Professional Documents

Culture Documents

Renk Single Marine Gears Units

Uploaded by

harith faizOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Renk Single Marine Gears Units

Uploaded by

harith faizCopyright:

Available Formats

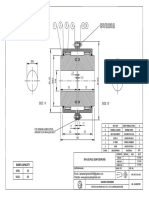

Gearboxes designed to meet maximum demands Specification / Accessories Specification / Accessories Main Dimensions

Power Take-Off

Gearing Casing Bearings Specification RSV / RSH :

• Single-stage design, driven PTOs for driving shaft gen-

by diesel engine or electric erators or pumps are avail-

The gearing is dimensioned The design of the casing and High-quality gearboxes require The following aspects are of

motor via flexible coupling. able in two different sys-

and designed for maximum foundation has a considerable bearings of special properties. particular benefit:

• Main shafts supported on tems:

safety and minimum noise and influence on the load-carrying RENK therefore pays close Maintenance of the thrust

vibration. These design targets characteristics of the gearing attention to the selection of bearing is possible without plain bearings

Secondary PTO (SPTO):

~ H (inclusive Oilcooler and Filter)

are achieved through optimum and bearings. safe and amply dimensioned draining the oil and disassem- • PTO shaft on standard roller

bearings, optionally on plain • Simultaneous operation

fine tuning of the macro and The casings are therefore tor- bearings that ensure high per- bling the gearbox housing.

bearings of shaft generator and

micro gearing geometry. sionally stiff structures with formance and an extraordinari- Astern and ahead pads of the

• Integrated thrust bearing propeller

strong internal ribs. ly long service life. Thick- thrust bearing are identical, a

The thrust bearing is located walled radial and axial bearings fact that simplifies replacement with circular thrust pads,

located on main engine Primary PTO (PPTO):

on the engine side. with circular thrust pads made to a considerable extent.

side. • Independent shaft gener-

for trouble-free operation and

• Attached and ready piped ator operation without

durability.

lube oil pumps: one electri- propeller.

cally / one mechanically

driven. The Primary PTO solution

• Instrumentation according requires 1 Multiple-Disc

to the rules and regulations Clutch.

of the relevant classification

society for unattended

operation.

• Housing of grey cast iron

with strong internal ribs for

maximum casing stiffness.

• Case-hardened helical gear-

RSV RSV PTO Shaft Casing Thrust approx.

ing with high-addendum

Size C- Position Position Weight

toothing Version

• Auxilliary equipment, such A A APTO E1 E2 E3 B C G H H M N [kN] [t]

as pumps, coolers, filters,

Power Take-In (PTI) RSVL 1000 wheel set with SPTO C-Version

Power Take-Home (PTH) and single stage PTH operation 500 560 315 500 450 360 600 180 690 2100 2160 1230 960 245 2,5

control & monitoring sys-

Dual-use electrical systems 560 630 315 530 500 380 670 200 770 2250 2320 1360 1060 302 3,5

tems, etc. ready piped and

Generator / Motor are 630 670 335 580 560 450 750 225 850 2400 2440 1510 1200 366 4,7

wired to the terminal box suited for two different

mounted on the gearbox. 670 710 335 630 600 460 800 250 900 2650 2690 1590 1130 472 5,6

operating modes:

• Spare parts according to 710 750 355 650 630 490 850 250 950 2750 2790 1700 1220 472 6,4

classification society • PTI: Power for propul- 750 800 375 670 670 500 900 280 1020 2850 2900 1780 1280 592 7,3

requirements. sion (Booster) 800 850 400 700 700 550 950 280 1070 3000 3050 1910 1380 592 8,8

850 900 425 780 750 570 1000 315 1140 3150 3200 1990 1440 774 10,5

Optional Accessories: • PTH: Auxiliary propulsion 900 950 450 800 800 610 1060 315 1200 3250 3300 2110 1530 774 12,5

• Turning device for turning for emergency operation 950 1000 450 850 850 650 1120 355 1270 3350 3400 2220 1620 979 14,5

the propeller shaft. (Prime Mover out of

1000 1060 475 900 900 680 1180 355 1370 3800 3860 2320 1700 979 17,0

• Multiple-Disc Clutches for

operation)

1060 1120 500 950 950 710 1250 400 1940 3950 4010 2460 1660 1068 20,6

PTO/PTH operation. RSV 630 with shaft brake

Power Take-Home systems 1120 1180 530 1020 1000 760 1320 400 2030 3400 3460 2560 1720 1209 23,8

• attached shaft brakes

usually require 2 Multiple- 1180 1250 530 1050 1000 790 1360 450 2100 3500 3570 2720 1850 1209 26,8

• wheel set for CPP pumps Disc Clutches 1250 1320 560 1100 1050 820 1400 450 2190 3650 3720 2880 1990 1319 31,2

1320 1400 560 1180 1120 880 1450 500 2330 3750 3830 3020 2100 1530 37,2

RSV 1060 1400 600 1240 1180 900 1500 500 2440 3950 3180 2230 1669 44,0

Further Products of our Programme

Product Support RENK Double Marine Gearboxes for Concepts – Types – Sizes

Ro-Pax-Ferries

All gearboxes are designed

and manufactured to the Type and Size Designations of RENK

following criteria: Single Marine Gearboxes

• Customer specification

• Classification rules and R RENK

regulations

S Single Marine Gearbox

• Internal RENK standards

V Vertical Offset

RENK´s internal standards H Horizontal Offset

cover the design and

Innovative Power Transmission L Multiple-Disc Clutch

dimensioning of the major

Our after-sales service team C Compact Version

gearbox components,

will arrange for and coordi-

Gearbox Concepts such as gearing, bearings,

nate all necessary meas-

for Propulsion thrust bearings and multi- Example 1:

ures to ensure competent

Systems ple-disc clutches. They

assistance and remedial

reflect the experience

action without any loss of

time. The gearbox is one of the

gained in the course of a

long tradition of gearbox

RSV 1060 C

key components of the pro- manufacturing.

We maintain the most pulsion system and RENK

advanced test and inspec- designed to perform a large RENK´s internal standards Single Marine Gearbox

tion facilities: Our highly qualified team of variety of functions, such as are in conformance with the

experts will be supporting

rules and regulations of the Vertical Offset

• 3D gear teeth measure- you once the ordered gear- • Reduction of the main 1060 mm Shaft Offset

classification societies.

ment box or coupling has left our engine speed to the Moreover, they are valuable Compact Version

• 3D coordinate measuring factory. The service team optimum propeller speed supplementary documents

machine can be contacted at any

and partly even exceed

• Crack testing, surface time to assist you with any • Power take-off (PTO) or classification requirements.

testing and ultrasonic questions or problems you power take-in (PTI) for or Example 2:

testing may have. Additionally, our NDSQL 4700 from auxiliary drives.

Gearing Measurement These standards therefore

• Endoscope for internal after-sales service depart-

RSHL 900

guarantee optimum per-

inspection ment is backed by a group The extensive experience formance, reliability and

of experienced field engi- RENK has gained over the longevity.

Upon completion of the neers. We continuously past several decades in the

analysis, you will receive a provide the members of design and manufacture of RENK

study report containing these teams with support in thousands of marine gear- Single Marine Gearbox

suggestions and recom- order to ensure that com- boxes constitutes a solid

mendations on how to pro- plex queries are resolved basis for the development

Horizontal Offset

ceed. fast and accurately. of optimum solutions which L Multiple-Disc Clutch

Single Marine

fully meet the customers´ 900 mm Shaft Offset

requirements. This experi-

ence guarantees maximum

reliability and a long service

life for one of the most

Standard Shaft Offset in mm:

Gears Units

essential components of a

ship´s propulsion system.

500 560 630 670 710

RENK Aktiengesellschaft 750 800 850 900 950

Rheine Plant • Rodder Damm 170 • D-48432 Rheine 1000 1060 1120 1180 1250

1320 1400

Type RSV/RSH

Phone: +49 5971 790 0 • Fax: +49 5971 790 208

Inspection of a Marine Gear Box Email: info.rheine@renk.biz

Internet: www.renk.biz 1500 to 22000 kw Power Range: 1 500 kW to 22 000 kW

Edition 02/2014

RENK - a member of the MAN Group

You might also like

- 08 - Newtons Laws Practice WorksheetDocument2 pages08 - Newtons Laws Practice WorksheetShiella Mae Baltazar Bulauitan50% (2)

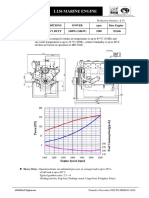

- Vpower / Mtu Series 1500RPM / 50HZ / 400V Vpower / Mtu Series 1500RPM / 50HZ / 400VDocument2 pagesVpower / Mtu Series 1500RPM / 50HZ / 400V Vpower / Mtu Series 1500RPM / 50HZ / 400Vchock channel 19No ratings yet

- MTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetDocument2 pagesMTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- V222Document2 pagesV222foxNo ratings yet

- PU158TI E1G Motor IndustrialDocument2 pagesPU158TI E1G Motor IndustrialANGEL UQUILLASNo ratings yet

- 2 Seats Go Kart Plans PDFDocument26 pages2 Seats Go Kart Plans PDFJorge EspinosaNo ratings yet

- Cambridge IGCSE™ Physics Workbook (Heather Kennett)Document82 pagesCambridge IGCSE™ Physics Workbook (Heather Kennett)sfaezali09No ratings yet

- Maintenance Manual, Sa S92A-Amm-000Document24 pagesMaintenance Manual, Sa S92A-Amm-000DanielNo ratings yet

- Renkmaag Synchronousclutchcouplings AllDocument4 pagesRenkmaag Synchronousclutchcouplings Allhumayun121No ratings yet

- RENK MAAG Turbo GearboxesDocument12 pagesRENK MAAG Turbo Gearboxeshumayun121100% (1)

- Technical Data: BCMU 700S-60 BCMU 650P-60Document3 pagesTechnical Data: BCMU 700S-60 BCMU 650P-60Jun AballeNo ratings yet

- RENK AED eDocument8 pagesRENK AED eZehraNo ratings yet

- 8N 8466Document3 pages8N 8466Rachid KerdidiNo ratings yet

- DE12TISDocument2 pagesDE12TISRowan CorneliusNo ratings yet

- Renk Curved Tooth Couplings Basic Construction Series enDocument52 pagesRenk Curved Tooth Couplings Basic Construction Series enhumayun121No ratings yet

- TNK60DG Taneko Gas Generator (TNK JKT)Document2 pagesTNK60DG Taneko Gas Generator (TNK JKT)hareudangNo ratings yet

- V222ti PDFDocument2 pagesV222ti PDFcmendezNo ratings yet

- Spec Sheet MTU 16V4000 DS2250 FC PDFDocument6 pagesSpec Sheet MTU 16V4000 DS2250 FC PDFMarison SaragihNo ratings yet

- 05 DPI May 17 ScribdDocument47 pages05 DPI May 17 Scribdratninp9368No ratings yet

- Renk Bearings RangeDocument2 pagesRenk Bearings Rangehumayun121No ratings yet

- Powerful and durable excavator for forestry workDocument9 pagesPowerful and durable excavator for forestry workAkhmad SebehNo ratings yet

- Operating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXDocument183 pagesOperating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXforuzzNo ratings yet

- P158LEDocument4 pagesP158LEjackacak100% (1)

- MTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratorDocument5 pagesMTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratordinukaeeNo ratings yet

- AVK MTU Diesel Generators 715-3300kVADocument2 pagesAVK MTU Diesel Generators 715-3300kVA5ofyNo ratings yet

- MTU Thesis FormatDocument23 pagesMTU Thesis FormatHla Min Htun100% (1)

- Dse8610 Data Sheet UsDocument2 pagesDse8610 Data Sheet UsAlfonso TorresNo ratings yet

- Engine DetailsDocument2 pagesEngine DetailsNeil GudiwallaNo ratings yet

- 21M Search and Rescue Vessel: Dimensional Data Standard FeaturesDocument1 page21M Search and Rescue Vessel: Dimensional Data Standard FeaturesNico BossiNo ratings yet

- Vietshipping 2008Document22 pagesVietshipping 2008minus89aspire100% (1)

- MTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2ADocument3 pagesMTU Gendrive Spec 12V16V18V2000Gx5 3D 3E W2Atinhotrading .jinchaoNo ratings yet

- Diesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)avinash_1229100% (1)

- Mtu 12v&16v2000m93Document2 pagesMtu 12v&16v2000m93vaibhavdabhade5No ratings yet

- MD196T Marine Engine SpecsDocument2 pagesMD196T Marine Engine SpecsMaurice ConnorNo ratings yet

- Renk PBLZ enDocument7 pagesRenk PBLZ enhumayun121No ratings yet

- L126TI Marine Engine Specs & RatingsDocument2 pagesL126TI Marine Engine Specs & RatingsmramicoNo ratings yet

- C1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Document62 pagesC1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Vinh Chu VănNo ratings yet

- 0505 Generel Description PDFDocument39 pages0505 Generel Description PDFVăn Tuấn NguyễnNo ratings yet

- RENK Range of CouplingsDocument2 pagesRENK Range of CouplingssurawutwijarnNo ratings yet

- FP 33 Fast Patrol Craft DatasheetDocument1 pageFP 33 Fast Patrol Craft DatasheetNico BossiNo ratings yet

- Billion M500 - UM - 1.04.1.1.1.01Document167 pagesBillion M500 - UM - 1.04.1.1.1.01Robert B. PopescuNo ratings yet

- 600kW Diesel Generator Set for Reliable PowerDocument5 pages600kW Diesel Generator Set for Reliable PowerheriNo ratings yet

- Renk Etax TechonologyDocument6 pagesRenk Etax Techonologyhumayun121No ratings yet

- MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670Document2 pagesMTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670jamal molana100% (1)

- Brochere Daewoo L126Document2 pagesBrochere Daewoo L126Farid Fuentes GonzalezNo ratings yet

- GV222TIDocument3 pagesGV222TInanocycleNo ratings yet

- Spec Sheet Mtu 16v4000 Ds2250 FCDocument6 pagesSpec Sheet Mtu 16v4000 Ds2250 FCMarison Saragih100% (1)

- TB 46204 f 50 Genset without heat recovery boxDocument7 pagesTB 46204 f 50 Genset without heat recovery boxmgewaliNo ratings yet

- Operating Instruction PWS 18-E (Gearbox) SEL 12 PDFDocument278 pagesOperating Instruction PWS 18-E (Gearbox) SEL 12 PDFGiannis MylonasNo ratings yet

- L136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146Document2 pagesL136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146RaymondNo ratings yet

- KG2Document3 pagesKG2anon_697917996No ratings yet

- Spec Sheet Mtu 12v4000 Ds1750 NeaDocument6 pagesSpec Sheet Mtu 12v4000 Ds1750 NeaTri Hudami WibowoNo ratings yet

- PIM130B1 - Honeywell AGT1500 Archived 03 2009 PDFDocument10 pagesPIM130B1 - Honeywell AGT1500 Archived 03 2009 PDF13421301508No ratings yet

- Qatar Coastguard 33m Patrol Boat NG956Document2 pagesQatar Coastguard 33m Patrol Boat NG956Nico BossiNo ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- (Approved) Doosan Infracore Integrated Report 2020 ENG (Final) PDFDocument72 pages(Approved) Doosan Infracore Integrated Report 2020 ENG (Final) PDFHeng GamingNo ratings yet

- DP222LB: Doosan Infracore Generator EngineDocument4 pagesDP222LB: Doosan Infracore Generator EnginemoisesNo ratings yet

- Mobil Delvac MX 15W40 Data SheetDocument4 pagesMobil Delvac MX 15W40 Data SheetJuan EstebanNo ratings yet

- MTU 1 ST YEAR SYLLABUSDocument80 pagesMTU 1 ST YEAR SYLLABUSaditya7195488No ratings yet

- Renk MaagDocument12 pagesRenk MaagDhananjay B KNo ratings yet

- E Molo MC001 E3 - Vis - DDocument85 pagesE Molo MC001 E3 - Vis - Deaglego00No ratings yet

- Shaft Mounted Speed Reducers SMSR & SMSR Plus SeriesDocument32 pagesShaft Mounted Speed Reducers SMSR & SMSR Plus SeriesAmit KumarNo ratings yet

- RB Flexible Coupling: The Standard Range ComprisesDocument12 pagesRB Flexible Coupling: The Standard Range ComprisesMoamenNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- FORM U-DR-2 USER REQUIREMENTSDocument2 pagesFORM U-DR-2 USER REQUIREMENTSCarlos Anibal OrtizNo ratings yet

- General Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)Document20 pagesGeneral Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)TuTuy AnNo ratings yet

- 6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityDocument1 page6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityShyam J VyasNo ratings yet

- Excavator Hydraulic Pump From Bailyn 20210616Document1 pageExcavator Hydraulic Pump From Bailyn 20210616luisNo ratings yet

- 50121-6-1 Eastern Pak PDFDocument1 page50121-6-1 Eastern Pak PDFJohn MaNo ratings yet

- FOCS Chiller RangeDocument8 pagesFOCS Chiller RangeDiogo PintoNo ratings yet

- Extra Wide Flange Beams - HL and HLZ: Section Properties - Dimensions and PropertiesDocument2 pagesExtra Wide Flange Beams - HL and HLZ: Section Properties - Dimensions and PropertiesdependNo ratings yet

- Stress AnalysisDocument4 pagesStress AnalysisSandeep BhatiaNo ratings yet

- XP Flare Article ReprintDocument5 pagesXP Flare Article ReprintAnonymous cuOIjrLINo ratings yet

- Gas Law FLORESDocument1 pageGas Law FLORESJustinne May SantosNo ratings yet

- Cpe 601 Mini ProjectDocument9 pagesCpe 601 Mini ProjectSchaieraNo ratings yet

- Pitch Angle Control For Variable Speed Wind TurbinesDocument6 pagesPitch Angle Control For Variable Speed Wind TurbinesNandan ModaniNo ratings yet

- Millis M. Warp Drives & WormholesDocument8 pagesMillis M. Warp Drives & WormholesAhmed Belber100% (1)

- AD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803Document46 pagesAD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803naokito AkemiNo ratings yet

- Lumbini Grade 9 Test 2 PhysDocument8 pagesLumbini Grade 9 Test 2 PhysSnow WhiteNo ratings yet

- Cooling of 1103A-33GDocument2 pagesCooling of 1103A-33GMd ShNo ratings yet

- Puch Magnum Owners ManualDocument34 pagesPuch Magnum Owners Manualrdf12345No ratings yet

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolNo ratings yet

- عزوزDocument3 pagesعزوزAhmad AbdNo ratings yet

- Lecture 01 PDFDocument7 pagesLecture 01 PDFNuta Marius AlexandruNo ratings yet

- Ae708 Question Bank 2Document5 pagesAe708 Question Bank 2pRoBoTRoGe OPNo ratings yet

- MotorDocument2 pagesMotorKeLvinLazyBoyNo ratings yet

- RT 8908LL Ingles PDFDocument254 pagesRT 8908LL Ingles PDFFernandoNo ratings yet

- Delivery Report Form ExcavatorDocument1 pageDelivery Report Form ExcavatorAkbarNo ratings yet