Professional Documents

Culture Documents

Rdm970 en Si5vw0a en

Rdm970 en Si5vw0a en

Uploaded by

Jonah HexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rdm970 en Si5vw0a en

Rdm970 en Si5vw0a en

Uploaded by

Jonah HexCopyright:

Available Formats

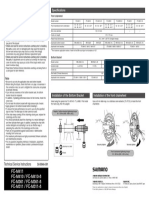

General Safety Information In order to realize the best performance, we recommend Specifications Installation of the lever Cutting the

r to realize the best performance, we recommend Specifications Installation of the lever Cutting the outer casing

that the following combination be used.

4 mm Allen key

When cutting the outer casing, cut the opposite end to the end

WARNING Series XTR Rear Derailleur Use a handlebar grip with a maximum with the marking. After cutting the outer

DUAL CONTROL lever ST-M975 Model number RD-M970 outer diameter of 32 mm. casing, make the end round so that the

• Use neutral detergent to clean the chain. Do not use alkali-based or acid based inside of the hole has a uniform diameter.

detergent such as rust cleaners as it may result in damage and/or failure of the Outer casing SIS-SP41 Type SGS GS Tightening torque :

chain. Rear derailleur RD-M970 Gears 9 9 6 - 8 N·m {53 - 69 in. lbs.} Attach the same outer

• Use the reinforced connecting pin only for connecting the narrow type of chain. end cap to the cut end Outer end cap

• There are two different types of reinforced connecting pins available. Be sure to Type SGS / GS Total capacity 43T 33T In the case of carbon handlebars, it may be of the outer casing.

check the table below before selecting which pin to use. If connecting pins other necessary to lower the tightening torque in

Freehub FH-M975 / FH-M970 Largest sprocket 34T 34T

than reinforced connecting pins are used, or if a reinforced connecting pin or tool order to prevent damage to the handlebar.

which is not suitable for the type of chain is used, sufficient connection force may Gears 9 Smallest sprocket 11T 11T Please consult the bicycle or handlebar The sealed cap with Be careful not to bend

not be obtained, which could cause the chain to break or fall off. Cassette sprocket CS-M970 Front chainwheel tooth difference 22T 22T manufacturer regarding the appropriate tongue and the rubber Rubber shield

level of tightening torque for carbon shield should be

Reinforced Chain CN-7701 handlebars.

Chain

connecting pin

Chain tool installed to the outer Sealed cap with tongue

Bottom bracket guide SM-SP17 / SM-BT17 casing stopper of the

9-speed super narrow Rubber shield

frame.

chain such as Silver TL-CN32 / TL-CN23

CN-7701 / CN-HG93 6.5mm

8- / 7- / 6-speed narrow

chain such as TL-CN32 / TL-CN23

CN-HG50 / CN-IG51 7.1mm

Black These Service Instructions describe the operation method when using the ST-M975 DUAL CONTROL lever in combination with the RD- SIS Adjustment

M970 reverse spring-type rear derailleur. If using in combination with the RD-M971 top normal-type derailleur, the operations will be

• If it is necessary to adjust the length of the chain Reinforced Connecting Pin reversed. * If the rear derailleur moves to a large degree, such as in

due to a change in the number of sprocket teeth, Installation of the chain bicycles with rear suspension, it is recommended that you

make the cut at some other place than the place Operating the levers Install the chain with the Pro-Set replace the cap with the

where the chain has been joined using a reinforced alignment block still attached. accessory aluminum cap. Derailleur side

connecting pin or an end pin. The chain will be End Pin Link Pin

■ Operating the brake ■ Gear shifting operation After installing, remove the Pro-Set

The end of the outer casing

damaged if it is cut at a place where it has been lever The INSTANT RELEASE The lever always returns to the initial position when it is released alignment block.

which has the aluminum cap

Aluminum cap

joined with a reinforced connecting pin or an end pin. mechanism makes fast gear after shifting. When operating the lever, always be sure to turn the should be at the derailleur side.

• Check that the tension of the chain is correct and that the chain is not damaged. If shifting possible because crank arm at the same time. Turn the crank arm to set the

the tension is too weak or the chain is damaged, the chain should be replaced. If cable tension is released derailleur to the low position. Pro-Set alignment block

this is not done, the chain may break and cause serious injury. immediately when either the To shift from a large sprocket to a smaller sprocket 4. How to use the B-tension adjustment screw

• Obtain and read the service instructions carefully prior to installing the parts. main lever or the secondary You can vary the lever stroke to shift the desired number of gears, Mount the chain on the smallest chainring and the largest

Loose, worn, or damaged parts may cause injury to the rider. We strongly release lever is depressed. so that to shift by one gear only, move the lever to the (1) position, 1. Low adjustment sprocket, and turn the crank arm backward. Then turn the

recommend only using genuine Shimano replacement parts. The levers are also equipped and to shift by two gears at one time, move the lever to the (2)

Turn the low adjustment screw so that the guide pulley moves to B-tension adjustment screw to adjust the guide pulley as close to

• Read these Technical Service Instructions carefully, and keep them in a safe place with a MULTI RELEASE position. A maximum two-gear shift can be made in this manner.

a position directly in line with the sprocket as possible but Largest sprocket Smallest sprocket

for later reference. mechanism so that you can

the largest sprocket. not so close that it touches.

now shift two gears with a Next, set the chain to the

Note single operation. smallest sprocket and

• If gear shifting operations do not feel smooth, wash the derailleur and lubricate all Lever initial position

Largest repeat the above to make

moving parts. sprocket

sure that the pulley does

• If the amount of looseness in the links is so great that adjustment is not possible, Low adjustment

screw not touch the sprocket.

you should replace the derailleur.

B-tension

• You should periodically clean the derailleur and lubricate all moving parts adjustment screw

(mechanism and pulleys). Adjusting the grip width Guide pulley

• If gear shifting adjustment cannot be carried out, check the degree of parallelism at It is recommended that you adjust the grip widths of the levers to

the rear end of the bicycle. Also check if the cable is lubricated and if the outer the most comfortable widths for gear shifting and braking.

casing is too long or too short. To shift from a small sprocket to a larger sprocket

• If you hear abnormal noise as a result of looseness in a pulley, you should replace (MULTI RELEASE ) 2. Top adjustment

5. SIS Adjustment

the pulley. 1st joint You can vary the lever stroke to shift the desired number of gears, Turn the crank arm while pulling the derailleur with your hand to

move the derailleur to the top position, and then turn the top Push lever while turning the crank arm to move the derailleur to

• If the chain keeps coming off the sprockets during use, replace the sprockets and so that to shift by one gear only, move the lever to the (1) position, the largest sprocket. Then operate lever once to move the

the chain. Approx. and to shift by two gears at one time, move the lever to the (2) adjustment screw to adjust so Outer line of

2 mm that the guide pulley is in line smallest sprocket

derailleur to the 2nd-gear sprocket. After this, operate lever just

• Adjust the RD-M970 reverse spring type rear derailleur from the low side. position. A maximum two-gear shift can be made in this manner. as far as the extent of play, and then turn the crank arm.

• Use a frame with internal cable routing is strongly discouraged as it has tendencies with the outer line of the

Lever end

to impair the SIS shifting function due to its high cable resistance. smallest sprocket when looking 23 23

When changing When no

• Always be sure to use the sprocket set bearing the same from the rear.

Group marks to 3rd noise is

group marks. Never use in combination with a sprocket Turn the crank arm to set the heard at all

bearing a different group mark. derailleur to the low position.

• Use an outer casing which still has some length to spare even ag - 18T

ag -15

T

ag Top adjustment

-1

when the handlebars are turned all the way to both sides. 3T

screw

Furthermore, check that the shifting lever does not touch the Lever initial position

bicycle frame when the handlebars are turned all the way. Guide pulley

Adjustment bolt 23 Adjustment bolt 23

SH

• Make sure that the gear shifting cable and the brake cable do

IM

Becomes

AN

O

HYPERGL I DE - C

narrower Auxiliary release lever

not obstruct each other during braking operations. If they do

obstruct, it may interfere with braking. Becomes wider 3. Connecting and securing the inner cable

Install the cables so that they still have some slack in them even when the Operate the lever eight times or more

handlebars are turned fully in either direction. 2 mm Allen key

to set the lever to the lowest position. Turn the cable adjustment bolt Turn the cable adjustment bolt

• A special grease is used for the gear shifting cable (SIS-SP41). Do not use DURA- Then remove the inner hole cover and clockwise to tighten it until the counterclockwise to loosen it until

ACE grease or other types of grease, otherwise they may cause deterioration in connect the inner cable. chain returns to the 2nd sprocket. the chain touches a sprocket and

gear shifting performance. * Turn the adjustment bolt together generates noise.

• Grease the inner cable and the inside of the outer casing before use to ensure that with the outer casing adjustment * Turn the adjustment bolt together with

they slide properly. barrel cover. the outer casing adjustment barrel

cover.

• For smooth operation, use the specified outer casing and the bottom bracket cable Installation of the rear derailleur Inner hole cover

guide. Inner cable

• Operation of the levers related to gear shifting should be made only when the front When installing, be careful not to let the B-tension adjustment screw 5 mm Allen key Inner hole cover

B-tension

chainwheel is turning. come into contact with the dropout tab, otherwise deformation may result. adjustment screw Install the inner hole cover by turning it as Best setting

• Parts are not guaranteed against natural wear or deterioration resulting from Do not remove the Pro-Set alignment block at this time. shown in the illustration until it stops. Do not The best setting is when the cable adjustment bolt is tightened

normal use. turn it any further than this, otherwise it may (turned clockwise) until noise occurs without lever being

• For maximum performance we highly recommend Shimano lubricants and damage the thread on the cover.

Bracket spindle Tightening torque : operated, and then loosened (turned counterclockwise) 90 - 180

maintenance products

8 - 10 N·m {70 - 86 in. lbs.} degrees from that point.

• For any questions regarding methods of installation, adjustment, maintenance or

operation, please contact a professional bicycle dealer. Tightening torque :

Dropout tab 0.3 - 0.5 N·m {3 - 4 in. lbs.} Operate lever to change gears, and check that no noise occurs

in any of the gear positions.

Connect the inner cable to For the best SIS performance, periodically lubricate all

the derailleur as shown in Note: Be sure that the cable is power-transmission parts.

the illustration. securely in the groove.

Chain length on bicycles with rear suspension

This service instruction explains how to use and maintain the

Groove Shimano bicycle parts which have been used on your new bicycle.

The length of A will vary depending on the movement of the For any questions regarding your bicycle or other matters which

rear suspension. Because of this, an excessive load may be are not related to Shimano parts, please contact the place of

placed on the drive system if the chain length is too short. Set purchase or the bicycle manufacturer.

the length of the chain by adding two links to the chain when

the rear suspension is at a position where dimension "A" is A'

longest and the chain is on the largest sprocket and the largest These service instructions are

Chain printed on recycled paper.

Largest Largest

chainring. If the amount of movement of the rear suspension is sprocket chainring

Technical Service Instructions SI-5VW0A large, the slack in the chain may not be taken up properly when

the chain is on the smallest chainring and smallest sprocket. Connect the cable to the rear derailleur and, One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

A after taking up the initial slack in the cable,

re-secure to the rear derailleur as shown in Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

RD-M970 Rear derailleur

Add 2 links (with the chain on both the largest

the illustration.

Tightening torque :

Pull

3-77 Oimatsu-cho Sakai-ku, Sakai, Osaka 590-8577, Japan

Please note: specifications are subject to change for improvement without notice. (English)

sprocket and the largest chainring) 5 - 7 N·m {44 - 60 in. lbs.} © Jun. 2006 by Shimano Inc. XBC SZK Printed in Japan.

You might also like

- Manual Taller Seat Ibiza Mk2Document3 pagesManual Taller Seat Ibiza Mk2Jonah Hex38% (8)

- Operating Instructions: MANUFACTURING YEARDocument11 pagesOperating Instructions: MANUFACTURING YEARwalk666No ratings yet

- 175 CacDocument5 pages175 CacshjefkeNo ratings yet

- Si 6rp0a 001 EngDocument1 pageSi 6rp0a 001 EngBernardo LizardiNo ratings yet

- Atlas Copco - Hydraulic Nut SplitterDocument3 pagesAtlas Copco - Hydraulic Nut Splitterlildevil277No ratings yet

- Eng Shimano Manu 07214Document1 pageEng Shimano Manu 07214RodrigoMacedoNo ratings yet

- Rear Drive System: Service InstructionsDocument6 pagesRear Drive System: Service InstructionsjimmyjoeNo ratings yet

- Shimano Deore Crankset User ManualDocument1 pageShimano Deore Crankset User ManualJose Luis GutierrezNo ratings yet

- Keyless Bushing Instruction Manual July 2019Document2 pagesKeyless Bushing Instruction Manual July 2019huseyinNo ratings yet

- SM-BB80: General Safety InformationDocument1 pageSM-BB80: General Safety InformationVIRAL WORLD IDNo ratings yet

- KONNECT CGL Hand Tools CatalogueDocument10 pagesKONNECT CGL Hand Tools CatalogueNeil MenezesNo ratings yet

- Specifications: FC-M411 FC-M410 / FC-M410-8 FC-M361 / FC-M361-8 FC-M311 / FC-M311-8Document1 pageSpecifications: FC-M411 FC-M410 / FC-M410-8 FC-M361 / FC-M361-8 FC-M311 / FC-M311-8Lawrence A. DyNo ratings yet

- Manuel SISL2Document2 pagesManuel SISL2stewenNo ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- Catálogo Sit SerlockDocument4 pagesCatálogo Sit Serlockalfonso_gonzale3544No ratings yet

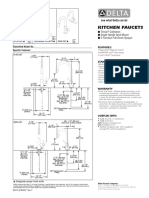

- 9159-CZ-DST - Kitchen FaucetDocument1 page9159-CZ-DST - Kitchen FaucetJoseph CephasNo ratings yet

- Bb86 / Bb92 Frame Gauge: Before You Install Praxis Works M30 Bb86 / Bb92 You Must Check Your Frame!Document3 pagesBb86 / Bb92 Frame Gauge: Before You Install Praxis Works M30 Bb86 / Bb92 You Must Check Your Frame!edwuinhr herreraNo ratings yet

- RMT 1240 Product Flyer (RMT)Document1 pageRMT 1240 Product Flyer (RMT)Hector OscarNo ratings yet

- Pushbutton Enclosures, Type 12: See Also AccessoriesDocument2 pagesPushbutton Enclosures, Type 12: See Also AccessoriessoayNo ratings yet

- KD Tools - Automotive Specialty Tools - 2010 Catalog PDFDocument172 pagesKD Tools - Automotive Specialty Tools - 2010 Catalog PDFGilberto Garcia100% (1)

- TK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14Document19 pagesTK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14MartinNo ratings yet

- KRX NTNDocument4 pagesKRX NTNDj ́s Mix LiveNo ratings yet

- Structure and Features: Strucfures of Cam FollowersDocument33 pagesStructure and Features: Strucfures of Cam FollowersAlejandro DerissoNo ratings yet

- Chain Saw Safety Univ. of MissouriDocument6 pagesChain Saw Safety Univ. of Missourijpfisher29519No ratings yet

- Samiflex en Product CatalogDocument16 pagesSamiflex en Product CatalogFitsum TadesseNo ratings yet

- VW GOLF 3 Front BrakesDocument38 pagesVW GOLF 3 Front BrakesNick PNo ratings yet

- 2023 English Catalog Full CompleteDocument91 pages2023 English Catalog Full Completeghost2humanNo ratings yet

- Control Chokes BR PDFDocument16 pagesControl Chokes BR PDFJorge EduardoNo ratings yet

- D-Series Rack & Pinion Pneumatic ActuatorsDocument6 pagesD-Series Rack & Pinion Pneumatic ActuatorsJandri JacobNo ratings yet

- TG 70Document1 pageTG 70Shisir ishaqNo ratings yet

- Strap Wrench Chain Wrench: KT No. Capacity MM Overall LengthDocument1 pageStrap Wrench Chain Wrench: KT No. Capacity MM Overall Lengthmina eissaNo ratings yet

- ERIEZ Separadores de LáminaDocument2 pagesERIEZ Separadores de LáminaangelsiddhartaNo ratings yet

- WC150XP: 16 Gauge 1" Wide Crown StaplerDocument2 pagesWC150XP: 16 Gauge 1" Wide Crown StaplerDmitry DanilovNo ratings yet

- Ignite Carbon 29": Frame PassportDocument7 pagesIgnite Carbon 29": Frame PassportvictorNo ratings yet

- Manual FD 7900 ENDocument2 pagesManual FD 7900 ENGvbbNo ratings yet

- Oc2 Dropper Bluepaper en EsDocument23 pagesOc2 Dropper Bluepaper en Esronare6613No ratings yet

- Shimano D CL LeversDocument1 pageShimano D CL LeversxjcaiNo ratings yet

- Oc2 Dropper Bluepaper En-EsDocument23 pagesOc2 Dropper Bluepaper En-EsAdolfo LeivaNo ratings yet

- Dedacciai Ran-Eng 2016Document14 pagesDedacciai Ran-Eng 2016pk50sNo ratings yet

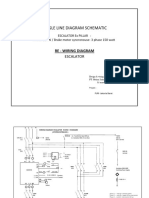

- 325CL 320CL Excavadora KomatsuDocument5 pages325CL 320CL Excavadora KomatsuOrlando RimarachinNo ratings yet

- ICG/653/UNIV: Cable Gland Selection TableDocument2 pagesICG/653/UNIV: Cable Gland Selection Table萧家一族No ratings yet

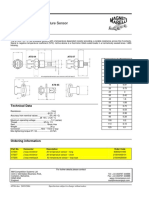

- Piston Ring Compressor: Treker MagnetDocument1 pagePiston Ring Compressor: Treker MagnetPutra IrwansyahNo ratings yet

- 280 Eb1gs - 115Document1 page280 Eb1gs - 115Adnane BensmaineNo ratings yet

- Catálogo de Correias PDFDocument152 pagesCatálogo de Correias PDFDeibe SantosNo ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- Serie Acr-Acb StucchiDocument4 pagesSerie Acr-Acb StucchiHIDRAFLUIDNo ratings yet

- 275/290//carbon - Exploded DiagramDocument2 pages275/290//carbon - Exploded DiagramNicky KiloNo ratings yet

- SKF KR 30 PP SpecificationDocument5 pagesSKF KR 30 PP SpecificationayoubmacNo ratings yet

- 2018 2019 Mega-275-290-Carbon-MY2018 Exploded DiagramDocument2 pages2018 2019 Mega-275-290-Carbon-MY2018 Exploded Diagramsvaleev846fNo ratings yet

- BSP-K-61075LF-LHP Rev ADocument1 pageBSP-K-61075LF-LHP Rev ALa Rinconada HuepacNo ratings yet

- Clamp DowntiltDocument2 pagesClamp DowntiltdanielNo ratings yet

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Document2 pagesConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1No ratings yet

- Tub and Shower Faucet: Submitted Model No.: Specific FeaturesDocument1 pageTub and Shower Faucet: Submitted Model No.: Specific FeaturesTenny SupNo ratings yet

- Owner S Manual: Suspension Front Fork W. Coil Spring or MCUDocument2 pagesOwner S Manual: Suspension Front Fork W. Coil Spring or MCUformilNo ratings yet

- Jensen. A Swagelok Company. Jenflo Series Pumps Sanitary Centrifugal PumpsDocument24 pagesJensen. A Swagelok Company. Jenflo Series Pumps Sanitary Centrifugal PumpsAgustin CesanNo ratings yet

- Standard Downtilt Kit For Panel Antennas (Wind Load Category "L" and "M")Document2 pagesStandard Downtilt Kit For Panel Antennas (Wind Load Category "L" and "M")Bedirhan KapkiçNo ratings yet

- Specialty Bearings: Electric Motor QualityDocument29 pagesSpecialty Bearings: Electric Motor QualityHenry Wilson AlvaradoNo ratings yet

- Ohmnews 180Document2 pagesOhmnews 180motorciNo ratings yet

- Harley-Davidson Softail Breakout / Cvo Breakout Big Radius Installation Instructions PART# 26065Document3 pagesHarley-Davidson Softail Breakout / Cvo Breakout Big Radius Installation Instructions PART# 26065Justin StewartNo ratings yet

- CTS Plunger Tips ABP 1Document2 pagesCTS Plunger Tips ABP 1Alson LeeNo ratings yet

- Pulleys and Sheaves 1060Document84 pagesPulleys and Sheaves 1060m s sankar raoNo ratings yet

- Pope FrancisDocument60 pagesPope FrancisJonah HexNo ratings yet

- Compute!s Second Book of Commodore 64Document300 pagesCompute!s Second Book of Commodore 64Jonah HexNo ratings yet

- 2005Document100 pages2005Jonah HexNo ratings yet

- Using The Commodore 64 in The HomeDocument120 pagesUsing The Commodore 64 in The HomeJonah HexNo ratings yet

- Instructional Strategies ManualDocument56 pagesInstructional Strategies ManualJonah HexNo ratings yet

- E11892 Tuf Z270 MK2 Um WebDocument98 pagesE11892 Tuf Z270 MK2 Um WebJonah HexNo ratings yet

- Motherboards Tuf z270 Mark 2Document70 pagesMotherboards Tuf z270 Mark 2Jonah HexNo ratings yet

- Revue Technique Derbi Euro 3Document42 pagesRevue Technique Derbi Euro 3Jonah HexNo ratings yet

- 2010 LeftyMax140PBR RLC Oms enDocument36 pages2010 LeftyMax140PBR RLC Oms enJonah HexNo ratings yet

- RD-M960 RD-M960: SHIMANO XTR Rear DerailleurDocument1 pageRD-M960 RD-M960: SHIMANO XTR Rear DerailleurJonah HexNo ratings yet

- Technology Overview: SPV - Stable Platform ValveDocument2 pagesTechnology Overview: SPV - Stable Platform ValveJonah HexNo ratings yet

- RD-M972 RD-M972: XTR Rear DerailleurDocument1 pageRD-M972 RD-M972: XTR Rear DerailleurJonah HexNo ratings yet

- 2007 Lefty Max 140 SPV TPC Owners Manual Supplement en 0Document36 pages2007 Lefty Max 140 SPV TPC Owners Manual Supplement en 0Jonah HexNo ratings yet

- LEFTY 2.0: Owner'S Man Ual Supplem ENTDocument21 pagesLEFTY 2.0: Owner'S Man Ual Supplem ENTJonah HexNo ratings yet

- RD-M980 RD-M980: XTR Rear Derailleur (GS) (SGS)Document1 pageRD-M980 RD-M980: XTR Rear Derailleur (GS) (SGS)Jonah HexNo ratings yet

- RD-M980 RD-M980: XTR Rear Derailleur (GS) (SGS)Document1 pageRD-M980 RD-M980: XTR Rear Derailleur (GS) (SGS)Jonah HexNo ratings yet

- RD-M972 RD-M972: XTR Rear DerailleurDocument1 pageRD-M972 RD-M972: XTR Rear DerailleurJonah HexNo ratings yet

- Manual Vespa PK 50 fl2 PDFDocument3 pagesManual Vespa PK 50 fl2 PDFJonah Hex0% (1)

- ManeualDocument92 pagesManeualJonah Hex100% (1)

- Ats04 05 07Document1 pageAts04 05 07Jonah HexNo ratings yet

- WMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1Document5 pagesWMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1tanaNo ratings yet

- ACRD20x Fluid Cooled InstallationDocument44 pagesACRD20x Fluid Cooled InstallationNelson Arturo GarciaNo ratings yet

- Craigtools 300 PDFDocument58 pagesCraigtools 300 PDFroshan mungurNo ratings yet

- Lighting and Small PowerDocument3 pagesLighting and Small PowerYo Wee LiamNo ratings yet

- Maxventuri DatasheetDocument2 pagesMaxventuri Datasheetmehmet çakırNo ratings yet

- CW Flyer Nsgaföu Orange En-2Document2 pagesCW Flyer Nsgaföu Orange En-2fjdksgdfgNo ratings yet

- Limoss Troubleshooting GuideDocument11 pagesLimoss Troubleshooting GuideiammiaNo ratings yet

- Omega J1065 Brosura Tehnica enDocument2 pagesOmega J1065 Brosura Tehnica enAdrian StiubeNo ratings yet

- Eim10 - q3 - wk1 - Select Wiring Device For Floor and Ground Fault Circuit Interrupter - v1Document17 pagesEim10 - q3 - wk1 - Select Wiring Device For Floor and Ground Fault Circuit Interrupter - v1Jessie Barrera100% (2)

- LS Cable - SimpleDocument68 pagesLS Cable - SimpleCodielNo ratings yet

- Mitsubishi Electric JointDocument1 pageMitsubishi Electric JointBach CaoNo ratings yet

- PowerLink Cable BrochureDocument6 pagesPowerLink Cable BrochuredfdsfdNo ratings yet

- 72 Cell 320-335W 17.3%: Multicrystalline ModuleDocument2 pages72 Cell 320-335W 17.3%: Multicrystalline Modulejgeorge095No ratings yet

- GT Helion SellsheetsDocument6 pagesGT Helion SellsheetsDavid_jcdNo ratings yet

- Bead Roller Forming Die SetDocument8 pagesBead Roller Forming Die SetHamada HamadaNo ratings yet

- B74GIM Norgren MK3Document2 pagesB74GIM Norgren MK3Ζαχος ΤσελιοςNo ratings yet

- NBS - 001-Services (Mechanical) Sample Specification-2019-07-29Document13 pagesNBS - 001-Services (Mechanical) Sample Specification-2019-07-29Nay Win MaungNo ratings yet

- Binder Wiring Puri Ex Pillar RewiringDocument10 pagesBinder Wiring Puri Ex Pillar RewiringWiratama MudaNo ratings yet

- Hanger Detail Collector Pipe: Plan SectionDocument1 pageHanger Detail Collector Pipe: Plan Sectionmaj31No ratings yet

- ECPRRole CardsDocument17 pagesECPRRole Cardsghg sddNo ratings yet

- Learners Activity Sheets For Week 1 Grade 12 Nga e Print Kay Naay BooksDocument6 pagesLearners Activity Sheets For Week 1 Grade 12 Nga e Print Kay Naay BooksLEA BANZUELO ANDUJAR0% (1)

- Helac Basket Rotator L20 ManualDocument24 pagesHelac Basket Rotator L20 ManualStuart Sainsbury100% (1)

- 3176 Diesel Truck Engine Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages3176 Diesel Truck Engine Electrical System: Electrical Schematic Symbols and DefinitionsAna LorcaNo ratings yet

- 3D SolutionDocument4 pages3D SolutionsamirNo ratings yet

- LEMKEN Cable Guide 2022 enDocument47 pagesLEMKEN Cable Guide 2022 enMaxi Reiter100% (1)

- Yb Series Pump ManualDocument8 pagesYb Series Pump ManualAlexander CallaNo ratings yet

- A319/ A320/ A321 Technical Training ManualDocument45 pagesA319/ A320/ A321 Technical Training ManualEnes ArslanNo ratings yet

- HPVM Series: Hydraulic Pilot ControlsDocument4 pagesHPVM Series: Hydraulic Pilot ControlsMichael AkhramovichNo ratings yet

- Adjustable Differential Pressure Switch: Penn Commercial RefrigerationDocument2 pagesAdjustable Differential Pressure Switch: Penn Commercial RefrigerationMarvin MarcaidaNo ratings yet