Professional Documents

Culture Documents

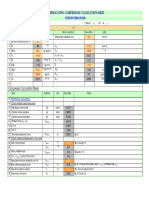

Pump Data Sheet

Uploaded by

ZUCEL ARLLETTE MAJUS CASTANEDA0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

Pump-Data-sheet

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pagePump Data Sheet

Uploaded by

ZUCEL ARLLETTE MAJUS CASTANEDACopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

A.K.C.

TECHNOLOGY

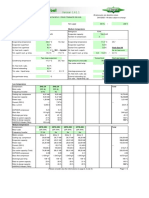

PUMP CALCULATION SHEET Document No.

Sheet of Rev.

Job Item No. (s)

Item Name. No. Working Total No. off

UNITS CASE I CASE II SKETCH OF PUMP HOOK-UP

1

2 Liquid Pumped

3 Corrosion/Erosion

4 Due To

5 Operating Temp. (T) o

C o

F

6 Specific Gravity at T

7 Viscosity cP cP

8 Vapor Pressure at T bar a psi a

9 Normal mass Flowrate kg/h lb/h

10 Normal Vol. Flowrate m3/h gpm

11 Min. Vol. Flowrate

12 Design Vol. Flowrate m3/h gpm

13 SUCTION CONDITION

14 Pressure at Equipment barg psi g + +

15 Static Head bar psi +/-

16 Total - Lines 14 + 15 bar psi + +

17 Suction Line P bar psi - -

18 Filter/Strainer P bar psi - -

19

20 Total Suction Pressure bar g psi g + +

21 DISCHARGE CONDITION

22 Pressure at Equipment bar g psi g + +

23 Static Head bar psi +/- +/-

24

25 Exchanger P bar psi + +

26

27 Furnace P bar psi + +

28 Orifice P bar psi + +

29 Control Valve P bar psi + +

30

31 Line P bar psi + +

32

33 Total Discharge Press. bar g psi g + +

34 Differential Pressure bar psi

35 Differential Head bar psi

36 NPSH NOTES

37 Total Suction Pressure bar a psi a 1. Pump shut-ff head not to exceed………

38 Vapor Pressure bar a psi a

39 NPSH - Lines 37 - 38 bar a psi a 2. Relief valve on pump discharge to be set at ……………

40 = m ft.

41 Safety Margin m ft. 3. Pump case design pressure…………

42 NPSH - Lines 40-41 m ft. design temperature……..

43 Hydraulic Power kW Hp

44 Estimated Efficiency % % 4. Sealing/flushing fluid available:

45 Estimated Abs. Power kW Hp

46 Type of Pump 5. Cooling medium available:

47 Drive

48 6. Insulation required:

49 Material - Casing

50 - Impeller 7. Start-up/commissioning fluid SG.

51 -Shaft

52

53 Sour Service Yes/No

54 HEAD m = 10.2 x bar /SG m = 10 x kg/cm2 / SG ft = 2.31 x psi / SG

55 VOLUME m3/h x SG x 1000 = kg/h igpm x SG x 600 = lb/h

56 POWER kW=m3/h x bar/36.0 kW=m3/h x kg/cm2 /36.71 Hp = igpm x psi/1427

57 1 Date 2 Date 3 Date 4 Date 5 Date

58 Description

59 Made/Revised by

60 Checked by

61 Approved Process

62 Approved

31

You might also like

- How to Read Circuit DiagramsDocument96 pagesHow to Read Circuit DiagramsDaniel CampbellNo ratings yet

- Koden Promotes Intelligent Foundation Work.: WWW - Koden-Electronics - Co.jpDocument2 pagesKoden Promotes Intelligent Foundation Work.: WWW - Koden-Electronics - Co.jpdennis rio perdana100% (1)

- Aircooled Heat Exchanger Process Data SheetDocument2 pagesAircooled Heat Exchanger Process Data SheetamitkrayNo ratings yet

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- Aecom PI&D PDFDocument1 pageAecom PI&D PDFJames HabibNo ratings yet

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 pagesPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNo ratings yet

- Turbine & AuxilariesDocument64 pagesTurbine & Auxilariesulhatolkargmailcom100% (1)

- Technical Information: Joystick Pvres and PvrelDocument16 pagesTechnical Information: Joystick Pvres and PvrelSUERDANOSSNo ratings yet

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- Performance Galileo Mx521Document1 pagePerformance Galileo Mx521Juan AlarconNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- Centrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryDocument1 pageCentrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryAthiphap Srisupareerath100% (1)

- Centrifugal Compressor System Design GuideDocument15 pagesCentrifugal Compressor System Design GuideใบบอนสิชลNo ratings yet

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Centrifugal Comp Calc Without ImpellerDocument8 pagesCentrifugal Comp Calc Without Impellersohail1985100% (1)

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Document8 pagesLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255No ratings yet

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Mekflu Lect4B Pumping System and Good PracticeDocument74 pagesMekflu Lect4B Pumping System and Good Practicebima0407No ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Pressurisation and Depressurization ResultsDocument8 pagesPressurisation and Depressurization ResultsQayyum KhanNo ratings yet

- PRESSURE SAFETY VALVE DATA SHEETDocument1 pagePRESSURE SAFETY VALVE DATA SHEETBABILIN VNo ratings yet

- ZIRCO PRESSURE/VACUUM RELIEF VALVE DATA SHEETDocument1 pageZIRCO PRESSURE/VACUUM RELIEF VALVE DATA SHEETharshkumar patelNo ratings yet

- Data Sheet SphericalDocument12 pagesData Sheet SphericalYosses Sang Nahkoda100% (2)

- 42 Pbab 399Document3 pages42 Pbab 399false mailNo ratings yet

- TSTPP Turbine InterlocksDocument39 pagesTSTPP Turbine InterlocksDenkaNo ratings yet

- Cara Menghitung Ukuran Pipa Kapiler RefrigerasiDocument54 pagesCara Menghitung Ukuran Pipa Kapiler RefrigerasiZikko FirmansyahNo ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Pump ScheduleDocument1 pagePump ScheduleZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- A List of Engineering Process Flow Diagrams and Process Data SheetsDocument97 pagesA List of Engineering Process Flow Diagrams and Process Data SheetsIsaias Garcia SanchezNo ratings yet

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- 附件1 海水泵浦之泵浦及馬達數據規格表Document3 pages附件1 海水泵浦之泵浦及馬達數據規格表駱建澄No ratings yet

- Log Sheet Lti Soda Recovery Description Unit RemarksDocument3 pagesLog Sheet Lti Soda Recovery Description Unit Remarkshemendra499No ratings yet

- Fan-Compressor Process Duty SpecificationDocument2 pagesFan-Compressor Process Duty SpecificationZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- CFBC ACL Log SheetDocument5 pagesCFBC ACL Log Sheetpulakjaiswal85No ratings yet

- BSPL PROJECT VIRAMGAM TERMINAL DATA SHEET FOR NON API CENTRIFUGAL PUMPSDocument2 pagesBSPL PROJECT VIRAMGAM TERMINAL DATA SHEET FOR NON API CENTRIFUGAL PUMPSsajeesh5113699No ratings yet

- Gas lift design finalDocument57 pagesGas lift design finalZehron ChemicalsNo ratings yet

- Run Compr Green Yellow Drycooler Bypass Final BudgetDocument5 pagesRun Compr Green Yellow Drycooler Bypass Final BudgetCamilo cardenasNo ratings yet

- Checking critical and subcritical flow conditionsDocument11 pagesChecking critical and subcritical flow conditionsDharmik PatelNo ratings yet

- Datasheet Valvulas de SeguridadDocument10 pagesDatasheet Valvulas de SeguridadEnderson OrtegaNo ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 pagesAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyNo ratings yet

- TBL 31 B HA en DC 004 A Safety Valve Design CalculationDocument37 pagesTBL 31 B HA en DC 004 A Safety Valve Design CalculationDangolNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- Data Sheet of Filtered WaterCentrifugal PumpDocument2 pagesData Sheet of Filtered WaterCentrifugal Pumpsajeesh5113699No ratings yet

- ALIVIATORDocument14 pagesALIVIATORPROCESOS PROCESOSNo ratings yet

- Pressure safety valve sizing for gas serviceDocument66 pagesPressure safety valve sizing for gas servicePROCESOS PROCESOSNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Department of Mechanical Engineering Refrigeration & Air Conditioning Lab Vapour Compression Unit AimDocument7 pagesDepartment of Mechanical Engineering Refrigeration & Air Conditioning Lab Vapour Compression Unit AimGaurav KhamesraNo ratings yet

- Boiler Control Room Data for NALCO Damanjodi 200 TPH UnitsDocument1 pageBoiler Control Room Data for NALCO Damanjodi 200 TPH Unitskoushikdey_2011No ratings yet

- Roll No: 184110033 Name: Dhiren MakwanaDocument4 pagesRoll No: 184110033 Name: Dhiren Makwanapoonam rathodNo ratings yet

- PA-FE-117Document2 pagesPA-FE-117milton1987No ratings yet

- Qatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1Document23 pagesQatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1varatharajan g rNo ratings yet

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- Rotary Pump Data SheetDocument6 pagesRotary Pump Data SheetCarlos GomezNo ratings yet

- 10.2478 - Scjme 2018 0030Document18 pages10.2478 - Scjme 2018 0030Eyob AdNo ratings yet

- Method Taken From Spirax Sarco Technical Guidance: Calculation No.: Sheet: Device Tag: DescriptionDocument9 pagesMethod Taken From Spirax Sarco Technical Guidance: Calculation No.: Sheet: Device Tag: Descriptionfahmi0% (1)

- EPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 ApprovedDocument15 pagesEPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 Approvedboy telerNo ratings yet

- Piping Pressure Drop and Pump SizingDocument3 pagesPiping Pressure Drop and Pump SizingElias EliasNo ratings yet

- Air Conditioning - Airteach - Provision Plant, A.C PlantDocument88 pagesAir Conditioning - Airteach - Provision Plant, A.C PlantGabriel AgafiteiNo ratings yet

- Éxito Unicentro Bogota Rev 3 1 Pack Transcr 230 3 60Document4 pagesÉxito Unicentro Bogota Rev 3 1 Pack Transcr 230 3 60Joaquin BusanicheNo ratings yet

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- A.K.C. TECHNOLOGY COLUMN SCHEDULEDocument1 pageA.K.C. TECHNOLOGY COLUMN SCHEDULEZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Tank Process Data SheetDocument2 pagesTank Process Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Fan-Compressor Process Duty SpecificationDocument2 pagesFan-Compressor Process Duty SpecificationZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Heat Exchanger Rating SheetDocument2 pagesHeat Exchanger Rating SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- PTS 13.90.012 Relay BoxDocument2 pagesPTS 13.90.012 Relay BoxNorisham Mohamed AliNo ratings yet

- Repair Parts - Combined UnitsDocument10 pagesRepair Parts - Combined Unitstotal totalNo ratings yet

- Manual PCUDocument32 pagesManual PCUAron VartaciNo ratings yet

- Format Data Loses & CentrifugeDocument2 pagesFormat Data Loses & CentrifugeDesberNatalyoSinagaNo ratings yet

- CAT4-2 Complete ENDocument264 pagesCAT4-2 Complete ENalltheloveintheworldNo ratings yet

- (Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394Document2 pages(Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394RD 88No ratings yet

- Understanding RelaysDocument75 pagesUnderstanding RelaysAnonymous vMzbUJNo ratings yet

- Gpd150-A N-Max Abs Electrical 1Document1 pageGpd150-A N-Max Abs Electrical 1apingNo ratings yet

- ZUEC 2022 Product GuideDocument12 pagesZUEC 2022 Product GuideBelly John CarbonellNo ratings yet

- Asiarep Indonesia CatalogDocument380 pagesAsiarep Indonesia Catalogaldino020203100% (1)

- 4100ES Fire Alarm System Installation Guide (574-848)Document222 pages4100ES Fire Alarm System Installation Guide (574-848)Mostafa AbdelhadiNo ratings yet

- 1.3 - Storage Revision WorkbookDocument8 pages1.3 - Storage Revision Workbook19iqbalmNo ratings yet

- Work Schedule Pet Value (Fire Pro)Document1 pageWork Schedule Pet Value (Fire Pro)Jayson TorresNo ratings yet

- Votoms RPG 1 4Document8 pagesVotoms RPG 1 4Javi NigranNo ratings yet

- Discipline Build GuideDocument11 pagesDiscipline Build Guidealmanet666No ratings yet

- Doble Bobina GS 125Document5 pagesDoble Bobina GS 125ROBINSON FERNEYNo ratings yet

- CID & SIA Event CodesDocument39 pagesCID & SIA Event CodesNestorNo ratings yet

- Ncase M1 v5 Build GuideDocument2 pagesNcase M1 v5 Build GuideLamanNo ratings yet

- Mac-Ts4: Magnetron Atmospheric Condition Test SetDocument15 pagesMac-Ts4: Magnetron Atmospheric Condition Test SetOctavian Antoniu RăducanuNo ratings yet

- ATS 125A-3200A Automatic Transfer SwitchDocument21 pagesATS 125A-3200A Automatic Transfer SwitchMark SheppardNo ratings yet

- MiniMk8 MM End User GuideDocument112 pagesMiniMk8 MM End User GuidemoatazNo ratings yet

- 250x200 CN4EA 518.5Document1 page250x200 CN4EA 518.5Hoàng Điệp NguyễnNo ratings yet

- GX531GS - GM - ServiceGuide - Chapter01-V1.0Document7 pagesGX531GS - GM - ServiceGuide - Chapter01-V1.0Dima RozhencovNo ratings yet

- Fiber Optic NotesDocument7 pagesFiber Optic NotesAmin JamaludinNo ratings yet

- Karoora Bitta Meeshalee 2014 - Jihaad Fi Firaol-1Document12 pagesKaroora Bitta Meeshalee 2014 - Jihaad Fi Firaol-1Firaol100% (1)

- g9sr Instruction Sheet enDocument2 pagesg9sr Instruction Sheet enSamer ChahroukNo ratings yet