Professional Documents

Culture Documents

Evel Ommand With Ompressor

Uploaded by

tesslik SlavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evel Ommand With Ompressor

Uploaded by

tesslik SlavaCopyright:

Available Formats

LEVEL COMMAND 2097 / 2187 / 2227 / 2233

WITH 9210 COMPRESSOR

60 90

400 600

120

30 200

800

1000

psi kPa

PSI

0 150

LEVEL COMMAND

INSTALLATION INSTRUCTIONS NOTE ON CONNECTING THE AIR LINE TUBING:

Congratulations on your purchase of a new Level Command Cut the air line tubing as squarely as possible. To connect

kit. This kit was designed to provide inflation control of your the air line tubing to the fittings, push the tubing into the fittings

air helper springs. This kit will be an asset to your vehicle, as far as possible. If for any reason the tubing must be removed,

meeting nearly all of your air supply needs. first release the air pressure from the air helper spring. Push the

Please take a few minutes to read through the instructions, collar toward the body of the fitting and the pull out the tubing.

identify the components, and learn how to properly install your To reassemble, make sure the tubing is cut squarely and push

Level Command kit. the tubing back into the fitting.

NOTE:

The Level Command kit can be used with all air helper TOOLS REQUIRED:

spring products. If you are installing an air suspension system, • 3/16" DRILL BIT • 3/8" DRILL BIT

do not install the air line tubing to the air springs as stated in • 1/4" DRILL BIT • POWER DRILL

the suspension system instruction manual. If you are adding • WIRE CRIMPER/STRIPPER • PLIERS

the Level Command kit to an existing air suspension system, • PHILLIPS SCREW DRIVER • UTILITY KNIFE

you will need to deflate the air springs and remove the air line • (2) 7/16" WRENCHES • CENTER PUNCH

tubing.

PARTS LIST

SINGLE AIR CONTROL PANEL 1 #10 FLAT WASHER 7

COMPRESSOR 9210 1 15 FT. 16 GAGE WIRE 1

30 FT. AIR LINE TUBING 1 IN-LINE FUSE HOLDER 1

1/8" NPT PUSH-TO-CONNECT 20 AMP BLADE FUSE 1

STRAIGHT FITTING 3055 1 FEMALE SPADE CONNECTOR 2

PUSH-TO-CONNECT MALE SPADE CONNECTOR 1

T-FITTING 3025 2 RING TERMINAL 1

10 -32 x 1" MACHINE SCREW 5 WIRE CONNECTOR 2

10 -32 LOCK NUT 5 NYLON TIE 15

24-8204 03-01 NAD-30665-2

STRAIGHT AIR FITTING 2227

AIR LINE

POSITIVE, 12 VOLT

DASHBOARD

ILLUMINATION

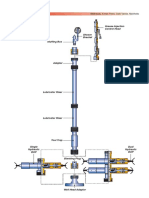

Air Line & Wiring Diagram CIRCUIT

RED

GROUND

BLACK (TO GROUND)

FUSE 60 90

400 600

12 VOLT, 20 AMP

120

MINIMUM IGNITION WHITE 30 200

800

ACTIVATED CIRCUIT

1000

WHITE psi kPa

PSI

0 150

AIR LINE

E

HIN

ACEW

M

1” SCR Compressor Attachment

S

AS S

BRERT

I N S OR

SS

PRE

ER OM

BB RS C “T” FITTING

RULATO AIR

ISO

AIR SPRING AIR SPRING

(sold separately) (sold separately)

V

E

H

IC

LE

Connectors:

P

A

N

1/ BE

E

L

4 D

H R

O IL

LE LE

S D

T

O

Male spade connector Femal spade connector

#1

0F

LA

TW

10 AS Ring Terminal Wire connector

/32 HE

L R

OC

KN

UT

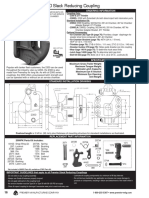

Inline fuse connector Figure “A”

STEP 1 - SELECT A MOUNTING LOCATION FOR THE CONTROL PANEL

LO Select a mounting surface under the dashboard or other protected location.

CK

WA

NU

TS Using the control panel as a template, mark each of the mounting points with a

SH

ER

S center punch. Drill a 3/16" diameter hole on each center mark see Figure "B".

Do not attach the control panel at this time.

C

O B

N R

T A

R C

O K

L E

P T

A

N

STEP 2 - PREPARE THE COMPRESSOR

E

L

Install the rubber isolator feet to the compressor from the bottom of the

WA compressor foot. Insert the brass sleeve into the top of the rubber isolator foot

MA SH

CH ER see Figure "C". Install the push-to-connect male fitting into the threaded

INE S

SR

EW exhaust port on the compressor head see Figure "A". Tighten the fitting

S

sufficiently to engage at least two threads with pre-applied orange thread

sealant. DO NOT OVERTIGHTEN THE FITTING. Install the air filter into the

Figure "B" threaded inlet port on the compressor head (finger tight).

STEP 3 - MOUNT THE COMPRESSOR

BRASS SLEEVE

Begin by removing the negative battery cable. Select a convenient location

COMPRESSOR

FOOT to mount the compressor. This location should provide ample air flow and be

protected from airborne debris and moisture. The mounting surface should be

RUBBER rigid to support the compressor, such as under the hood on a fender well or in

ISOLATOR

a vented storage compartment. The compressor is oil-less and can be mounted

10 -32 x 1”

PHILLIPS 3/16” FLAT WASHER

in any orientation necessary for installation.

PAN HEAD

SCREW BRASS SLEEVE Using the compressor template and a center punch, mark and drill three

COMPRESSOR 3/16" holes. Any burrs in the holes should be removed to prevent damage to the

FOOT

rubber isolators. Mount the compressor using the supplied 10 -32 x 1" machine

screws, 10 -32 lock nuts, and 3/16" washers see Figure "C". Maximum

RUBBER

ISOLATOR vibration isolation can be achieved by properly mounting the compressor. The

VEHICLE

machine screw and nut should be tightened only enough to bottom-out the brass

MOUNTING

SURFACE

insert see Figure "C". DO NOT OVERTIGHTEN. Overtightening will crush

10 -32

the brass insert and the rubber isolator, thereby reducing vibration isolation.

3/16” FLAT WASHER

LOCK

NUT

STEP 4 - ROUTE THE AIR LINE

Figure "C"

Before installing the air line tubing, ensure that there is no pressure in the air

springs. To release the air pressure, remove the valve core from the manual

inflation valves or release the pressure by using a tire gauge to depress the valve

SIDE VIEW OF CONTROL PANEL

stem.

TO AIR SPRINGS A) COMPRESSOR TO CONTROL PANEL

DEL SUP

Cut a piece of air line tubing that will reach from the control panel to the

BARB FITTING

compressor. Cut the air line tubing as squarely as possible and install the tubing

FROM COMPRESSOR on to the barbed fitting on the back of the switch marked SUP (supply) see

Figures "A" & "D". Before attaching the air line tubing to the control panel,

soak the end (1") of the air line in warm water for a few minutes to soften the

Figure "D" tubing. Do not use pliers to work the tubing on to the barbed fitting, as the tubing

may be damaged. It may be necessary to drill a hole in the firewall to route the

tubing. Do not fold or kink the tubing. Ensure that the tubing is protected from

sharp edges when passing through the firewall.

B) CONTROL PANEL TO AIR SPRINGS

Cut a length of air line tubing that will reach from the control panel to the rear of the vehicle. Slide the tubing as far as possible

onto the barbed fitting marked DEL (delivery) on the back of the paddle switch see Figures "A" & "D". Before attaching the air

line tubing to the barbed fitting on the gauge panel, soak the end of the tube (1") in hot water for a few minutes to soften the tubing.

Do not use pliers to work the tubing on to the barbed fitting, as the tubing may be damaged. Install a T-fitting on the opposite end

of the tubing at the rear of the vehicle. Route a length of air line tubing from the T-fitting to each air spring. Use the suppled nylon

ties to secure the tubing to the vehicle. Make sure that the tubing is protected from sharp edges when passing through the firewall.

STEP 6 - ATTACH THE CONTROL PANEL TO THE DASHBOARD

Place the air control panel on the dash where the holes were drilled in Step 1.

Using the provided machine screws, lock nuts, and washers attach the air control

TIC R

AS TO

panel to the dashboard or selected mounting surface see Figure "B".

PLNEC

O N

C

STEP 7 - ROUTE THE ELECTRICAL WIRE

All necessary 16 gage electrical wire and connectors are enclosed with the

kit. Review the electrical schematic before beginning installation see Figure "A".

CO

NN

W

PAIRE

Cut a length of 16 gage wire that will reach from the positive wire (red) on

EC NE FR

TIN

G

L L OM

IG the compressor to either white wire on the control panel. Strip 1/4" off each end

WI HT

RE of the 16 gage wire and crimp a female spade connector on to each end. Crimp

a male spade connector on to the positive wire (red) from the compressor.

Attach the 16 gage wire to the positive compressor wire by pushing the female

and male spade connectors together. Attach the other end of the 16 gage wire

to either white wire on the control panel in the same manner.

Cut another length of 16 gage wire that will reach from the control panel to

a positive 12 Volt, 20 Amp minimum, ignition activated power source. Strip

1/4" off one end of the 16 gage length and crimp a female spade connector onto

the wire. Attach the wire to the remaining white wire on the control panel by

pushing the male and female spade connectors together. Attach the wire from

the control panel to the power source using the supplied wire connector. Slide

the wire connector over the existing power wire, then slide the un-stripped

compressor wire into the wire connector. Close the wire connector over both

wires with pliers see Figure "E". Next, install the in-line fuse holder. Cut the

FUSE HOLDER compressor wire near the power source. Insert the un-stripped ends of the wires

into the fuse holder. Use pliers to close the fuse holder over the wires and insert

the 20 Amp blade fuse see Figure "F".

BA

STEP 8 - WIRE THE CONTROL PANEL FOR ILLUMINATION

C

GA K O

UG F There are two wires (one red and one black) attached to the

E

gauge on the back of the control panel. Connect the red wire to a

fused dashboard illumination wire. Connect the black wire to a

suitable ground source see Figure "G".

G R

RINCTOD) Attach the end of the positive wire to a dashboard illumination

N E UN

N O

CO GR

wire using a wire connector. Slip the wire connector over the

(TO RE existing dashboard illumination wire and insert the un-stripped

E WI RD )

I V O IRE

A

gauge panel wire into the wire connector. Close the wire connector

SIT HB W

PO DASTION over the wires with pliers see Figure "E". Attach the black wire to

A

(TOMIN

U a ground source by crimping a ring connector on to the wire and

ILL

Figure "G" securing it to a suitable ground source on the vehicle. Note: Should

additional wire be necessary to reach the dashboard illumination

wire and ground source, use 16 gage multi-strand wire.

STEP 9 - CHECK THE SYSTEM

With the Level Command kit and your air helper springs installed, you are ready to test the system. Reattach the negative battery

cable. Turn on the vehicle's ignition. Push the paddle switch up to inflate the air springs. The gauge will display how much air

pressure is in the air springs. Inflate the air helper springs to 70 psi and check the fittings for air leaks with an applied solution of

soap and water. If a leak is detected at a tubing connection, check to make sure that the tube is cut as square as possible and that

it is pushed completely into the fitting. The tubing can easily be removed from the fitting. First, release the pressure from the air

spring. Push the collar towards the body of the fitting and pull out the tube.

SYSTEM OPERATION

The Level Command kit allows the air springs to be inflated from the inside of the vehicle. Push the paddle switch up to inflate

the air springs and push the paddle switch down to deflate the air springs.

R R TM

FIRESTONE INDUSTRIAL PRODUCTS TELEPHONE: 317-818-8600

12650 HAMILTON CROSSING BOULEVARD 1-800-247-4337

CARMEL, IN 46032 www.ride-rite.com FAX: 317-818-8645

You might also like

- Pressure Switch Directional Valves: InstallationDocument2 pagesPressure Switch Directional Valves: InstallationEliud Rodriguez100% (1)

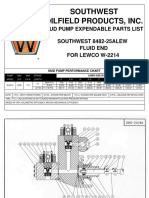

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListDocument8 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts Listjuan penaNo ratings yet

- Gas Regulator Pilots Accessories SupplyDocument2 pagesGas Regulator Pilots Accessories SupplyBraulio CollanteNo ratings yet

- Pilots and Accessories: Application: OperationDocument2 pagesPilots and Accessories: Application: OperationJairo andres Guarnizo SuarezNo ratings yet

- PCR Autolube Intecs PDFDocument27 pagesPCR Autolube Intecs PDFstrong holdNo ratings yet

- PARVEEN Measuring Line Stuffing Boxes and Lubricator RisersDocument46 pagesPARVEEN Measuring Line Stuffing Boxes and Lubricator RisersKedai KopiNo ratings yet

- Double Vane Type PumpDocument4 pagesDouble Vane Type PumpMiguel VlntìnNo ratings yet

- Ordering Information: Operation With or Without Air Service ChamberDocument1 pageOrdering Information: Operation With or Without Air Service ChamberRoman Cupul RuizNo ratings yet

- EE - 02 (Revised) MalawaanDocument1 pageEE - 02 (Revised) MalawaanArnulfo Jose Pi DiNo ratings yet

- Installation and Parts Manual: FOR Caterpillar D8T & D9T TractorsDocument28 pagesInstallation and Parts Manual: FOR Caterpillar D8T & D9T TractorsJusaNadaNo ratings yet

- Wireline-Tools String ParvenDocument51 pagesWireline-Tools String ParvenDidik SafdaliNo ratings yet

- Gambar 04 Intake: Nomor Refere Nomor Part Nama Part KeteranganDocument2 pagesGambar 04 Intake: Nomor Refere Nomor Part Nama Part KeteranganDevii AryaNo ratings yet

- Mode 4143: Differential Pressure ValveDocument2 pagesMode 4143: Differential Pressure Valvezinstr1No ratings yet

- 19-0699 SPDocument2 pages19-0699 SPOmar turco curiNo ratings yet

- 2249-00-01-003 - Cv-02a NewDocument1 page2249-00-01-003 - Cv-02a NewDeandra Galih TamaNo ratings yet

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts List SOUTHWEST 8482-25ALEW Fluid End For Lewco W-2214Document7 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts List SOUTHWEST 8482-25ALEW Fluid End For Lewco W-2214Alejandro AlejandreNo ratings yet

- Operating, Service and Maintenance Manual: Powermaster Series 20,000 LBDocument20 pagesOperating, Service and Maintenance Manual: Powermaster Series 20,000 LBTIPAZONo ratings yet

- CompAir LeROI CL20-25-30SS,CUB Parts ListDocument59 pagesCompAir LeROI CL20-25-30SS,CUB Parts ListDiana Zar100% (1)

- Vicinity Map: Panelboard-1 DesignationDocument1 pageVicinity Map: Panelboard-1 DesignationMatty IgtibenNo ratings yet

- Lincoln Instruction Manual PN 1828 and 1830Document2 pagesLincoln Instruction Manual PN 1828 and 1830eduardoNo ratings yet

- S05 Drilling CompartmentDocument58 pagesS05 Drilling CompartmentJoseNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Wijaya GultomNo ratings yet

- Avco Lycoming Technical Publication Supplement SSP-1184-1Document96 pagesAvco Lycoming Technical Publication Supplement SSP-1184-1Jim Rodriguez100% (1)

- Valvula DROPSA 3155116Document2 pagesValvula DROPSA 3155116Rodrigo Munoz GarridoNo ratings yet

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Document12 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Alejandro AlejandreNo ratings yet

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- 125 and 160kva Material Cost For 3 YearDocument1 page125 and 160kva Material Cost For 3 Yearnirav patelNo ratings yet

- Laser Sand Filter l140c-l250c 1Document10 pagesLaser Sand Filter l140c-l250c 1Amit Bhundhoo, CPANo ratings yet

- Material Request: United Caravan Trading & Contracting (Oil & Gas Division)Document1 pageMaterial Request: United Caravan Trading & Contracting (Oil & Gas Division)farman ali ahmedNo ratings yet

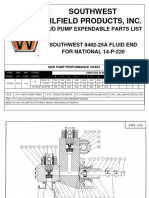

- 14-P-220 Mud Pump & Parts SouthwestDocument8 pages14-P-220 Mud Pump & Parts SouthwestLuis Manuel Montoya RiveraNo ratings yet

- Requirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSDocument1 pageRequirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSfarman ali ahmedNo ratings yet

- Mangueras y BombaDocument3 pagesMangueras y BombaRamón ManglesNo ratings yet

- Act BrochureDocument101 pagesAct BrochurePHILIPUAENo ratings yet

- R32000 - Spare Parts ListDocument78 pagesR32000 - Spare Parts ListLefialgaNo ratings yet

- Piston & Motors: PumpsDocument4 pagesPiston & Motors: PumpshoiNo ratings yet

- ContinuaciónDocument4 pagesContinuaciónRamón ManglesNo ratings yet

- Parts List Quincy QGS 10-15 - (C55) - 2200773152 04Document72 pagesParts List Quincy QGS 10-15 - (C55) - 2200773152 04RUN GO0% (1)

- Tarsheed - Static Pressure For Ac - First FloorDocument8 pagesTarsheed - Static Pressure For Ac - First FloorAamerNo ratings yet

- Time Flow Basin Pillar Tap - Push ButtonDocument6 pagesTime Flow Basin Pillar Tap - Push ButtonDota NgNo ratings yet

- Engine & Attaching Parts (Radiator Water Exchanger) - (S - N AZNB11001 - AZNB11027) - S570Document3 pagesEngine & Attaching Parts (Radiator Water Exchanger) - (S - N AZNB11001 - AZNB11027) - S570ferneyNo ratings yet

- Check Valve CV1 08: UcsonDocument2 pagesCheck Valve CV1 08: UcsonpavankumarNo ratings yet

- Bijur Spray MistDocument4 pagesBijur Spray MistDavid BentleyNo ratings yet

- אני משתף איתך את 'קטלוג 2023'Document96 pagesאני משתף איתך את 'קטלוג 2023'גילי יעקוביNo ratings yet

- 125Document2 pages125aliasghar yadegariNo ratings yet

- KIEMBOM2Document20 pagesKIEMBOM2Anh TrầnsvbkNo ratings yet

- Curtis RS30B Parts ListDocument28 pagesCurtis RS30B Parts Listrobert100% (2)

- Static Pressure Calculation Sheet For Ducts & Fittings - ASHRAE MethodDocument1 pageStatic Pressure Calculation Sheet For Ducts & Fittings - ASHRAE Methodsumair uddinNo ratings yet

- Parts Manual Locator for SKF Rotary Blasthole DrillDocument515 pagesParts Manual Locator for SKF Rotary Blasthole DrillHVariantza100% (7)

- DR0741 SCH5000CL Parts Manual S N 1K PDFDocument416 pagesDR0741 SCH5000CL Parts Manual S N 1K PDFNova Kurniawan100% (2)

- Schedule Equipment Fan LT b3Document1 pageSchedule Equipment Fan LT b3imam wardhanaNo ratings yet

- 2015 Ast ProductsDocument35 pages2015 Ast ProductsRezaul Islam RizonNo ratings yet

- 01 Water Catalogue 2013 EN PDFDocument217 pages01 Water Catalogue 2013 EN PDFSabikun NaharNo ratings yet

- Funai Ciwp4206a Service ManualDocument24 pagesFunai Ciwp4206a Service ManualAchim F.No ratings yet

- High Chiept PCR & Maint - BWPDocument27 pagesHigh Chiept PCR & Maint - BWPMuhammadSyarifudinNo ratings yet

- Sb342e Lineas de Fuel e Insp. de ClampDocument42 pagesSb342e Lineas de Fuel e Insp. de ClampJesus Martin Muñante RamosNo ratings yet

- Engine InstallationDocument5 pagesEngine InstallationAnonymous cS9UMvhBqNo ratings yet

- Dropsa Shut Off Valve 2013Document2 pagesDropsa Shut Off Valve 2013ANo ratings yet

- Washer UvDocument23 pagesWasher UvEdgarBelianisMarroquinGonzalezNo ratings yet

- PULMPINGDocument1 pagePULMPINGSamir AjiNo ratings yet

- Surveying - Mcqs On Unit I - SJMDocument6 pagesSurveying - Mcqs On Unit I - SJMKalyani ingole100% (1)

- Memo-on-Orientation and Submission of PNPKIDocument5 pagesMemo-on-Orientation and Submission of PNPKICoronia Mermaly LamsenNo ratings yet

- Unit 3 Nis 22620Document6 pagesUnit 3 Nis 22620Komal JadhavNo ratings yet

- 9607 Syllabus Media StudiesDocument28 pages9607 Syllabus Media StudiesmisterNo ratings yet

- Manual HandlingDocument14 pagesManual Handlingkacang mete100% (1)

- Advanced Long Range Proximity Reader PDFDocument1 pageAdvanced Long Range Proximity Reader PDFPhangkie RecolizadoNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- Speed Control Methods of 3-Phase Induction MotorsDocument3 pagesSpeed Control Methods of 3-Phase Induction MotorsBenzene diazonium saltNo ratings yet

- PC200-8 SM - 013 Troubleshooting by Failure Code Part-3Document50 pagesPC200-8 SM - 013 Troubleshooting by Failure Code Part-3t5442071100% (2)

- GE 5 Purposive Communication Course OverviewDocument10 pagesGE 5 Purposive Communication Course OverviewHarold LuceroNo ratings yet

- Perceptron: Tirtharaj DashDocument22 pagesPerceptron: Tirtharaj DashKishan Kumar GuptaNo ratings yet

- Vastu House PlanDocument187 pagesVastu House Planshilpa shahNo ratings yet

- DL1 - Epicyclic Gear Train & Holding Torque ManualDocument4 pagesDL1 - Epicyclic Gear Train & Holding Torque Manualer_arun76100% (1)

- Jhamuna Tower Design DataDocument15 pagesJhamuna Tower Design DataArindam RoyNo ratings yet

- D Series: Instruction ManualDocument2 pagesD Series: Instruction ManualMartin del ValleNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- Oven Nordson ElectronicDocument60 pagesOven Nordson ElectronicDanijela KoNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- Internship Reflection PaperDocument8 pagesInternship Reflection Paperapi-622170417No ratings yet

- Batch RecordDocument11 pagesBatch RecordInes Concepcion TupasNo ratings yet

- UID Module Wise TopicsDocument3 pagesUID Module Wise TopicsPavan KumarNo ratings yet

- GPS InspectionDocument48 pagesGPS InspectionAhmed AluoshNo ratings yet

- Certificate of Incorporation Phlips India LimitedDocument1 pageCertificate of Incorporation Phlips India LimitedRam AgarwalNo ratings yet

- BID 2021 046 6913 VendorList3. (237110)Document1 pageBID 2021 046 6913 VendorList3. (237110)JAGUAR GAMINGNo ratings yet

- Achmad Nurdianto, S.PD: About MeDocument2 pagesAchmad Nurdianto, S.PD: About Medidon knowrezNo ratings yet

- MSC Dissertation Gantt ChartDocument6 pagesMSC Dissertation Gantt ChartProfessionalPaperWritingServiceUK100% (1)

- Six Sigma Statistical Methods Using Minitab 13 Manual4754Document95 pagesSix Sigma Statistical Methods Using Minitab 13 Manual4754vinaytoshchoudharyNo ratings yet

- Arduino PWM To DC Voltage Op Amp Converter - Henry's BenchDocument8 pagesArduino PWM To DC Voltage Op Amp Converter - Henry's BenchAlan A. TorresNo ratings yet

- Yuken Series PVL Vane Pumps Catalogue en PDFDocument69 pagesYuken Series PVL Vane Pumps Catalogue en PDFAgilRinaldiNo ratings yet

- Final Portfolio Cover LetterDocument2 pagesFinal Portfolio Cover Letterapi-321017157No ratings yet