Professional Documents

Culture Documents

X-Tite ResiLoc E Brochure

X-Tite ResiLoc E Brochure

Uploaded by

dimuthu lasintha0 ratings0% found this document useful (0 votes)

28 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views6 pagesX-Tite ResiLoc E Brochure

X-Tite ResiLoc E Brochure

Uploaded by

dimuthu lasinthaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

AULSINEHS NOLLINULSNOD

HNSIIvoD

Fast Cure

Resin

Anchor

The

a zy

1 ene

K ” .

= 8

A 4 |

Sta 1 Ne?

IS Ft A

A Fil)

i # * ‘

|

The X-Tite ResiLoc E system is one

of the most technologically advanced

Self Mixing Cartridge Resin = SMR™

anchors on the market today.

Tg

X-Tite ResiLoc E SMR™ Advantages

'* Accommodates long-term loads

* High early strength

+ Easy tose

+ Consistent mixing

+ Fest assured cure

+ Same day loading

*+ Withstand high ambient temperatures

* Can be applied in damp and wet conditions

+ Fire rated

+ Can be used with hollow masonry units

+ Can be used at low temperatures

+ Creep-resistant formulation

+ 50 year designed life

+ Styrene free

+ Sefe to use

+ Can be dispensed with low-cost applicator guns

+ Low wastage

Certified SMR™ Anchor Installers

Ensure that your SMR™ anchors are installed correctly first,

time, by enrolling your operatives in the X-Calibur Resin

Anchor Installer training course. This 5 hour practical training

rogram can be conducted at one of our facilities or at the

Jobsite and includes:

Correct drill and drill bit selection

+ Embedment depths

Hole drilling

* Hole cleaning and preparation

* Cartridge set up and injection

‘= Installation of anchor bars

© Safety

Proof load tests

The certification is valid for two years, and re-certification

Is achieved via a 1 hour update program. All attendees who

satisfactorily complete the program receive a certificate,

a Certified Installer I.D. Card and Safety Helmet Decal to

allow Construction Inspectors to check easily that trained

‘operatives are installing the anchors. The program is also

useful in helping contractors meet ISO 9000 Training

Requirements.

Gel and Loading times

PT hs

od meas

nainte 10 mins

loro 20°c 7O mins

ewe aware | mine

ResiLoc E is commonly ResiLoc E is widely used ‘This steel beam was fixed using

used for supporting for fixings in mechanical ResiLoc E to provide additional

architectural canopi and electrical works. support to a concrete slab.

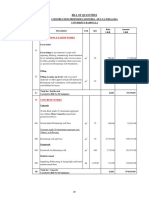

DESIGN IN FORMATION

‘The information to follow is specific only to anchors or bars installed using the X-Tite ResiLoc E SMR™ system.

In citcal applications X-Calibur recommends pull out or proof testing be performed.

This datas apocabl oa orades of corbon and stainless

steel threaded bar up to 1040 MPa (160,000 psi) ultimate

fe sea arco

Accommodate the loads show blow

h a 4

ry

96

19)

2s

o

2,

150.

19,

95

ie

160

204 235

228 255

60

160 195

182, 2s 95

20 75. BE

ze 305, 15,

308 35, 156,

160 20 75

220 oo

240 290

200 15 5

340 a0 165 2

300 185 103

12 20 eo

12 4

288 35. 170 944

30 eT 7

408 255 238 1 a6

256 505 266 16 46 12

‘ole aap erewn in Bold and ved color are the typical ndusiy tancar” bond engin Tor tat anchor damier.

Ifthe dose ede dstarce or anchr spac ae bewoen the characteristic and mirinum then alba reducon factor must be caadated and ape.

Character A

io 2 i 34 7A

2 14 16 452 at

16 zu zz ean 355

20 25 2 200 700.5 358

2 35 250 174 763

EJ 38 5 320 225.2 Ds

"Nee (i) The maximum hole damctr Sod ony be used whan he oles greta han 15, or when he bar balng Weed as a veISae Tb.

Embedment Depths for Reinforcing steel

‘The tensile load capacity data has been based on embedment depts of 10 times bar Eo

diameter. Some Design codes require a higher embedment depth. Load capacity is,

‘dependent on the fully bonded depth. The load factors shown on the opposite table

may be used when the bars are to be installed at bond lengths other than 10 times.

bar diameter (d).

Effect of Concrete Compressive Strength

The quote values of tensile loads have been calculated for grade C20/25 concrete, for higher strength concretes apply the factors shown in the table below.

Soe? 40/50 50/80 Underwater Use

Close Edge and Anchor Spacing iaatecte Wirth

‘The characteristic edge distance (C,,,) is the minimum edge distance at which the anchor wit | UNGerwater. When used

- underwater, the tensile loads

achieve ts chaacersie strength C= hy (Chigiseraeielteagene

“The characteristic cose spacing starve (S.,) I the minimum spacing between two anchors | By 30M, Wherever possible,

which wl allow each of them to achleve ts characterise strength, S, cay outa tral appication and

The minimum edge (C,q) and spacing (S,) distances must be o sn = 05h, | test the load capacty of the

Concrete Capacity Tensile Load Reduction Factors essed ones)

& anchor nomna meter (rm or)

5 rl te dame (mm o ne)

hole depth = hep Crum or ns)

fee eect borength (rm os)

C Gese cage dxance (mm ons)

SS anchr spacing (mm ons)

Cay mum dose edge distance to achieve Ny,

(Gare capac redaction fcr tension (od Sin inimum anchor spacing to achive Nyy

Se aco cee € Yen =05 (cm) +05<1 Nine, Charades tensie ced (kN)

Twoarcors core sata S on = 02505) +051 ipa dsig esstance eX)

Troan ppd to dose edpec, ry = 028) + 25 (Ey) +0255 -1

Tiwoarchr fara cen Cp Wen = 025 (Ch) + O25 i) + 025(C Ma + 0354

Concrete capcty reduction for more complex anchor confauratios In tesion, an for shear forces acing tonarcsa cose ede, shuld be determined

Using the design metnod A, given in ETAS OO, annex CA copy Of ETAG OD, nex C can be povided ve Of Cage

Shear Load Data

‘The superior properties of X-Tte ResiLoc E are such that the shear strength of an anchor bonded with this resin system Is

dependent on the shear capacity of the grade of steel, and of the ability of the concrete to accept the shear load.

Corton rebar 00 500 360

Carbon. 5a 20 28

Caren. 7 200 a0 320

Carbon 10s io eel Ea

Sraiess 316 B45 soo. zi 0

Stariess 316 14-70 700 2507 94

Sores 316 ne 00 0 “0 2

High Ambient Temperature

X-Tite ResiLoc E has been designed to withstand long-term service conditions of up to 50°C (122°F), and short-term

‘exposure to 80°C (176°F), without any reduction in performance.

Designing for Fire

“The performance of X-Tite ResiLoc E was evaluated in fre conditions from this testing the following fire rating table was calculated

N10 x90 so

Mize 110 30

Wa 170 240

Haan 210 350

Creep (Long Term Load Performance)

Creep tests were carried out on M12 x 120mm (0.47 x 4.7in) anchors in accordance with the European Technical Approval,

ETAG 001 Part 5, at 20°C (68°F) and 50°C (122°F). At both temperatures the extrapolated displacements were significantly

Jess than the displacement at loss of adhesion (Su,adh ) for the corresponding reference test at 20°C (68°F), and therefore

‘complying with the European Technical Approval requirements.

Ze Pr el

CS a Se

sa 500 78 306 251 a oa

INSTALLATION AND ESTIMATING

Method of Use

‘Importance of hole driling

‘and cleaning

‘tesco that holes are drilled

vith a rotary percussive dil to

Drodiuce a hole with roughened

ledges of the correct dlameter.

If, for any reason, the holes

hhave to be damond cored then

they must be roughened and

cleaned in order fo maximise

the high performance of the

anchors. One way to achieve

this ito re-ril te holes with 3

sultably-sized rotary-percussive

Gril, Drilling debris and dust

‘must be thoroughly cleaned

fom the hole using the corect

Saad Xie SOR Brsh and san

compressed air and/or clean

Water If waters used the hole

‘may be left amp or even full

(of water, but the water and the

‘Sides ofthe hole must be dean,

Maximum Hole Size

Genera, the maximum pole s lene fa

Sze for Vireaded rod is 4mm aco |e,

(5/32") more than the ber SS | eh

diameter, and for rebar itis 1.4

times the nomial bar ameter.

For specic sizes please refer to

the relevant Load Capecty table. For 300 mil cartridge, follow instructions on cartridge.

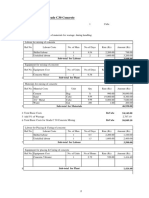

Estimating Guide: Number of Holes per Cartridge

Hole Dopth in mm

eee eee eid

‘Threaded Rod in Concrete

[Number of Holes per Cartridge

ls [2] 0] ele

ml s[ala| |e

w/e [2] ||

ulw[wolofele

wi e[s[s|7|7

sl7i7ls 5

Number of Holes per Cartridge

ml ole lelula

25 | | 2] | 9 | 7

ua [a7 [ae [as |e

vias[ul al ela

ra | a |

Ble wf 99

7/6 s[s|4

sie 5 a

E Number of Holes per Cartridge

20 2 [a|%/e]»]=|~]alel|v]slululelululwlw

2 25 nfs [ a5] 29 }o[ af fslis|s|2]n|ulw]s]s)s

25 ~% [ola |s|slalw)w||2| ull mis fe

X-Tite ResiLoc E

Specification

‘The resin anchoring material shall be

X-Tite ResiLoc E or equivalent. It shall

be a fest curing epoxy acryate resin

system supplied in self mixing resin

(G4R) dispensers, and shall have

been tested and manufactured. in

accordance with the ETAG (European

Technical Approval) 001 Part 5 Option

7 and be suitable for load term loads.

“The manufacturer of the resin anchor

shall provide test data to show the

effects of fire on the performance of

the anchor and to allow forthe desion

(of anchors for a 60 to 120 minute fire

rating as determined by the Engineer.

The resin anchor shall be of a

‘composition that is safe to use during

installation and in use. It will have a

long-term service temperature (as

determined by the ETAG 001 Part 5)

(of 50°C (122°F) or higher. The resin

anchor willhave a geltime of § minutes

(or less at 20°C (68°F) will be able to

accept full design load at 40 minutes

after installation at 20°C (68°F). The

Use of polyester or styrene containing

resin will not be permitted.

‘The manufacturer of the resin to

provide independently certified pull

‘out test data. In critical areas the

Contractor is to arrange independent

proof testing on site, The resin anchors

will be installed by installers that have

been certified by the manufacturer

‘and should carry proof of such training

with them any time they are installing

anchors on the project.

Dispensing Equipment

400ml (13.5 1e2)

cannages!

Jette SHR HAO

oasis Appcator

Note: 300m (10.1

fescrelaes cn

Sandor sileone

Sion gan

Additional SMR Mixing Nozzles are

available along with 0.5m extensions,

Blow Tools

Holes can be blown dean using the XTite SHR.

Marwal Air Pump of tha Xie SMR Ale Lance

that can be connected to alow pressure ar

Supply. Extension tubes are availabe for bath

products for cleaning deepes holes.

X-Tite SMR Hollow Wall Inserts

Faxing nto nolw masoney unt sage

cary ye woe of

Site Ai iotow

Wal inser. exe

rove spread insert

{favalone the ast

tbearuas ang st

fering arr

Srpandedlaros than

dareter anchor

thats as stone athe

masonry uni ise

Tite SMR Hollow Wall Inserts are avaliable in

the folowing sizes:

Hole Cleaning Brushes

The SHR Bushes ae avalable nthe folowing ses:

sis 100 12 mm

0 14 18mm

5 20 26mm

xia 2stea6mm

XcTite Resin Stoppers

The Resin Stoppers are specifically designed

te reduce the pesity ot gy sic ar

belated ian overhead suai, priany

Slametor ba. When

fitted to the end of

the injection tube

they ensure thatthe

Injeted resin fs te

hole from the back,

thusheping elimina

ny educton nbn

os oF petomancs

1250 2 so

1sss 5 fs

1siu20 5 2

as 2 ©

1GOrs901 CONSTRUCTION F)/ XINGS

Ha cc

'ETAG 001 Part 5 Option 7

You might also like

- Estimate - Elect-Keeper Room Lion DensDocument4 pagesEstimate - Elect-Keeper Room Lion Densdimuthu lasinthaNo ratings yet

- Product List 2011Document12 pagesProduct List 2011dimuthu lasinthaNo ratings yet

- L Excavation & Earth Works: Bill of QuantitiesDocument2 pagesL Excavation & Earth Works: Bill of Quantitiesdimuthu lasinthaNo ratings yet

- BOQ CanteenDocument35 pagesBOQ Canteendimuthu lasinthaNo ratings yet

- Polyurea BrochureDocument3 pagesPolyurea Brochuredimuthu lasinthaNo ratings yet

- Keepers AreaDocument162 pagesKeepers Areadimuthu lasinthaNo ratings yet

- 6 Boq PDFDocument1 page6 Boq PDFdimuthu lasinthaNo ratings yet

- 7 Boq PDFDocument1 page7 Boq PDFdimuthu lasinthaNo ratings yet

- Construction of Proposed Cafeteria of Uva Wellassa University-BaddullaDocument1 pageConstruction of Proposed Cafeteria of Uva Wellassa University-Baddulladimuthu lasinthaNo ratings yet

- 4 Boq PDFDocument1 page4 Boq PDFdimuthu lasinthaNo ratings yet

- Summary 01: University - Baddulla Construction of Proposed Cafeteria of Uva WellassaDocument1 pageSummary 01: University - Baddulla Construction of Proposed Cafeteria of Uva Wellassadimuthu lasinthaNo ratings yet

- A Excavation & Earth Works: Bill of QuantitiesDocument24 pagesA Excavation & Earth Works: Bill of Quantitiesdimuthu lasinthaNo ratings yet

- Removing Top Soil To A Depth Not Exceeding 150 MM: 16,400.00 Sub-Total For LabourDocument1 pageRemoving Top Soil To A Depth Not Exceeding 150 MM: 16,400.00 Sub-Total For Labourdimuthu lasinthaNo ratings yet

- Random Rubble Masonry in Cement Mortar 1:5 in SuperstructureDocument6 pagesRandom Rubble Masonry in Cement Mortar 1:5 in Superstructuredimuthu lasinthaNo ratings yet

- ETABS PPT 24-03-2018 PDFDocument52 pagesETABS PPT 24-03-2018 PDFdimuthu lasinthaNo ratings yet

- Mixing & Placing of Grade C30 Concrete: 3,948.00 Sub-Total For LabourDocument2 pagesMixing & Placing of Grade C30 Concrete: 3,948.00 Sub-Total For Labourdimuthu lasinthaNo ratings yet

- 225 MM Thick Brick Wall in Cement Sand 1:5 in SuperstructureDocument1 page225 MM Thick Brick Wall in Cement Sand 1:5 in Superstructuredimuthu lasinthaNo ratings yet

- Random Rubble Masonry in Cement Mortar 1:5 in SuperstructureDocument1 pageRandom Rubble Masonry in Cement Mortar 1:5 in Superstructuredimuthu lasinthaNo ratings yet

- Bar Spacing ChartDocument4 pagesBar Spacing Chartdimuthu lasinthaNo ratings yet

- Clearing Site and Grubbing Up All Small Trees Not Exceeding 500mm Girth and Including Bushes, Scrubs, Undergrowth Hedges EtcDocument1 pageClearing Site and Grubbing Up All Small Trees Not Exceeding 500mm Girth and Including Bushes, Scrubs, Undergrowth Hedges Etcdimuthu lasintha100% (1)

- Inspection and Test Plan Deep Cement Mixing PilesDocument6 pagesInspection and Test Plan Deep Cement Mixing Pilesdimuthu lasinthaNo ratings yet

- Time Sign Dimensions Squaring Description: Top Soil ExcavationDocument11 pagesTime Sign Dimensions Squaring Description: Top Soil Excavationdimuthu lasinthaNo ratings yet

- Time Sign Dimensions Squaring Description: Top Soil ExcavationDocument11 pagesTime Sign Dimensions Squaring Description: Top Soil Excavationdimuthu lasinthaNo ratings yet

- Admixtureredosing PDFDocument2 pagesAdmixtureredosing PDFdimuthu lasinthaNo ratings yet

- ETABS PPT 24-03-2018 PDFDocument52 pagesETABS PPT 24-03-2018 PDFdimuthu lasinthaNo ratings yet

- Building MaterialDocument25 pagesBuilding Materialdimuthu lasinthaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)