Professional Documents

Culture Documents

Toolbox4Planning - Concept of Engineering Work Flow For Process, Mechanical and Piping Engineeirng

Uploaded by

MuslimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toolbox4Planning - Concept of Engineering Work Flow For Process, Mechanical and Piping Engineeirng

Uploaded by

MuslimCopyright:

Available Formats

7/24/2021 Toolbox4Planning: Concept of Engineering Work Flow for Process,Mechanical and Piping Engineeirng

Lainnya

Buat Blog

Masuk

Toolbox4Planning

Where Planning Resources and Techniques are

Home About Download Tutorials Search This Site...

Search

6

Like

Subscribe to Primavera P6 and Project Controls

Concept of Engineering Work Flow for Process,Mechanical Share

Articles by Email: and Piping Engineeirng 60

E-mail Adress:

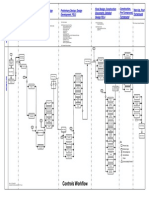

The concept of engineering work flow is required to understand for someone who involved in the activity

Share

Subscribe sequencing. This concept is applied when the EPC level 3 schedule is developed. The process of engineering

work to produce the required deliverables depends on not only within the functional discipline itself but also

ARCHIVES among the process, mechanical and piping engineering functions. The below net work diagram shows the links

December 2010 (7) among the process, mechanical and piping engineering deliverables for oil, gas and petrochemical project.

INDEX The diagram shows the input of process/utility engineering flow scheme (PEFS/UEFS) drawing is the process

Baseline flow scheme or process flow diagram (PFD) and process study.The input of engineering data requisition sheet

Constraint Date for mechanical equipment is the process data sheet consist of fluid properties, temperature and pressure rating.

Construction Planning

The requisition for equipments can be prepared when the specification and process data sheets are available.

The technical and commercial analysis report to be submitted to client and finalized prior to issue purchase

Construction schedule

order to equipment suppliers. The equipment loading data which is the inputs for civil and structure would be

Earned Value

available after the vendor started working on equipment drawings.

EPC planning

Excel Tutorial The plot plan is started to prepare when the process flow diagrams includes major equipment tap numbers are

Lookahead Schedule confirmed. Piping general arrangement (GA) drawings can be produced when the process and utility

Maintenance Planning engineering scheme and piping routing drawings are available. Iso drawings can be started to prepare after the

pipe support data and the latest PEFS/UEFS drawings are available. Piping material requisition can be

Maintenance schedule

prepared after the confirmation of piping specification and standard. The final MTO (material take off) and tie-in

Planner's Resources

list (if revamp scope is involved) are finalized upon the ISO drawings are issued. Upon confirmation of order,

Primavera P6 vendor drawings will be started working and issued for approval. The materials would be manufactured if the

Primavera P6 Tutorial drawings are approved.

Progress Calculation/Measurement

Sample Layout

Sample WBS

Sample Work Activity

Schedule Control

schedule design

Schedule development

Schedule Options

Schedule Report

Tank Construction

POPULAR POSTS

How to Get Resource Loading Histogram/S

Curve in Primavera P6

WBS ( Work Breakdown Structure ) for

Engineering and Construction

Tutorial-How to generate S curve/histogram

from Primavera, P6 - Part I

8 comments:

Excel 2003 Tutorial-Creating Progress S

curve

P6Ñ May 2, 2013 at 1:51 AM

Thanks for posting this explanation, it helped me.

Reply

Replies

Min Oo May 2, 2013 at 7:50 AM

www.toolboxforplanning.com/2010/12/concept-of-engineering-work-flow-is.html#.YPvM6XdR3IU 1/2

You might also like

- Certificate of ComplianceDocument3 pagesCertificate of ComplianceNeil100% (1)

- Project phases and deliverablesDocument1 pageProject phases and deliverablesEmmanuel Cervantes VelázquezNo ratings yet

- Manhours TableDocument9 pagesManhours TableJing JingNo ratings yet

- Deliverable List Rev.5-08062017Document6 pagesDeliverable List Rev.5-08062017rajkamal_e100% (1)

- COP WFP CHK 13 2013 v1 Structural Steel ErectionDocument3 pagesCOP WFP CHK 13 2013 v1 Structural Steel ErectionAbdelmuneimNo ratings yet

- Project SequenceDocument1 pageProject SequenceHamed ArianNo ratings yet

- Project Standards and Specifications Liquid and Gas Storage Rev01Document19 pagesProject Standards and Specifications Liquid and Gas Storage Rev01mhidayat108No ratings yet

- EPC For ASAB Phase-II Stage-2-LatestDocument2 pagesEPC For ASAB Phase-II Stage-2-LatestGokulprabhuNo ratings yet

- EPC Project - Typical Engineering Schedule Time (Project Month) Disc. ActivityDocument1 pageEPC Project - Typical Engineering Schedule Time (Project Month) Disc. ActivityDANIELNo ratings yet

- Nuts and Bolts of Project Management: Right Timing + Right Decision = SuccessFrom EverandNuts and Bolts of Project Management: Right Timing + Right Decision = SuccessRating: 5 out of 5 stars5/5 (1)

- Oil& Gas Projects Guided TourDocument206 pagesOil& Gas Projects Guided TourZeeshan Ahuja100% (1)

- FEED - Front End Engineering & Design in Oil & Gas Projects - CPO INNOVATIONDocument6 pagesFEED - Front End Engineering & Design in Oil & Gas Projects - CPO INNOVATIONdriveamar21No ratings yet

- Pre-Fab Headers Keep Job Ahead of ScheduleDocument1 pagePre-Fab Headers Keep Job Ahead of ScheduleMcKenney's IncNo ratings yet

- Head Manufacturing - ResumeDocument6 pagesHead Manufacturing - Resumerkgnanduri100% (4)

- I-70B Design Project ScopeDocument37 pagesI-70B Design Project ScopeRohan DangareNo ratings yet

- Engineering Documents in EPCDocument9 pagesEngineering Documents in EPCEditan IwedNo ratings yet

- Schedule LevelsDocument4 pagesSchedule LevelsNalini TiwariNo ratings yet

- Primavera P6 Reference Table For EPC andDocument1 pagePrimavera P6 Reference Table For EPC andhichemokokNo ratings yet

- Fluor Upfront BrochureDocument8 pagesFluor Upfront BrochureRiccardo GastaldoNo ratings yet

- Toolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringDocument1 pageToolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringMuslimNo ratings yet

- Toolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringDocument1 pageToolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringMuslimNo ratings yet

- List Documents DeliverablesDocument7 pagesList Documents DeliverablesDini Sulastri100% (1)

- Project Controls Flow Chart: Project Strategy Packaging Strategy Project Deliverables Project Maintenance Project ChangeDocument1 pageProject Controls Flow Chart: Project Strategy Packaging Strategy Project Deliverables Project Maintenance Project ChangeKhaled AbdelbakiNo ratings yet

- Lire KZHXQ PDFDocument1 pageLire KZHXQ PDFأصلان أصلانNo ratings yet

- SDI Service Desk Standard v6 1Document57 pagesSDI Service Desk Standard v6 1josecsantos83No ratings yet

- GM-TEG1-6220-006a1-p22 (Eingineering Work Flow)Document1 pageGM-TEG1-6220-006a1-p22 (Eingineering Work Flow)Sulist N WahyudieNo ratings yet

- German and International Cost IndicesDocument25 pagesGerman and International Cost IndicesagueromaNo ratings yet

- Siddhesh Updated Sp3dDocument4 pagesSiddhesh Updated Sp3dSiddhu DudwadkarNo ratings yet

- PROC-G-001 Procedure To Ensure Impartiality, Independence and Confidentiality.Document6 pagesPROC-G-001 Procedure To Ensure Impartiality, Independence and Confidentiality.Emily BrockNo ratings yet

- Lecture 6 EstimatingDocument97 pagesLecture 6 EstimatingrezadNo ratings yet

- 01 Teaching Front End Engineering Design FEEDDocument13 pages01 Teaching Front End Engineering Design FEEDJoshua Johnson100% (4)

- Engineering checklistDocument5 pagesEngineering checklistatocfemiaNo ratings yet

- 1-Industry Overview (TDP-101) PDFDocument35 pages1-Industry Overview (TDP-101) PDFtonylyf100% (7)

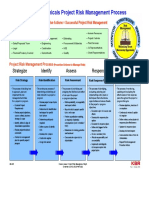

- Energy & Chemicals Project Risk Management ProcessDocument2 pagesEnergy & Chemicals Project Risk Management ProcessnbnbNo ratings yet

- Engineering Management WorkshopDocument20 pagesEngineering Management Workshopvantayusd0% (1)

- ALP-WP-3.05 Rev 1 PDFDocument60 pagesALP-WP-3.05 Rev 1 PDFOliverBrayanNo ratings yet

- Saipem Triune Engineering PVT Ltd. New Delhi, IndiaDocument18 pagesSaipem Triune Engineering PVT Ltd. New Delhi, IndiaKhurram Shadab IqbalNo ratings yet

- Yanbu Export Refinery Interface ManagementDocument14 pagesYanbu Export Refinery Interface ManagementIonut LefterNo ratings yet

- Business Process ManagementDocument36 pagesBusiness Process ManagementLuminita GrecuNo ratings yet

- Data Sheet for Power TransformerDocument3 pagesData Sheet for Power TransformerMuhammad Ibad AlamNo ratings yet

- Pistep Act ModDocument13 pagesPistep Act ModkamlNo ratings yet

- FEEDBasic EngineeringDocument4 pagesFEEDBasic EngineeringmgkvprNo ratings yet

- Protech Corporate PresentationDocument30 pagesProtech Corporate PresentationKamalMuralikumarNo ratings yet

- Dokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfDocument103 pagesDokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfAhmed AggourNo ratings yet

- Pitfalls of Testing and CommissioningDocument43 pagesPitfalls of Testing and CommissioningSCottNo ratings yet

- Tecnimont - Civil&InfrastructuresDocument17 pagesTecnimont - Civil&InfrastructuresAtish RedizNo ratings yet

- A Baron DefDocument2 pagesA Baron DefvonvoioNo ratings yet

- EPC SPAM - Conceptual DesignDocument20 pagesEPC SPAM - Conceptual DesignMeylisa SinagaNo ratings yet

- Execution PlanDocument4 pagesExecution Plansir1982No ratings yet

- Work Package - WBSDocument18 pagesWork Package - WBSRakesh RanaNo ratings yet

- ALASKA NATURAL GAS Pipeline Construction CostDocument1 pageALASKA NATURAL GAS Pipeline Construction CostNazar Mohamed Abd Elghani100% (2)

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaFrom EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNo ratings yet

- Toolbox4Planning - Basic Concept of Civil - Structure Engineering Work Flow For Schedule DevelopmentDocument1 pageToolbox4Planning - Basic Concept of Civil - Structure Engineering Work Flow For Schedule DevelopmentMuslimNo ratings yet

- An Introduction to Prefabricated Data CentersDocument36 pagesAn Introduction to Prefabricated Data CentersthongNo ratings yet

- Digital HR Project RAID Log Emplate V1.0Document11 pagesDigital HR Project RAID Log Emplate V1.0puuziNo ratings yet

- Issues, Risks, Assumptions, Questions & Decisions TemplateDocument5 pagesIssues, Risks, Assumptions, Questions & Decisions TemplateSimonGianoutsosNo ratings yet

- SPRDDocument49 pagesSPRDnomurapreNo ratings yet

- CO2 Plant Work Progress MeasurementDocument21 pagesCO2 Plant Work Progress Measurementt_i_f_ano100% (1)

- Piping - Process Design & DraftingDocument2 pagesPiping - Process Design & DraftingSuvidya Institute of TechnologyNo ratings yet

- Techno-Commercial Proposal PDFDocument5 pagesTechno-Commercial Proposal PDFHaris KhalidNo ratings yet

- Greenesol Power Systems Engineering CapabilitiesDocument30 pagesGreenesol Power Systems Engineering CapabilitiessrinivasanNo ratings yet

- BL Responsibilities TemplateDocument3 pagesBL Responsibilities TemplateAbdul MalikNo ratings yet

- Basrah Gas E+ps Contract InductionDocument4 pagesBasrah Gas E+ps Contract InductionraghebomNo ratings yet

- EPC ScheduleDocument81 pagesEPC ScheduleSatyajit MondalNo ratings yet

- 5s Evaluation Radar ChartDocument2 pages5s Evaluation Radar ChartUğur SAYILINo ratings yet

- Cost Estimating Planning - Petrofac PDFDocument2 pagesCost Estimating Planning - Petrofac PDFaliyousifNo ratings yet

- DOR-MER-PMT-RPT-0082 - QIT DORMS Project March. 2021 Monthly Progress ReportDocument26 pagesDOR-MER-PMT-RPT-0082 - QIT DORMS Project March. 2021 Monthly Progress ReportKENNETH IFEOSAMENo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IIank_mehra100% (1)

- Current Trend in Computer Aided Process Planning: Authers: Nafis Ahmad, Dr. A.F.M. Anwarul Haque, Dr. A. A. HasinDocument12 pagesCurrent Trend in Computer Aided Process Planning: Authers: Nafis Ahmad, Dr. A.F.M. Anwarul Haque, Dr. A. A. HasinRajeshNo ratings yet

- Resource-Controlling Template Eng v.2.0Document25 pagesResource-Controlling Template Eng v.2.0MuslimNo ratings yet

- Kolorsori Early Works Proposal November-March 2021-2022-Oct2021 - v2Document5 pagesKolorsori Early Works Proposal November-March 2021-2022-Oct2021 - v2MuslimNo ratings yet

- Analyzing P6 Schedules With Schedulereader: Online Training CourseDocument8 pagesAnalyzing P6 Schedules With Schedulereader: Online Training CourseMuslimNo ratings yet

- Primavera P6 FoundationDocument23 pagesPrimavera P6 FoundationMuslimNo ratings yet

- Advanced Primavera P6: Planning Construction Projects: On-Demand Video CourseDocument15 pagesAdvanced Primavera P6: Planning Construction Projects: On-Demand Video CourseMuslimNo ratings yet

- Forensik Schedule DelayDocument14 pagesForensik Schedule DelayMuslimNo ratings yet

- 375Document1 page375daniel_diazinesfacomNo ratings yet

- Case Study 1 - CRUZ (IS1)Document2 pagesCase Study 1 - CRUZ (IS1)Romano Cruz100% (1)

- BLF574Document18 pagesBLF574terminator_palitoNo ratings yet

- Field Notice / Site Instruction: Project Ref. Field Order No. Location Date Contractor Time Copies ToDocument3 pagesField Notice / Site Instruction: Project Ref. Field Order No. Location Date Contractor Time Copies ToCMGroupDavaoGrainTerminal Archen TechNo ratings yet

- B2B Technical TipsDocument24 pagesB2B Technical Tipskalva7No ratings yet

- Oracle® Database Patch 22243551 - Database Patch For Engineered Systems and DB In-Memory 12.1.0.2Document10 pagesOracle® Database Patch 22243551 - Database Patch For Engineered Systems and DB In-Memory 12.1.0.2Thiago MedeirosNo ratings yet

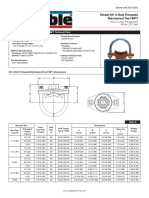

- Te Mecanica U-BoltDocument2 pagesTe Mecanica U-BoltJuan carlos santos jimenezNo ratings yet

- Exposre in Weblogic Server 11g and Experience in Integration Ebs With Sso/oamDocument6 pagesExposre in Weblogic Server 11g and Experience in Integration Ebs With Sso/oamMohammad ZaheerNo ratings yet

- Government OF Rajasthan Energy Department: Chapter-I Preliminary L. Short Title and Commencement.Document28 pagesGovernment OF Rajasthan Energy Department: Chapter-I Preliminary L. Short Title and Commencement.Anurag100% (1)

- Birdair Tensotherm Brochure - 2014Document4 pagesBirdair Tensotherm Brochure - 2014Angel ReyesNo ratings yet

- MW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Document7 pagesMW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Våïbhäv Çhåühåñ100% (1)

- MassDOT 5-Year Capital Investment PlanDocument150 pagesMassDOT 5-Year Capital Investment PlanThe Republican/MassLive.comNo ratings yet

- Iip Project On Cease FireDocument74 pagesIip Project On Cease FireSomraj Pathak100% (1)

- Godrej Product MixDocument10 pagesGodrej Product MixAritra SilNo ratings yet

- Value Analysis and Value Engineering in Material ManagementDocument12 pagesValue Analysis and Value Engineering in Material ManagementKarthik Soundarajan100% (1)

- Petrothene NA214000Document1 pagePetrothene NA214000Julio GarcíaNo ratings yet

- Pega Foundation Financial ServicesDocument29 pagesPega Foundation Financial ServicesUmangNo ratings yet

- Lean ThinkingDocument2 pagesLean ThinkingMMFAWZYNo ratings yet

- How to Renew Car Registration in RiyadhDocument4 pagesHow to Renew Car Registration in RiyadhterramocoNo ratings yet

- Be York Industrial Commercial Hvac 2018 PDFDocument220 pagesBe York Industrial Commercial Hvac 2018 PDFBruno VellinhaNo ratings yet

- KALIBRASI ALAT MITRAPAK-RecordDocument10 pagesKALIBRASI ALAT MITRAPAK-RecordfebiNo ratings yet

- Final Catalogue Tong AttachmentDocument5 pagesFinal Catalogue Tong AttachmentInamMuradNo ratings yet