Professional Documents

Culture Documents

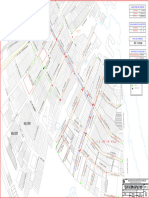

Smbi Bacolod Brewery: Visitor'S Parking Lot (1,330 SQ.M)

Uploaded by

William Jefferson RañadaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smbi Bacolod Brewery: Visitor'S Parking Lot (1,330 SQ.M)

Uploaded by

William Jefferson RañadaCopyright:

Available Formats

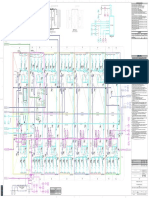

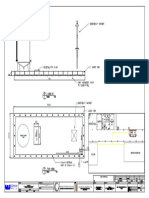

VISITOR'S PARKING LOT T

R

A

(1,330 SQ.M) P

E

Z

O

I D

A

L

C

AN

AL

ADMIN'S PARKING LOT

(1,080 SQ.M)

CENECO

METERING

EXISTING SUBSTATION EXPANSION

PARKING LOT TRAINING CENTER, RECORD SERVICE TRANSFORMER

CENTER &CHAPEL

AREA

GENSET

BUS VT

STN. S.

SPARE

SPARE

BATT

MAIN

F1

F2

F3

F4

F5

F6

F7

CHARGER

0.70

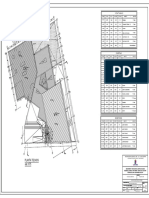

(±482.00 SQM)

BATTERY ROOM

SCADA I/O's

ROLL UP ACCESS

EXISTING H1

X0X1X2X3

H2H3

MVSG

SUBTATION

ADMIN BUILDING

GUARD

HOUSE

OPE

NT

RAP

SPENT GRAIN SPENT GRAIN

E ZOID

SILO SILO

AL C

ANA

170

170

L

Ø3360

Ø3160

Ø3600

Ø3400 170

Ø3160 Ø2960

Ø4760

SPENT GRAIN Ø5000

AIR RECEIVER UNIT

CONVEYOR Ø4560

BWG WATER

BWG WATER

(500 cu.m)

(500 cu.m)

TANK

TANK

WORT

HEATER

COOLER

STAGE 3

WORT

Ø5000

COOLER

STAGE

WORT

1+2

MATERIALS

X

X

D

PROPOSED

STORAGE

BREWING WATER TANKS

MCC ROOM

TREATED WATER TANKS

BREWING WATER TANKS

100

Ø3000

100

Ø2500

(6000 HLS.)

(2600 HLS.)

(6000 HLS.)

NO. 1

BLDG.

100

NO. 2

Ø3000

100

Ø3000

R O A

BALANCE

TABLE

SALES &

LOGISTIC

100

Ø3000

100

Ø3000

Ø2250 Ø2250 Ø2250

Ø2700

100

Ø3000

WHSE

HCL TANKS (HLS.)

(3000 L)

NO. 2

Ø1750 Ø1750 Ø1750

(3000 L)

Ø1300 Ø1300

CHLORINATED RAW WATER

Ø1300

NO. 1

Demineralization

(10800 HLS.)

Tank

Demi water supply pumps

BIRM FILTER TANK

BIRM FILTER TANK

No. 2

Ø1300

Day Tank

Caustic

100 100

100

Ø2250 Ø2250

TANK

NO. 1

NO. 01

NO. 02

Ø2700

NO. 4

NO. 3

Ø2700

No. 1

HCL TANKS

Regenerant

Degasifier

Caustic

Tank

NO. 5

(HLS.)

Pump

Recirculating

Water

Brewing

Regenerant

Tank

Caustic

CHLORINATOR

Supply Pumps

Brewing Water

No. 2

Anion

B

HOUSE

No. 1

WTP EXPANSION

Anion

A

Cation

pumps for

Raw water

No. 2

No. 1

RO water raw water Soda bisulfit acid dosing

chlorination chlorination dosing

BIRM PUMPS

K

Blending

pumps for

Raw water

(160.0 SQM)

No. 2

control cabinets

L

No. 1

water Pump

Unchlo Raw Raw water pumps

01 02

05

No. 3

Hydronomic RWA

No. 2

RH min = 4000mm

No. 1

Pressurized

Water

Demi

Tank

PROPOSED

Hydronomic UF 10-2

LxH: 3.00m x 4.0m

BRING IN OPENING:

RH min = 4300mm

LABORATORY

CHLORINATED RAW WATER

C I A

Hydronomic RO 10-6-3/5

PROPOSED SEGREGATION

ROOM

RH min = 3800mm

UNCHLORINATED RAW

Hydrant

Electric

LIFTING

Pump

Jockey

WATER TANK

(10800 HLS.)

(10800 HLS.)

PROPOSED WAREHOUSE

Air main pipe

Brewing water

Raw water (BGS)

Raw water (PGS)

Demi water for Wort Cooling

BREWING

03 04

NO. 2

TANK

01 02

ELECTRICAL

EXISTING ROOM

NEW GENSET

PIPEBRIDGE TYPE PF/1

ROOM

CR

FORKLIFT OPERATIONS ENG'G STATION

AREA FOR

AREA

(800.00 SQ.M)

Hydronomic UF 10-2

RH min = 4300mm

E

TRANSFERPOINT

SPENT SPENT

OFFICE

FILTER FILTER

BUILDING

AID PIT AID PIT

01

Softener

Softener

Lae

Lae

OFFICE

PROPOSED NEW CO2 TANK

PH TANK

HCL

17.84m x 5.66m

for Soaker

Water Pumps

No. 2

HAZARDOUS WASTE

No. 1

WASTE KG TANK

Header

Blended

Water

EXISTING TANK

EXISTING VESSEL

FUTURE PG TANK

HYDRANT

BLENDED WATER TANKS

BLENDED WATER TANKS

WAREHOUSE & SCRAP YARD

DIESEL

V I N

PROPOSED PIPE BRIDGE

E

(600 HLS.)

(600 HLS.)

NO. 1

NO. 1

ADDITIONAL GLYCOL

FOAM

TANK

PROPOSED WCP POWER (400.00 SQM)

TRAP LUBRICATION AREA

EXISTING TANK

AMMONIA

DIESEL

TANK ACCESS RAMP

CENTER

FUEL

SCRUBBER

(102.00 SQ.M)

EXISTING

CONTROL PANEL

EXISTING MCC

MAIN GLYCOL HEADER LVSG3 BRANCHES TIE

NEW LD8000

MVSG MVSG DRY AIR

GLYCOL PUMPS RECEIVER TANK

FARMS ELEV. ±62.71m

NEW AIR DRYER

NEW ZT-200

NEW ZT-200

NEW BD-1100+

AIR DRYER

NEW ZT-200

ROAD - 5

SMC 1600 KVA 1600 KVA NEW LD8000

NHR NHR MDP BRANCHES LVSG4 WET AIR

TRANSFORMER TRANSFORMER RECEIVER TANK

BREWING

SEPARATOR 2 SEPARATOR 1

EXISTING

WET AIR

P R O

RECEIVER TANK

AMMONIA SEPARATOR

DONALDSON

AMMONIA PUMPS AREA

HRE 2250

CAP CAP AIR

CONTROL PANEL

EXISTING PHE 01 BANK BANK DRYER

16m WIDE ROAD

1

R I P R A P

RO

REFGN FUTURE

EXISTING

EXISTING OFA-3

EXISTING OFA-1

COOLING TOWER

EXISTING OFA-2

CBP4203

EXISTING

GA37VSD

E2H01BB01

E2H02BB01

E2C01BF01

CB6103 CB7001

BUILDING EXISTING PHE 02 NHR

SEPARATOR 3

AD

CB7002

CB6004

E2B01BB01

E2L01BB01

CB6202

CB6007

CB6102

CONTROL PANEL CONTROL PANEL

CB6002/CB6003 CBP6006 CB6101

CB6201

CB6005

PROPOSED PERMANENT FENCE WALL (CYCLONE WIRE)

WEIGH BRIDGE

CONTROL ROOM

STB STANDARDKESSEL

5 TPH 12 Bar, DIESEL-BIOGAS

-7

ECONOMIZER

ROAD - 5a

FUTURE STB STANDARDKESSEL

MAINTENANCE AREA 12 TPH

CO2 RECOVERY

EXISTING BASKETBALL

DRIER NHR

PLANT CONTROL COMPRESSOR

NH3

C

PANEL

FEED WATER TANK

COMPRESSOR LH

DRIER

CAP. 20 CBM

COURT

LH RH

DRIER DRIER

(4

RH INTERCOOLER

DRIER

UNLOADING

CO2 CO2 NHR

DEODORIZER DEODORIZER LH LH

DEODORIZER

COMPRESSOR EXISTING BOILER NO. 3 EXISTING BOILER NO. 2

DEODORIZER

4 3

m

EXTG.

RH

RH

CO2 CO2 DEODORIZER

LH

DEODORIZER

COMPRESSOR CO2 COMPRESSOR SCRUBBER

BLOWERS

3 MCC 1 ECONOMIZER

GLYCOL CHILLER

GLYCOL CHILLER

NEW STEAM HEADER

RH

SCRUBBER

MAINTENANCE AREA

AREA

HP LP

W

KNOCKOUT KNOCKOUT

EXISTING BOILER NO. 1

CO2 PROPOSED WWTP PERIMETER FENCE (with CYCLONE WIRE & NO BARBED WIRE)

CO2 COMPRESSOR KMNO4 SCRUBBER STB STANDARDKESSEL

DEODORIZER 2

SCRUBBER

12 TPH 12 Bar, DIESEL

SUMP PIT

5

NH3 GAS BLOWER

CONDENSER CO2 VAPORIZER (OLD)

ID

SINK EXISTING STEAM HEADER

CO2 VAPORIZER (NEW)

DIESEL DAY

E)

TANK

CHIMNEY

LIQUID CO2 TANK

COMMUNITY ROAD - 8 (6m WIDE, 140 MTS. LENGTH)

ROAD - 6

CONCRETE

WALKWAY

PAVEMENT PAVEMENT

CLINIC

CONCRETE CONCRETE

ROOF LINE

ROOF LINE

DEWATERING

NON-WORKABLE

TRANSFORMER AREA

1200mm x 1000mm

BLOWER ROOM

LAB RM. 1490x1250mm

BLOCKOUT

(SPARE)

POWER CENTER

ELEC. &

DEWATERING EQUIPMENT

DEWATERING EQUIPMENT

1490x1250mm

3602 x 1590 x 1553

3602 x 1590 x 1553

BLOWER 2

MCC RM.

ACCESS ROAD

1490x1250mm

BLOWER 1

REJECT BOX REJECT BOX

Water Level = 3.0m

(4 M WIDE)

Wall Height = 3.3m

TANK

WITH DOSING PUMP

POLYMER TANK

THICKENING STAIR

BC 7

BC 6 SLUDGE

A

UP

116 M1 UP

Tank

107 M1

FeCl3 Storage 6.82m x 4.925m x 6.5m 6.82m x 4.925m x 6.5m CATWALK

117 M1 108 M1

106 M1 CONNECTING

AREA

SUMP PIT (T831)

+ Concrete Bunds & Shelter

(B110) Storage Storage

3x 10m³ HDPE TANK

Alkaline Water

CEY

Acid Water

Anae. Eff. Channel 2

105 M1 Tank (B2012) (B2013)

118 M1 109 M1

Acid Storage 14.5m x 12m x 7.25m

(T803) UASB 2

BC 9

BC 8

(B3022)

119 M1 110 M1

LAGOON 5

104 M1 BC 10 Tank

BC 37

124 M1 RC 18 RC 19

RC 20

Caustic Storage Water Level = 4.0m Water Level = 4.0m

Wall Height = 4.3m Wall Height = 4.3m

LAGOON 4

BC 35 (T805)

120 M1 111 M1 BC 3 SEQUENCE BATCH REACTOR 2 SEQUENCE BATCH REACTOR 1

BC 36 BC 2

BC 1

BC 38

PROPOSED COVERED EMPTIES YARD

115 M1 123 M1

CANTEEN &

CCE 24 CCE 27

PCE 18

DOSING STN

PCF 6

SLAB

BC 11 CCE 26 PCE 17 PCF 1

CCE 25 PCE 19 PCE 20 PCF 2 PCF 3 PCF 4 PCF 5 PCF 5A PUMP

CCE 22

CCE 23 CCE 28 PCE 16

CCE 21

16m WIDE ROAD

Wl = 6.0m

PCE 15 CCF 22 CCF 21 6m x 6m x 6.5m

U

CCF 9 22.33m x 10.3m x 6.5m

LOCKER ROOM

CCF 11 CCF 13

114 M1 CCF 15

(9, 779.00 SQM)

PCF 7

CCF 3 CCF 5 CCF 7

BC 40 RC 10 CCF 17 CCF 19

STORAGE

TANK

CCF20

BC 39 RC 16 ANAER. SLUDGE

RC 7 RC 14 RC 15 CCF 16

RC 8 122 M1 CCF 18 EQUALIZATION

RC 9 CCF 4 CCF 6 14" Ø DECANT PIPE S/S

121 M1 112 M1 CCF 8

CCF 12

PCE 14 CCF 14 (T304) (B2011)

RC 6 RC 17

Anae. Eff. Channel 1

CCE 19

CCF 10

BC 43

PCF 8

CCE 4 14.5m x 12m x 7.25m

CCE 20

BC 42

129 R1 130 R1 CCE 17 CCE 15 CCE 14 CCE 11 PCE 13 CCE 5 CCE 3

BC 44 STAIR UP UASB 1

BC 41 CCE 9 CCE 7

(B3021) UP

CCF 1

CCE 1

ROAD - 4

CCE 8

CCF 2

113 M1 CCE 6

126 R1 125 R1 CCE 18 CCE 16 CCE 13 CCE 12 CCE 10 STAIR

PCF 9

127 R1 CCE 2

CCE 29

128 R1 Wall Height = 3.3m

PCE 12 DAY TANK W/ SHED CONTACT TANK

PCE 2 CHLORINE

PCE 11

PCE 7 PCE 6 PCE 5

PCE 10 PCE 4 PCE 3 PCE 1

RC 5 BC 77 PCE 9 PCE 8

2 x 3.4 x 1 m

CCF23

6 in. CHB

PCF 10

BC 78 Catch Basin

BC 45 RC 21

BC 46

BC 106

CCE 47

BC 102 BC 100

BC 103 BC 98

CHECKER'S

BC 76

PCF 11

24" Ø RCP OUTLET PIPE, EMBEDDED

CCE 46

CCE 45

BC 86 BC 88 96

BC

BC 90 BC 94

BC 50 BC 48 BC 99

BC 54 BC 52

BC 84

BC 51

+1000

+1000

BC 92

+1000

+1000

+1000

BC 49 Désignation Depalletizer

BC 53 Référence Decrater

131 R1 X=38718.9

RC 22 E

PCF 12

ACM 2000 A #### 1.0% 100 Y=26548.3

SPE 101 M1

+1000

RC 4 1 #### A #### A 1000 #### A A####

RC 3 RC 2 A F6

LSD

F7

BC 53-A

90DG

SSD

CCE 44

R860

BOOTH

BC 95

97

1000

CCE 43

BC

+1000

+1000

ACM 3000 #### A A####

#### A

+1000 A F6

LSD

F7

SSD

A

####

BC 83 Type Marque

90DG

R860

BC 85 1.0%

BC 55 BC 74 RC 23 100 X=35178.9

BC 82

93

Y=25548.3 10000 b/h

BC 75

1000

BC 57 BC 59 BC 87 BC +1000 +1000

100 mm PROPOSED WWTP PERIMETER FENCE (with CYCLONE WIRE & NO BARBED WIRE)

A

Désignation

101 M1

Référence

10 b

101 M1

BC 104

BC 81

PCF 13

####

BC 56 A

+1000

BC 61 BC 105 BC 89 BC 91 Chain for all TCTR

CCE 30

Désignation

1300 Référence X=37981.5

SEW Motor position

Y=21636.8

BC 79

RC 1 RC 24 M1A-180 M1B-0

####

A A

.

100

####

595

####

Désignation

Référence

1000

PCF 14

1.0%

BC 60 BC 62 BC 63

BC 58

SIDINGS)

STORAGE 1045

X=44081.4 X=47081.4 EXISTING TEMPORARY FENCE WALL (CORRUGATED ROOF

CCE 42

884.5

CCE 41

+1000

Y=21651.8 Y=21651.8

BC 80

ACM 3000

COSTUMER

A A

PART OF EXISTING BUILDING

####

####

CCE 32

PCF 15

DN DN +1000 +1000

RAMP A A

####

####

DOWN CCE 39 CCE 37

PROPOSED PERMANENT FENCE WALL (with CYCLONE WIRE & BARBED WIRE)

SIDEL

132 R1

PCF 16

+1000 +1000

+1000

CCE 38 Désignation

CCE 40 X=26261.5 Référence

101 M1

101 M1

CCE 33 Y=16001.8

####

A

Col de

Cygne

Col de

Cygne

+1000

A A

A A +1000

[ DW] [ F2]

A A

PCF 17

####

####

Watch out: the coordinate

is for the cirdle

[ F2] PQC OFFICE [ F2] X=63561.4

+1000

Y=9556.8

(NON-WORKABLE)

CONFERENCE

ELECTRICAL RESTO

+1000

A

CROWN ROOM

X=72761.4 X=76861.4

Type Marque

UP ROOM 10000 b/h

Y=8386.8 Y=8386.8

SHOP STAGING AREA A A

PCF 18

100 mm

####

####

10 b

[ W1] [ W1]

PQC +1000

X=37981.4

Y=9586.8

LOADING AREA

Cygne

Col de

####

####

A A

+1000

Cygne

Col de

DOWN

A A +1000

+1000 500.2 Désignation

C

Référence

101 M1

PCF 19

101 M1

+1000

+1000

+1000

A

+1000

####

+1000

+1000

+1000

X=28164.4

+1000

Désignation

X=28759.4 Référence

Y=5283.1

939.1

Y=5283.1+1000

1066.6

+1000

####

515

1000

A R860 A A A

PACKAGING BLDG. EXPANSION

A 101 M1

2

+1000 90DG #### A #### A #### ####

+1000

A ####

+1000

+1000

+1000

A R860

+1000

+1000

+1000

+1000

+1000

NON-WORKABLE

+1000

+1000

A 90DG

4

100 1.0%

+1000

Désignation Désignation 5

R860 A

A

Référence Référence

1000 101 M1

90DG +1000 3 X=72746.4

101 M1 A A X=76876.4

A A ####

####101 M1

####

A Y=3586.8

####

531

#### #### A #### A #### #### #### A #### Y=3586.8

PCF 20

####

#### R860 #### #### A #### A #### A ####

Pas :

1000 ####

A 101 M1 A A A

90DG

90DG A A #### A A

LF 735 R860

100 1.0%

1000

1000

90DG

A

R860

+1000

1000 1000

1000 1000

1000

1300

1555

A A ####

735

####

####

1000

1000

595

A +1000

A ####

####

+1000

+1000

1300 1000

LF 735

A A A #### A #### A #### A #### A

PROPOSAL

HMI

R860

Pas ####

####

101 M1

90DG

####

90DG

####101 M1 A

R860

:

####

####

####

101 M1

A #### A

SPE

1

1300 A

+1000

101 M1

101 M1 3 5 A

+1000

PALLETIZER LINK

####

+1000

595 SPE

####

DISTANCE BETWEEN THE AXIS OF TWO BELTS 16585 Désignation

4

Type Marque

PROPOSED X:Y REFERENCE Référence A A 1 1045

1820

B

Output Vgraph: 10000 b/h +1000 Type Marque

100 mm A A X=63531.4

A

Désignation

101 M1

serie

####

####

10 b

PUMP SIDE 20570 Référence Désignation

Référence A Crater

Palletizer

595 Y=-543.2

Pitch: 100 mm A 1000

254M1 250M1 GEBO Depalletizer Type Marque

101 M1

Empty out: Type X=37726.9

101 M1 Marque Decrater

1820

Output Vgraph: 10000 b/h

#### D ####C #### B #### A ####B GEBO Sidel CN EBI Sidel CN Output Vgraph:

10000 b/h 100 mm 491.3

255M1 249M1 Y=-501.8 +1000 +1000

ACM R500 ####A Type Marque

H=750

Washer 100 mm X=44053.9 10 b

B Sidel ITALY Sidel CN

282M1

Filler

#### C ####B #### A ####A #### C Sidel ITALY Sidel CN 90DG serie Washer Sidel ITALY Sidel CN 10 b Y=-1051.8

2447

Filler H=750

+1000

+1000

251M1 A A

Sidel CN

1552

101 M1

+1000

#### B

#### E

750

+1000

+1000

LAGOON 6

252M1 #### D

####

####

800 (-140)

GEBO

101M1

2100

A Désignation

#### A

#### A

B 2100 A Référence

#### C

R500A

Washer

Decrater

90DG

1450 C

R1000 328

#### D V-Reject

C

A

Sidel ITALY

PUMP SIDE 101 M1 SPE

90DG

90DG

#### B #### A

C

90DG R860 ####

R1000

220M1

R1000

101 M1

Chain supplied by Sidel CN B

1

241M1 ####

Sidel ITALY

101 M1

UNDER FILLED 90DG #### A #### A

223M1

Crater

Washer

Decrater

+1000

Sidel CN Sidel ITALY

1300 A

#### D #### C #### B #### A #### C COLLECTION AREA Chain supplied by Sidel CN

1300 A

FHI

SPEA A

248M1

#### C

MAINTENANCE AREA

#### D

#### A

800 (-140)

Sidel CN

R860

1753.09 Référence

Désignation

90DG

1

400

101 M1

101 M1

door opening door opening door opening door opening

Sidel CN Sidel ITALY

INCA

door opening door opening door opening

OLEP GUIDE

ACM

ACM

SPE

####A

#### B

Sidel CN

X=44053.9

####A

####A

1

#### B

233M1

355

H=1100

229M1

232M1

79x6 plat

+1000 +1000

####

Pasteurizer

Infeed guide supplied by washer

Y=-3243.8 #### A A

Pasteurizer

90DG

#### A B #### C A

#### B

R860

####

####

####B ####

#### C

1300 A

A R860 A A

#### A

#### A

Sidel ITALY

101 M1

A

Crater

#### A

230M1 +1000

6700

6700

R500 90DG

R1000

+1000

Filler

90DG

+1000

#### C #### A

#### C

####

90DG

Bottle shower in Filler's supply scope A

A

A

DECA

####

####

#### B X=37726.9 H=1100 A

#### C

LEF = 6350

####

####

Type Marque Y=-5009.8

A A

#### A

A A

240M1

231M1

9870

5966

Output Vgraph: 10000 b/h

101 M1

90DG

1300 A

####B

R500

100

####

####

#### A

BOTTLE WASHER

100 mm SPE

Chain supplied by Sidel CN

B

#### B

1

INSPECTION 10 b

#### D

####C R500 +1000

1000

+1000

1.0%

#### D #### A #### B #### C 90DG

####B

328

ACM

FILLER ####D ####A #### C X=76881.7

#### B

224M1

B

####B

X=72741.4 Y=-7193.1

219M1

225M1

####

####

####

+1000

AREA

#### B

####

H=750 Y=-7193.1 +1000

+1000

ACM 2000 ####

101 M1

C

Type Marque

#### A

####

101 M1

ACM

H=1100

X=37726.9 A A A A

####

####D

Output Vgraph: 10000 b/h A A

246M1

247M1

+1000

#### C

Y=-7204.3

7380

FLOW DIRECTION Decrater H=750 +1000

100 mm R1000 Crater

1820

10 b C LUBRICATION X=44053.9 A

Sidel ITALY Sidel CN

400

####

####

90DG #### B ####A

ACM 2000

SYSTEM STATION

421

230

Decrater +1000

101 M1

#### B 1300 A V-INLINER 02 Y=-7751.8 A

2311 +1000

####

Désignation Désignation

For Bottle Line A Crater

####

####

Référence Référence

#### D

#### A A

234M1

#### E

299M1

239M1

100

ACM

Référence

Désignation +1000

101 M1

#### C

A A

Crater

#### C

A A

#### B

238M1

1820

100

Désignation +1000

1000

101 M1

213M1 214M1

LF

+1000 Référence Palletizer

1.0%

+1000

101 M1

#### B #### A

HMI

####

100

####

####

101 M1

101 M1

#### E

215M1

####

####

1000

90DG

#### D #### A #### B A A A

#### B

237M1

R500

#### F

Désignation

1.0%

Désignation

A

R500

ACM

+1000 556.9 +1000

1000

Référence Référence

90DG

C

#### A

A

####A

1552

SPE

####

####

+1000 +1000 Désignation

#### A 216M1

FG

####

1.0%

Référence

101 M1

101 M1

101 M1

101 M1

1

236M1 +1000

#### C #### B

#### A

####

595

SPE A

101 M1

####

####

Pasteurizer

4x 9

####C

####D

#### A #### B A A 1 A +1000

+1000

+1000

ACM 3000

235M1 217M1 A A

J-Reject

+1000

+1000

ACM

800 (-140)

#### ####

+1000

####D

+1000 SPE A

Chain supplied by Sidel CN 218M1 A A

####

1 +1000

FHI

#### A

242M1

ACTUAL CONSTRUCTED FULL GOODS WAREHOUSE

Sidel ITALY Sidel CN

####

####

####

####

Désignation +1000

Taraudage #### B A A D Référence

V-INLINER 01 A R860 A

####

1300 A R1000 R500 A ACM 2000

LF

R860

SPE

####

101 M1

Pasteurizer

M8x30

90DG

A90DG A A

#### A

101 M1

90DG

1

#### B 90DG 90DG #### ####

A

Sidel ITALY Sidel CN

R860

+1000

####A #### B #### C #### A #### A #### A

243M1

281M1

GEAR SIDE +1000 +1000

#### H ####B #### C #### D #### E ####F

ACM 3000

A

#### A

201M1

310

SPE Désignation

Filler

A #### A #### G SPE ACM ACM A Référence

90DG

90DG

1

A A

R500

R860

1

+1000

+1000

R500

256M1

227M1 ACM 2000

####

####

595

4x

+1000

+1000

+1000

+1000

+1000

+1000

1300 A R860

#### B

253M1

####B

101M1

+1000

+1000

#### G

90DG ####B #### C

#### B

595

B B 90DG

#### A

GUIDE Désignation +1000

#### F #### E ####D #### C #### B #### A

1300 A

#### A #### B #### C #### D

244M1

EXTEND 300 298M1 +1000 Référence

90DG

A A

####B

####A

R860

+1000 +1000

90DG

R860 #### A #### A #### A #### A

#### B

297M1

R500

205M1

####

1045

####

500 door opening door opening door opening door opening door opening 101 M1

212M1 #### ####

ACM

1750 door opening door opening door opening MAINTENANCE AREA 101 M1 101 M1

A 90DG A A A #### A

####C A ####

#### B

258M1

#### A #### A A A

#### A

100 1.0%

+1000 Désignation

#### D #### C #### B #### A 800 (-140)

#### C

A

A

SPE 101M1

1000

Référence

90DG

A A

R500

202M1

####

####

~20873

90DG

259M1 1

203M1

R860

ACM

####

595

####

+1000

B

+1000

#### B #### A A #### D #### C

#### C

257M1

#### A

+1000

+1000

+1000

+1000

#### C

#### D

A R500 A A

#### F

ACM

#### B

R1000

Désignation

90DG

R1000 245M1 90DG Référence R860 ####

#### #### A #### A

B

209M1 +1000 +1000 +1000

90DG

LF 735

90DG Type Marque V-ACCU #### C #### B #### A A

R500

101 M1

600.8

Cygne

#### C R860 90DG A A ACM 2000 X=54038.8 A X=57138.8

####

R500 serie A

260M1

211M1 210M1 101M1 101 M1 Col de 101 M1 101 M1

ACM 90DG #### A #### Y=-15884.3 #### Y=-15516.8

#### B

90DG A

B

90DG

A #### B #### A 800 (-140)

#### C

#### C A A #### A #### A #### A #### A A #### A #### A

R500

Désignation

1300 A +1000 Référence

Sidel CN COATER Sidel CN 287M1 Cygne

#### E #### D #### C #### C O-INLINER 01 Col de X=57138.8

(8,500 SQM)

####B

283M1 284M1

1555

1300

1555

1725

#### F 269M1 270M1 SPE 285M1 A

735

+1000

1

266M1 #### D 286M1 B A #### A #### A #### A #### Cygne #### Y=-15884.3

+1000

+1000

+1000

+1000

+1000

+1000

Col de

262M1 261M1 #### D ####A #### B #### C ACM R500 R860

104.65

+1000

+1000

#### A #### B #### C #### A #### B #### C #### A #### B #### C

90DG 90DG

716.75 [18205.41] 341.14

265M1 Type Marque

1300 A 800 A Taraudage 101

M1 A A 101 M1 #### A

#### B #### A #### B #### #### #### A #### +1000 serie

#### A #### B #### A A Col de #### X=5713

9

101.27 [2572.29]

M8x30 SPE

LF 735

#### A

R860

SPE

R860

####

Ejection 8.4 1

90DG

A 1450 B Cygne A A A Y=-16252 A A

45DG

SPE Désignation

#### A 1450 C ####A #### B #### C A ####

#### E

1

1 Référence

90DG

O-REJECT 01 ACM ####D #### A ####

R500

268M1 Taraudage 101 M1

C

M8x30 271M1 R860 #### D #### C #### A #### B #### C A 101

M1 ####

LAGOON 2 LAGOON 3

#### A 279M1 Chain supplied by Sidel CN #### F #### G #### SPE 2750 E

ACM

267M1 90DG E H 295M1 296M1

ACM

1

101 M1

Type Marque Type Marque 291M1

#### D #### A FHI A

D

+1000

Référence

Désignation

Taraudage

30 19 274M1 serie Crater serie 292M1 Type Marque

####

+1000

+1000

+1000

+1000

90DG

263M1 ####B ####

R860

19

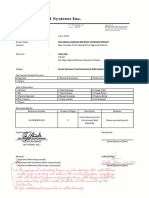

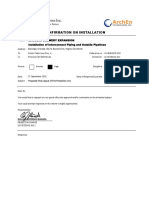

G0534 San Miguel Bacolod RGB Line

A #### A 23 280M1 serie

M8x30

#### D

2721 275M1 278M1

264M1 ####B #### A 1300 A 25 O-REJECT 02 Taraudage ACM D

27 25 SPE M8x30 #### D COATER #### #### 101 M1 #### A

#### A #### A #### B #### C R860 Sidel CN Sidel CN ####

290M1

A

25 1 Ejection 8.4

272M1 2525 A A ####A A

25 90DG

E

1300 A ####B

####

101.27 [2572.29]

800 A

+1000

#### A 1450 B #### A #### B #### C D

228M1

####E

273M1

716.75 [18205.41]

1450 C #### A #### B #### C #### D #### A #### B ####C CHIP LIPS BOTTLE COLLETION

341.14

#### D R860

O-INLINER 02 276M1

104.65

277M1 288M1 289M1

45DG

600 600

Pasteurizer

FHI

1.0%

100

1000

+1000

PROPOSED BOTTLING

+1000

LINE 2

LAGOON 7

C

ROAD - 3

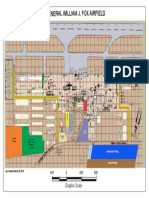

16m WIDE ROAD LEGEND:

EXISTING STRUCTURE

ON-GOING CONSTRUCTION

PROPOSED FULL GOODS

16m WIDE ROAD

WAREHOUSE

ROAD - 2

(6,000 SQ.M) TO BE CONSTRUCTED

EXISTING LAGOONS

SMBI BACOLOD BREWERY

GUARD

PSO OFFICE

NOT TO SCALE NON-WORKABLE AREAS

HOUSE

GATE 4

ROAD - 1 PROPOSED CYCLONE FENCE

16m WIDE ROAD

DRIVER'S

COMFORT LOUNGE TRUCK MARSHALLING

ROOM

You might also like

- (3rz-Fe) Engine ControlDocument11 pages(3rz-Fe) Engine ControlJhon Sanchez Lopez100% (1)

- Bizhub 423 - 363 - 283 - 223 Overall Wiring DiagramDocument1 pageBizhub 423 - 363 - 283 - 223 Overall Wiring DiagramHugo Luis Escalante50% (2)

- Steam Heating Troubleshooting GuideDocument9 pagesSteam Heating Troubleshooting GuideSagar RaneNo ratings yet

- Activity On Diode Waveshaping Circuits Group2 PDFDocument15 pagesActivity On Diode Waveshaping Circuits Group2 PDFRaymund TanapNo ratings yet

- Silicon - Controlled Rectifiers: Group MembersDocument13 pagesSilicon - Controlled Rectifiers: Group MembersMartin John Ramirez100% (1)

- Avance Terminaciones Ver.4Document1 pageAvance Terminaciones Ver.4manuelNo ratings yet

- Drive basketball skills with Lochatto drillsDocument24 pagesDrive basketball skills with Lochatto drillsRoLando Bautista Rotol Jr.No ratings yet

- To Be Revised: N Brown Fint Ube France SaDocument4 pagesTo Be Revised: N Brown Fint Ube France Sadhiaa mohammedNo ratings yet

- Setting Out PlanDocument1 pageSetting Out Plangaurav2289No ratings yet

- PDF Nomograma Heukelom CompressDocument1 pagePDF Nomograma Heukelom CompressWeimar Jurado GonzalesNo ratings yet

- TPCC 4 Site DevelopmentDocument1 pageTPCC 4 Site DevelopmentChris ChanNo ratings yet

- Flange ø1 1/2Document4 pagesFlange ø1 1/2dhiaa mohammedNo ratings yet

- ShamrockDocument1 pageShamrockhamparan arthaNo ratings yet

- To Be Re Vise D: Brown Fintube France Sa NDocument4 pagesTo Be Re Vise D: Brown Fintube France Sa Ndhiaa mohammedNo ratings yet

- 02 - AA - HH 28 DE JULIO-ModelDocument1 page02 - AA - HH 28 DE JULIO-ModelCarlos Augusto Navas ArmasNo ratings yet

- 03-Proposed WS SystemDocument1 page03-Proposed WS SystemKhalid YousafNo ratings yet

- Total Tuition & FeesDocument1 pageTotal Tuition & FeesGerald PardalesNo ratings yet

- Arquitectura CoberturasDocument1 pageArquitectura CoberturasMiguelIzaguirreNo ratings yet

- DePaul University Chicago Campus MapDocument1 pageDePaul University Chicago Campus MapIvory PlatypusNo ratings yet

- PLANS_Student Services CenterDocument23 pagesPLANS_Student Services Centerronulfo fabulaNo ratings yet

- 4983-DS120-402, Protección Contra SobretensiónDocument2 pages4983-DS120-402, Protección Contra SobretensiónAnthonyNo ratings yet

- Aficio MP161 MP161L MP161LN Series Point To Point DiagramDocument2 pagesAficio MP161 MP161L MP161LN Series Point To Point DiagramGeison RodriguesNo ratings yet

- Power Pack-BCT (PCB11) Key Card (Option) : Operation Panel Board (GW) (PCB12)Document4 pagesPower Pack-BCT (PCB11) Key Card (Option) : Operation Panel Board (GW) (PCB12)Lediano PradoNo ratings yet

- Yash Vihar LayoutDocument1 pageYash Vihar LayoutArvin DabasNo ratings yet

- 2018 LACAS Ramp LayoutDocument1 page2018 LACAS Ramp LayouttimboritusNo ratings yet

- Michigan Rail 430289 7Document1 pageMichigan Rail 430289 7mike_mckeown_3No ratings yet

- I.E 03Document1 pageI.E 03Byron SpencerNo ratings yet

- Church Floor Plans (Double Line) 16041AA033Document1 pageChurch Floor Plans (Double Line) 16041AA033e m solutions indiaNo ratings yet

- Sidewalk: Power House Front Elevation Power House SectionDocument1 pageSidewalk: Power House Front Elevation Power House Sectionalezandro del rossiNo ratings yet

- Overall Electrical Wiring DiagramDocument5 pagesOverall Electrical Wiring DiagramENGINEERING AUTOSNo ratings yet

- HS2 Map West Midlands wm15103Document1 pageHS2 Map West Midlands wm15103HighSpeedRailNo ratings yet

- Denah RafterDocument1 pageDenah RafterYusuf KhoirNo ratings yet

- Proposed Two Storey Res BLDGDocument17 pagesProposed Two Storey Res BLDGJefwardjohnNo ratings yet

- Cv-00 Proposed Linear Heat Detection Layout 1Document1 pageCv-00 Proposed Linear Heat Detection Layout 1Ramces AsisiNo ratings yet

- HPT-4240 V5 Psu Circuit Diagram PDFDocument1 pageHPT-4240 V5 Psu Circuit Diagram PDFAndrew RichardsNo ratings yet

- Isolation Bay Isolation Bay Isolation Bay: RESA 240M X 90M RESA 240M X 90M RESA 240M X 90MDocument1 pageIsolation Bay Isolation Bay Isolation Bay: RESA 240M X 90M RESA 240M X 90M RESA 240M X 90MErSoravNo ratings yet

- Gs (C A - 100 Q and Key)Document6 pagesGs (C A - 100 Q and Key)BhavithavNo ratings yet

- Joanne Sophia - Teachers Training Institute and Icse SchoolDocument28 pagesJoanne Sophia - Teachers Training Institute and Icse SchoolGayathri KathiravanNo ratings yet

- 4-To-16 - Decoder: 22/01/2017 16:31 /Users/Klausaschenbrenner/Onedrive/Kpu/Eagle/Cpu Design/Cpu - SCH (Alu: Sheet: 1/1)Document1 page4-To-16 - Decoder: 22/01/2017 16:31 /Users/Klausaschenbrenner/Onedrive/Kpu/Eagle/Cpu Design/Cpu - SCH (Alu: Sheet: 1/1)kernexNo ratings yet

- BulkleyGoat OrderMap Nov4Document1 pageBulkleyGoat OrderMap Nov4The Interior NewsNo ratings yet

- Mapa de Aforos 2017Document1 pageMapa de Aforos 2017jesus manuel cediel martinezNo ratings yet

- Plan Plan: Department of Public Works and HighwaysDocument1 pagePlan Plan: Department of Public Works and HighwaysEngr'Shemaiah JimenezNo ratings yet

- SA048-SD-TC-SIB-GN-ST-GA-0002_00Document1 pageSA048-SD-TC-SIB-GN-ST-GA-0002_00Belal HyariNo ratings yet

- Gobierno Regional de Ancash: LeyendaDocument1 pageGobierno Regional de Ancash: LeyendaAntonio ColoniaNo ratings yet

- Plan SPGGDocument1 pagePlan SPGGGerardo FernandezNo ratings yet

- Typical Detail Ii Typical Detail Iv Typical Detail Iii Typical Detail IDocument1 pageTypical Detail Ii Typical Detail Iv Typical Detail Iii Typical Detail IChoong K WNo ratings yet

- Denah Lantai 16-20Document1 pageDenah Lantai 16-20WA ODE SITTI AISYAH ANo ratings yet

- TQ-5133502 TQ-5133501A TQ-5133503: D.O. Service TK P D.O. Settling TK S D.O. Storage TK SDocument1 pageTQ-5133502 TQ-5133501A TQ-5133503: D.O. Service TK P D.O. Settling TK S D.O. Storage TK SRobles DreschNo ratings yet

- Espy Kitchen Menu Jan18Document2 pagesEspy Kitchen Menu Jan18Anonymous zNdbKT993YNo ratings yet

- Floor Plan Notes and Restroom AccessoriesDocument1 pageFloor Plan Notes and Restroom AccessoriesMuhammad AbuBakarNo ratings yet

- Edicro S.A.: República de NicaraguaDocument1 pageEdicro S.A.: República de NicaraguaNorlan O Diaz GarciaNo ratings yet

- Sbornik Ot Bŭlgarski Narodni UmotvoreniDocument682 pagesSbornik Ot Bŭlgarski Narodni UmotvoreniEdion PetritiNo ratings yet

- Bp2021-C026s-Jwn02-A01-Drainage System-Fp-1001-Ground and Roof Floor Plans - CafeteriaDocument1 pageBp2021-C026s-Jwn02-A01-Drainage System-Fp-1001-Ground and Roof Floor Plans - CafeteriaMohammad IsmailNo ratings yet

- Au1GeU PDFDocument1 pageAu1GeU PDFYOOOOOOONo ratings yet

- 5 Secretos para Iniciar Tu Negocio de Marketing de AfiliadosDocument28 pages5 Secretos para Iniciar Tu Negocio de Marketing de AfiliadosMaría Del Carmen Carrillo de RenteríaNo ratings yet

- Fixed Point Side View Looking Toward South Front View Looking Toward EastDocument1 pageFixed Point Side View Looking Toward South Front View Looking Toward EastDima Fon NmskNo ratings yet

- Drawing Pekerjaan em Gi Tentena (Ext) RevisiDocument7 pagesDrawing Pekerjaan em Gi Tentena (Ext) Revisiwandy RJNo ratings yet

- Dowland - Lachrimae Antiquae - ATDocument2 pagesDowland - Lachrimae Antiquae - ATAllemando SarabandisNo ratings yet

- Johnson Controls - Building Efficiency: Label Wiring - Haf Fan Wiring Std/Inv Opt 5-Fan System 1-1Document2 pagesJohnson Controls - Building Efficiency: Label Wiring - Haf Fan Wiring Std/Inv Opt 5-Fan System 1-1PetricaNo ratings yet

- Ref docs for commissioningDocument1 pageRef docs for commissioningRobles DreschNo ratings yet

- Espe Mep SQ SD R.sump.r2-4Document1 pageEspe Mep SQ SD R.sump.r2-4Tri SafrilNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- Response To RFA 09 Rev.2 Caustic Recovery Tank Containment Wall Details (ICI)Document4 pagesResponse To RFA 09 Rev.2 Caustic Recovery Tank Containment Wall Details (ICI)William Jefferson RañadaNo ratings yet

- RFCI 103 Proposed Final Layout of Fire Protection Line (ICI)Document4 pagesRFCI 103 Proposed Final Layout of Fire Protection Line (ICI)William Jefferson RañadaNo ratings yet

- Bacolod Brewery: Additive and Deductive Works: Material Diameter LengthDocument1 pageBacolod Brewery: Additive and Deductive Works: Material Diameter LengthWilliam Jefferson RañadaNo ratings yet

- Rfi Smbbac 002 ResponseDocument1 pageRfi Smbbac 002 ResponseWilliam Jefferson RañadaNo ratings yet

- ICI-SMB-BCD-104 - Piping Obstruction On Proposed Section C3 Pipebridge in Front of Filtration BuildingDocument3 pagesICI-SMB-BCD-104 - Piping Obstruction On Proposed Section C3 Pipebridge in Front of Filtration BuildingWilliam Jefferson RañadaNo ratings yet

- Technical Information Cerabar M PMC51, PMP51, PMP55: Process Pressure MeasurementDocument120 pagesTechnical Information Cerabar M PMC51, PMP51, PMP55: Process Pressure MeasurementWilliam Jefferson RañadaNo ratings yet

- Stop Valve With Bellows Seal: Edition 02/10 - Data Subject To Alteration Data Sheet 040005 Englisch (English)Document14 pagesStop Valve With Bellows Seal: Edition 02/10 - Data Subject To Alteration Data Sheet 040005 Englisch (English)William Jefferson RañadaNo ratings yet

- Fresh Caustic Tank Containment Wall DetailsDocument1 pageFresh Caustic Tank Containment Wall DetailsWilliam Jefferson RañadaNo ratings yet

- Technical Information Cerabar M PMC51, PMP51, PMP55: Process Pressure MeasurementDocument120 pagesTechnical Information Cerabar M PMC51, PMP51, PMP55: Process Pressure MeasurementWilliam Jefferson RañadaNo ratings yet

- Data Sheet For SINAMICS Control Unit CU230P-2 PN: Ambient Conditions Electrical DataDocument1 pageData Sheet For SINAMICS Control Unit CU230P-2 PN: Ambient Conditions Electrical DataWilliam Jefferson RañadaNo ratings yet

- Conveyor Auxiliaries - WPDocument47 pagesConveyor Auxiliaries - WPPaulNo ratings yet

- Configure XE Series ControllerDocument22 pagesConfigure XE Series Controllerarturo_ceballos_11100% (1)

- Perkin Elmer Lambda 20-40 Uv Vis Spectrometer Manual EngDocument106 pagesPerkin Elmer Lambda 20-40 Uv Vis Spectrometer Manual EngLucio Alan100% (2)

- k23269 Teflon FilmsDocument4 pagesk23269 Teflon FilmsSathishBerryNo ratings yet

- Oxygenerator User ManulDocument29 pagesOxygenerator User ManulRafikul RahemanNo ratings yet

- 150 BulletinDocument8 pages150 BulletinFranco YnquillaNo ratings yet

- Door Motor VVVFDocument15 pagesDoor Motor VVVFEdhimj UnmeNo ratings yet

- Interview Guidance by S K MondalDocument16 pagesInterview Guidance by S K MondaljishnuNo ratings yet

- SV420XVT1A LPL Service ManualDocument30 pagesSV420XVT1A LPL Service ManualJay HunterNo ratings yet

- Advances in Cryojet Machining: Development and Improvement AreasDocument11 pagesAdvances in Cryojet Machining: Development and Improvement AreasAnupama ChattorajNo ratings yet

- ML 063460464Document64 pagesML 063460464Nathan BlockNo ratings yet

- CP Silo Tech 260809 - WebDocument24 pagesCP Silo Tech 260809 - WebHuyentrang NguyenNo ratings yet

- Venus User Manual-ENDocument58 pagesVenus User Manual-ENAsif KhanNo ratings yet

- Jagdish Dukre's Guide to Phacoemulsification Machine Components and FunctionsDocument38 pagesJagdish Dukre's Guide to Phacoemulsification Machine Components and FunctionsRizkyAgustriaNo ratings yet

- Synopsis Mini Hydraulic PressDocument4 pagesSynopsis Mini Hydraulic PressRaja Mane0% (2)

- Joule-Thomson Coefficient of CO2Document16 pagesJoule-Thomson Coefficient of CO2Justine GuerreroNo ratings yet

- Resilite 2735Document2 pagesResilite 2735pwmvsi100% (1)

- Eurosun2014-Proceedings - ImportentDocument1,524 pagesEurosun2014-Proceedings - ImportentAkhileshkumar PandeyNo ratings yet

- STF-000118 Rev.02 VT-evo Kubota Wiring DiagramDocument5 pagesSTF-000118 Rev.02 VT-evo Kubota Wiring DiagramJustice MachiwanaNo ratings yet

- NH 6035448106 PreviewDocument51 pagesNH 6035448106 PreviewYesenia Gpe VegaNo ratings yet

- Chapter 2 PhotosynthesisDocument41 pagesChapter 2 PhotosynthesisTshering ChodenNo ratings yet

- Science Lab Lists 2018 High School With PricesDocument35 pagesScience Lab Lists 2018 High School With Prices11Brad11No ratings yet

- Optimize XC1008-1011-1015D controller manualDocument70 pagesOptimize XC1008-1011-1015D controller manualHoàngViệtAnhNo ratings yet

- Forces Motion EnergyDocument68 pagesForces Motion EnergyMark Niño JavierNo ratings yet

- Pre-Feasibility Report: Shree Shyam Sponge & Power LTDDocument32 pagesPre-Feasibility Report: Shree Shyam Sponge & Power LTDفردوس سليمان100% (2)

- Fuel Injection System - St313046: Parts ListDocument6 pagesFuel Injection System - St313046: Parts ListRoberto Emilio Bermudez ColomaNo ratings yet