Professional Documents

Culture Documents

Schedule of Accreditation United Kingdom Accreditation Service

Uploaded by

Noor N000rOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schedule of Accreditation United Kingdom Accreditation Service

Uploaded by

Noor N000rCopyright:

Available Formats

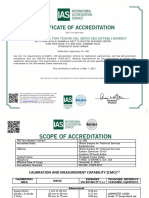

Schedule of Accreditation

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

SDL Atlas Ltd

Issue No: 030 Issue date: 18 May 2020

1B, Building B Contact: Andy Wan

Junxiang Da Mansion Tel: +86 (755) 2671 1168

No. 9 Zhongshan Yuan Road Fax: +86 (755) 2671 1337

0688 Nanshan E-Mail: Andy_Wan@sdlatlas.com.cn

Shenzhen Website: www.sdlatlas.com

Accredited to 518052

ISO/IEC 17025:2017 P.R.C.

Calibration performed by the Organisations at the locations specified below

Locations covered by the organisation and their relevant activities

Laboratory locations:

Location details Activity Location

code

Address Local contact Force P

1B, Building B Mr Andy Wan Textile

Junxiang Da Mansion

No. 9 Zhongshan Yuan Road

Nanshan

Shenzhen

518052

P.R.C.

Site activities performed away from the locations listed above:

Location details Activity Location

code

Customers’ sites or premises Local contact Force S

Mr Andy Wan Textile

The customer’s sites or

premises must be suitable for

the nature of the particular

calibrations undertaken and

will be subject of contract

review arrangements

between the laboratory and

the customer

Assessment Manager: CD1 Page 1 of 5

S c he dul e of Ac c re di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

SDL Atlas Ltd

0688 Issue No: 030 Issue date: 18 May 2020

Accredited to

ISO/IEC 17025:2017

Calibration performed by the Organisation at the locations specified

DETAIL OF ACCREDITATION

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability

Expressed

(CMC) as an

Expanded

Uncertainty (k=2)

TEXTILE TESTING MACHINES Unless otherwise

indicated. Physical

Martindale abrasion machines measurement of mass,

time, temperature,

Mass 100 g to 1000 g 0.20 g pressure and linear P &S

1000 g to 3000 g 0.40 g dimensions in accordance

with multiple industry

Linear 0.5 mm to 1.5 mm 0.01 mm standards, manufacturers

1.5 mm to 130 mm 0.050 mm specifications and

customer requirements.

Speed (specific value) 47.5 rpm 0. 17 rpm

Crockmeters

Force 1 N to 11 N 0.030 N

Linear 5 mm to 110 mm (stroke) 0.80 mm

5 mm to 15 mm (peg diameter) 0.020 mm

Pilling Tester (Box & Drum)

Linear 5 mm to 320 mm 0.80 mm

Speed (specific value) 60 rpm 0.20 rpm

Pilling Tester (Random)

Linear 5 mm to 160 mm 1.0 mm

Speed 1 rpm to 5000 rpm 2.0 rpm

Time 1 s to 300 s 0.30 s

Burst Strength Tester

Linear 0 mm to 100 mm 0.070 mm

Time 1 s to 60 s 0.30 s

Pressure 0 kPa to 1000 kPa 2.0 kPa

1000 kPa to 7000 kPa 8.5 kPa

Wascator

Temperature 25 C to 90 C 0.80 C

Linear 50 mm to 200 mm 1.0 mm

Spin speed 500 rpm to 800 rpm 0.70 rpm

Wash speed 52 rpm 0.30 rpm

Assessment Manager: CD1 Page 2 of 5

S c he dul e of Ac c re di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

SDL Atlas Ltd

0688 Issue No: 030 Issue date: 18 May 2020

Accredited to

ISO/IEC 17025:2017

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability

Expressed

(CMC) as an

Expanded

Uncertainty (k=2)

TEXTILE TESTING MACHINES (continued)

Digital Tumble Dryers P&S

Temperature From 25 C up to 90 C 0.80 C

Time 10 s to 600 s 0.50 s

Linear 550 mm to 1000 mm 2.0 mm

Volume 80 L to 120 L 0.90 L

Rotawash, Gyrowash and

Washwheels

Linear 100 mm to 175 mm 0.80 mm

Temperature 30 C to 95 C 0.80 C

Timer (specific value) 600 s 0.30 s

Speed (specific value) 40 rpm 0.70 rpm

Capacity 500 ml to 600 ml 10 ml

Sample cutters

Diameter of cut sample 20 mm to 145 mm 0.15 mm

Incubators up to 120 litres

Temperature 35 C to 41 C 0.50 C

Perspirometer

Mass 100 g to 5100 g 0.50 g

Hydrostatic Head Tester

Rate of increase in water 10 cmH2O/minute 0.12 cmH2O/minute

pressure (Specific values) 60 cmH2O/minute 0.25 cmH2O/minute

Pressure 0 cmH2O to 1500 cmH2O 2.0 cmH2O

1500 cmH2O to 3500 cmH2O 4.0 cmH2O

Linear 0 mm to 140 mm 0.05 mm

Flameability tester

Linear 1 mm to 200 mm 0.060 mm

200 mm to 800 mm 1.5 mm

Time 1 s to 20 s 0.20 s

Assessment Manager: CD1 Page 3 of 5

S c he dul e of Ac c re di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

SDL Atlas Ltd

0688 Issue No: 030 Issue date: 18 May 2020

Accredited to

ISO/IEC 17025:2017

Calibration performed by the Organisation at the locations specified

Measured Quantity Range Calibration and Remarks Location

Instrument or Gauge Measurement Code

Capability

Expressed

(CMC) as an

Expanded

Uncertainty (k=2)

TEXTILE TESTING MACHINES (continued)

Angle 10 to 90 0.3

Mass 10 g to 500 g 0.25 g

Reference Standard Washer

including digital programmeable

machines

Temperture 10 C to 90 C 0.80 C

Capacity 10 L to 80 L 0.50 L

Time 60 s to 1 200 s 3.0 s

Agitation speed 10 to 200 strokes per minute 1.8 strokes per

minute

Spin speed 300 rpm to 800 rpm 2.5 rpm

FORCE

Universal Testing Machines P&S

Verification and calibration of From 0.15 kN up to 50 kN for 0.22 %

the force measuring system by Class 0.5, 1, 2 and 3 machines to

force proving instruments in BS EN ISO 7500-1:2018

tension and compression

Verification and calibration of From 1 N up to 150 N for 0.10 %

the force measuring system by Class 0.5, 1., 2 and 3 machines to

calibrated masses in tension BS EN ISO 7500-1:2018

and compression

Cross head displacement 50 mm to 600 mm 0.35 %

Cross head speed 100 mm/min to 600 mm/min 0. 70 %

END

Assessment Manager: CD1 Page 4 of 5

S c he dul e of Ac c re di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

SDL Atlas Ltd

0688 Issue No: 030 Issue date: 18 May 2020

Accredited to

ISO/IEC 17025:2017

Calibration performed by the Organisation at the locations specified

Appendix - Calibration and Measurement Capabilities

Introduction

The definitive statement of the accreditation status of a calibration laboratory is the Accreditation Certificate and the associated Schedule of

Accreditation. This Schedule of Accreditation is a critical document, as it defines the measurement capabilities, ranges and boundaries of the

calibration activities for which the organisation holds accreditation.

Calibration and Measurement Capabilities (CMCs)

The capabilities provided by accredited calibration laboratories are described by the Calibration and Measurement Capability (CMC), which

expresses the lowest uncertainty of measurement that can be achieved during a calibration. If a particular device under calibration itself

contributes significantly to the uncertainty (for example, if it has limited resolution or exhibits significant non-repeatability) then the uncertainty

quoted on a calibration certificate will be increased to account for such factors. The CIPM-ILAC definition of the CMC is as follows:

A CMC is a calibration and measurement capability available to customers under normal conditions:

(a) as published in the BIPM key comparison database (KCDB) of the CIPM MRA; or

(b) as described in the laboratory’s scope of accreditation granted by a signatory to the ILAC Arrangement.

The CMC is normally used to describe the uncertainty that appears in an accredited calibration laboratory's schedule of accreditation and is the

uncertainty for which the laboratory has been accredited using the procedure that was the subject of assessment. The CMC is calculated

according to the procedures given in M3003 and is normally stated as an expanded uncertainty at a coverage probability of 95 %, which

usually requires the use of a coverage factor of k = 2. An accredited laboratory is not permitted to quote an uncertainty that is smaller than the

published CMC in certificates issued under its accreditation.

The CMC may be described using various methods in the Schedule of Accreditation:

As a single value that is valid throughout the range.

As an explicit function of the measurand or of a parameter (see below).

As a range of values. The range is stated such that the customer can make a reasonable estimate of the likely uncertainty at any point within

the range.

As a matrix or table where the CMCs depend on the values of the measurand and a further quantity.

In graphical form, providing there is sufficient resolution on each axis to obtain at least two significant figures for the CMC.

Expression of CMCs - symbols and units

In general, only units of the SI and those units recognised for use with the SI are used to express the values of quantities and of the associated

CMCs. Nevertheless, other commonly used units may be used where considered appropriate for the intended audience. For example, the term

“ppm” (part per million) is frequently used by manufacturers of test and measurement equipment to specify the performance of their products.

Terms like this may be used in Schedules of Accreditation where they are in common use and understood by the users of such equipment,

providing their use does not introduce any ambiguity in the capability that is being described.

When the CMC is expressed as an explicit function of the measurand or of a parameter, this often comprises a relative term (e.g., percentage)

and an absolute term, i.e. one expressed in the same units as those of the measurand. This form of expression is used to describe the

capability that can be achieved over a range of values. Some examples are shown below. It should be noted that these expressions are not

mathematical formulae but are instead written in a commonly used shorthand for expressing uncertainties - therefore, for purposes of clarity,

an indication of how they are to be interpreted is also provided below.

DC voltage, 100 mV to 1 V: 0.0025 % + 5.0 μV

Over the range 100 mV to 1 V, the CMC is 0.0025 %∙V + 5.0 μV, where V is the measured voltage.

Hydraulic pressure, 0.5 MPa to 140 MPa: 0.0036 % + 0.12 ppm/MPa + 4.0 Pa

Over the range 0.5 MPa to 140 MPa, the CMC is 0.0036 %∙p + (0.12∙10-6∙p∙10-6) + 4.0 Pa, where p is the measured pressure in Pa.

It should be noted that the percentage symbol (%) simply represents the number 0.01. In cases where the CMC is stated only as a percentage,

this is to be interpreted as meaning percentage of the measured value or indication.

Thus, for example, a CMC of 1.5 % means 1.5 ∙ 0.01 ∙ i, where i is the instrument indication.

Assessment Manager: CD1 Page 5 of 5

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Etymologicon Universale v.1 PDFDocument682 pagesEtymologicon Universale v.1 PDFLeigh Smith100% (1)

- Vernier and Measuring Tape CalibrationDocument2 pagesVernier and Measuring Tape CalibrationVIKASH RAI50% (2)

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Book - Python - Hands-On Simulation Model PythonDocument347 pagesBook - Python - Hands-On Simulation Model PythonKiều Nhi Nguyễn100% (3)

- KC EntDocument12 pagesKC Entsai associatesNo ratings yet

- UKAS Hydrometer Calibration CertificateDocument2 pagesUKAS Hydrometer Calibration Certificatejepri purwanto0% (1)

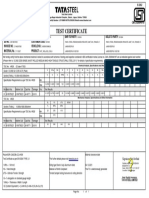

- Tata Steel Hot Rolled Coils IS 2062 Test CertificateDocument1 pageTata Steel Hot Rolled Coils IS 2062 Test CertificateStructures ProductionNo ratings yet

- 304 Hex Nut M10-1.5Document1 page304 Hex Nut M10-1.5ugi putriNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- MCQs Basic Statistics 1Document6 pagesMCQs Basic Statistics 1secret student100% (1)

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- Dimension Scope HelpDocument16 pagesDimension Scope HelpEby JoyNo ratings yet

- Global Insignia For Technical Services Establishment: This Is To Attest ThatDocument3 pagesGlobal Insignia For Technical Services Establishment: This Is To Attest ThatAlmansoori MPSNo ratings yet

- Accreditation Certificate-0269calibration MultipleDocument6 pagesAccreditation Certificate-0269calibration MultipleebbasinghNo ratings yet

- 0478Calibration-MultipleDocument67 pages0478Calibration-MultipleJose ramon cornelio torresNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Wedge Anchor M10x150 CERTDocument1 pageWedge Anchor M10x150 CERTAlina DimaNo ratings yet

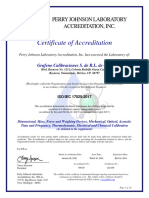

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument11 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncJoel MelendezNo ratings yet

- UKAS Accredited Calibration of Length GaugesDocument1 pageUKAS Accredited Calibration of Length Gaugesdanielbo2220No ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument3 pagesSchedule of Accreditation United Kingdom Accreditation ServiceashishtrueNo ratings yet

- A2LA Accredits Alpha Technologies Services Laboratory for Calibration CompetenceDocument5 pagesA2LA Accredits Alpha Technologies Services Laboratory for Calibration CompetenceNg Wei LihNo ratings yet

- Analog Outside Micrometer - 130262486 - 25 MM YDocument15 pagesAnalog Outside Micrometer - 130262486 - 25 MM YishraqaliahsanNo ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- A2LA 1101 01 Valid To February 28 2017Document4 pagesA2LA 1101 01 Valid To February 28 2017QA LAB ISMNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument32 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNo ratings yet

- L19-456-2 Com FinalDocument7 pagesL19-456-2 Com FinalVERONICANo ratings yet

- Product certification report analysisDocument2 pagesProduct certification report analysisFreddy Taipe CruNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument20 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncIsela ArrietaNo ratings yet

- Ies-Industrial Engineering Services: Proposalfor PVT (Pressure Vesseltest) WorksDocument2 pagesIes-Industrial Engineering Services: Proposalfor PVT (Pressure Vesseltest) WorksSadia HasanNo ratings yet

- Hai Point JKR Requirement Channel and Batten 2020Document23 pagesHai Point JKR Requirement Channel and Batten 2020kimchewlim82No ratings yet

- Corton Steel PresentationDocument18 pagesCorton Steel PresentationjayminNo ratings yet

- Tornillo Autop. P.BR ZN 14 X 1 1-2 T (Pat-20020)Document1 pageTornillo Autop. P.BR ZN 14 X 1 1-2 T (Pat-20020)Luisa Ortega mendozaNo ratings yet

- Tornillo Autop. P-BR ZN 10 X 3-4 (Pat-21138 + T)Document1 pageTornillo Autop. P-BR ZN 10 X 3-4 (Pat-21138 + T)L Caqui PascacioNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument20 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncAlonso FraireNo ratings yet

- Chandan Steel MTC for Stainless Steel Round Bars to ArgentinaDocument1 pageChandan Steel MTC for Stainless Steel Round Bars to ArgentinaAceros DessolNo ratings yet

- Msme Technology CentersDocument94 pagesMsme Technology Centersnishad saifiNo ratings yet

- A105 (VF863)Document1 pageA105 (VF863)Suli HartoNo ratings yet

- l21-413 New Tech Calibration Acreditacion Perry Johnson Jul-2021Document5 pagesl21-413 New Tech Calibration Acreditacion Perry Johnson Jul-2021Alfredo AngelesNo ratings yet

- Diplomate ServivveDocument1 pageDiplomate ServivveSunil Kumar GoudaNo ratings yet

- Tuerca Hex Inox 304 Unc 5.8-11Document1 pageTuerca Hex Inox 304 Unc 5.8-11RENmo123No ratings yet

- Crs 000007Document2 pagesCrs 000007ahetesham marufNo ratings yet

- L22-51 Sistemas M Meril Cal MK Approval (3)Document8 pagesL22-51 Sistemas M Meril Cal MK Approval (3)IsaacNo ratings yet

- Scope of ISO/IEC 17025:2005 accreditation for dimensional calibrationDocument16 pagesScope of ISO/IEC 17025:2005 accreditation for dimensional calibrationebbasinghNo ratings yet

- MTC Pipa Kotak 60x2, 50x2Document1 pageMTC Pipa Kotak 60x2, 50x2Pahala LumbantoruanNo ratings yet

- ISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateDocument16 pagesISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateSales ITANo ratings yet

- Avery Weigh Tronix 054Document2 pagesAvery Weigh Tronix 054huidhyiuodghNo ratings yet

- Structural design and audit services for RCC buildingDocument1 pageStructural design and audit services for RCC buildingmasih ansariNo ratings yet

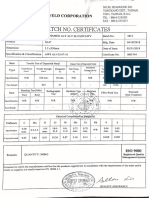

- Cood Goodweld Corporation: Batch No. CertificatesDocument2 pagesCood Goodweld Corporation: Batch No. CertificatesmoodydoodyNo ratings yet

- Opposite Party QuoteDocument4 pagesOpposite Party QuoteAnithaDurai1990No ratings yet

- Window MTCDocument4 pagesWindow MTCshamshadkadavath1998No ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- HM/QCD/Mech/F-04 Mill Test CertificateDocument1 pageHM/QCD/Mech/F-04 Mill Test CertificateholoNo ratings yet

- TEST REPORT FINDINGSDocument1 pageTEST REPORT FINDINGSAbhinav SinghNo ratings yet

- Barra Astm A193 Grado B7 1Document1 pageBarra Astm A193 Grado B7 1Patrocinio Parra GalindoNo ratings yet

- Sample MTC -C276-69.85mmDocument2 pagesSample MTC -C276-69.85mmsachin.meshramNo ratings yet

- Testing Protocol for Steel Seamless PipesDocument7 pagesTesting Protocol for Steel Seamless Pipesqc deNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument12 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVictor Arciga GranadosNo ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument4 pagesSchedule of Accreditation United Kingdom Accreditation ServiceRangaNo ratings yet

- Sertifikat Produksi Caa-2212-00097Document1 pageSertifikat Produksi Caa-2212-00097figo zaliNo ratings yet

- Vibration 2 Marks For All Intrance ExamDocument11 pagesVibration 2 Marks For All Intrance ExamSeeandgrow ByabdulsamadNo ratings yet

- Py Code Example 11 0 Baird Semi Gradient DP LikeDocument3 pagesPy Code Example 11 0 Baird Semi Gradient DP LikeEmily ChengNo ratings yet

- Final Year Project Phase 1 ReportDocument25 pagesFinal Year Project Phase 1 ReportAman SharmaNo ratings yet

- Calibration of Special Relative Humidity and TempeDocument8 pagesCalibration of Special Relative Humidity and TempeAGUS KURNIAWANNo ratings yet

- Ultrasonic MachiningDocument20 pagesUltrasonic MachiningKoushik Rao100% (1)

- AP Physics 1 Summer Assignment 2020 PDFDocument20 pagesAP Physics 1 Summer Assignment 2020 PDFSohom PalNo ratings yet

- Dokumen - Tips Homework 3 Solution Department of Statistics Ovitekstat526 Spring11filespdfshw3 SolpdfstatDocument12 pagesDokumen - Tips Homework 3 Solution Department of Statistics Ovitekstat526 Spring11filespdfshw3 Solpdfstatbourday RachidNo ratings yet

- Articulo - Coriolis Flowmeters Industrial Practice and Published Information - Baker1994Document18 pagesArticulo - Coriolis Flowmeters Industrial Practice and Published Information - Baker1994Alex Willy Pilco NuñezNo ratings yet

- Introduction to FORTRANDocument114 pagesIntroduction to FORTRANKalpesh KarkeliNo ratings yet

- Seemingly Unrelated Estimation with suestDocument19 pagesSeemingly Unrelated Estimation with suesteko abiNo ratings yet

- Lecture 2 Bearing and Punching Stress, StrainDocument16 pagesLecture 2 Bearing and Punching Stress, StrainDennisVigoNo ratings yet

- Research Methodology: by Asaye Gebrewold (PHD Candidate)Document17 pagesResearch Methodology: by Asaye Gebrewold (PHD Candidate)natnael haileNo ratings yet

- Beam Analysis2dDocument80 pagesBeam Analysis2dMSNo ratings yet

- Vo MAT 267 ONLINE B Fall 2022.ddeskinn - Section 12.1Document2 pagesVo MAT 267 ONLINE B Fall 2022.ddeskinn - Section 12.1NHƯ NGUYỄN THANHNo ratings yet

- Excel Lesson 5Document28 pagesExcel Lesson 5Faisal QureshiNo ratings yet

- CBSE Class 12th - TERM - II Worksheet - Q&ADocument61 pagesCBSE Class 12th - TERM - II Worksheet - Q&ATasneem ANo ratings yet

- 2.4 Calculation of Metallic Pillar (St1)Document2 pages2.4 Calculation of Metallic Pillar (St1)Virginia Elena IordacheNo ratings yet

- Spring 2014 Geometry Review Packet QuestionsDocument13 pagesSpring 2014 Geometry Review Packet Questionsapi-195266051No ratings yet

- IE 303 Discrete-Event Simulation: Lecture 3: Event-Scheduling AlgorithmDocument26 pagesIE 303 Discrete-Event Simulation: Lecture 3: Event-Scheduling AlgorithmBhagya PatilNo ratings yet

- To Find Gradation of Coarse Aggregate by Sieve AnalysisDocument4 pagesTo Find Gradation of Coarse Aggregate by Sieve AnalysisHaris AlamNo ratings yet

- (USED) OR1 - 04 - Formulations (Case Studies)Document19 pages(USED) OR1 - 04 - Formulations (Case Studies)FrandesNo ratings yet

- Multiple-Choice Test Eigenvalues and Eigenvectors: Complete Solution SetDocument7 pagesMultiple-Choice Test Eigenvalues and Eigenvectors: Complete Solution SetMegala SeshaNo ratings yet

- A4 - G10 - Q3 - Module 2 - MELC 3&4Document12 pagesA4 - G10 - Q3 - Module 2 - MELC 3&4Jayzi VicenteNo ratings yet

- Webster Theory of Electricity and Magnetism, Being Lectures On Mathematical Physics (1897)Document600 pagesWebster Theory of Electricity and Magnetism, Being Lectures On Mathematical Physics (1897)Marcelo Silvano de CamargoNo ratings yet

- NCERT Class 11 Computer Science Algorithms and FlowchartsDocument11 pagesNCERT Class 11 Computer Science Algorithms and FlowchartsAditya KumarNo ratings yet

- Fluent Chp07-Defining Physical PropertiesDocument74 pagesFluent Chp07-Defining Physical PropertiesPiyush SandujaNo ratings yet

- Math Operation Table TarpDocument5 pagesMath Operation Table TarpAna Mirata DumaogNo ratings yet