100% (1)

- Mugher Cement EnterpriseDocument27 pagesMugher Cement EnterpriseTasisa Kuma100% (7)

- Chapter One: 1.1objectives of InternshipDocument30 pagesChapter One: 1.1objectives of InternshipTasisa KumaNo ratings yet