Professional Documents

Culture Documents

Current Clamp Adaptor For Multimeters: by John Clarke

Uploaded by

mor3danOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Current Clamp Adaptor For Multimeters: by John Clarke

Uploaded by

mor3danCopyright:

Available Formats

Current Clamp

Adaptor For

Multimeters

By JOHN CLARKE

Looking for a current clamp meter that won’t current transformers, comprising

turns of wire around a magnetic core.

break the bank? Here’s a simple clamp meter This magnetic core is clipped around

adaptor that you can build for about £15. It the wire to be measured, which

effectively behaves as a half-turn

plugs into a standard DMM and can measure primary winding. The winding on the

core itself acts as the secondary and

both AC and DC currents. connects to the multimeter’s current

terminals.

C

lamp meters are very con- but is often a lot safer as well; eg, The measured current is a divided

venient when it comes to meas- where high voltages and currents are down value of the true current flowing

uring current, since they do involved. However, clamp meters are in the wire. Usually, the division ratio

not require breaking the current path. not particularly useful for making is 1000:1 so that 1mA shown on the

Instead, they simply clip over the wire low-current measurements (ie, below meter equates to 1A through the wire

or lead that’s carrying the current and 1A) due to their inaccuracy and lack that’s being measured.

the reading is then displayed on the of resolution. Clamp meters capable of measuring

meter. Unlike this unit, many commercial DC as well as AC do not use a current

This is not only much easier than current clamp meters can only measure transformer but a Hall effect sensor

“in-circuit” current measurements AC. That’s because they are basically instead. This sensor is placed inside

60 Everyday Practical Electronics, January 2006

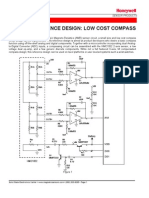

Fig.1: the circuit uses Hall effect sensor HS1 which produces a voltage at its pin 3 output that depends on the

magnetic field induced into an iron-powdered toroid core. This voltage is fed to op amp IC1a which then drives

the negative terminal of the multimeter. IC1b drives the meter’s positive terminal and provides null adjustment.

a gap in an iron-powdered toroid 3dB down at 20kHz (ie, 0.7071 of the others begin to roll off the signal above

core. It measures the magnetic flux real value). However, the actual meas- 1kHz (ie, frequencies above this will

produced as a result of the current urement displayed will also depend not be accurately measured).

flowing through the wire and produces on the high-frequency response of the If necessary, the output from the

a proportional output voltage. multimeter itself. Some multimeters Clamp Meter Adaptor can be mon-

give useful readings up to 20kHz, while itored using an oscilloscope if AC

How it works measurements have to be made at

To make it as versatile as possible, high frequencies. However, AC current

the Clamp Meter Adaptor also uses a Specifications measurements at 50Hz (ie, the mains

Hall effect sensor so that it can measure frequency) will be accurate using vir-

both DC and AC currents. The output Output: 1A = 1mV for AC and DC tually any multimeter.

of this sensor is then processed using ranges Note that most multimeters are

a couple of low-cost op amps which calibrated to display the RMS val-

then provide a signal for a standard Resolution: multimeter dependent ues of AC current measurements,

DMM or analog multimeter. (100mA with 0.1mV resolution on although they are only accurate for

When measuring DC current, the multimeter) sinusoidal waveforms. This unit

multimeter is set to its DC mV range Maximum DC current: 150A will not affect meter calibration,

and 1A through the wire in the core recommended (up to 900A if core since it does not change the shape

equates to a reading of 1mV on the me- is demagnetised afterwards) of the waveform for signals below

ter. A potentiometer allows the output 20kHz and only converts the cur-

to be nulled (ie, adjusted to 0mV) when Maximum AC current: 630A rent waveform to a voltage wave-

there is no current flow. recommended form. However, for non-sinusoidal

Similarly, for AC current measure- Linearity: typically better than 4% waveforms, the multimeter will

ments using the clamp meter, the mul- over range at 25°C display an erroneous result unless

timeter is simply set to its AC mV range. it is a true RMS type.

In this case, the DC offset potentiometer AC frequency response: -3dB at

is not needed, since the multimeter au- 20kHz (meter reading depends on Demagnetising the core

tomatically ignores any DC levels. multimeter AC response) One problem with clamp meters

The high-frequency response of Current consumption: 15mA is that the core can remain magnet-

the adaptor for AC measurements is ised after making high DC current

Everyday Practical Electronics, January 2006 61

measurements; ie, even when the

current flow has been reduced to

zero. In fact, this effect becomes ap-

parent when measuring DC currents

above about 150A. It is easily detected

because the output from the sensor

remains at several millivolts after the

current ceases flowing.

Fortunately, there’s an easy solution

to this. If the core does become mag-

netised, it can be demagnetised again

by momentarily reversing the current

flow in the core.

In practice, this is done by un

clipping the core from the wire, re-

placing it over the wire upside down

and applying the current again for a

brief period of time.

Modified battery clamp

To keep costs down, the Clamp

Meter Adaptor uses a modified car

battery clip as the current clamp. This

is fitted with an iron-powdered toroid

core which is cut in half so that the clip

can be opened and slipped over the

current-carrying wire. The Hall effect

sensor sits in a gap in the toroid, near

the front of the clip – see Fig.2.

The output from this sensor is fed Fig.2: if a steel (ie, magnetic) clamp is used, the Hall sensor

to a processing circuit which is built must be placed in an air gap in the toroidal core as shown in

on a small PC board and housed in a the bottom diagram. This is necessary to ensure that it is not

plastic case, along with the battery. bypassed by magnetic flux flowing through the clamp instead.

This circuit in turn connects to the

meter via two leads.

By the way, commercial clamp me- the Hall sensor output will vary with In practice, VR1 is adjusted so that

ters using Hall effect sensors usually supply rail variations. it produces an output of 1mV per amp

place the sensor at the hinge end of the In operation, the Hall effect sensor flowing through the current-carrying

core. This can be done when the clamp produces a voltage at its pin 3 output wire.

material is non-magnetic. However, that depends on the magnetic field Op amp IC1b and its associated

when the clamp is magnetic, as in this in the core. If the marked face of the circuitry compensate for the initial DC

design, the magnetic flux is conducted sensor faces a south magnetic field, its voltage at the output of the Hall effect

through it instead and bypasses the air output voltage will rise. Conversely, if sensor (ie, with no magnetic field ap-

gap where the sensor sits – see Fig.2 it faces a north field, the output volt- plied). As shown, IC1b is connected

(top drawing). age will fall. as a unity gain buffer with its output

This problem is solved by simply The sensor’s output with no mag- connected to its pin 6 inverting input.

placing the sensor in an air gap at the netic field applied to it will sit between The non-inverting input at pin 5 con-

front of the clamp, so that it cannot 2.25V and 2.75V, depending on the nects to a resistive divider network

be bypassed. sensor. This voltage remains stable, consisting of VR2, VR3 and a 22kΩ

providing the supply voltage remains resistor.

Circuit details stable. The output from IC1b (pin 7) goes

Refer now to Fig.1 for the circuit The output of the Hall effect sensor to the positive meter terminal and

details. It’s relatively simple and com- is fed to op amp IC1a. This stage is is also used to bias pin 3 of IC1a via

prises a dual op amp (IC1a & IC1b), a wired as an inverting amplifier and a 10kΩ resistor. This bias voltage is

3-terminal regulator (REG1), the Hall it attenuates the signal by an amount nominally about 2.5V (ie, 0.5Vcc) and

effect sensor (HS1) and a few resistors that depends on the setting of trimpot allows the output of IC1a to swing up

and capacitors. VR1 (calibrate). Note that the gain of or down about this voltage, depend-

Power for the circuit is derived IC1a is set by the resistance between ing on the sensor input. It also ef-

from a 9V battery and is fed to REG1 pins 1 & 2 divided by the 18kΩ input fectively allows the quiescent voltage

which provides a regulated +5V rail. resistor. from the Hall sensor to be nulled so

This then powers the Hall effect sensor This means that if VR1 is set to that we get a 0V reading on the meter

and op amps IC1a & IC1b. Note that a half-way, IC1a has a gain of (2.5kΩ + when no current is being measured.

regulated supply is necessary, since 1kΩ)/18kΩ = 0.19. VR2 is initially adjusted with VR3

62 Everyday Practical Electronics, January 2006

per pattern. Also check that the hole

sizes are all correct for the various

components, particularly those for the

PC-mount stereo socket and the on/off

switch (S1).

Note that two of the corners on the

PC board need to removed, so that

the board later clears the corner pil-

lars inside the case. If your board is

supplied with these corners intact,

they can be cut away using a small

hacksaw and carefully finished off

Fig.3: install the parts on the PC board as shown here. using a rat-tail file.

The Zero Adjust pot (VR3) is installed by soldering its Fig.3 shows the assembly details.

terminals to three PC stakes. Install the resistors and wire link

first, using Table 1 to guide you on the

resistor colour codes. It’s also a good

idea to check the resistor values with

a DMM, just to make sure.

IC1 can go in next, taking care to

ensure that it is oriented correctly.

That done, install the trimpots and

the capacitors, noting that the elec-

trolytics must be oriented with the

polarity shown. The trimpots are usu-

Fig.4: the full-size etching pattern for the PC board.

ally labelled with a code value, with

502 equivalent to 5kΩ (VR1) and 503

equivalent to 50kΩ (VR2).

set to mid-range, so that the multimeter effect sensor – ie, the voltage between Next, install PC stakes at the two

reads 0V with no magnetic field ap- pins 1 & 7 is 0V. power supply inputs, the +5V ter-

plied to the Hall sensor. VR3 is then The outputs from both op amps minal, the three VR3 terminal posi-

adjusted during subsequent use of the are fed to the multimeter via 100Ω tions and the two multimeter outputs.

clamp meter – it can vary IC1b’s output resistors. These provide short-circuit These can be followed with the switch

by about 25mV to null out any small protection for the op amp outputs and and the PC-mount stereo socket.

voltage readings. also decouple the outputs from the Finally, complete the board as-

In effect, trimpot VR2 acts as a cable capacitance. sembly by installing potentiometer

coarse offset adjustment, while VR3 VR3 – it is mounted with its terminals

allows fine adjustment to precisely Construction soldered to the top of its PC stakes.

zero the reading. Building the circuit is easy since all Position it so that the top of its mount-

Looked at another way, VR2 & VR3 the parts are mounted on a small PC ing thread is at the same height as the

are simply adjusted so that the voltage board coded 548 and measuring 75 × top of the switch thread.

on pin 7 of IC1b is the same as the 30mm. Begin construction by checking

voltage on pin 1 of IC1a when there is the PC board for any shorts between Drilling the case

no magnetic field applied to the Hall tracks and for any breaks in the cop- The front panel artwork (Fig.8) can

now be used as a template to mark out

and drill the lid of the small plastic

utility case that’s used to house the

board. You will need to drill two holes

– one for the switch and the other for

the potentiometer.

In addition, you will have to drill a

4mm hole in one end of the case for

the multimeter leads, plus a 7mm hole

in one side to accept the stereo socket.

The latter should be positioned 14mm

down from the top of the case and

21mm in from the outside edge.

Note that it’s always best to drill

small pilot holes first and then care-

fully enlarge them to size using a

Check your completed PC board assembly carefully to ensure that all polarised tapered reamer.

components have been correctly installed. These parts include IC1, REG1 and Next, the integral side clips inside

the two electrolytic capacitors. the box need to be removed using a

Everyday Practical Electronics, January 2006 63

Fig.6 (below): a 60mm-length of 3-way

rainbow cable is used to make the

connections to the Hall sensor. This

cable is then joined to a 300mm length

of 2-core shielded cable which is then

terminated in 3.5mm stereo plug.

Fig.5 (above): this exploded diagram shows how the toroid

core and Hall sensor are fitted to the clamp. Each core half

is secured in position using builders’ adhesive, as are the

Hall sensor and the adjacent plastic rectangle. Note the

earth connection to the metalwork of the clamp.

chisel. Be sure to protect your eyes This view of the

when doing this, as the plastic tends completed current

to splinter and fly out. You can then clamp clearly

attach the front panel label and cut the shows the general

holes out with a sharp knife. arrangement. If the

toroid core becomes

The next step is to solder the battery

magnetised during

clip leads to the supply terminals (red use, it can be

to positive, black to negative). That demagnetised

done, connect the multimeter leads to by momentarily

the output terminals, then feed these reversing the

wires through the hole in the box and current flow in the

attach banana plugs to each free end. core.

Don’t fit the board to the case lid at

this stage. That step comes later, after

calibration has been completed.

be sheathed in heatshrink tubing (see lating tape should be used to prevent

Clamp assembly Fig.5). The other end of this cable is shorts between the wires where the

The clamp assembly comprises a car then connected to a 300mm length of cables join, after which the join should

battery clip, the toroidal core and the 2-core shielded cable which in turn is be covered using heatshrink tubing.

Hall effect sensor. Figs.5 & 6 show the terminated with a 3.5mm stereo plug.

assembly details for this unit. As shown in Fig.6, the cable shields

The first step is to cut the core in are joined together and connected to

Table 2: Capacitor Codes

half using a fine-toothed hacksaw the earth lead of the rainbow cable. Value μF Code EIA Code IEC Code

blade. That done, the Hall sensor They are also connected to the metal 100nF 0.1μF 104 100n

should be wired using a 60mm length work of the clip using a short length 1nF 0.001μF 102 1n0

of 3-way rainbow cable which should of hookup wire. Small pieces of insu-

Table 1: Resistor Colour Codes

o No. Value 4-Band Code (1%) 5-Band Code (1%)

o 1 22kΩ red red orange brown red red black red brown

o 1 18kΩ brown grey orange brown brown grey black red brown

o 1 10kΩ brown black orange brown brown black black red brown

o 1 1kΩ brown black red brown brown black black brown brown

o 2 100Ω brown black brown brown brown black black black brown

64 Everyday Practical Electronics, January 2006

As it stands, the clamp can be

slipped over leads up to 7mm in dia

meter. A larger clamp with jaws that

open wider than the specified unit will

be necessary if you intend measuring

currents flowing in leads that are

thicker than 7mm.

Note that the clamp adapter is not

suitable for use with 240VAC mains

when the wiring is uninsulated.

Testing

The unit is now ready for testing.

First, connect the battery and check

that there is +5V at the test point on

the PC board (ie, 5V between this test

point and ground). There should also

Fig.7: this simple setup can be used to calibrate the Clamp Meter be +5V on pin 8 of IC1.

Adapter. Null the reading first using potentiometer VR3, then switch If these measurements check OK,

on the 12V supply and adjust trimpot VR1 for a reading of 66.7mV. plug the clamp assembly into the

socket on the PC board and check the

voltages again. If they are no longer

The next step is to glue the Hall wiring for the Hall sensor can be glued correct, check component placement

sensor to one of the core pieces using in position and secured at the end of and the wiring to the Hall sensor.

some builders’ adhesive (it can go in the clip with a cable tie. In addition, Next, connect the output leads from

either way up). That done, glue a small the metal tabs on the clip should be the unit to the voltage inputs on your

piece of plastic to the remaining part of bent over to hold the wire in place. multimeter and set the range to mV DC.

the core gap to protect the Hall sensor This must also be done on the other That done, set VR3 to its mid-position

from damage when the clamp closes. handle, so that the jaws of the clamp and adjust VR2 for a reading of 0mV.

Naturally, this piece of plastic needs to can be opened as wide as possible.

be slightly thicker than the Hall sensor The 3.5mm stereo plug is wired as Calibration

to provide this protection. shown, with the tip and ring terminals The Current Clamp Adaptor is cali

The two core pieces can now be connecting to the red and black wires brated using a 12V power supply, a 5m

glued in position on the jaws of the respectively. If your twin shielded length of 0.5mm enamelled copper

battery clip, again using builders’ ad wire has different colours, take care wire and an 18Ω 5W resistor.

hesive. Make sure that the two halves to ensure that pin 1 on the Hall sensor First, wind 100 turns of the ECW

are correctly aligned before the glue goes to the tip connection. Pin 3 must around the core and connect it to the

sets. go to the ring terminal and pin 2 is the 12V supply via the 18Ω resistor as

Once the core pieces are secure, the ground and shield. shown in Fig.7. The current through

the wire will be 12/18 = 0.667A and,

as far as the clamp meter is concerned,

this is effectively multiplied by 100

due to the number of turns on the

core.

All you have to do now is adjust VR1

for a reading of 66.7mV. And that’s it

– the calibration is complete!

Note that if the power supply is not

exactly 12V, you can compensate for

this by calibrating to a different read

ing. Just measure the supply voltage,

divide the value by 18 (to get the cur

rent) and multiply by 100 to obtain the

calibration number.

For example, if you are using a 13.8V

supply, you will have to set VR1 for

a reading of 76.7mV on the meter (ie,

13.8/18 × 100 = 76.7).

Once the calibration has been com

pleted, the PC board can be attached to

the case lid. It’s held in place simply

There’s plenty of room inside the case for the PC board and a 9V battery. The

board is held in position by slipping the case lid over the switch and pot shafts

by slipping the lid over the switch and

and doing up the nuts. pot shafts and doing up the nuts.

Everyday Practical Electronics, January 2006 65

Parts List

1 PC board, code 548, 75 x 1 200mm length of black heavy

30mm, available from the EPE duty hookup wire

PCB Service 1 50mm length of green heavy

1 plastic box, 82 x 54 x 30mm duty hookup wire

1 iron powdered toroidal core, 28 1 50mm length of 4.8mm diam-

x 14 x 11mm eter heatshrink tubing

1 50A car battery clip 1 100mm cable tie

1 3.5mm stereo PC board mount 8 PC stakes

socket

1 3.5mm stereo jack plug Semiconductors

1 SPDT toggle switch (S1) 1 LM358 dual op amp (IC1)

1 5kΩ (code 502) horizontal trim- 1 UGN3503 Hall effect sensor

pot (VR1) 1 78L05 5V regulator (REG1)

1 50kΩ (code 503) horizontal

trimpot (VR2)

Capacitors

1 1kΩ 16mm linear potentiometer

1 100μF 16V PC electrolytic

(VR3)

Fig.8: this full-size artwork for the

1 10μF 16V PC electrolytic

1 red banana line plug

front panel. 1 100nF MKT polyester

1 black banana line plug

1 1nF MKT polyester

Using the clamp meter 1 9V battery clip

Note that before making a measure- 1 9V battery

1 potentiometer knob Resistors (1% 0.25W)

ment, the DC Zero potentiometer must

1 4 x 4 x 2mm piece of soft 1 22kΩ 1 1kΩ

first be adjusted so the multimeter

reads 0mV when there is no current plastic 1 18kΩ 2 100Ω

flow. Note also that the core may need 1 300mm length of twin core 1 10kΩ

to be demagnetised after measuring shielded cable

high DC currents, as described pre- 1 60mm length of 3-way rainbow Calibration parts

viously. This will be necessary when cable 1 5m length of 0.5mm enamelled

the DC Zero control no longer has suffi 1 200mm length of red heavy copper wire

cient range to null the reading. duty hookup wire 1 18Ω 5W resistor

When measuring relatively low currents

(eg, between 100mA and 10A), increasing

the number of turns of the current-carrying

wire through the core will improve the

resolution. However, this will only be pos-

sible if the wire diameter allows the extra

turns to be fed through the core.

Note that the readout on the mul-

timeter must be divided by the number

of turns through the core to obtain the

correct current reading. Note also that

the accuracy of the unit will vary ac-

cording to the temperature of the Hall

sensor, particularly when making high

current measurements.

By the way, it's a good idea to mark

the top of the clamp with an arrow

to indicate the direction of positive

current flow once you have the unit

working correctly. This can easily be

determined by trial and error.

Finally, do not forget to switch the

unit off when it is not in use. There’s no

power indicator LED to warn you that

the unit is on, so take care here! EPE

There’s no power LED on the front panel to warn you when the power is on,

Reproduced by arrangement with so be sure to switch the unit off when it is not in use to save battery life. Also,

SILICON CHIP magazine 2006.

www.siliconchip.com.au be sure to null the reading on the multimeter (ie, when there is no current flow

through the core) before taking a measurement.

66 Everyday Practical Electronics, January 2006

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- New generation of ultra-compact universal current sensorsDocument4 pagesNew generation of ultra-compact universal current sensorsmsivakumarvarmaNo ratings yet

- Multimeter VIMPDocument61 pagesMultimeter VIMPSysu KumarNo ratings yet

- Antenna FundamentalsDocument44 pagesAntenna FundamentalsMarco Aurelio PereiraNo ratings yet

- TN22 Vibration Sensor Wiring and Cabling 1Document11 pagesTN22 Vibration Sensor Wiring and Cabling 1Suresh KumarNo ratings yet

- Using The MultimeterDocument5 pagesUsing The MultimeterAlfred GaleaNo ratings yet

- Universal Current SensorDocument12 pagesUniversal Current SensorBhargav MushiniNo ratings yet

- VoltmetersDocument35 pagesVoltmetersjunaydNo ratings yet

- Capacimetre FemtoDocument30 pagesCapacimetre FemtoJean-Marie ChaputNo ratings yet

- Chapter 6 16052020 045213pm 19062023 052331pmDocument49 pagesChapter 6 16052020 045213pm 19062023 052331pmAbdullah ZamirNo ratings yet

- Current Measurement Techniques and D'Arsonval Meter OperationDocument5 pagesCurrent Measurement Techniques and D'Arsonval Meter OperationAddisu Safo BoseraNo ratings yet

- Digital Multimeter - Basic GuideDocument4 pagesDigital Multimeter - Basic GuidetowfiqeeeNo ratings yet

- Presentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-ModeDocument30 pagesPresentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-Modesohailasghar_tNo ratings yet

- Electrical & Electronic InstrumentationDocument26 pagesElectrical & Electronic InstrumentationKamal PhyNo ratings yet

- Chapter 2 - DC Meter PDFDocument75 pagesChapter 2 - DC Meter PDFMuhammad Izz IzzuddinNo ratings yet

- Fuente de 12 VDC Sin TransformadorDocument16 pagesFuente de 12 VDC Sin TransformadorElvis Fernando Ñaupari ChahuaNo ratings yet

- Using a Multimeter to Measure CircuitsDocument32 pagesUsing a Multimeter to Measure CircuitsDamodaran SrinivasanNo ratings yet

- Milli Ohm AdapterDocument6 pagesMilli Ohm AdapterPeter JordanNo ratings yet

- DiDocument6 pagesDipani256No ratings yet

- Toaz - Info Laporan Lengkap Coaxial LN Asaiful Rijal 32219048 PRDocument41 pagesToaz - Info Laporan Lengkap Coaxial LN Asaiful Rijal 32219048 PRInda Fuji LestariNo ratings yet

- Electrical Measurements and InstrumentationDocument17 pagesElectrical Measurements and InstrumentationRinita Datta100% (1)

- Measurement of Current With A Voltage DAQDocument3 pagesMeasurement of Current With A Voltage DAQKh SabNo ratings yet

- Universal Currnet SensorDocument15 pagesUniversal Currnet SensorJohnny Rider100% (1)

- AC Current Measurement Using CTDocument22 pagesAC Current Measurement Using CTKoushik MaityNo ratings yet

- Eee225 02-1Document39 pagesEee225 02-1Djirangmor JosephNo ratings yet

- Eee225 02Document20 pagesEee225 02Djirangmor JosephNo ratings yet

- Electrical General Test Equipment OperationDocument2 pagesElectrical General Test Equipment OperationMarcin MecaNo ratings yet

- Cable Fault DetectorDocument25 pagesCable Fault DetectorHarshalNo ratings yet

- Internet HandbookDocument15 pagesInternet HandbookhagasyNo ratings yet

- Design Precise Ohmmeter Circuit Measure Resistances 0.01-10kΩ 0.1% AccuracyDocument5 pagesDesign Precise Ohmmeter Circuit Measure Resistances 0.01-10kΩ 0.1% AccuracyNabil IshamNo ratings yet

- Acc Measure Nanoamperes AppNotesDocument3 pagesAcc Measure Nanoamperes AppNotesRabshaqaNo ratings yet

- Clamp MeterDocument3 pagesClamp MeterAnkush SharmaNo ratings yet

- Assignment of Measurements and InstrumentationDocument8 pagesAssignment of Measurements and InstrumentationAmna AamirNo ratings yet

- AnshuDocument26 pagesAnshuAnubha ChaudharyNo ratings yet

- Universal - Current - Sensors - Report KARTHIKDocument23 pagesUniversal - Current - Sensors - Report KARTHIKKarthik SDNo ratings yet

- Basics of 4-20ma Current LoopDocument7 pagesBasics of 4-20ma Current LoopsandystaysNo ratings yet

- Magnetic field meter circuit design and constructionDocument7 pagesMagnetic field meter circuit design and constructionJohurul IslamNo ratings yet

- Unit 4 NotesDocument9 pagesUnit 4 NotesPrathamesh BhavsarNo ratings yet

- Measuring Electrical Quantities with Electromechanical InstrumentsDocument5 pagesMeasuring Electrical Quantities with Electromechanical InstrumentskhuzaimNo ratings yet

- GSM Module Based Integrative Detection of Open Drainage Over Flow and CurrentDocument91 pagesGSM Module Based Integrative Detection of Open Drainage Over Flow and Currentvijay4vlrNo ratings yet

- Error Amplifier Design and ApplicationsDocument6 pagesError Amplifier Design and ApplicationsGhulam Abbas100% (1)

- DC METER CIRCUITS AND LOADING EFFECTSDocument38 pagesDC METER CIRCUITS AND LOADING EFFECTSImran AbdullahNo ratings yet

- Ammeter ShortDocument2 pagesAmmeter ShortkappubhattNo ratings yet

- DC and AC Meter Circuit AnalysisDocument45 pagesDC and AC Meter Circuit AnalysisSepul SisiputNo ratings yet

- VOM Measurement AnalogDocument23 pagesVOM Measurement AnalogMark Philip MarananNo ratings yet

- Reference Design Low Cost CompassDocument4 pagesReference Design Low Cost CompassHany MaximousNo ratings yet

- LIC Question BankDocument7 pagesLIC Question BankParvathy S ParvathyNo ratings yet

- Measuring Electrical Potential with VoltmetersDocument5 pagesMeasuring Electrical Potential with Voltmetershumaid15No ratings yet

- E 3042 – INSTRUMENTATION 1: Meter Types and Multimeter BasicsDocument20 pagesE 3042 – INSTRUMENTATION 1: Meter Types and Multimeter BasicsZaidi OsmanNo ratings yet

- Measure circuit current with a CTDocument9 pagesMeasure circuit current with a CTAvishek SapkotaNo ratings yet

- Current Voltage MeasurementDocument35 pagesCurrent Voltage MeasurementAaqib AliNo ratings yet

- Lecture Notes 08Document25 pagesLecture Notes 08Abdul Hakeem Semar KamaluddinNo ratings yet

- CHAPTER 2 InstrumentationDocument11 pagesCHAPTER 2 InstrumentationhariNo ratings yet

- Simple Ac Millivoltmeter: T. GlffardDocument6 pagesSimple Ac Millivoltmeter: T. GlffardAg CristianNo ratings yet

- ICL8038 Function GeneratorDocument6 pagesICL8038 Function Generatorvali dNo ratings yet

- Isolated Open Loop Current Sensing Using Hall Effect Technology in An Optimized Magnetic CircuitDocument12 pagesIsolated Open Loop Current Sensing Using Hall Effect Technology in An Optimized Magnetic Circuitapi-3805241No ratings yet

- 6 Ranges AC Millivoltmeter CircuitDocument2 pages6 Ranges AC Millivoltmeter CircuitjlguedesNo ratings yet

- Multimeter - Wikipedia, The Free EncyclopediaDocument13 pagesMultimeter - Wikipedia, The Free Encyclopediad_richard_dNo ratings yet

- VoltmeterDocument6 pagesVoltmeterAndi DelimaNo ratings yet

- TP 7 22-23Document33 pagesTP 7 22-23Denisa CameliaNo ratings yet

- PDF-XChange 3.0 reviewDocument15 pagesPDF-XChange 3.0 reviewmor3danNo ratings yet

- Aisin AW TF-80SC: Click On Part Numbers For Product Details or VisitDocument1 pageAisin AW TF-80SC: Click On Part Numbers For Product Details or Visittejonmx100% (1)

- Aisin AW TF-81SC: Click On Part Numbers For Product Details or VisitDocument1 pageAisin AW TF-81SC: Click On Part Numbers For Product Details or Visittejonmx100% (1)

- Sem InfoDocument2 pagesSem Infomor3danNo ratings yet

- .,, " - 5.1",, - Bosch MP7.0, - , - ., " - 5.1" " " - Bosh MP7.0Document5 pages.,, " - 5.1",, - Bosch MP7.0, - , - ., " - 5.1" " " - Bosh MP7.0mor3danNo ratings yet

- Maintenance PDFDocument11 pagesMaintenance PDFAndrey GladyshevNo ratings yet

- Opel Vectra ADocument3 pagesOpel Vectra Amor3dan100% (1)

- Ignition FaultsDocument35 pagesIgnition Faultsopa952ya.ruNo ratings yet

- Ford Focus Wiring Diagrams Table of ContentsDocument734 pagesFord Focus Wiring Diagrams Table of Contentsmor3danNo ratings yet

- Check your charging system for proper operationDocument16 pagesCheck your charging system for proper operationAbu AliNo ratings yet

- Lubrication PDFDocument22 pagesLubrication PDFAndrey GladyshevNo ratings yet

- Ignition PDFDocument13 pagesIgnition PDFAndrey GladyshevNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Emission Control PDFDocument11 pagesEmission Control PDFAndrey GladyshevNo ratings yet

- Cooling (Ordenado)Document20 pagesCooling (Ordenado)Roger CalizayaNo ratings yet

- CollisionDocument130 pagesCollisiontelhamiNo ratings yet

- Body Electrical PDFDocument212 pagesBody Electrical PDFtelhamiNo ratings yet

- TPR Piston Rings Catalogue for Japanese Vehicles Vol16; Кольца поршневые TP vol16Document160 pagesTPR Piston Rings Catalogue for Japanese Vehicles Vol16; Кольца поршневые TP vol16rexmist88% (109)

- Body Mechanical PDFDocument155 pagesBody Mechanical PDFAndrey GladyshevNo ratings yet

- Air Conditioning PDFDocument113 pagesAir Conditioning PDFAndrey Gladyshev100% (3)

- Руководство по ремонту АКПП 5HP19Document40 pagesРуководство по ремонту АКПП 5HP19mor3danNo ratings yet

- Automatic TransmissionDocument38 pagesAutomatic TransmissionFabi Fabian H C100% (1)

- SB 10074567 2280Document17 pagesSB 10074567 2280mor3danNo ratings yet

- Engine Workshop Manual SKYACTIV-G 2.0 PDFDocument90 pagesEngine Workshop Manual SKYACTIV-G 2.0 PDFdmitry100% (1)

- FWD 3 & 4 Speed FWD 3 & 4 SpeedDocument15 pagesFWD 3 & 4 Speed FWD 3 & 4 Speedmor3danNo ratings yet

- DAIHATSU piston rings and cylinder liners documentDocument148 pagesDAIHATSU piston rings and cylinder liners documentAldo Omar82% (38)

- Oracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralDocument17 pagesOracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralAndreea Mirosnicencu100% (1)

- Financial Accounting IFRS 3rd Edition Weygandt Solutions Manual 1Document8 pagesFinancial Accounting IFRS 3rd Edition Weygandt Solutions Manual 1jacob100% (34)

- Eagle Test ReportDocument25 pagesEagle Test ReportMuhammad FahadNo ratings yet

- Manual Handling Risk Assessment ProcedureDocument6 pagesManual Handling Risk Assessment ProcedureSarfraz RandhawaNo ratings yet

- TNG UPDATE InstructionsDocument10 pagesTNG UPDATE InstructionsDiogo Alexandre Crivelari CrivelNo ratings yet

- More Than Moore: by M. Mitchell WaldropDocument4 pagesMore Than Moore: by M. Mitchell WaldropJuanjo ThepresisNo ratings yet

- Body Shaming Among School Going AdolesceDocument5 pagesBody Shaming Among School Going AdolesceClara Widya Mulya MNo ratings yet

- Translation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Document20 pagesTranslation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Aldandy OckadeyaNo ratings yet

- Classroom Observation Form 1Document4 pagesClassroom Observation Form 1api-252809250No ratings yet

- Staining TechniquesDocument31 pagesStaining TechniquesKhadija JaraNo ratings yet

- Travis Walton Part 1 MUFON Case FileDocument346 pagesTravis Walton Part 1 MUFON Case FileClaudio Silva100% (1)

- Telephone Triggered SwitchesDocument22 pagesTelephone Triggered SwitchesSuresh Shah100% (1)

- Reference - Unit-V PDFDocument128 pagesReference - Unit-V PDFRamesh BalakrishnanNo ratings yet

- Variables in Language Teaching - The Role of The TeacherDocument34 pagesVariables in Language Teaching - The Role of The TeacherFatin AqilahNo ratings yet

- General Biology 2-Week 2-Module 4-Evidence of EvolutionDocument16 pagesGeneral Biology 2-Week 2-Module 4-Evidence of EvolutionFEMALE Dawal LaizaNo ratings yet

- Circuit AnalysisDocument98 pagesCircuit Analysisahtisham shahNo ratings yet

- Appendix 1 Application FormDocument13 pagesAppendix 1 Application FormSharifahrodiah SemaunNo ratings yet

- 1 PBDocument11 pages1 PBAnggita Wulan RezkyanaNo ratings yet

- spl400 Stereo Power Amplifier ManualDocument4 pagesspl400 Stereo Power Amplifier ManualRichter SiegfriedNo ratings yet

- 3.1 C 4.5 Algorithm-19Document10 pages3.1 C 4.5 Algorithm-19nayan jainNo ratings yet

- Daily Assessment RecordDocument4 pagesDaily Assessment Recordapi-342236522100% (2)

- Oral Medication PharmacologyDocument4 pagesOral Medication PharmacologyElaisa Mae Delos SantosNo ratings yet

- Themes in Romeo and JulietDocument7 pagesThemes in Romeo and JulietChiosa AdinaNo ratings yet

- Basic LCI To High LCIDocument3 pagesBasic LCI To High LCIIonut VladNo ratings yet

- $R6RN116Document20 pages$R6RN116chinmay gulhaneNo ratings yet

- Lecture 29: Curl, Divergence and FluxDocument2 pagesLecture 29: Curl, Divergence and FluxKen LimoNo ratings yet

- People v. Lagarto, 326 SCRA 693 (2000)Document43 pagesPeople v. Lagarto, 326 SCRA 693 (2000)GioNo ratings yet

- 03 - 42 STCP-Ahm AssetDocument46 pages03 - 42 STCP-Ahm AssetARP MEILNo ratings yet

- Lateral capacity of pile in clayDocument10 pagesLateral capacity of pile in clayGeetha MaNo ratings yet

- Continuous Sampling PlanDocument2 pagesContinuous Sampling PlanAnonymous wA6NGuyklDNo ratings yet