Professional Documents

Culture Documents

Tu-863p MF - Datasheet

Uploaded by

huan nguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tu-863p MF - Datasheet

Uploaded by

huan nguyenCopyright:

Available Formats

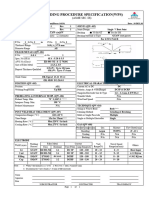

High Tg Low Loss Halogen Free Low flow Prepreg

1 of 2

TU-863P MF Prepreg: TU-863P MF

TU-863P MF low loss, low flow halogen-free prepreg consist of optimal resin flow specially

formulated for unique purpose bonding applications. The special design TU-863P MF low flow,

low loss halogen-free prepreg is appropriate for applying in multiple layer rigid-flex bonding,

heat sink bonding and die cavity board applications. TU-863P MF low flow prepreg also provide

excellent bonding performance with a variety of materials and with excellent high Tg, low CTE

thermal performance for sequential lamination and lead-free processes.

Applications

High Speed Rigid-flex Board

Heat sink, Cavity

Performance and Processing Advantages

Stable resin flow

Excellent bonding strength with polyimide materials

Low resin powder dust generation

High Tg, low loss and halogen free characteristics

Lead Free process compatible

Reduced z-axis thermal expansion

Superior dimensional stability, thickness uniformity and flatness

Good drilling & lamination processes friendly

Superior dielectric thickness control

Industry Approvals

IPC-4101E Type Designation : /127, /128, /130

IPC-4101E/130 Validation Services QPL Certified

UL Designation - ANSI Grade: FR-4.1

UL File Number: E189572

Flammability Rating: 94V-0

Maximum Operating Temperature: 130°C

Standard Availability

Prepregs: Available in roll or panel form

Glass Styles: 106 and 1080, other prepreg grades are available upon request

DS1802003A

Copyright © 2012-2018 Taiwan Union Technology

Corporation

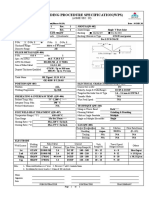

High Tg Low Loss Halogen Free Low flow Prepreg

2 of 2

Typical Properties for TU-863P MF Prepreg

Cured Typical Values Conditioning IPC-4101 /130

Thermal

Tg (DMA) 200°C >170°C

Tg (TMA) 165°C E-2/105 -

Td (TGA) 375°C >340°C

CTE x-axis 11~15 ppm/°C N/A

CTE y-axis 11~15 ppm/°C E-2/105 N/A

CTE z-axis 2.5 % < 3.0%

Thermal Stress,

> 60 sec A > 10 sec

Solder Float, 288°C

T260 > 60 min > 30 min

T288 > 60 min E-2/105 > 15 min

T300 > 30 min > 2 min

Flammability 94V-0 E-24/125 94V-0

Electrical

Permittivity (RC50%)

1GHz (HP4291B) 4.1

5GHz (SPC method) 4.0 E-2/105 N/A

10GHz (SPC method) 3.9

Loss Tangent (RC50%)

1GHz (SPC method) 0.007

5GHz (SPC method) 0.008 E-2/105 N/A

10GHz (SPC method) 0.0085

Volume Resistivity > 1010 MΩ•cm C-96/35/90 > 106 MΩ•cm

Surface Resistivity > 108 MΩ C-96/35/90 > 104 MΩ

Electric Strength > 40 KV/mm > 30 KV/mm

Dielectric Breakdown > 50 KV > 40 KV

Mechanical

Young’s Modulus

Warp Direction 26 GPa

A N/A

Fill Direction 24 GPa

Peel Strength,

1.0 oz. Cu foil 5~8 lb/in A > 4 lb/in

Water Absorption 0.13 % E-1/105+D-24/23 < 0.8 %

NOTE:

1. Property values are for information purposes only and not intended for specification.

2. Any sales of these products will be governed by the terms and conditions of the agreement under which they are sold.

3. This product is based on a patent pending technology

DS1802003A

Copyright © 2012-2018 Taiwan Union Technology

Corporation

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Thunderclad 1+ - DatasheetDocument2 pagesThunderclad 1+ - Datasheethuan nguyenNo ratings yet

- Tuc-872 SLKDocument2 pagesTuc-872 SLKmNo ratings yet

- 353ND TDocument1 page353ND TCothuru Santosh KumarNo ratings yet

- SA12A90 - F10 Data Sheet On-OffDocument1 pageSA12A90 - F10 Data Sheet On-Offanbarasan100% (1)

- KB Fr4 61606160a6160c Raw Material Technical Information Data SheetDocument2 pagesKB Fr4 61606160a6160c Raw Material Technical Information Data Sheettrupzup7No ratings yet

- TVSS Wallmount Tranquell LE & MEDocument4 pagesTVSS Wallmount Tranquell LE & MEEldie TappaNo ratings yet

- CC5V T1aDocument2 pagesCC5V T1aNivlaisoka RomaNo ratings yet

- Ventec: Professional Manufacturer in Copper Clad LaminatesDocument3 pagesVentec: Professional Manufacturer in Copper Clad LaminatesBenyamin Farzaneh AghajarieNo ratings yet

- Critec TSG SRF Single PhaseDocument3 pagesCritec TSG SRF Single PhaseDrgnNo ratings yet

- Actuator and Governor Control Operation SpecsDocument7 pagesActuator and Governor Control Operation SpecsstmeuNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Compact 103dB alarm horn for fire, industrial & process controlDocument3 pagesCompact 103dB alarm horn for fire, industrial & process controlGajapathy HariNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- ETI Zaštita Od PrenaponaDocument2 pagesETI Zaštita Od Prenaponajosip miskovicNo ratings yet

- NSB 180FT Red Battery (SES-542!46!03) NetsphereDocument2 pagesNSB 180FT Red Battery (SES-542!46!03) NetsphereRaul OrtizNo ratings yet

- Shielded Power Inductors - PFL2015Document2 pagesShielded Power Inductors - PFL2015DamianNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Ma121 Alarm Horn Sounder Ip66 67 DatasheetDocument4 pagesMa121 Alarm Horn Sounder Ip66 67 DatasheetCésaire Aimé NdjemNo ratings yet

- NTB5860NL, NTP5860NL, NVB5860NL N-Channel Power MOSFET: 60 V, 220 A, 3.0 MWDocument9 pagesNTB5860NL, NTP5860NL, NVB5860NL N-Channel Power MOSFET: 60 V, 220 A, 3.0 MWalllim88No ratings yet

- data-sheet-HLSA25G-255-4-0-10 465-EnDocument3 pagesdata-sheet-HLSA25G-255-4-0-10 465-EnThe Anh NguyenNo ratings yet

- Static / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILDocument2 pagesStatic / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILNilesh MahajanNo ratings yet

- Tap1000 SeriesDocument1 pageTap1000 Seriescjsalazarb78No ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- NIC Components NNT SeriesDocument3 pagesNIC Components NNT SeriesNICCompNo ratings yet

- High-flow, low-contamination light-conducting PC resin propertiesDocument1 pageHigh-flow, low-contamination light-conducting PC resin propertiesLeandro LacerdaNo ratings yet

- Adsl 402Document9 pagesAdsl 402edward blancoNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- EMC EM827 PCB ManufacturerDocument6 pagesEMC EM827 PCB ManufacturerHenry zhangNo ratings yet

- Erapol E90A: Technical DatasheetDocument2 pagesErapol E90A: Technical Datasheetmgamal1080No ratings yet

- MKP-X2 interference suppression capacitorDocument2 pagesMKP-X2 interference suppression capacitorgunsakNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- PDS (PN.008 Epoxy Resin System)Document4 pagesPDS (PN.008 Epoxy Resin System)GustavoNo ratings yet

- 2 21 190 Ma112 - DatasheetDocument3 pages2 21 190 Ma112 - DatasheetBrion Bara IndonesiaNo ratings yet

- Coilcraft HTX7045C LLC HB TransformersDocument1 pageCoilcraft HTX7045C LLC HB TransformersgcamarcaNo ratings yet

- Dynamic Mechanical AnalysisDocument22 pagesDynamic Mechanical Analysisrudy ammeNo ratings yet

- Ul10086 22awg FT111021Document2 pagesUl10086 22awg FT111021Trần Long VũNo ratings yet

- Datasheet AD711 JNDocument12 pagesDatasheet AD711 JNDA OscNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- Transformercare Unit Tcu Series: Technical Specifications DescriptionDocument2 pagesTransformercare Unit Tcu Series: Technical Specifications DescriptionJoão Paulo SacramentoNo ratings yet

- Cal TA100Document2 pagesCal TA100Diego MorotoNo ratings yet

- Vectra: LCP (Liquid Crystal Polymer)Document4 pagesVectra: LCP (Liquid Crystal Polymer)顏健軒No ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- Exhaust Rim E722 - Epoxy - PDSDocument5 pagesExhaust Rim E722 - Epoxy - PDSSpace MuskNo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- Messrs.: Specification For ApprovalDocument8 pagesMessrs.: Specification For ApprovalallendohorizontNo ratings yet

- 60APU02Document7 pages60APU02Abderrahim ErragragyNo ratings yet

- SON4L Alarm Sounder & LED BeaconDocument3 pagesSON4L Alarm Sounder & LED BeaconCarlos Correa SalasNo ratings yet

- High Efficiency Solid State Amplifiers - 1Document44 pagesHigh Efficiency Solid State Amplifiers - 1wingchaoNo ratings yet

- Buna EP LanxessDocument51 pagesBuna EP LanxessANHVUDRCNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Comprit 185H 0 6Document1 pageComprit 185H 0 6Ahmed AbdelhamidNo ratings yet

- Temt 1000Document9 pagesTemt 1000Jerome JinNo ratings yet

- Ramcroil - Instrumentation Cable: Multi-Pair, HT 105°-Insulation, Collective Screen, PVC-Sheath, Sunlight ResistantDocument1 pageRamcroil - Instrumentation Cable: Multi-Pair, HT 105°-Insulation, Collective Screen, PVC-Sheath, Sunlight ResistantOrlando SantofimioNo ratings yet

- Eols Gu 35XXDocument8 pagesEols Gu 35XXTestgame GameonlyNo ratings yet

- Technology Corporation: FeaturesDocument16 pagesTechnology Corporation: Featuresosmanandac1No ratings yet

- CM8V-T1A32 768kHz7pF 20ppmTAQCDocument2 pagesCM8V-T1A32 768kHz7pF 20ppmTAQCcafosokNo ratings yet

- AOS Semiconductor Product Reliability Report: Plastic Encapsulated DeviceDocument3 pagesAOS Semiconductor Product Reliability Report: Plastic Encapsulated DevicekalanghoNo ratings yet

- Chip Beads (2508056007Y3) : Recommended Soldering ProfileDocument3 pagesChip Beads (2508056007Y3) : Recommended Soldering Profilehuan nguyenNo ratings yet

- Jesd209 2FDocument284 pagesJesd209 2Fhuan nguyenNo ratings yet

- TXB0101 1-Bit Bidirectional Level-Shifting and Voltage Translator With Auto Direction-Sensing and 15-kV ESD ProtectionDocument33 pagesTXB0101 1-Bit Bidirectional Level-Shifting and Voltage Translator With Auto Direction-Sensing and 15-kV ESD Protectionhuan nguyenNo ratings yet

- Tu-863p MF - DatasheetDocument2 pagesTu-863p MF - Datasheethuan nguyenNo ratings yet

- En DM00314099 PDFDocument3,289 pagesEn DM00314099 PDFRajeev AroraNo ratings yet

- DS90C401 Dual Low Voltage Differential Signaling (LVDS) DriverDocument19 pagesDS90C401 Dual Low Voltage Differential Signaling (LVDS) Driverhuan nguyenNo ratings yet

- SMD Power Inductors (NR Series) NR3012T100M: Spec SheetDocument3 pagesSMD Power Inductors (NR Series) NR3012T100M: Spec SheetbonaquaNo ratings yet

- BTX DatasheetDocument22 pagesBTX Datasheethuan nguyenNo ratings yet

- DS90C032 LVDS Quad CMOS Differential Line Receiver: Features DescriptionDocument18 pagesDS90C032 LVDS Quad CMOS Differential Line Receiver: Features Descriptionhuan nguyenNo ratings yet

- DRV120 Single-Channel Relay, Solenoid, Valve Low-Side Driver With Current RegulationDocument23 pagesDRV120 Single-Channel Relay, Solenoid, Valve Low-Side Driver With Current Regulationhuan nguyenNo ratings yet

- AN2651 Configuration of Microchip USB47xx USB49xx Application Note 00002651BDocument76 pagesAN2651 Configuration of Microchip USB47xx USB49xx Application Note 00002651Bhuan nguyenNo ratings yet

- TXB0108 8-Bit Bidirectional Voltage-Level Translator With Auto-Direction Sensing and 15-kV ESD ProtectionDocument40 pagesTXB0108 8-Bit Bidirectional Voltage-Level Translator With Auto-Direction Sensing and 15-kV ESD Protectionhuan nguyenNo ratings yet

- DRV84x2 Dual Full-Bridge PWM Motor Driver: 1 FeaturesDocument45 pagesDRV84x2 Dual Full-Bridge PWM Motor Driver: 1 Featureshuan nguyenNo ratings yet

- CD54HC243, CD74HC243, CD54HCT243, CD74HCT243: High-Speed CMOS Logic Quad-Bus Transceiver With Three-State OutputsDocument17 pagesCD54HC243, CD74HC243, CD54HCT243, CD74HCT243: High-Speed CMOS Logic Quad-Bus Transceiver With Three-State Outputshuan nguyenNo ratings yet

- USB-to-I C Bridging With USB47xx/USB49xx HubsDocument16 pagesUSB-to-I C Bridging With USB47xx/USB49xx Hubshuan nguyenNo ratings yet

- SMD Power Inductors (NR Series) NR3012T100M: Spec SheetDocument3 pagesSMD Power Inductors (NR Series) NR3012T100M: Spec SheetbonaquaNo ratings yet

- TLV758P 500-Ma, High-Accuracy, Adjustable LDO in A Small Size PackageDocument35 pagesTLV758P 500-Ma, High-Accuracy, Adjustable LDO in A Small Size Packagehuan nguyenNo ratings yet

- 150ma, Low-Dropout Regulator, Ultralow-Power, I 1 A With Pin-Selectable, Dual-Level Output VoltageDocument31 pages150ma, Low-Dropout Regulator, Ultralow-Power, I 1 A With Pin-Selectable, Dual-Level Output Voltagehuan nguyenNo ratings yet

- Ds 90 C 401Document19 pagesDs 90 C 401Ignatius Elga Pm100% (1)

- TXB0101 1-Bit Bidirectional Level-Shifting and Voltage Translator With Auto Direction-Sensing and 15-kV ESD ProtectionDocument33 pagesTXB0101 1-Bit Bidirectional Level-Shifting and Voltage Translator With Auto Direction-Sensing and 15-kV ESD Protectionhuan nguyenNo ratings yet

- DS90C032 LVDS Quad CMOS Differential Line Receiver: Features DescriptionDocument18 pagesDS90C032 LVDS Quad CMOS Differential Line Receiver: Features Descriptionhuan nguyenNo ratings yet

- Microwave ConnectorsDocument44 pagesMicrowave Connectorshuan nguyenNo ratings yet

- TXB0108 8-Bit Bidirectional Voltage-Level Translator With Auto-Direction Sensing and 15-kV ESD ProtectionDocument40 pagesTXB0108 8-Bit Bidirectional Voltage-Level Translator With Auto-Direction Sensing and 15-kV ESD Protectionhuan nguyenNo ratings yet

- 74LVC1T45 74LVCH1T45: 1. General DescriptionDocument31 pages74LVC1T45 74LVCH1T45: 1. General Descriptionhuan nguyenNo ratings yet

- Cancer Poster 840x552Document1 pageCancer Poster 840x552Sreeharsha GurrapuNo ratings yet

- Amistco: AMISTCO Improved Pall RingDocument1 pageAmistco: AMISTCO Improved Pall RingAdhe Irma SuryaniNo ratings yet

- 02 - Screening AnalysisDocument45 pages02 - Screening AnalysisLEIAH MARIE JOY RIONo ratings yet

- Chemical Engineering Principles for First Year StudentsDocument132 pagesChemical Engineering Principles for First Year StudentsMaui GupitaNo ratings yet

- UCB008 Lab Manual 2018-19Document47 pagesUCB008 Lab Manual 2018-19Rahul AnandNo ratings yet

- Formulae For: Alcohol, Phenols and EthersDocument10 pagesFormulae For: Alcohol, Phenols and EthersSâmïr Kumar MundariNo ratings yet

- Organometallic Chemistry OverviewDocument40 pagesOrganometallic Chemistry OverviewRabiul IslamNo ratings yet

- Gerak Gempur Sem 1 2023Document11 pagesGerak Gempur Sem 1 2023Siva RajaNo ratings yet

- Biochemistry and Nutrition of Carbohydrates: June 2021Document10 pagesBiochemistry and Nutrition of Carbohydrates: June 2021Sely wulan widya ningsihNo ratings yet

- Nano Material EsDocument156 pagesNano Material EsAreitos DelgadoNo ratings yet

- A Level Chemistry SolutionsDocument8 pagesA Level Chemistry SolutionsImagreenbucklegirl SGNo ratings yet

- 06 - BIO IX ICSE Respiration in Plants PDFDocument5 pages06 - BIO IX ICSE Respiration in Plants PDFthe lillyNo ratings yet

- Technical Catalogue VSF Iec Atex en Rev0 2017 PDFDocument172 pagesTechnical Catalogue VSF Iec Atex en Rev0 2017 PDFshivv230No ratings yet

- Organic Chemistry Chapter 4Document58 pagesOrganic Chemistry Chapter 4Laiba KhanNo ratings yet

- 03 Ib Chemistry (SL+HL) - S1.5 Ideal GasesDocument33 pages03 Ib Chemistry (SL+HL) - S1.5 Ideal GasesricardochavezrNo ratings yet

- Engineering Materials Note by Me For Ctevt-1Document20 pagesEngineering Materials Note by Me For Ctevt-1VedhPrakas Gupta67% (6)

- IGNOU BCHEL - 150 Quantitative DirectionsDocument8 pagesIGNOU BCHEL - 150 Quantitative DirectionsSUBHODIP SAMANTANo ratings yet

- Fd-Fan Blade FailureDocument8 pagesFd-Fan Blade FailurePRAMOD KUMAR NANDANo ratings yet

- Conteo 02 CFDocument42 pagesConteo 02 CFgiovanni triviñoNo ratings yet

- Vegan CDS Glycolic - 01 TD V05Document10 pagesVegan CDS Glycolic - 01 TD V05gongjuofficial.idNo ratings yet

- Kvs Sample Paper Chemistry Page 2 - 6Document5 pagesKvs Sample Paper Chemistry Page 2 - 6Rohan BaghelNo ratings yet

- Bio Inorganic 1 PPT ChemistryDocument57 pagesBio Inorganic 1 PPT ChemistryShantanu MawaskarNo ratings yet

- 2019 Jun Chemistry QPDocument16 pages2019 Jun Chemistry QPDini WarnaNo ratings yet

- Balancing Redox Reactions PDFDocument5 pagesBalancing Redox Reactions PDFAjay Kumar GantiNo ratings yet

- BS en Iso 18134-3-2015Document14 pagesBS en Iso 18134-3-2015Lucas CoêlhoNo ratings yet

- Wordlywise Book 9 Lesson 9Document1 pageWordlywise Book 9 Lesson 9choiNo ratings yet

- PVC AdditiveDocument35 pagesPVC AdditivePinyaporn VeerapraditNo ratings yet

- Reversible ReactionsDocument10 pagesReversible ReactionsHamza KhalidNo ratings yet

- Prestressing For Concrete StructuresDocument18 pagesPrestressing For Concrete StructuresIm ChinithNo ratings yet

- 2013 HSC ChemistryDocument46 pages2013 HSC Chemistrysophiehee1234No ratings yet