Professional Documents

Culture Documents

General Description Features: High Performance Current Mode PWM Controller

Uploaded by

Phạm Tấn HảiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Description Features: High Performance Current Mode PWM Controller

Uploaded by

Phạm Tấn HảiCopyright:

Available Formats

OB2283

High Performance Current Mode PWM Controller

GENERAL DESCRIPTION FEATURES

OB2283 is a highly integrated current mode PWM ■ Power on soft start reducing MOSFET Vds

control IC optimized for high performance, low stress

standby power and cost effective offline flyback ■ Frequency shuffling for EMI

converter applications. ■ Extended burst mode control for improved

PWM switching frequency at normal operation is efficiency and low standby power design

internally fixed and is trimmed to tight range. At no ■ Audio noise free operation

load or light load condition, the IC operates in ■ Peak load operation with increased frequency

extended ‘burst mode’ to minimize switching loss. ■ Comprehensive protection coverage

晖

Lower standby power and higher conversion o VCC Under Voltage Lockout with

efficiency is thus achieved. hysteresis (UVLO)

VCC low startup current and low operating current o VCC Over Voltage Protection (VCC OVP)

天

contribute to a reliable power on startup and low o Cycle-by-cycle over current threshold

standby design with OB2283. setting for constant output power limiting

OB2283 offers comprehensive protection over universal input voltage range

coverage with auto-recovery including Cycle-by- o Over Load Protection (OLP) with auto-

Cycle current limiting (OCP), over load protection recovery

(OLP), and VCC under voltage lockout (UVLO). It o External (if NTC resistor is connected at

also provides the protections with latched shut PRT pin)or internal Over Temperature

down including over temperature protection (OTP), Protection (OTP) with latched shut down

and over voltage protection (OVP). Excellent EMI o Output Over Voltage Protection(Output

performance is achieved with On-Bright OVP) with latched shut down, and the

proprietary frequency shuffling technique. OVP triggered voltage can be adjusted by

The tone energy at below 25KHz is minimized in the resistor connected between auxiliary

the design and audio noise is eliminated during winding and PRT pin

operation. o Output diode short protection with auto-

OB2283 is offered in SOT23-6 package. recovery

o GND open protection with auto-recovery

APPLICATIONS

Offline AC/DC flyback converter for

■ Printer, Storage power supply

■ Power Adapter

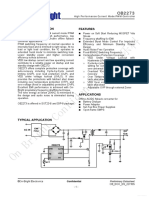

TYPICAL APPLICATION

EMI

AC IN

Filter DC

Out

Vaux

OB2283

6 FB VCC 1

5 PRT CS 2

4 GND GATE 3

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-1-

OB2283

High Performance Current Mode PWM Controller

Absolute Maximum Ratings

GENERAL INFORMATION

Parameter Value

Pin Configuration

VCC DC Supply Voltage VOVP-1V

FB Input Voltage -0.3 to 7V

VCC 1 6 FB CS Input Voltage -0.3 to 7V

PRT Input Voltage -0.3 to 7V

CS 2 5 PRT

Min/Max Operating

-40 to 150 ℃

Junction Temperature TJ

晖

Gate 3 4 GND

Min/Max Storage

-55 to 150 ℃

Temperature Tstg

天

Ordering Information Lead Temperature

260 ℃

Part Number Description (Soldering, 10secs)

OB2283MP SOT23-6, Pb-free in T&R Note: Stresses beyond those listed under “absolute

maximum ratings” may cause permanent damage to the device.

These are stress ratings only, functional operation of the device

Package Dissipation Rating at these or any other conditions beyond those indicated under

Package RJA(℃/W) “recommended operating conditions” is not implied. Exposure

SOT23-6 200 to absolute maximum-rated conditions for extended periods

may affect device reliability.

Recommended operating condition

Symbol Parameter Range

VCC VCC Supply Voltage 12 to 28V

Operating Ambient

TA -20 to 85 ℃

Temperature

OB2283 X X

High Performance Current Mode PWM

Package Package Pb-free

Controller

M:SOT23-6 P:Pb-free

Marking Information

83YWW S

. ZZZ

Y:Year Code

WW:Week Code(01-52)

s: Internal code

ZZZ: Lot code

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-2-

OB2283

High Performance Current Mode PWM Controller

TERMINAL ASSIGNMENTS

Pin Name I/O Description

VCC P Power Supply

CS I Current sense input

Gate O Totem-pole gate driver output for power MOSFET

GND P Ground

晖

Dual functions pin. Connecting a NTC resistor to ground for OTP detection.

Connecting a resistor from Vaux can adjust OVP trigger voltage. If both OTP and

PRT I

OVP are needed, a diode should be connected between PRT pin and the NTC

天

resistor.

Feedback input pin. The PWM duty cycle is determined by voltage level into this pin

FB I

and the current-sense signal at Pin CS.

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-3-

OB2283

High Performance Current Mode PWM Controller

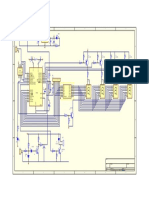

FUNCTIONAL BLOCK DIAGRAM

Logic

S Q Soft Driver

Control

R

OVP

OVP

晖

AVDD Diode

UVLO short

Diode

天

short

Internal

blocks OSC Slope LEB

Vref& OCP compensation

Iref Comparator Vocp

Diode

short OLP

AVDD

GND

open PWM

PK/Green/ Comparator

Burst

Temp

sense Timer OLP

OTP

EX OTP OVP

Latch

EX OVP

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-4-

OB2283

High Performance Current Mode PWM Controller

ELECTRICAL CHARACTERISTICS

(TA = 25℃, VCC=18V, unless otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VDD)

VCC=UVLO(OFF)-1V,

Istartup VCC Start up Current measure leakage 3 10 uA

current into VCC

VDD=18V,CS=4V,

I_VCC_Operation Operation Current FB=3.5V,measure 2.5 3 mA

晖

I(VCC)

CS=0V,FB=0.5V,

I_VCC_Burst Burst Current 0.55 0.65 mA

measure I(VCC)

天

VCC Under Voltage Lockout

UVLO(ON) 7 8 9 V

Enter

VCC Under Voltage Lockout

UVLO(OFF) 19 21 23 V

Exit (Recovery)

Vpull-up Pull-up PMOS active 10 V

FB=3V,CS=0V. Slowly

VCC Over Voltage Protection

OVP ramp VCC, until no 29 30 31 V

threshold voltage

gate switching.

Vlatch_release Latch release voltage 5 V

Feedback Input Section(FB Pin)

VFB_Open VFB Open Loop Voltage 5.1 V

Avcs PWM input gain ∆VFB/∆VCS 3.5 V/V

Maximum duty Max duty cycle @

75 78 81 %

cycle VCC=18V,VFB=3V,VCS=0V

Vref_green The threshold enter green mode 1.85 V

Vref_burst_H The threshold exits burst mode 1.33 V

The threshold enters burst

Vref_burst_L 1.23 V

mode

Short FB pin to GND

IFB_Short FB pin short circuit current 0.3 mA

and measure current

Open loop protection, FB

VTH_OLP 4.4 V

Threshold Voltage

Open loop protection,

Td_OLP 15 ms

Debounce Time

ZFB_IN Input Impedance 16 Kohm

Current Sense Input(CS Pin)

SST_CS Soft start time for CS peak 4 ms

T_blanking Leading edge blanking time 250 ns

From Over Current

Over Current Detection and Occurs till the Gate

Td_OC 90 ns

Control Delay driver output start to

turn off

Internal Current Limiting

VTH_OC Threshold Voltage with zero 0.43 0.45 0.47 V

duty cycle

VTH_OC_Clamp OCP CS voltage clamper 0.69 V

Vdiode_scp Diode short protection voltage 1.4 V

Td_dio Diode short debounce time 8 Cycles

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-5-

OB2283

High Performance Current Mode PWM Controller

GND open protection voltage

Vgnd_open difference between GND and 0.3 V

CS

GND open protection

Td_gnd_open 20 us

debounce time

Over Current protection

Td_OCP 60 ms

debounce Time

PRT pin

Output current for external OTP

IRT 95 100 105 uA

detection

晖

Threshold voltage for external

VOTP 0.95 1 1.05 V

OTP

天

Td_OTP External OTP debounce time 5 Cycles

Current threshold for adjustable

Ioutput_ovp 70 uA

output OVP

Td_output_ovp Output OVP debounce time 5 Cycles

In-chip OTP

OTP enter 150 ℃

OTP exit 120 ℃

Oscillator

VDD=18V,FB=3V,

FOSC Normal Oscillation Frequency 60 65 70 KHz

CS=0V

VDD=18V,FB=4.5V,

Fosc_PK Peak frequency 142 KHz

CS=0V

SST_freq Soft start time of frequency 30 ms

△f_OSC Frequency jittering +/-6 %

F_shuffling Shuffling frequency 32 Hz

Frequency Temperature

△f_Temp 1 %

Stability

△f_VCC Frequency Voltage Stability 1 %

F_Burst Burst Mode Switch Frequency 25 KHz

Gate driver

Output low level @ VDD=18V,

VOL 1 V

Io=5mA

Output high level @ VCC=18V,

VOH 6 V

Io=20mA

V_clamping Output clamp voltage 12 V

Output rising time 1.2V ~ 10.8V

T_r 160 ns

@ CL=1000pF

Output falling time 10.8V ~ 1.2V

T_f 50 ns

@ CL=1000pF

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-6-

OB2283

High Performance Current Mode PWM Controller

CHARACTERIZATION PLOTS

VDD = 18V, TA = 25℃ condition applies if not otherwise noted.

UVLO_ON vs Temperature UVLO_OFF vs Temperature

8 21

7.8 20.8

UVLO_OFF(V)

UVLO_ON(V)

7.6 20.6

7.4 20.4

晖

7.2 20.2

7 20

天

-40 -10 20 50 80 110 140 -40 -10 20 50 80 110 140

Tem perature(℃) Tem perature(℃)

Fosc vs Tem perature Ton_com p vs Tem perature

70 8

68 7.8

Ton_comp (us)

Fosc(KHz)

66 7.6

64 7.4

62 7.2

60 7

-40 -10 20 50 80 110 140 -40 -10 20 50 80 110 140

Temperature( ℃) Temperature( ℃)

VOTP vs Tem perature V TH_OC vs Tem perature

1.05 0.6

1.03 0.54

VTH _OC(V)

VOTP(V)

1.01 0.48

0.99 0.42

0.97 0.36

0.95 0.3

-40 -10 20 50 80 110 140 -40 -10 20 50 80 110 140

Temperature( ℃) Temperature( ℃)

OVP vs Tem perature IRT vs Tem perature

120

30

29.6 110

IRT (V)

29.2

OVP (V)

100

28.8

28.4 90

28 80

-40 -10 20 50 80 110 140 -40 -10 20 50 80 110 140

Temperature( ℃) Temperature( ℃)

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

7

OB2283

High Performance Current Mode PWM Controller

OPERATION DESCRIPTION

OB2283 is a highly integrated current mode PWM snubber circuit. The magnitude of power loss is in

control IC optimized for high performance, low proportion to the switching frequency. Lower

standby power and cost effective offline flyback switching frequency leads to the reduction on the

converter applications. The ‘extended burst mode’ power loss and thus conserves the energy.

control greatly reduces the standby power The switching frequency is internally adjusted at

consumption and helps the design easier to meet no load or light load condition. The switch

the international power conservation requirements. frequency reduces at light/no load condition to

improve the conversion efficiency. At light load or

Startup Current and Start up Control no load condition, the FB input drops below

晖

Startup current of OB2283 is designed to be very Vref_burst_L (the threshold enter burst mode) and

low so that VCC could be charged up above device enters Burst Mode control. The Gate drive

UVLO threshold level and device starts up quickly. output switches when FB input rises back to

天

A large value startup resistor can therefore be Vref_burst_H (the threshold exit burst mode).

used to minimize the power loss yet achieve a Otherwise the gate drive remains at off state to

reliable startup in application. minimize the switching loss and reduces the

standby power consumption to the greatest

Operating Current extend.

The Operating current of OB2283 is low at 2.5mA

(typical). Good efficiency is achieved with OB2283 Oscillator Operation

low operation current together with the ‘extended During the full load power operation, OB2283

burst mode’ control features. operates at a 65KHz (typical) fixed frequency. The

efficiency and system cost is controlled at an

Soft Start optimal level. A peak power mode is implemented

OB2283 features an internal 4ms (typical) soft to supply a peak current output requirement. In

start to soften the electrical stress occurring in the peak power mode, frequency is increased from

power supply during startup. It is activated during 65KHz (typical) to 142KHz (typical).

the power on sequence. As soon as VCC reaches At light load levels, OB2283 enters the light load

UVLO(OFF), the CS peak voltage is gradually mode, where the output current is reduced. The

increased from 0.05V to the maximum level. switching losses are reduced by lowering the

Every restart up is followed by a soft start. switching frequency.

Frequency shuffling for EMI improvement

The frequency shuffling (switching frequency

modulation) is implemented in OB2283. The

oscillation frequency is modulated so that the tone

energy is spread out. The spread spectrum

minimizes the conduction band EMI and therefore

eases the system design.

Current Sensing and Leading Edge

Blanking

Cycle-by-Cycle current limiting is offered in

OB2283 current mode PWM control. The switch

current is detected by a sense resistor into the CS

pin. An internal leading edge blanking circuit

chops off the sensed voltage spike at initial

internal power MOSFET on state due to snubber

Extended Burst Mode Operation diode reverse recovery and surge gate current of

At light load or no load condition, most of the power MOSFET. The current limiting comparator

power dissipation in a switching mode power is disabled and cannot turn off the internal power

supply is from switching loss of the MOSFET, the MOSFET during the blanking period. The PWM

core loss of the transformer and the loss of the

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

8

OB2283

High Performance Current Mode PWM Controller

duty cycle is determined by the current sense realized through time-division technology as

input voltage and the FB input voltage. shown in the figure.

For external OTP detecttion, when switch control

Internal Synchronized Slope Compensation signal S1= “1”, about 20uA (typical) current flows

Built-in slope compensation circuit adds voltage out from PRT pin. When switch control signal S0=

ramp into the current sense input voltage for PWM “1”,about 120uA (typical) current flows out from

generation. This greatly improves the close loop PRT pin. The PRT pin voltage difference △Votp

stability at CCM and prevents the sub-harmonic at phase S0 and S1 phase is equal to RT*Iotp.

oscillation and thus reduces the output ripple When △Votp<1V , external OTP latch protection

voltage. is triggered after 5 Gate cycles debounce.

晖

Driver For output OVP detection, when Sovp= “1”, Iovp is

The power MOSFET is driven by a dedicated gate equal to Vo/ROVP. If Iovp is larger than 70uA

driver for power switch control. Too weak the gate

天

(typical), OVP latch protection is triggered after 5

driver strength results in higher conduction and Gate cycles debounce. By selecting proper Rovp

switch loss of MOSFET while too strong gate resistance, output OVP level can be programmed.

driver strength results the compromise of EMI.

A good tradeoff is achieved through the built-in Protection Controls

totem pole gate design with right output strength Good power supply system reliability is achieved

and dead time control. The low idle loss and good with auto-recovery protection features including

EMI system design is easier to achieve with this Cycle-by-Cycle current limiting (OCP), and Under

dedicated control scheme. Voltage Lockout on VDD (UVLO), and latched

shutdown features including Over Temperature

Dual Function of External OTP and Output Protection (OTP), VCC and output Over Voltage

OVP Protection (OVP).

With On-Bright proprietary technology, the OCP is

line voltage compensated to achieve constant

output power limit over the universal input voltage

range.

At overload condition when FB input voltage

exceeds power limit threshold value for more than

Td_OLP, control circuit reacts to shut down the

converter. It restarts when VDD voltage drops

below UVLO limit. For protection with latched shut

down mode, control circuit shuts down (latch) the

power MOSFET when an over temperature

condition or over voltage condition is detected

until VDD drops below 5V (typical) (Latch release

voltage), and the device enters power on restart-

up sequence thereafter.

At output diode short condition, CS can ramp

higher than 1.4V (typical). After 8 cycles debounce

time for CS higher than 1.4V (typical), auto-

recover protection is triggered.

At GND open condition, the voltage of GND is

higher than CS. If GND is greater than CS+0.3V

(typical) for more than 20us (typical), auto-recover

protection is triggered.

On-Bright proprietary dual function of external Pin Floating and Short Protection

OTP and output OVP provides feasible and OB2283 provides PIN floating protection for all the

accurate detection of external OTP through NTC pins and pin short protection for adjacent pins. In

resistor and output OVP. The dual function is the cases when a pin is floating or two adjacent

pins are shorted, Gate switching is disabled.

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

-9-

OB2283

High Performance Current Mode PWM Controller

PACKAGE MECHANICAL DATA

晖

天

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 1.000 1.450 0.039 0.057

A1 0.000 0.150 0.000 0.006

A2 0.900 1.300 0.035 0.051

b 0.300 0.500 0.012 0.020

c 0.080 0.220 0.003 0.009

D 2.800 3.020 0.110 0.119

E 1.500 1.726 0.059 0.068

E1 2.600 3.000 0.102 0.118

e 0.950 (BSC) 0.037 (BSC)

e1 1.800 2.000 0.071 0.079

L 0.300 0.600 0.012 0.024

θ 0º 8º 0º 8º

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

- 10 -

OB2283

High Performance Current Mode PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements and other changes to its products and services at any time and to discontinue any product

or service without notice. Customers should obtain the latest relevant information before placing orders

and should verify that such information is current and complete.

WARRANTY INFORMATION

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications

applicable at the time of sale in accordance with its standard warranty. Testing and other quality control

晖

techniques are used to the extent it deems necessary to support this warranty. Except where mandated

by government requirements, testing of all parameters of each product is not necessarily performed.

天

On-Bright Electronics Corp. assumes no liability for application assistance or customer product design.

Customers are responsible for their products and applications using On-Bright’s components, data sheet

and application notes. To minimize the risks associated with customer products and applications,

customers should provide adequate design and operating safeguards.

LIFE SUPPORT

On-Bright Electronics Corp.’s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or

claims resulting from the use of its products in medical applications.

MILITARY

On-Bright Electronics Corp.’s products are not designed for use in military applications. On-Bright

Electronics Corp. will not be held liable for any damages or claims resulting from the use of its products in

military applications.

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_228300

- 11 -

You might also like

- ZS6312 V1.0Document12 pagesZS6312 V1.0Franzua PlasenciaNo ratings yet

- Circuit Diagram for 5V USB Power SupplyDocument1 pageCircuit Diagram for 5V USB Power Supplyelectro med100% (1)

- Boost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Document14 pagesBoost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Loengrin MontillaNo ratings yet

- LG 50PC5D Repair ManualDocument20 pagesLG 50PC5D Repair ManualJon HuttyNo ratings yet

- 20W Stereo Class-D Audio Amplifier With Power Limit and Dynamic Temperature ControlDocument3 pages20W Stereo Class-D Audio Amplifier With Power Limit and Dynamic Temperature ControlJibon DasNo ratings yet

- PF6000AGDocument1 pagePF6000AGlibre2009No ratings yet

- AMT SS-11aDocument2 pagesAMT SS-11aIR StudioNo ratings yet

- Jiuzhou dtt1609 Service Manual PDFDocument44 pagesJiuzhou dtt1609 Service Manual PDFVishu JoshiNo ratings yet

- Oscilador de TV Plasma Samsung MC34067P - MC33067PDocument17 pagesOscilador de TV Plasma Samsung MC34067P - MC33067PAntonio ChavezNo ratings yet

- SOD-80 (Melf) DiodesDocument3 pagesSOD-80 (Melf) DiodesWalter MarquezNo ratings yet

- HS8108Document8 pagesHS8108Miloš ZorićNo ratings yet

- Stormshield SN510: Business Continuity in Complex ArchitecturesDocument4 pagesStormshield SN510: Business Continuity in Complex ArchitecturesT AnnapooraniNo ratings yet

- Driver Rack DBX 480 - Power BoardDocument4 pagesDriver Rack DBX 480 - Power BoardWalter CruzNo ratings yet

- Pa-9312 9324 9336Document2 pagesPa-9312 9324 9336cadatiNo ratings yet

- Dual Synchronous Buck Converter: BD93291EFJDocument25 pagesDual Synchronous Buck Converter: BD93291EFJDjalma MotaNo ratings yet

- 715G6677 P02 001 0020+psuDocument6 pages715G6677 P02 001 0020+psuIvanilto Martins da Cruz100% (2)

- Panel Chimei Innolux v320bj3-p02 0Document30 pagesPanel Chimei Innolux v320bj3-p02 0doniNo ratings yet

- RSN311W64B PDocument1 pageRSN311W64B Pmiguel angel jaramilloNo ratings yet

- GTO Series: Service ManualDocument32 pagesGTO Series: Service ManualHardikNo ratings yet

- Clevo c4100 c4105 - 6-7p-c4104-003Document92 pagesClevo c4100 c4105 - 6-7p-c4104-003Łukasz Żurek0% (1)

- BN44-00554B PD32GV0Document3 pagesBN44-00554B PD32GV0Devorador De PecadosNo ratings yet

- Ka2206B 2.3W Dual Audio Power Amp: O CC L O CC LDocument4 pagesKa2206B 2.3W Dual Audio Power Amp: O CC L O CC LEdgar Robert DolarNo ratings yet

- U Supply Bench Rev BDocument1 pageU Supply Bench Rev BStoica Valentin CatalinNo ratings yet

- 500w Pro Audio-SchemaDocument1 page500w Pro Audio-SchemausernamescuNo ratings yet

- Scanning LIB. SPECIFICATION FOR APPROVALDocument14 pagesScanning LIB. SPECIFICATION FOR APPROVALgeorgelu100% (1)

- Circuit diagram with transistor layoutDocument1 pageCircuit diagram with transistor layoutFederico Urquiza100% (1)

- 13101715433434Document1 page13101715433434atomo33100% (3)

- Onkyo HT-R 397, HT-S 3900, HTP-395Document82 pagesOnkyo HT-R 397, HT-S 3900, HTP-395testperdidaNo ratings yet

- Assembly Manual K2639Document32 pagesAssembly Manual K2639Asse NavNo ratings yet

- ZUK Z1 - MB - H301-схемаDocument36 pagesZUK Z1 - MB - H301-схемаSergey GordienkoNo ratings yet

- DX 1227Document11 pagesDX 1227Marcos Daniel Muñoz ToledoNo ratings yet

- Piq201 Piq201: Pid101 Pid102 Piq502 Piq203 Piq403 Pid102 Pid101 Piq502Document3 pagesPiq201 Piq201: Pid101 Pid102 Piq502 Piq203 Piq403 Pid102 Pid101 Piq502dejanNo ratings yet

- PIC16 Sine-Wave InverterDocument2 pagesPIC16 Sine-Wave InverterNon DorelNo ratings yet

- WR - DA7 Manual de ServicioDocument86 pagesWR - DA7 Manual de ServicioDanielNo ratings yet

- Manual Service LN40C550J1RDocument86 pagesManual Service LN40C550J1RAngel Luciano Ramon GomezNo ratings yet

- MA5002VZ SM 130446-1amplificator ManualDocument140 pagesMA5002VZ SM 130446-1amplificator Manualtiganiada100% (1)

- Sony HCD Rv222 Ver 1.1Document86 pagesSony HCD Rv222 Ver 1.1Carlos Raul100% (2)

- 480 Communication BoardDocument4 pages480 Communication BoardTadas PNo ratings yet

- Ad52060 PDFDocument1 pageAd52060 PDFReyniel VazquezNo ratings yet

- Yamaha Rx330Document6 pagesYamaha Rx330George CtNo ratings yet

- PlxmanDocument83 pagesPlxmantedmich100% (1)

- SLC 7015Document1 pageSLC 7015Дмитрий КопышевNo ratings yet

- 2 Channel in 4 Channel Out ADAU1701 Sigma DSP Pre-Amplifier With Bluetooth Plug-In ModuleDocument12 pages2 Channel in 4 Channel Out ADAU1701 Sigma DSP Pre-Amplifier With Bluetooth Plug-In ModuleNicolae Nechifor100% (1)

- Map3202sirh Ic6900Document1 pageMap3202sirh Ic6900rammerDankovNo ratings yet

- Brojac BalaDocument1 pageBrojac Balamladen100% (1)

- 2m SCHDocument1 page2m SCHfsm400No ratings yet

- DDS RF Signal Generator Design GuideDocument9 pagesDDS RF Signal Generator Design GuideIan McNairNo ratings yet

- LG Eax41678701 Pspu-J706aDocument3 pagesLG Eax41678701 Pspu-J706aSérgio Henrique da Silva100% (1)

- High Performance Low Cost Off-Line PWM Power Switch: Features General DescriptionDocument1 pageHigh Performance Low Cost Off-Line PWM Power Switch: Features General DescriptionDesenvolvimento Qualitronix0% (1)

- Studiomaster Dja SeriesDocument2 pagesStudiomaster Dja SeriesJai Prakash ChauhanNo ratings yet

- Service Manual CD Stereo System NSX-D20 NSX-R20Document56 pagesService Manual CD Stereo System NSX-D20 NSX-R20taz1mxNo ratings yet

- Build a NiCd Battery Charger CircuitDocument1 pageBuild a NiCd Battery Charger CircuitdewasuryantoNo ratings yet

- 5L0380R PDFDocument1 page5L0380R PDFAyanda Mkhumane100% (1)

- Datasheet CM6802Document18 pagesDatasheet CM6802Gilson3DNo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- Sunrom 814104Document13 pagesSunrom 814104Valentin LeonteNo ratings yet

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- On-Bright Confidential To ACT: General Description FE AturesDocument10 pagesOn-Bright Confidential To ACT: General Description FE AturesJose BenavidesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- So Do Mach Nguon SwitchingDocument1 pageSo Do Mach Nguon SwitchingPhạm Tấn HảiNo ratings yet

- So Do Mach Nguon SwitchingDocument1 pageSo Do Mach Nguon SwitchingPhạm Tấn HảiNo ratings yet

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- So Do Mach Nguon SwitchingDocument1 pageSo Do Mach Nguon SwitchingPhạm Tấn HảiNo ratings yet

- MQ07 enDocument22 pagesMQ07 enmabruk12No ratings yet

- VFD M User Manual PDFDocument173 pagesVFD M User Manual PDFBarbara GamaNo ratings yet

- So Do Mach Nguon SwitchingDocument1 pageSo Do Mach Nguon SwitchingPhạm Tấn HảiNo ratings yet

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- MQ07 enDocument22 pagesMQ07 enmabruk12No ratings yet

- So Do Mach Nguon SwitchingDocument1 pageSo Do Mach Nguon SwitchingPhạm Tấn HảiNo ratings yet

- VFD M User Manual PDFDocument173 pagesVFD M User Manual PDFBarbara GamaNo ratings yet

- GNURadio Tutorials ReportDocument2 pagesGNURadio Tutorials Reportvignesh126No ratings yet

- ECEN620 - Network Theory Broadband Circuit Design Fall 2014 Lec 15 - Delay Locked Loops (DLLS)Document29 pagesECEN620 - Network Theory Broadband Circuit Design Fall 2014 Lec 15 - Delay Locked Loops (DLLS)Apoorva Bhatt100% (1)

- Ployphase DecompositionDocument29 pagesPloyphase DecompositionTechy GuyNo ratings yet

- MCQs Protection Engineering Booklet 2Document25 pagesMCQs Protection Engineering Booklet 2arsalanhamid100% (4)

- Roche Cardiac Reader ManualDocument59 pagesRoche Cardiac Reader ManualKate Camat FaminialagaoNo ratings yet

- Cathode Ray Oscilloscope - Class NotesDocument14 pagesCathode Ray Oscilloscope - Class NotesyayavaramNo ratings yet

- Fire Attitutes of Cable 2622Document16 pagesFire Attitutes of Cable 2622Farah WidyaNo ratings yet

- Title: Decoder Instruction AimsDocument4 pagesTitle: Decoder Instruction Aimssuv_fameNo ratings yet

- Kpi 2020Document7 pagesKpi 2020jemi rieNo ratings yet

- 10 Full Dual HVDCDocument21 pages10 Full Dual HVDCmohamedNo ratings yet

- Rigel Safetest 60: Electrical Safety AnalysersDocument2 pagesRigel Safetest 60: Electrical Safety Analysersheru pratiknoNo ratings yet

- 30073Document32 pages30073Faby GemeNo ratings yet

- LG Ffh-8900 AudioDocument34 pagesLG Ffh-8900 AudioRosario De Dios SanchezNo ratings yet

- Certificado Iec 62109 Up3000-Hm8041Document2 pagesCertificado Iec 62109 Up3000-Hm8041EMSE RENOVABLESNo ratings yet

- Manuel de Maintenance TEREXDocument454 pagesManuel de Maintenance TEREXanon_964686176100% (1)

- Common PB11486 enDocument144 pagesCommon PB11486 enAlessandro Ferrini0% (1)

- Non Idrive To Cic Retrofit Vlad's E92 (MR - Vys)Document6 pagesNon Idrive To Cic Retrofit Vlad's E92 (MR - Vys)leonNo ratings yet

- CM600DX 24T/CM600DXP 24TDocument14 pagesCM600DX 24T/CM600DXP 24TSherif SabryNo ratings yet

- Low Smoke HalogenDocument17 pagesLow Smoke HalogenquycoctuNo ratings yet

- MONITOR DE ISOLAÇÃO TERASAKI Earth - LeakageDocument5 pagesMONITOR DE ISOLAÇÃO TERASAKI Earth - LeakageclaudioandrevalverdeNo ratings yet

- 4 ECNG Over Current Relay CT CalcDocument28 pages4 ECNG Over Current Relay CT Calcom_23123062No ratings yet

- Prosys ps8810 User Manual PDFDocument121 pagesProsys ps8810 User Manual PDFcontrol remote02No ratings yet

- Temperature-Controllers English 2022-09 Lowres 8Document12 pagesTemperature-Controllers English 2022-09 Lowres 8javierNo ratings yet

- Lab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)Document13 pagesLab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)zain islamNo ratings yet

- Ignite User GuideDocument148 pagesIgnite User GuideTester QuesterNo ratings yet

- High Resolution and Standard Resolution Image ConduitsDocument6 pagesHigh Resolution and Standard Resolution Image ConduitsF Javier García DíazNo ratings yet

- Commodity ThermoplasticsDocument55 pagesCommodity ThermoplasticsBernard GanzwaNo ratings yet

- Astm G 138 2006 PDFDocument8 pagesAstm G 138 2006 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Sexto Reporte-ApéndiceDocument131 pagesSexto Reporte-Apéndiceduje_20081050No ratings yet

- XPSMC Hardware ManualDocument164 pagesXPSMC Hardware ManualEjaz Ahmed100% (1)