Professional Documents

Culture Documents

Redesigning An Experiment To Determine The Coefficient of Friction

Redesigning An Experiment To Determine The Coefficient of Friction

Uploaded by

POH HSIN TANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Redesigning An Experiment To Determine The Coefficient of Friction

Redesigning An Experiment To Determine The Coefficient of Friction

Uploaded by

POH HSIN TANCopyright:

Available Formats

Journal of

Emerging Investigators

Redesigning an Experiment to Determine the Coefficient of

Friction

Alexander Hu and Bruce Peachey

Pittsford Mendon High School, Pittsford, NY

Summary

Typical high school physics experiments that investigate

friction coefficients usually use a weighted mass that

is dragged across a surface and is attached to a spring

scale; the spring scale measures the frictional force

occurring in the system. In such an experiment, a

constant velocity (zero net force) is necessary in order

to ensure that the measured force is only the friction

force. While this configuration is simple to conduct and

construct, it can be rather difficult to maintain a constant

velocity of the weighted mass and to read the moving

spring scale at the same time, which may result in large

errors. We attempted to solve these issues by designing a

new friction-coefficient experiment involving only static

measurements. To conduct our experiment, we slid a

block down a sloped surface and observed where the

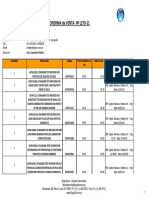

block landed. By measuring the horizontal distance of Figure 1: (a) shows the old, traditional experiment set up

the block’s landing location, we could definitively derive in high school labs and (b) shows the coefficients of kinetic

friction measured using this method.

the kinetic friction coefficient between the wood block

and the sloped board. The standard deviation from our

newly designed experiment is ~3 times smaller than observer can obtain the frictional force (Fμ) by reading

that of the traditional experiment, which demonstrates the spring scale. Then, one can directly calculate the

that our experiment may be a viable replacement for coefficient of kinetic friction for the setup (i.e., μ = Fμ/

standard high school physics experiments on kinetic Fn). The measurements of the coefficients of friction from

friction. This experiment can also enhance the learning

the traditional dynamic experiment are shown in Figure

of physics topics like Newton’s second law, motion in two

1b for twenty trials using a smooth wood-on-wood

dimensions, friction, and programming.

surface. The measured data fluctuated significantly.

Received: March 11, 2015; Accepted: February 18, This is because the observer must measure the friction

2016; Published: June 27, 2016 force by reading the moving spring scale while pulling

the object at a constant velocity. This makes precise

Copyright: (C) 2016 Hu and Peachey. All JEI articles measurement of μ difficult. In order to build a precise

are distributed under the attribution non-commercial, no system to determine the coefficient of kinetic friction,

derivative license (http://creativecommons.org/licenses/ we redesigned the experiment. By removing the need

by-nc-nd/3.0/). This means that anyone is free to to dynamically measure any forces, the redesigned

share, copy and distribute an unaltered article for non- experiment avoids the difficulty of keeping a constant

commercial purposes provided the original author and velocity in the traditional experiment, which can lead

source is credited. to large errors. The only measurements involved in

our newly designed experiment are the length (L) of a

Introduction sloped board, the height (H1) of the sloped board, the

In high school physics experiments, the most height (H2) of the table that the sloped board rests on,

common way to determine the kinetic friction coefficient and the horizontal distance D, as shown in Figure 2.

is to measure the normal force (Fn) produced by an Since all these quantities can be easily measured, we

object placed on a horizontal surface (1). Figure 1a hypothesized that this type of experiment should be

displays how such an experiment would be done. Fn more precise in comparison to the traditional experiment.

can be obtained by taking the mass of the object, then In addition, because this experiment uses well known

attaching a spring scale and pulling it horizontally until equations (like Newton’s second law, distance formula,

it overcomes the static friction. When the object is motion in two dimensions), performing this experiment

moving at a constant velocity, the horizontal net force can aid in the learning of physics concepts and

is zero according to Newton’s second law. Thus, the mathematical skills.

Journal of Emerging Investigators June 27, 2016 1

Journal of

Emerging Investigators

than the standard error of 0.005 in our new experiment.

This confirms that the results we obtained are more

precise, producing a much smaller standard deviation

than the traditional method.

Figure 3: The average kinetic friction coefficient for

each surface with error bars marking the standard

deviation.

Discussion

Figure 4 shows the expected result that the smooth

Figure 2: (a) and (b) show our experiment set up. As shown surface had a lower kinetic friction coefficient, ranging

in both figures, a block was initially balanced at the top on

its center of mass. It then slid down the sloped surface. from 0.32 to 0.397, for the twenty trials performed. The

Once it reached the end, it fell off with a horizontal and rough and the sanded surfaces had similar kinetic friction

vertical velocity. It impacted the sand-box at distance D. coefficients at about 0.45 to 0.55, which were higher

than that of the smooth surface. The sanded surface had

Results greater variation than the other surfaces. This is likely

The results from our new experiment are μ = in part because of the sawdust left on the board. As the

0.37±0.023, 0.49±0.017, and 0.50±0.027 for smooth, block slid down the sloped surface, it could have swept

rough, and sanded surfaces, respectively. The data are some of the sawdust off the board. Then when the block

presented in Figure 3, in which the measurement of the travels down the same path on a different trial, there is

friction between smooth surfaces using the traditional less sawdust left to slow it down. To try to avoid this,

dynamic method is also presented. Interestingly, the we re-sanded the surface every 5 runs. However, this

average kinetic friction coefficient for the smooth surface could still be the reason why we see large variation in

was μ = 0.37±0.023, which is reasonably similar, but the measured coefficients for the sanded surface. The

not exactly the same as the kinetic friction coefficient other possible source of error may be the fact that the

(μ = 0.30) for wood on wood given in the University of testing block tended to tumble in free-fall. This tumbling

the State of New York’s Reference Tables for Physical made the point of impact harder to determine in the sand

Setting/PHYSICS, 2006 Edition (2). This discrepancy box. This could have also caused variation in the data.

most likely lies in using different types of wood. The We expect that the error could be further reduced if a

results from the traditional method were μ = 0.388±0.063 heavier and smaller block were used. We also believe

for the smooth wood-on-wood surface, and the standard that by adjusting the angle of our sloped board, while

deviation (±16.24%) of the traditional experiment is keeping the board the same length, we could further

approximately ~3 times larger than what we got in our improve our experiment. In principle, changing the angle

new experiment (error-bar of ±6.2%), which reflects should not change our determined coefficient of friction.

the fact that the 20 trials yielded a larger distribution of This could be done in future experiments to further test

values for the predicted coefficient. The standard error and improve our system.

for the traditional experiment is 0.014, which is larger The goal of this project was to measure the coefficient

Journal of Emerging Investigators June 27, 2016 2

Journal of

Emerging Investigators

reference book. Since the friction coefficient derived

from both the traditional method and the new experiment

appears to agree, we conclude that the discrepancy lies

in differences between our specific wood samples and

those used in the reference book.

Methods

To test whether our newly designed experimental

system yielded a more precise measurement of

the coefficient of friction, we first established a new

experimental setup (Figure 2a). The experiment was

conducted as follows: a white pine-wood board with a

length of L was sloped at a certain angle, θ, set such

that the resulting height of the sloped board was H1. The

sloped board was placed at the edge of a table, with the

table’s height (H2) measured from the floor box. A wood

block with a mass (m), was placed at rest on the top of

Figure 4: The coefficients of friction for each

the sloped board, so that it balanced on its center of

surface and each trial, calculated with the measured

distances listed in Table 1 and the formulae in the mass. The block then slid down the sloped surface and

theory section. fell off the edge of the table in a parabolic manner. The

wood block landed in the sand box on the floor. This was

of friction in a system more precisely. We created a static repeated twenty times for each tested surface.

setup, shown in Figure 2, which consisted of a sloped In the experimental setup (Figure 2), H1, H2, and L

board, a table, and a box with sand to measure the were constant for all trials. A trial was defined as one

coefficient of kinetic friction. By measuring the length of run of the block sliding down the full length of the sloped

the sloped board (L) and the heights, H1 and H2, as well surface and falling into the box filled with sand. For all

as D, the horizontal distance that the block falls, we were experimental trials, the constants were: L = 91.76 cm,

able to calculate the coefficient of kinetic friction for the H1 = 45.56 cm, H2 = 75.57 cm. The tested surfaces were

wooden surfaces by using a FORTRAN-90 program. The smooth white pine, rough white pine, and sanded white

average kinetic friction coefficients and their standard pine with sawdust. The frictional coefficients for these

deviations were obtained by averaging the twenty three surfaces should be different, even for the same

experimental trials for each surface. We compared the wood block. The sanded board was re-sanded every 5

smooth surface data to the data measured from the trials to ensure the amount of sawdust on the board was

traditional method and found that our new method had approximately the same. The distance traveled by the

a much lower error. In the traditional experiment, the block, as shown in Figure 2b, was measured in every

standard deviation was approximately three times greater trial by a tape measure. The measurements are recorded

than the standard deviation in our new experiment. This in Table 1 and plotted in Figure 5. The distance was

suggests the traditional experiment is, as we expected, greater in the smooth-surface case than in the other

flawed in its precision. Furthermore, our newly designed two cases. Since there is less friction with the smooth

experiment enhances the learning of physics concepts, surface, the block had a higher horizontal velocity when

mathematical skills, and computer programming, and it fell off the end of the board and thus traveled farther.

promotes learning at the high-school level. We hope Our setup was built on top of a ping-pong table, as

that this easier and more precise method will be used shown in Figure 2a. We started by cutting a notch in the

to teach physics and replace the traditional method. vertical support to fit the sloped board. To stabilize the

We hope that the derivation of the formulas involved structure, we added a slanted support behind the vertical

will help high school students hone their physics skills support (see Figure 2a). We then prepared three sloped

and improve their understanding of mechanics such as boards for measuring the coefficient of friction: one with

acceleration, motion in two dimensions, friction, sloped a smooth surface, one with a rough surface, and one with

planes, and free-fall. a surface that was sanded with 60-grit sandpaper. Then

After conducting our experiment, we noticed that we acquired a box sufficiently large for our experiment,

the coefficients we determined did not quite agree with filled the bottom with sand, and put it directly under the

the result given in the reference book. The wood we edge of the table (see Figure 2a). We measured L, H1,

used was pine obtained from a local home improvement H2, and D with a tape measure. The small wooden block

store, while the type of wood was not specified in the was purchased at Home Depot.

Journal of Emerging Investigators June 27, 2016 3

Journal of

Emerging Investigators

Derivation and Theory

The net force acting on the block in this set-up

is parallel to the sloped surface and is equal to the

gravitational force component minus the friction force

(Figure 2b). According to Newton’s second law, the

system of motion along the sloped surface can be

described by the following equation:

In this equation, g is the gravitational constant

on earth, which is assumed to be 9.8066 m/s2 in this

experiment; μ is the frictional coefficient between

the wood block and the sloped surface, which is the

experimentally determined quantity. The variable α is the

acceleration of the block when it slides down the sloped

surface. From equation (1), we can express the friction

coefficient as:

Table 1: Distances in cm for D measured in the new

Equation (2) indicates that the friction coefficient is

experiment.

independent of the block mass, and if the acceleration

(α) of the block is known, we can determine the friction

coefficient. To determine the acceleration, we used the

distance and velocity formula:

Here, ν t = 0 because the block is at rest initially. By

combining the above two equations and eliminating time

(t), we obtain a = v2 /2L, with the final velocity (ν) of the

block at the end of the slope. Thus, plugging α into Eq.

(2), we can rewrite μ as:

Figure 5: Data collected for the length of D in

centimeters. As one can see, the distance traveled for Now, if we know the final velocity (ν), we can determine

each surface remains relatively concentrated except for μ using the above equation. As the schematic diagram

the sanded surface.

Figure 2b shows, the block, having the velocity ν at the

end of the sloped board, fell off the board at the table

For each experimental trial, we balanced the block edge at a height of H2. It landed in the sand box at a

on top of the sloped board and nudged it to initiate distance of D, which was measured from the table edge.

movement. The block slid down the slope and fell into With distance D, we calculated the falling time, t 2:

the sand box on the floor. We marked the spot where

the block first impacted the sand and measured the

distance, D, using a measuring tape. The data from these

measurements was then inputted into our program that This gave the free-fall time:

calculated the coefficients of friction. The FORTRAN-90

program also did the statistics, calculating the averaged

frictional coefficients and their standard deviations.

Journal of Emerging Investigators June 27, 2016 4

Journal of

Emerging Investigators

Here, νh is the horizontal component, relative to the

ground, of velocity ν, as shown by Figure 2b. With t 2 in

Eq. (7), we can find the vertical component, ν v, since we

know the height of H2, by using the distance formula:

The standard error of the mean is defined as

These calculations have also been

coded in the same FORTRAN-90 program that can

We substituted Eq. (7) into the above equation and be available upon request (please email questions@

obtained: emerginginvestigators.org).

References

1. Wilson, Jerry D., Anthony J. Buffa, and Bo Lou.

Because νh in this system is equal to νcosθ and that ν v Physics. Seventh ed. San Francisco: Addison-Wesley,

is equal to νsinθ, we substituted them into Eq. (9) to get: 2010.

2. University of the State of New York’s Reference Tables

for Physical Setting/PHYSICS, 2006 Edition.

Because tanθ = sinθ/cosθ, the above Eq. (10) can be

simplified as:

This yielded the following expression:

Thus, we further simplified it to isolate ν 2:

Substituting the expression for ν 2 into Eq. (5), we

obtained:

This can be finally simplified into:

Because and ,

we only have to measure the quantities of H1, H2, L, and

D to determine the coefficient of kinetic friction between

the wood block and wood surface using Eq. (15).

The data presented in Table 1 and Figure 5 was

calculated using Eq. (15) in a FORTRAN-90 program,

shown in the appendix. The calculated friction

coefficients for the three testing surfaces are displayed

in Figure 4. The average kinetic friction coefficients

and their standard deviation (δμ) were calculated

using the following formula:

Journal of Emerging Investigators June 27, 2016 5

You might also like

- Anthony Esposito - Fluid Power With Applications - 7ed PDFDocument653 pagesAnthony Esposito - Fluid Power With Applications - 7ed PDFCarina Roper100% (10)

- Report Full Direct Shear Test Edit (Repaired)Document15 pagesReport Full Direct Shear Test Edit (Repaired)Asyraf Malik100% (15)

- Dynamic Experiment 1 (Vibration)Document16 pagesDynamic Experiment 1 (Vibration)Apostrophe Fareez Imprezza100% (1)

- Compression Lab ReportDocument15 pagesCompression Lab ReportThomas Owens43% (14)

- From Burst Test To Bi-Axial Tensile TestDocument15 pagesFrom Burst Test To Bi-Axial Tensile TestJustin MillerNo ratings yet

- MAE 409A Finite Element Methods 1 Final LabDocument21 pagesMAE 409A Finite Element Methods 1 Final LabChris OrozcoNo ratings yet

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocument26 pagesHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- Instruction: Se RviceDocument3 pagesInstruction: Se RvicecarlNo ratings yet

- An Oscillating System With Sliding FrictionDocument5 pagesAn Oscillating System With Sliding FrictionKATERINE POSSO TRUJILLONo ratings yet

- Kinetic Friction: Experiment #13Document8 pagesKinetic Friction: Experiment #13kate anne del castroNo ratings yet

- 4 Sliding Friction LabDocument3 pages4 Sliding Friction LabMichelle BandieraNo ratings yet

- Mec 424 - Laboratory Report Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingDocument16 pagesMec 424 - Laboratory Report Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingNonaneNo ratings yet

- Lab 5 Lab ReportDocument5 pagesLab 5 Lab Reportapi-272572831100% (7)

- DiscussionDocument5 pagesDiscussionmtrego9441No ratings yet

- LABREP3Document4 pagesLABREP3Julia LovinoNo ratings yet

- Stress in SilosDocument4 pagesStress in SilospartomaneshNo ratings yet

- Mallet2013 Article EffectiveElasticPropertiesOfCrDocument8 pagesMallet2013 Article EffectiveElasticPropertiesOfCrHaziq QureshiNo ratings yet

- Iss15 Art2 - Simulation of Soil Nail's Dynamic Pullout ResponseDocument3 pagesIss15 Art2 - Simulation of Soil Nail's Dynamic Pullout ResponseLincoln FernandezNo ratings yet

- Measurement of Gravitational Constant: Stephen TranovichDocument5 pagesMeasurement of Gravitational Constant: Stephen TranovichEnrayNo ratings yet

- Impulse Momentum LabDocument3 pagesImpulse Momentum LabAbhinav RaghavanNo ratings yet

- Experiment 5: Hooke's LawDocument8 pagesExperiment 5: Hooke's LawDave Vendivil SambranoNo ratings yet

- Week 8Document17 pagesWeek 8Aniculaesi MirceaNo ratings yet

- Seismic Earth Pressure On Deep Stiff Soil (Wagner, Sitar-UC Berkeley)Document10 pagesSeismic Earth Pressure On Deep Stiff Soil (Wagner, Sitar-UC Berkeley)Germar PorquerinoNo ratings yet

- SPE 152595 Optimizing Hydraulic Fracture Spacing in Unconventional ShalesDocument12 pagesSPE 152595 Optimizing Hydraulic Fracture Spacing in Unconventional ShalesRanggaNo ratings yet

- Research JournalDocument10 pagesResearch JournalNagarajan PNo ratings yet

- E Xperiment 102 Friction: InstructorDocument6 pagesE Xperiment 102 Friction: InstructorHunter JonesNo ratings yet

- E205: Hooke'S Law POLICIOUS, Mark Angelo FDocument6 pagesE205: Hooke'S Law POLICIOUS, Mark Angelo FMark Angelo PoliciosNo ratings yet

- pvp2000 Vol399Document4 pagespvp2000 Vol399Bogdan GabrielNo ratings yet

- PHYS201 - Lab 5 Coefficient of Friction: Instructional GoalsDocument8 pagesPHYS201 - Lab 5 Coefficient of Friction: Instructional GoalsEmily SilmanNo ratings yet

- Damping Lab 1Document60 pagesDamping Lab 1Robert Lau Yik SiangNo ratings yet

- E105 - FrictionDocument11 pagesE105 - FrictionvinceNo ratings yet

- VL2 ReportDocument25 pagesVL2 ReportMatthew NelsonNo ratings yet

- Direct Shear TestDocument19 pagesDirect Shear Testshahrolhazrien75% (4)

- Shear Tests On PhyllitesDocument8 pagesShear Tests On PhyllitesDelvin JacobsNo ratings yet

- 68406-Ch 02Document28 pages68406-Ch 02Kirat Kamboz100% (1)

- Bi Axial ExtensionDocument8 pagesBi Axial ExtensionPHAM Duong HungNo ratings yet

- 6 - Budijanto Widjaja-UNPARDocument5 pages6 - Budijanto Widjaja-UNPARMuhammad LutfhiNo ratings yet

- Report 5Document6 pagesReport 5Paul Adrian JavénNo ratings yet

- Physics Spa Skill 3 Planning OutlineDocument3 pagesPhysics Spa Skill 3 Planning OutlinexeonzwongNo ratings yet

- Learning Objectives: IB Physics Verification of G 9.81 MsDocument13 pagesLearning Objectives: IB Physics Verification of G 9.81 MsMehdi KhfifiNo ratings yet

- Experiment of Free Vibration: Natural Frequency of Spring-Mass System Without DampingDocument18 pagesExperiment of Free Vibration: Natural Frequency of Spring-Mass System Without DampingSuperHero JeroJeroNo ratings yet

- Sample Data Atwood's MachineDocument8 pagesSample Data Atwood's MachineBrenn WhitingNo ratings yet

- Coefficient of Kinetic Friction and Drag ForceDocument7 pagesCoefficient of Kinetic Friction and Drag ForcejhhjjhNo ratings yet

- Friction LAB DefaultDocument4 pagesFriction LAB DefaultUmar HayatNo ratings yet

- A Simplified Method To Simulate Residual Stresses in PlatesDocument8 pagesA Simplified Method To Simulate Residual Stresses in PlatesJosé Manuel Antunes Mendes GordoNo ratings yet

- Final Prac Manuals Signature-SignedDocument33 pagesFinal Prac Manuals Signature-SignedTheolan PillayNo ratings yet

- Ansys Full ReportDocument12 pagesAnsys Full ReportikhwanmazliNo ratings yet

- Carltonand Dahl 2022 ICSMGEDocument7 pagesCarltonand Dahl 2022 ICSMGEjuan muneraNo ratings yet

- Stress Inhomogeneity in Powder Specimens Tested in The Jenike Shear Cell: Myth or Fact?Document10 pagesStress Inhomogeneity in Powder Specimens Tested in The Jenike Shear Cell: Myth or Fact?Andres VallebellaNo ratings yet

- Khalfallah - Et - Al - 2002 - EJMAS - Anisotropic Parameter Identification Using Inhomogeneous Tensile TestDocument16 pagesKhalfallah - Et - Al - 2002 - EJMAS - Anisotropic Parameter Identification Using Inhomogeneous Tensile TestYasser BouktirNo ratings yet

- j4 2004 Yuruiz CacDocument18 pagesj4 2004 Yuruiz CacRena C. YuNo ratings yet

- A Semiempirical Approach To A Viscously Damped Oscillating SphereDocument10 pagesA Semiempirical Approach To A Viscously Damped Oscillating SphereMuramasa SenpaiNo ratings yet

- Shear Box Experiment ResultDocument5 pagesShear Box Experiment ResultBgee LeeNo ratings yet

- Simple Harmonic Motion 4-Factor Doe Lab ReportDocument6 pagesSimple Harmonic Motion 4-Factor Doe Lab Reportapi-501574538No ratings yet

- CheckongDocument25 pagesCheckongMaajith MarzookNo ratings yet

- PhysicslabwriteupDocument4 pagesPhysicslabwriteupapi-245070267No ratings yet

- Research Article: Friction Characteristics of Post-Tensioned Tendons of Full-Scale Structures Based On Site TestsDocument10 pagesResearch Article: Friction Characteristics of Post-Tensioned Tendons of Full-Scale Structures Based On Site Testselev lookNo ratings yet

- Wujhs: Detection of Structural Damage Through Changes in FrequencyDocument5 pagesWujhs: Detection of Structural Damage Through Changes in FrequencyvbdawariNo ratings yet

- The Nature of Quasistatic Deformation in Granular Materials: J.-N. RouxDocument5 pagesThe Nature of Quasistatic Deformation in Granular Materials: J.-N. RouxFionaRoyNo ratings yet

- Physics Lab ReportDocument8 pagesPhysics Lab ReportJoseph Bernard Cantre DalusongNo ratings yet

- Stress ConcentrationsDocument0 pagesStress Concentrations777894292No ratings yet

- Standard-Slope Integration: A New Approach to Numerical IntegrationFrom EverandStandard-Slope Integration: A New Approach to Numerical IntegrationNo ratings yet

- Blow-up Theory for Elliptic PDEs in Riemannian Geometry (MN-45)From EverandBlow-up Theory for Elliptic PDEs in Riemannian Geometry (MN-45)No ratings yet

- Heat Transfer in RadiatorsDocument20 pagesHeat Transfer in RadiatorsJignesh Gandhi100% (2)

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- L279-11 Proforma de Venta de Libros Formato Digital - GYM SADocument2 pagesL279-11 Proforma de Venta de Libros Formato Digital - GYM SAMarco RiveraNo ratings yet

- Arcelor en 10028-3Document5 pagesArcelor en 10028-3bugrauzgNo ratings yet

- FLUOR Lesson05 - Pumps TurbinsDocument155 pagesFLUOR Lesson05 - Pumps TurbinsHernâni CruzNo ratings yet

- Importance of Dimensionless Numbers in Mass TransferDocument27 pagesImportance of Dimensionless Numbers in Mass TransferAli AmmarNo ratings yet

- SKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveDocument11 pagesSKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveMohamed Abo elkhairNo ratings yet

- Module-Wise Questions (Prev Exams)Document10 pagesModule-Wise Questions (Prev Exams)Kiran ChristopherNo ratings yet

- ° To The Horizontal From A Point 80m Above A Level Plain. What Horizontal Distance Will It Cover Before It Strikes The Plain? AnsDocument4 pages° To The Horizontal From A Point 80m Above A Level Plain. What Horizontal Distance Will It Cover Before It Strikes The Plain? AnsClarence PortoNo ratings yet

- 4 Question 2 Worked ExampleDocument8 pages4 Question 2 Worked ExampleTomislav ŠimagNo ratings yet

- EC - I MCQ Question Bank On Unit 5 & 6-1Document12 pagesEC - I MCQ Question Bank On Unit 5 & 6-1Harshad jambhaleNo ratings yet

- Design of Steel StructuresDocument48 pagesDesign of Steel Structuressudhakarummadi87% (15)

- Mechanical BMC1.125 MC Us1 2BSP PN6 Q200Document8 pagesMechanical BMC1.125 MC Us1 2BSP PN6 Q200Obinna Okomgbor100% (1)

- Synchronous MotorsDocument16 pagesSynchronous MotorsSiddique MuhammadNo ratings yet

- BS en 10109-1-1996Document18 pagesBS en 10109-1-1996Martijn GrootNo ratings yet

- 6 ProblemsDocument10 pages6 ProblemsKobeNo ratings yet

- Base-Plate & AngkurDocument15 pagesBase-Plate & AngkurRicky al ikhsaniNo ratings yet

- Design Fabrication of Universal Driving Wheel With Forklift ApplicationDocument10 pagesDesign Fabrication of Universal Driving Wheel With Forklift Applicationkifle abelNo ratings yet

- FIG FIG F4300W32.051 F4300W32.051 FIG Fig No. NO. F4350-51A0 F4350-51A0 TRANSMISSION Transmission Transmission Transmission Case CaseDocument2 pagesFIG FIG F4300W32.051 F4300W32.051 FIG Fig No. NO. F4350-51A0 F4350-51A0 TRANSMISSION Transmission Transmission Transmission Case CaseIvan PalominoNo ratings yet

- Tyco - Fleksibilna CrijevaDocument10 pagesTyco - Fleksibilna CrijevaMuhidin KozicaNo ratings yet

- Vector Solved PDFDocument27 pagesVector Solved PDFtopherskiNo ratings yet

- Bridge Engg-Live Load Moment and Shear in BridgesDocument38 pagesBridge Engg-Live Load Moment and Shear in BridgesAdithya SKNo ratings yet

- Temporary Structures: Slab Form DesignDocument9 pagesTemporary Structures: Slab Form Designapi-19878202No ratings yet

- PSV WordDocument1 pagePSV WordL KISHORE REDDYNo ratings yet

- ME Engine Training Course MAN B W Diesel PDFDocument436 pagesME Engine Training Course MAN B W Diesel PDFTimmyJuriNo ratings yet

- Hryw 45 t5 GB PDFDocument6 pagesHryw 45 t5 GB PDFJonathan CastilloNo ratings yet

- Valve Actuators Technical Specs PDFDocument11 pagesValve Actuators Technical Specs PDFDeny Safari0% (1)