Professional Documents

Culture Documents

Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)

Uploaded by

ruizinho 1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)

Uploaded by

ruizinho 1Copyright:

Available Formats

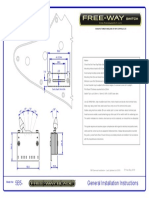

Installation Instructions Bulletin 237321 Revision B Page 1 of 2

Connectors

for 75-ohm HELIAX® and RADIAX® Coaxial Cable

of nominal diameter 7/8" (22 mm) Andrew Institute offers installation training.

4

Tools and Materials Required for Assembly

Solder gun Hacksaw, fine tooth blade

3 Clean Conductor and Add O-ring. Clean the outer

conductor with solvent. Add the small O-ring gasket

to the second, fully-exposed conductor groove from the

Knife Wrenches: 1-1/4” jacket. Apply a thin coating of silicone grease to the outer

Flat file Solvent:comothene, vythene or other surface of the O-ring and to the O-ring lead chamfer in

Wire Brush non-flammable cleaning solvent the clamping nut. Note: The clamping nut threads must

3

be kept free of grease.

Notice

The installation, maintenance or removal of antenna sys- Apply silicone grease

tems requires qualified, experienced personnel. Andrew

installation instructions have been written for such per-

sonnel. Antenna systems should be inspected once a

2

year by qualified personnel to verify proper installation,

maintenance and condition of equipment.

Clamping nut Small O-ring

Andrew disclaims any responsibility for the results of

improper or unsafe installation practices.

4 Add Clamping Nut and Cut Cable. Push the clamping

1

nut onto the cable. Use a twisting motion to assure

1 Pepare Cable. The end of the cable must be straight the spring contacts snap into the groove. Refer to the

for at least 10 inches (254 mm). Remove the jacket to cutaway view in Step 7. Grip the clamping nut with one

the approximate dimension shown. Use a knife. Deburr hand and align the edge with the line scribed in Step 2.

Inches

the sharp end of the cut outer conductor. Then carefully cut the outer conductor and foam dielectric

material flush with the end of the clamping nut exposing

Corrugated outer the inner conductor. Note: Make shallow cuts to prevent

Jacket

conductor

damaging the inner conductor. Use a hacksaw with a

100

fine-toothed blade or a model maker’s saw.

Saw blade

90

Inner conductor

1” (25 mm)

80

70

2 Make Second Jacketing Cut. Scribe a line on the

ridge of the exposed corrugated outer conductor.

The line must be at least 13/32 inch (10 mm) from the end 60

of the cable. Remove the jacket to the dimension shown

5 Trim Inner Conductor. Cut the inner conductor to the

50

using a straight-edged piece of heavy paper wrapped

around the cable to guide the cut. Cut the jacket with a length shown. Use a file to deburr the cut end of the

sharp knife. inner conductor.

40

Scribe line

7/32” (5 mm)

30

at ridge 1-1/2” (38 mm)

20

Millimeters

13/32” (10 mm)

minimum Straight-edged paper

Bulletin 237321 Revision B Page 2 of 2

6 Separate Foam from Outer Conductor. Insert the tip

of a knife to a depth of 3/32 inch (2 mm) between the

foam and the outer conductor of the cable and separate

8 Install Inner Connector. Clean the inner conductor.

Slip the inner connector onto the inner conductor.

Use the spacing gauge as indicated. Solder the inner

them so that the outer conductor can be flared. Move connector to the inner conductor while pressing the inner

the knife around the entire circumference of the outer connector against the spacing gauge. Cool the soldered

conductor. Scrape away any foam clinging to the outer connection with a damp cloth and clean with garnet cloth.

conductor. Remove any burrs from the inner edge of the Make certain the inner connector is straight; i.e. square to

outer conductor. Remove particles from the foam with a the flared outer conductor. Place the large O-ring into the

wire brush. groove in the clamping nut and apply a thin coating of sili-

cone grease to the outer surface of the O-ring. Keep the

Foam connector threads free of grease. Thread the connector

outer body onto the clamping nut and tighten the connec-

tion with wrenches. Hold the clamping nut stationary and

turn the outer body only to 17 ±2 lbf.ft (23 ±2.7 N.m).

Knife Outer 150 W Spacing Clamping

3/32” (2.4 mm) body gauge nut

Sn63-Pb37

7 Flare Outer Conductor. Thread the connector outer

body onto the clamping nut and tighten the connec-

tion with wrenches. Hold the clamping nut stationary and

turn only the outer body to 17 ±2 lbf.ft (23 ±2.7 N.m).

The flaring surface of the outer body will flatten the outer Male inner

conductor against the clamping nut ring. Disassemble the connector

connection and inspect the flare to ensure good metal-to-

Female inner Large

metal contact at final assembly. connector O-ring

Internal Flaring Details of

Connector Assembly

Outer body Clamping N-jack N-plug

flaring surface nut ring

4.75 - 5.26 mm 5.33 - 5.84 mm

(0.187 - 0.207”) (0.210 - 0.230”)

Good contact here Outer conductor

50

(Part Name)

(Pb) (Hg) (Cd) (Cr6+) (PBB) (PBDE)

(Connector) X O O O O O

O: SJ/T 11363-2006 .

X: SJ/T 11363-2006 .

Andrew Corporation Customer Service 24 hours

3 Westbrook Corporate Center, Suite 900, Westchester, Illinois U.S.A. 60154 U.S.A., Canada, Mexico: 1-800-255-1479

+1 (708) 349-3300 Fax (U.S.A.): 1-800-349-5444 U.K.: 0800 250055

www.andrew.com Other Europe: +44 592 782 612

Notice: Andrew disclaims any liability or responsibility for the results of improper or unsafe installation, inspection, maintenance, or removal practices.

Aviso: Andrews no acepta ninguna obligación ni responsabilidad como resultado de prácticas incorrectas o peligrosas de instalación, inspección, mantenimiento o retiro.

Avis : Andrew décline toute responsabilité pour les conséquences de procédures d’installation, d’inspection, d’entretien ou de retrait incorrectes ou dangereuses.

Hinweis: Andrew lehnt jede Haftung oder Verantwortung für Schäden ab, die aufgrund unsachgemäßer Installation, Überprüfung, Wartung oder Demontage auftreten.

Atenção: A Andrew abdica do direito de toda responsabilidade pelos resultados de práticas inadequadas e sem segurança de instalação, inspeção, manutenção ou remoção.

Avvertenza: Andrew declina eventuali responsabilità derivanti dell’esecuzione di procedure di installazione, ispezione, manutenzione e smontaggio improprie o poco sicure.

© 2007 Andrew Corporation

You might also like

- Tricks For Cable Accessories InstallationDocument30 pagesTricks For Cable Accessories InstallationcxfuentesNo ratings yet

- Paracord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsFrom EverandParacord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsRating: 4.5 out of 5 stars4.5/5 (2)

- 001-2. Fast ConnectorDocument4 pages001-2. Fast ConnectorHebert SánchezNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Instruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsDocument2 pagesInstruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsrichintukNo ratings yet

- 1-1/4Document2 pages1-1/4richintukNo ratings yet

- MB Crimper 2022 en WebDocument20 pagesMB Crimper 2022 en WebDavidMarianNo ratings yet

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocument10 pagesDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqNo ratings yet

- 200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsDocument4 pages200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsCesar PreciadoNo ratings yet

- Surface Mining Brochure 2 PDFDocument25 pagesSurface Mining Brochure 2 PDFhugo sobrinoNo ratings yet

- INSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVDocument6 pagesINSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNo ratings yet

- RG6 Cable Mounting InstructionsDocument2 pagesRG6 Cable Mounting InstructionsStaffan FogelbergNo ratings yet

- Small Headless Screws PDFDocument4 pagesSmall Headless Screws PDFAngulo HernandezNo ratings yet

- Wire WrapDocument16 pagesWire Wrapgretta kopectneNo ratings yet

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsDocument12 pagesRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayNo ratings yet

- Installation instructions for SEIK 14, 24, 34 plug-in cable terminationsDocument5 pagesInstallation instructions for SEIK 14, 24, 34 plug-in cable terminationsSonia Noval LlorianNo ratings yet

- How To Terminate Coaxial CableDocument16 pagesHow To Terminate Coaxial CableghostdreamNo ratings yet

- Application Tooling Specification Sheet: Manual Wire StripperDocument3 pagesApplication Tooling Specification Sheet: Manual Wire StripperGuilhermeNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- Bosch Aftertreatment DEF Controller ConnectorDocument4 pagesBosch Aftertreatment DEF Controller ConnectorO mecanicoNo ratings yet

- Fibra Optica - RS DataSheetDocument8 pagesFibra Optica - RS DataSheetAlex MoralesNo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- 25 K VInstall GuideDocument23 pages25 K VInstall GuideMarcelo ConchaNo ratings yet

- MZ590803EX - Luz Interior PortonDocument11 pagesMZ590803EX - Luz Interior PortonPepe PerezNo ratings yet

- Catalog No. 120Document80 pagesCatalog No. 120Haider FiberNo ratings yet

- Silver Soldering To SG-2433 - tt602Document4 pagesSilver Soldering To SG-2433 - tt602sultanrandhawaNo ratings yet

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideDocument7 pagesRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisNo ratings yet

- DT436 500 Sq. MM PDFDocument3 pagesDT436 500 Sq. MM PDFHamedObaidNo ratings yet

- A Review of Polarization Index and IEEE Standard 43-2000Document7 pagesA Review of Polarization Index and IEEE Standard 43-2000Noel RazaNo ratings yet

- Operating Instructions Cleaver A8Document2 pagesOperating Instructions Cleaver A8عبدالله الشهاريNo ratings yet

- Uso y Catalogo de Herramientras para El CrimpingDocument34 pagesUso y Catalogo de Herramientras para El CrimpingGriselda SanchezNo ratings yet

- Antenna Flower Pot 2M 70cm Dual BandDocument5 pagesAntenna Flower Pot 2M 70cm Dual BandSidney GireliNo ratings yet

- INSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVDocument7 pagesINSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNo ratings yet

- TLE-EPAS Grade10 Q2 LAS2Document3 pagesTLE-EPAS Grade10 Q2 LAS2JAMES HONRUBIANo ratings yet

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDocument10 pagesEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidNo ratings yet

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDocument10 pagesEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidNo ratings yet

- IM&OM - PC-AR - enDocument12 pagesIM&OM - PC-AR - enzodenapeNo ratings yet

- 9K688NDocument7 pages9K688NHelar Armejo VasquezNo ratings yet

- Mitd1 PDFDocument4 pagesMitd1 PDFwizaarzNo ratings yet

- Agricultural Chain Saw SafetyDocument6 pagesAgricultural Chain Saw Safetyjpfisher29519No ratings yet

- BRFACH16GB 11 2017 I GB Klauke Technical ArticleDocument44 pagesBRFACH16GB 11 2017 I GB Klauke Technical ArticlesujaraghupsNo ratings yet

- 9211B Installation Kistler PDFDocument2 pages9211B Installation Kistler PDFCristian MaldonadoNo ratings yet

- Cable Installation GripsDocument5 pagesCable Installation GripsdachinicuNo ratings yet

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Micro Electronics, Inc.: Micro-Strip® and Soft-Strip® Tool Resource GuideDocument12 pagesMicro Electronics, Inc.: Micro-Strip® and Soft-Strip® Tool Resource GuideEnrico PiccininiNo ratings yet

- 65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingDocument8 pages65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingJohnfromFresnoNo ratings yet

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDocument12 pagesYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenNo ratings yet

- Troubleshooting Manual, TS2712EN 04Document82 pagesTroubleshooting Manual, TS2712EN 04thibierozNo ratings yet

- TE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportDocument8 pagesTE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportHossam AlzubairyNo ratings yet

- Cable Preparation Best Practices For Fiber Optic Indoor/Outdoor Stranded Loose Tube CableDocument14 pagesCable Preparation Best Practices For Fiber Optic Indoor/Outdoor Stranded Loose Tube CableSAMNo ratings yet

- Single Conductor Re Head InstructionsDocument14 pagesSingle Conductor Re Head Instructionsanksri07No ratings yet

- GE752 Drilling Motor Commutator Maintenance GuideDocument10 pagesGE752 Drilling Motor Commutator Maintenance Guidesertecs polNo ratings yet

- cn-14a_eDocument1 pagecn-14a_eAjay MayalNo ratings yet

- 5B5-General Installation Instructions: Lever Slot & Mounting Hole DimensionsDocument1 page5B5-General Installation Instructions: Lever Slot & Mounting Hole DimensionsWitit WattanaNo ratings yet

- Bostitch Stitch Head ManualDocument31 pagesBostitch Stitch Head ManualCesar NZNo ratings yet

- Tbo Quality CrimpingDocument27 pagesTbo Quality Crimpingyavuz772No ratings yet

- Electrical Formulas Power FactorDocument2 pagesElectrical Formulas Power Factorruizinho 1No ratings yet

- ADVISOR II™ POCSAG Alpha-Numeric PagerDocument2 pagesADVISOR II™ POCSAG Alpha-Numeric Pagerruizinho 1No ratings yet

- Stored Energy Solutions For A Demanding WorldDocument2 pagesStored Energy Solutions For A Demanding Worldruizinho 1No ratings yet

- Advisor Gold User ManualDocument5 pagesAdvisor Gold User Manualruizinho 1No ratings yet

- Echsounder Theory - of - OperationsDocument24 pagesEchsounder Theory - of - Operationsruizinho 1No ratings yet

- The Most Dependable Commercial Salt Chlorinators in The IndustryDocument2 pagesThe Most Dependable Commercial Salt Chlorinators in The Industryruizinho 1No ratings yet

- Failcodes NeanderDocument30 pagesFailcodes Neanderruizinho 1100% (1)

- System overview and architectureDocument98 pagesSystem overview and architectureruizinho 1No ratings yet

- 07 ManitouDocument44 pages07 Manitouruizinho 1No ratings yet

- SOP Chlorine Probe - Filling Electrolyte and Decommissioning A Probe From ServiceDocument2 pagesSOP Chlorine Probe - Filling Electrolyte and Decommissioning A Probe From Serviceruizinho 1No ratings yet

- Busch Dolphin LX 0430 B 190 KG Compact Liquid Ring Vacuum PumpDocument19 pagesBusch Dolphin LX 0430 B 190 KG Compact Liquid Ring Vacuum Pumpruizinho 1No ratings yet

- 100vjr User ManualDocument92 pages100vjr User Manualruizinho 1No ratings yet

- Desigo InsightDocument146 pagesDesigo Insightruizinho 1No ratings yet

- Haulotte-H12-H15-H18-Compact10-Compact12 - DIESEL ENDocument76 pagesHaulotte-H12-H15-H18-Compact10-Compact12 - DIESEL ENruizinho 1No ratings yet

- ABB Low Power Consumption S2SP - White PaperDocument12 pagesABB Low Power Consumption S2SP - White Paperruizinho 1No ratings yet

- Lte Epc Umts 3GPPDocument222 pagesLte Epc Umts 3GPPjbarriospNo ratings yet

- ASTM D747 Overview PDFDocument41 pagesASTM D747 Overview PDFtangogll11No ratings yet

- Data StructuresDocument41 pagesData StructuresSree Charan ReddyNo ratings yet

- Modified o and G Slides 2Document21 pagesModified o and G Slides 2Salam FaithNo ratings yet

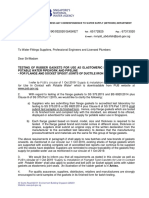

- Testing of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedDocument5 pagesTesting of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedKok WaiNo ratings yet

- M-Tech Industrial Training Report on Production Management at KELDocument51 pagesM-Tech Industrial Training Report on Production Management at KELniyassalim100% (1)

- Dubai Application FormDocument13 pagesDubai Application Formishq ka ain100% (1)

- Abraision ResistanceDocument28 pagesAbraision ResistancekattaaaaNo ratings yet

- Industrial VisitDocument22 pagesIndustrial VisitInvincible GamerNo ratings yet

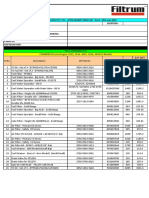

- Location:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDocument23 pagesLocation:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDadasaheb More100% (2)

- Kleppner (Introduction To Mechanics) (Errata)Document3 pagesKleppner (Introduction To Mechanics) (Errata)almarpa0% (1)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Design and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsDocument5 pagesDesign and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsPhạm Công ÁnhNo ratings yet

- 9-KinRoad XT250GK-8 Parts ManualDocument20 pages9-KinRoad XT250GK-8 Parts Manualoakstr50% (2)

- Conducting Polymers: 22-2-96 by Colin PrattDocument7 pagesConducting Polymers: 22-2-96 by Colin PrattkshitijscribdNo ratings yet

- Method Statement (RC Slab)Document3 pagesMethod Statement (RC Slab)group2sd131486% (7)

- DebugDocument295 pagesDebugkarthikNo ratings yet

- BO Consultant Resume Summary Role SAPDocument5 pagesBO Consultant Resume Summary Role SAPsundeep2kumgmailcomNo ratings yet

- Galaxy Y S5360 Android 2.3.6 Gingerbread Official FirmwareDocument23 pagesGalaxy Y S5360 Android 2.3.6 Gingerbread Official Firmwarekharishkhan0% (1)

- Inspection Request FormDocument1 pageInspection Request FormNieves GuardianNo ratings yet

- SLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsDocument3 pagesSLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsTOPdeskNo ratings yet

- Racing Boy Catalog - 2014Document117 pagesRacing Boy Catalog - 2014Eddie BoyzNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Dropped ObjectsDocument26 pagesDropped Objectsgunnery0250% (2)

- Excel 10 Smart Vav ActuatorDocument4 pagesExcel 10 Smart Vav ActuatorTan Chun KeatNo ratings yet

- Compressor Tech May 2013Document89 pagesCompressor Tech May 2013H.a. UlicesNo ratings yet

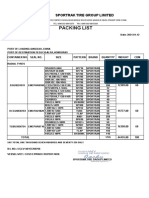

- Packing List: Sportrak Tire Group LimitedDocument1 pagePacking List: Sportrak Tire Group Limitedissa lamarNo ratings yet

- BPUT Preformulation Studies Chapter 1 SummaryDocument18 pagesBPUT Preformulation Studies Chapter 1 Summarykartik sharmaNo ratings yet

- 12 HOUSEKEEPING Q1 W2 M2 FinalDocument20 pages12 HOUSEKEEPING Q1 W2 M2 FinalWyn Ave CagakitNo ratings yet

- Project: Inventory Management System For Music Store: SynopsisDocument7 pagesProject: Inventory Management System For Music Store: SynopsisSoumitra ChakravartyNo ratings yet