Professional Documents

Culture Documents

Checksheet Pre-Operational PEUP5

Uploaded by

riki0 ratings0% found this document useful (0 votes)

32 views8 pagesOriginal Title

78151416-09d6-4897-bd75-e7d7c37501ed_Checksheet Pre-Operational PEUP5

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views8 pagesChecksheet Pre-Operational PEUP5

Uploaded by

rikiCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 8

PIC Mengetahui

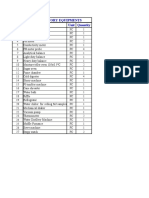

CHECKSHEET PRE-OPERATIONAL

WWT MACHINING PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel Area Scrap

2 Panel RO MC

3 Panel WWT Machining

Pompa Centrifugal Area Seksi Penghasil Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

4 Pompa Trf. Sentrifugal Coolant No. 1 & 2

5 Pompa Trf. Sentrifugal Pel No. 1 & 2

Pompa Centrifugal Area UPL Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

6 Pompa Proses Pel No.1 & 2

7 Pompa Transfer Pel No.1 & 2 ke Tangki Traping Pel

8 Pump Transfer Coolant 1 & 2 ke Trapping Tank

9 Pompa Aktif Carbon 3 & 4

10 Pompa Aktif Carbon 5 & 6

11 Pompa Backwash Aktif Carbon MC No. 3 & 4

12 Pompa Backwash Aktif Carbon MC No. 5 & 6

13 Pompa Sentrifugal UF Proses

14 Pompa Sentrifugal Backwash UF

15 Pompa Sentrifugal Softener

16 Pompa Produk RO

Pompa Wlden Body Air Valve Membran

17 Wilden Pump Transfer Coolant / Pel kedalam Tangki

18 Wilden Pump Produk Elektrokoagulasi

Skimmer Elmo Puley Belt scraper

19 Belt Skimer Under Ground Receiver Coolant

20 Belt Skimer Under Ground Holding Coolant

21 Disk Skimer Trapping Pel Tank

22 Belt Skimer Trapping Coolant Tank

23 Belt Skimer Under Ground Receiver Pel

24 Belt Skimer Under Ground Holding Pel

Watermeter Angka meteran Jarum Body

25 Watermeter Transfer Coolant Ke Underground UPL

26 Watermeter Transfer Pel ke Underground UPL

27 Watermeter Produk RO

28 Watermeter Side Produk RO

29 Watermeter Raw RO

30 Watermeter Flushing RO

Filter Piping Flowrate Hosing membran

31 Bag Filter

32 UF Module 1 & 2

33 RO Catridge

34 RO Module 1 & 2

35 RO Catridge Multistage

36 RO Module Multistage 1

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

WWT PAINTING PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel WWT Painting

2 Panel RO PNT

Pompa Centrifugal Area UPL Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

3 Pompa Proses Sentrifugal Pretreatment No. 1 & 2

4 Pompa Proses Sentrifugal Pretreatment No. 3 & 4

5 Pompa Trf. Sentrifugal ED UPL

6 Pompa Trf. Sentrifugal Seamwelder & Leaktester

7 Pompa Active Carbon Filter No. 1 & 2

8 Pompa Backwash ACF Painting No. 1 & 2

9 Pompa Supply RO Product dari UG Final RO ke Tangki Chemical

Pompa Centrifugal Area Seksi Penghasil Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

10 Pompa Trf. Sentrifugal Pretreatment Steel No. 1 & 2

11 Pompa Trf. Sentrifugal Phospate Steel No. 1 & 2

12 Pompa Trf. Sentrifugal Degreasing Steel No. 1 & 2

13 Pompa Trf. Sentrifugal ED Paint Steel No. 1 & 2

14 Pompa Trf. Sentrifugal Pretreatment ABS Steel No. 1 & 2

15 Pompa Trf. Sentrifugal Washing No. 1 & 2

16 Pompa Trf. Sentrifugal Leaktester No. 1 & 2

Pompa Membrane Body Air Valve Membran

17 Pompa Wilden P8 Trf. Slurry ke Intermediate Tank

18 Pompa Supply Chemical Flock

Mixer Electro motor Shaft Blade gearbox

19 Mixer Tangki Reduksi A & B

20 Mixer Tangki Koagulasi A & B

21 Mixer Tangki Flockulasi A & B

22 Mixer Tangki Chemical Kapur A & B

23 Mixer Tangki Chemical Flock

Watermeter Angka meteran Jarum Body

24 Water Meter Pretreatment dari Steel

25 Water Meter Pretreatment dari ABS

26 Water Meter Seam Welder & Washing dari Welding

27 Water Meter Leak Tester dari Welding

28 Water Meter Proses WWT PNT dari Tangki Clarifier

29 Watermeter Produk RO

30 Watermeter Side Produk RO

Display ph sensor

PH Meter sambungan Kabel

Muncul pembacaan Buffer 4 Bufer 7

31 Sensor pH Tanki Reduksi A & B

32 Sensor pH Tanki Koagulasi A & B

Filter Piping Flowrate Hosing membran

33 Bag Filter

34 UF modul 1 & 2

35 RO Catridge

36 RO modul 1 & 2

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

WWT DIECASTING PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel WWT Painting

2 Panel RO PNT

Pompa Centrifugal Area UPL Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

3 Pompa Trf. Sentrifugal Dielube No.1 & 2 ke Tangki Trapping

4 Pompa Sentrifugal Proses Dielube No. 1 & 2

5 Pompa CDX Proses Leaktester

6 Pompa CDX Proses Produk Elektrokoagulasi No.1

7 Pompa CDX Proses Produk Elektrokoagulasi No.2

Pompa Centrifugal Area Seksi Penghasil Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

8 Pompa Trf. Sentrifugal Dielube No.1 & 2 - STEP 1

9 Pompa Trf. Sentrifugal Dielube No.1 & 2 - STEP 2

Pompa Membrane Body Air Valve Membran

10 Pompa Wilden P8 Trf. Slurry ke Intermediate Tank

11 Dosing Pump Supply Coagulant ( PAC ) Line A

12 Dosing Pump Supply Floculant Line A

Mixer Electro motor Shaft Blade gearbox

13 Mixer Koagulasi A

14 Mixer Netralisasi A

15 Mixer Flokulasi A

16 Mixer Chemical Koagulant ( PAC ) Tank A

17 Mixer Chemical Kapur Tangki A

18 Mixer Chemical Floculant Tangki A

Watermeter Angka meteran Jarum Body

19 Watermeter Dielube - STEP 1

20 Watermeter Dielube - STEP 2

21 Watermeter Inlet Proses Limbah Produk Elektrokoagulasi

22 Watermeter Inlet Proses Limbah Leaktester

23 Watermeter Inlet Proses Limbah Dielube

Display ph sensor

PH Meter sambungan Kabel

Muncul pembacaan Buffer 4 Bufer 7

24 Sensor pH Tanki Reduksi A & B

25 Sensor pH Tanki Koagulasi A & B

Skimmer Elmo Puley Belt scraper

26 Belt Oil Skimmer Receiver Dielube

27 Disk Oil Skimmer Tangki Trapping Dielube No.1

28 Disk Oil Skimmer Tangki Trapping Dielube No.2

29 Belt Oil Skimmer Holding Dielube

30 Belt Oil Skimmer Receiver Leaktester

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

SLUDGE DRYER & EVAPORATOR PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN SLUDGE DRYER KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel Kontrol Sludge Dryer

Conveyor Elmo Rantai Conveyort Gearbox Roller

2 Loading Conveyor

3 Drying Conveyor

4 Unloading Conveyor

Ruang bakar Suhu Plat ruangan

5 Sludge Drier Oven

Burner display temp indikator Valve Gas

6 Burner

Fan Elmo V-belt Shaft

7 Exhaust Fan

NO EQUIPMENT ITEM PENGECHECKAN NEW EVAPORATOR KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel New Evaporator

Pompa Membrane Body Air Valve Membran

2 Pompa Supply Evaporator

Ruang bakar Suhu Plat ruangan

3 New evaporator

Burner display temp indikator Valve Gas

4 Burner

Exhaust Elmo V-belt Shaft

5 Exhaust Fan 1

6 Exhaust Fan 2

NO EQUIPMENT ITEM PENGECHECKAN EVAPORATOR 1 & 2 KETERANGAN

PANEL Body panel MCB Lampu ind Push But S.Switch

1 Panel Evaporator

Watermeter Angka meteran Jarum Body

2 Watermeter Evaporator 1

3 Watermeter Evaporator 2

Pompa Sentrifugal Remis Packing Karet Kopling Kopling Mech Seal Electro Motor

4 Pompa Supply Evaporator 1 & 2

5 Pompa Sirkulasi Evaporator 1 & 2

Damper Indikator Display Pneumatic Piston Valve Udara

6 Damper Evaporator 1

7 Damper Evaporator 2

8 Damper Bypass

Exhaust Elmo V-belt Shaft

9 Exhaust Fan Evaporator 1

10 Exhaust Fan Evaporator 2

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

Underground & Tangki PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN KETERANGAN

Tidak ada

DIECASTING Pipa Inlet Pipa Outlet Control Level Level

Kebocoran

1 Underground Receiver Dielube

2 Underground Holding Dielube

3 Under ground Leaktester DC

4 Underground Effluent

5 Underground Spare

6 Underground Slurry Diecasting

7 Underground Produk Balancing

8 Tangki Chemical PAC

9 Tangki Chemical Kapur N/A

10 Tangki Chemical Flock

Tidak ada

MACHINING Pipa Inlet Pipa Outlet Control Level Level

Kebocoran

11 Underground Receiver Coolant

12 Underground Holding Coolant

13 Underground Receiver Pel

14 Underground Holding Pel

15 Underground Aerasi Machining

16 Underground Intermediate

N/A

17 Underground Final

18 Underground Reject

19 Underground Produk Elektrokoagulasi Sekat 1 & 2

20 Tangki Coolant Area Scrap

21 Tangki Pel Area Scrap

Tidak ada

PAINTING Pipa Inlet Pipa Outlet Control Level Level

Kebocoran

22 Under Ground Pretreatment UPL

23 Under Ground Phospate UPL

24 Under Ground ED Paint UPL

25 Under Ground Seam Welder PT

26 Under Ground Filtrat UPL

27 Under Ground Leak Tester PT

28 Under Ground Rain Harvest 1

29 Under Ground Rain Harvest 2

N/A

30 Under Ground Netralis

31 Under Ground Aerasi Painting

32 Under Ground Slurry Painting

33 Tangki Acid

34 Tangki Kapur N/A

35 Tangki flokulasi

Tidak ada

RO Sistem Pipa Inlet Pipa Outlet Control Level Level

Kebocoran

36 Tangki Raw

37 Tangki Produk UF

N/A

38 Tangki Produk RO

39 Tangki Side Produk RO

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

Chemical & APD PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

EQUIPMENT ITEM PENGECHECKAN

NO Ket

Chemical Min MAX OK NG pH chemical

1 PAC 5 Krg 60 krg

2 KAPUR 5 Krg 30 krg

3 ASAM SULFAT 5 can 16 can

4 FLOCK 1 Dus 3 Dus

5 GARAM 2 Krg 10 krg

6 HCL 1 can 2 can

7 Buffer 4 1 Btl 1 Btl

8 Buffer 7 1 Btl 1 Btl

9 Aquadest 1 can 2 can

10 Permaclean 77 2 Btl 16 Btl

11 Caustic Soda 1 Krg 10 Krg

12 Ortho phosporic acid 1 Btl 16 Btl

APD

10 Sarung Tangan Katun 50 Paa 200 Paa

11 Masker 50 Pcs 200 Pcs

12 Majun 10 Kg 25 kg

13 Sarung tangan karet 10 Paa 20 Paa

14 Baju Lab 1 pcs 1 pcs

15 Kaca Mata 1 pcs 3 pcs

16 Respirator 1 pcs 2 pcs

PIC Mengetahui

CHECKSHEET PRE-OPERATIONAL

LABORATORIUM PEUP5

HARI/TANGGAL : Ket : OK : V

PIC : NG : X Fransiska M.

NO EQUIPMENT ITEM PENGECHECKAN

Verifikasi pH meter Conduct meter KETERANGAN

Kelistrikan/batre

Alat Lab Bersih Sample Aquadest

(fungsi) Buffer Ph 4 Buffer Ph 7 Larutan KCL

1 pH Portable

2 Conduct meter

Pengujian dengan sampel Pengujian dengan

aquades sampel limbah

TSS : TSS :

COD : COD :

3 Spectro (pastel UV)

BOD : BOD :

TOC : TOC :

NO3 : NO3 :

Surf : Surf :

4 Photo Lab

5 Spektro AAS

Note : Pengecekan parameter mohon merefer ke IK - PED5 - 001 s/d 0019

Alat Ukur Availability Bersih Tidak retak Tidak bocor

6 Pipet Morh 5 ml

7 Pipet Morh 10 ml

8 Sentik DWA

9 Sentik Lab

10 Kuvet Spektro 50 mm

11 Pipet Morh 20 ml

12 Bulb Merah

13 Gelas Kimia 50 ml

14 Gelas Kimia 100 ml

15 Labu Takar 100 ml

16 Kaca Arloji

17 Kertas Saring

18 Petri Film

19 Gelas kimia 1000 ml

20 Kuvet Secomam

21 Corong kaca

22 Batang Pengaduk

23 Pipet Tetes

24 Gelas Ukur 100 ml

25 Gelas Ukur 1000 ml

26 Gelas Ukur 250 ml

27 Pipet morh 1 ml

28 Labu Takar 50 ml

29 Gelas Teko 2 Liter

30 Gelas Teko 5 Liter

31 Gelas Ukur 50 ml

32 Helas Ukur 20 ml

33 Gelas Ukur 5 ml

34 Thermometer Batang

PIC Mengetahui

CHECKSHEET HASIL UJI LAB

Data Analisa Lab Ket : OK : V

Tanggal : NG : X Fransiska M.

WWT Item PH TSS COD BOD TOC NO3 SUR Cond Ket

Standard

Inlet Die Lube Aktual

Judgement (OK/NG)

WWT Die Casting

Standard

Outlet WWT Die Casting Aktual

Judgement (OK/NG)

Standard

Inlet Coolant Aktual

WWT Machining / Judgement (OK/NG)

Elektrokoagulasi Standard

Outlet WWT Machining Aktual

Judgement (OK/NG)

Standard

Inlet Pretreatment Aktual

Judgement (OK/NG)

WWT Painting

Standard

Outlet WWT Painting Aktual

Judgement (OK/NG)

Standard

Inlet Raw Aktual

UF - RO SYSTEM Judgement (OK/NG)

MC Standard

Outlet UF- RO System Aktual

Judgement (OK/NG)

Standard

Inlet Raw Aktual

Judgement (OK/NG)

UF - RO SYSTEM PT

Standard

Outlet UF- RO System Aktual

Judgement (OK/NG)

You might also like

- Check List Start Up and Comissioning of Fire Pumps 2Document6 pagesCheck List Start Up and Comissioning of Fire Pumps 2ismail_khansNo ratings yet

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 pagesPunch List For Fire Water Pump & Foam Pump PackageGomathyselviNo ratings yet

- ZF5HP19 PDFDocument80 pagesZF5HP19 PDFtambache69100% (1)

- Lecture Part 5 - Plumbing ToolsDocument24 pagesLecture Part 5 - Plumbing Toolsruel_galutan100% (3)

- 03 TransmissionDocument121 pages03 TransmissionBeary McBeary100% (3)

- 3L Dads0002 M134D Minigun 03 22 18Document2 pages3L Dads0002 M134D Minigun 03 22 18Theodor EikeNo ratings yet

- Flare and BlowdownDocument37 pagesFlare and BlowdownAnonymous a4Jwz14W100% (3)

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- Database FundamentalsDocument31 pagesDatabase FundamentalsSoumen MandalNo ratings yet

- Tle - Cookery 7 - Q2 - W2Document10 pagesTle - Cookery 7 - Q2 - W2LUCILLE ANDREA DAUIS100% (1)

- Sewage Treatment Plant (STP) Log Book: KALYANI HOSPITAL Gurgaon Sector 14Document16 pagesSewage Treatment Plant (STP) Log Book: KALYANI HOSPITAL Gurgaon Sector 14Deepak panditNo ratings yet

- Industrial Brake Catalogue - Web 1Document15 pagesIndustrial Brake Catalogue - Web 1ashraf elsayedNo ratings yet

- 3.1.A Appendix - 1Document14 pages3.1.A Appendix - 1Lara ArinelliNo ratings yet

- Well Control and Subsea Drilling EquipmentDocument48 pagesWell Control and Subsea Drilling EquipmentYunita SelonikaNo ratings yet

- Daily Log Sheet EngineeringDocument10 pagesDaily Log Sheet EngineeringFakhriNo ratings yet

- 1185028747.2 en-US - Mining and Rock Excavation Torque SpecificationsDocument24 pages1185028747.2 en-US - Mining and Rock Excavation Torque SpecificationsJuan Yanayaco Ramos100% (1)

- Item Found Secnd TimeDocument73 pagesItem Found Secnd TimejunaidssNo ratings yet

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Prismaflex Illustrated Parts Manual 2014-07Document68 pagesPrismaflex Illustrated Parts Manual 2014-07Ricardo Cardenas100% (1)

- DJJ40142- MECHANICAL WORKSHOP PRACTICE 4 (GRINDINGDocument14 pagesDJJ40142- MECHANICAL WORKSHOP PRACTICE 4 (GRINDINGMira Amira100% (1)

- Machinetools 6Document40 pagesMachinetools 6Archit GyaneshwarNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- MSDS N7330Document11 pagesMSDS N7330rikiNo ratings yet

- BSB Rupture Disk With Safety Relief ValvesDocument8 pagesBSB Rupture Disk With Safety Relief ValvesChitikala RajeshNo ratings yet

- S/N Description StatusDocument40 pagesS/N Description Statusnay lin aungNo ratings yet

- SR - No Name Object Class CodeDocument5 pagesSR - No Name Object Class CodeYadav ShwetaNo ratings yet

- Daily Check Sheet PC2000-8 & PC1250 0708Document6 pagesDaily Check Sheet PC2000-8 & PC1250 0708Ferry SandraNo ratings yet

- TG-PM ChecklistDocument106 pagesTG-PM Checklistsudhansu8beheraNo ratings yet

- Technical Service Manual GuideDocument38 pagesTechnical Service Manual GuideJose Luis DiazNo ratings yet

- BUKU Installation Guide Attachment JTHB 210Document18 pagesBUKU Installation Guide Attachment JTHB 210ary guswantoroNo ratings yet

- Logsheet Housekeeping AmurangDocument21 pagesLogsheet Housekeeping AmurangPandu RhiNoz RespatiNo ratings yet

- 8 Maintenance Master Paln 2015 PrintingDocument20 pages8 Maintenance Master Paln 2015 PrintingyannesNo ratings yet

- SEML 2018 OJT Kamojang Presentation OKDocument56 pagesSEML 2018 OJT Kamojang Presentation OKRahmatul AnggiNo ratings yet

- Pump Data SheetDocument1 pagePump Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Welder Qualification Test: Field Inspection & Certification DossierDocument7 pagesWelder Qualification Test: Field Inspection & Certification Dossieradnanbutt1984No ratings yet

- PT Mandiangin Batu Bara Periodic Service Check SheetDocument12 pagesPT Mandiangin Batu Bara Periodic Service Check SheetkkmechNo ratings yet

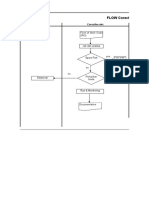

- Flow Chart AirDocument6 pagesFlow Chart AirAputMartinNo ratings yet

- PFD Bwro 4000 LPHDocument1 pagePFD Bwro 4000 LPHachmadinNo ratings yet

- Pre - Launching Check List TB 159Document2 pagesPre - Launching Check List TB 159konsultanptkarbatamNo ratings yet

- VL10 Service Installation Ver2c SN 001-012Document62 pagesVL10 Service Installation Ver2c SN 001-012andrea772No ratings yet

- Solenoid Valve: GeneralDocument3 pagesSolenoid Valve: GeneralJorge RodríguezNo ratings yet

- PSCS Periodic Service Check SheetDocument13 pagesPSCS Periodic Service Check SheetkkmechNo ratings yet

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- PVG32 Каталог SAE Версия HK.57.B1.22 PDFDocument44 pagesPVG32 Каталог SAE Версия HK.57.B1.22 PDFDeutsch themeNo ratings yet

- Inspection DT Scania 21633Document8 pagesInspection DT Scania 21633Sarohman RohmanNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- Service Manual - Lid45w13n (7312d)Document37 pagesService Manual - Lid45w13n (7312d)jupecas matosinhosNo ratings yet

- Logsheet 3hrDocument11 pagesLogsheet 3hrfaiz budiNo ratings yet

- Data Motor (New)Document10 pagesData Motor (New)riskyputrautama28No ratings yet

- SET UP THE AQUABLAST PRO WASHOUT MACHINEDocument19 pagesSET UP THE AQUABLAST PRO WASHOUT MACHINEAsadNo ratings yet

- Boiler HT CommDocument3 pagesBoiler HT CommBatsi BatsiNo ratings yet

- 360 BP'MCV, ReceivingDocument2 pages360 BP'MCV, ReceivingAimHighNo ratings yet

- Daily Kiln Job ListDocument6 pagesDaily Kiln Job ListbalakrishnaNo ratings yet

- Powerpoint Templates for Deepwater Drilling Equipment & Well Control < 40Document48 pagesPowerpoint Templates for Deepwater Drilling Equipment & Well Control < 40baharmarineNo ratings yet

- TRIAL RUN REPORTDocument1 pageTRIAL RUN REPORTMukesh GautamNo ratings yet

- APCOTEX Punch Point Document Listing Key TasksDocument20 pagesAPCOTEX Punch Point Document Listing Key TaskspowermuruganNo ratings yet

- Plant 5 Liquefaction ProcessDocument19 pagesPlant 5 Liquefaction ProcessLutfi FuadiNo ratings yet

- Generator OperationDocument26 pagesGenerator OperationNaren MeenaNo ratings yet

- SLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListDocument1 pageSLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListoksaNo ratings yet

- PVT ExpressDocument28 pagesPVT ExpressAlbertoNo ratings yet

- Establish Daily ChecklistDocument2 pagesEstablish Daily ChecklistRischa Br.TampubolonNo ratings yet

- Laboratory EquipmentDocument1 pageLaboratory EquipmentHuruma KibonaNo ratings yet

- List of Equipment To Be Included in AmendmentDocument10 pagesList of Equipment To Be Included in AmendmentElfawizzyNo ratings yet

- Top Source for Quality Water Filters & RO SystemsDocument52 pagesTop Source for Quality Water Filters & RO SystemsFranklin Jácome VargasNo ratings yet

- ROT104 RO Plant StartupDocument82 pagesROT104 RO Plant StartupAsma sultanNo ratings yet

- Preliminary Sewage Treatment ComponentsDocument3 pagesPreliminary Sewage Treatment ComponentsJudy Ann CastorNo ratings yet

- Cara Menghitung Ukuran Pipa Kapiler RefrigerasiDocument54 pagesCara Menghitung Ukuran Pipa Kapiler RefrigerasiZikko FirmansyahNo ratings yet

- Log Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018Document11 pagesLog Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018faiz budiNo ratings yet

- Lpu Pit ElektronikDocument1 pageLpu Pit ElektronikMerauke Town SquareNo ratings yet

- USER'S GUIDE TO CAMPER VAN FEATURESDocument84 pagesUSER'S GUIDE TO CAMPER VAN FEATURESxavi horNo ratings yet

- 4modelingandcontrolofdistillationcolumninapetroleumprocess 140320113744 Phpapp01 PDFDocument14 pages4modelingandcontrolofdistillationcolumninapetroleumprocess 140320113744 Phpapp01 PDFMohamed GuenouneNo ratings yet

- NS2-YT01-P0GN-120002-AB (Waste Water Treatment Plant) - MOTOR DATA SHEETDocument270 pagesNS2-YT01-P0GN-120002-AB (Waste Water Treatment Plant) - MOTOR DATA SHEETtrong ngoc PhanNo ratings yet

- JPKK - SUBMISSION STATUS FOR BUILDING MATERIALS AND EQUIPMENTDocument3 pagesJPKK - SUBMISSION STATUS FOR BUILDING MATERIALS AND EQUIPMENTReino YuNo ratings yet

- The Examination of Total Hardness On Drinking Water With Boiling and Filter Process Using Complexometry MethodDocument10 pagesThe Examination of Total Hardness On Drinking Water With Boiling and Filter Process Using Complexometry MethodrikiNo ratings yet

- List Pipa Inlet & Outlet Referensi P5 UpdateDocument2 pagesList Pipa Inlet & Outlet Referensi P5 UpdaterikiNo ratings yet

- CHECKSHEET ITEM KERJA WWT P5 LAYOFF (Responses)Document57 pagesCHECKSHEET ITEM KERJA WWT P5 LAYOFF (Responses)rikiNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- CO2 SolubilityDocument8 pagesCO2 SolubilityAnand SelveindranNo ratings yet

- Sertifikat EMS ISO 14001-2015 IATKP April 2018Document1 pageSertifikat EMS ISO 14001-2015 IATKP April 2018rikiNo ratings yet

- CC14 Pipe FlowDocument33 pagesCC14 Pipe Flow999impactNo ratings yet

- (KALO ADA YG SALAH BILANG YA!) OTK Perancangan Kolom Distilat Paw PDFDocument4 pages(KALO ADA YG SALAH BILANG YA!) OTK Perancangan Kolom Distilat Paw PDFrikiNo ratings yet

- MSDS N8073Document10 pagesMSDS N8073rikiNo ratings yet

- System TankDocument1 pageSystem TankrikiNo ratings yet

- Amalan YaumiyahDocument1 pageAmalan YaumiyahrikiNo ratings yet

- MSDS N9514 PDFDocument9 pagesMSDS N9514 PDFrikiNo ratings yet

- CC20 Measurement - PPT RepairedDocument34 pagesCC20 Measurement - PPT Repaired999impactNo ratings yet

- Databases For Beginners PDFDocument113 pagesDatabases For Beginners PDFDivaNo ratings yet

- Reiner AnderlDocument37 pagesReiner AnderlrikiNo ratings yet

- DistillationDocument10 pagesDistillationrikiNo ratings yet

- Reiner AnderlDocument37 pagesReiner AnderlrikiNo ratings yet

- ICBPT Cht3sep PDFDocument10 pagesICBPT Cht3sep PDFINGELAP. EIRLNo ratings yet

- CLE12T SparePartsDocument50 pagesCLE12T SparePartsХелфор УкраинаNo ratings yet

- Battlestrike Force of Resistance CheatsDocument2 pagesBattlestrike Force of Resistance CheatsRyan AguilarNo ratings yet

- ANSI-SAAMI Z299.5 2016 Abusive MishandlingDocument12 pagesANSI-SAAMI Z299.5 2016 Abusive Mishandlingbo cephusNo ratings yet

- 24 Brake SystemDocument36 pages24 Brake SystemTecnoCar Services SDRNo ratings yet

- Respaldos Eléctricos Planta MolyDocument3 pagesRespaldos Eléctricos Planta MolyEdwing William Salhuana MendozaNo ratings yet

- Pencil Grip Wire Driver: SERIES 1000Document2 pagesPencil Grip Wire Driver: SERIES 1000Mauricio MedinaNo ratings yet

- Mitsubishi C004B 2009-2010Document1,444 pagesMitsubishi C004B 2009-2010bhuppimehraNo ratings yet

- MODEL 1332 MODEL 1432: Slide LengthDocument8 pagesMODEL 1332 MODEL 1432: Slide LengthFabian FragosoNo ratings yet

- SD6 Valve DetailsDocument1 pageSD6 Valve DetailsVEERAMANINo ratings yet

- Hanabishi - February 2015Document4 pagesHanabishi - February 2015M Grazielle Egenias50% (2)

- MM1500i UK 1.4 DS 014 0218Document3 pagesMM1500i UK 1.4 DS 014 0218budi handoyo100% (1)

- Case wheel loader transmission repair kitDocument2 pagesCase wheel loader transmission repair kitJESUSNo ratings yet

- Metering DeviceDocument11 pagesMetering DeviceAshutosh PandeyNo ratings yet

- B41C - Spec Sheet BDocument1 pageB41C - Spec Sheet BgusmilexaNo ratings yet

- Juk MS-1190 1190MDocument28 pagesJuk MS-1190 1190MRHoskaNo ratings yet

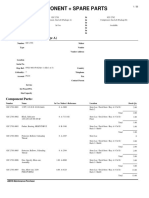

- Component + Spare Parts: Compressor, Gas Lift (Package A)Document30 pagesComponent + Spare Parts: Compressor, Gas Lift (Package A)VAN VIET NGONo ratings yet

- GH Manual 2014Document24 pagesGH Manual 2014Krisvell ArmentaNo ratings yet

- Legris Compression Fitting With PLDocument36 pagesLegris Compression Fitting With PLhannahveluz_iasNo ratings yet

- AUTOMATIC RIFLE 7.5", 11.5" / 14.5" / 20" : 5.56mm X 45mm Direct Impingement Gas-SystemDocument1 pageAUTOMATIC RIFLE 7.5", 11.5" / 14.5" / 20" : 5.56mm X 45mm Direct Impingement Gas-SystemCollin FarNo ratings yet