Professional Documents

Culture Documents

Service Bulletin: Power Distribution Box 17-3048 October 2010 New Power Distribution Box Water Integrity All With ESM

Uploaded by

dfmolinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Bulletin: Power Distribution Box 17-3048 October 2010 New Power Distribution Box Water Integrity All With ESM

Uploaded by

dfmolinaCopyright:

Available Formats

SERVICE BULLETIN

TOPIC: Power Distribution Box

IDENT NO: 17-3048

DATE: October 2010

SUPERSEDES: New

SUBJECT: Power Distribution Box Water Integrity

MODELS AFFECTED: All With ESM

The purpose of this Service Bulletin is to inform the

field of the need to maintain, at all times including

shipping, packaging, operation and troubleshooting,

the NEMA 4 watertight integrity that the Power

Distribution Box (PDB), A309204B, has when it leaves

the factory. 3

DESCRIPTION OF PDB

The PDB is the hub of the increasingly sophisticated 2

electronics used on modern Dresser Waukesha

engines. It serves as the power input point and

distributes power to most electrical subsystems

including the ESM. It also provides overcurrent 1

protection and has troubleshooting capabilities

(reference current release of SB 17-2996 for

information on resetting PDB). The PDB has been

factory-tested and proven to be watertight under

reasonable conditions. For proper engine operation

and to maintain the factory warranty, it is imperative to

preserve the watertight integrity of the PDB. Figure 1

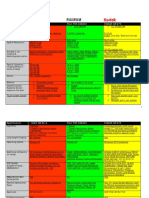

ADDING CUSTOMER-SUPPLIED WIRING 1 - Proper NEMA 4 3 - Factory-Supplied,

Style Connector Self-Centering 1-1/2

TO PDB 2 - Non-Approved in. Plug

Connector Without

When adding customer-supplied wiring to the PDB, all Grommet (allows

connectors, fittings and grommets used must have an water entry)

equivalent NEMA 4 rating. Using connectors, fittings or

As shipped from the factory, the PDB has several

grommets other than NEMA 4 rated style could allow

openings meant for unused electrical options and/or

water to enter the PDB, causing problems up to and

including failure of the PDB. See Figure 1 for customer connections. These openings are factory-

examples of both good and bad practice. sealed with either a push-in, self-centering, rubber

plug (1-1/2 in.) or a steel with rubber gasket plug that

must be manually centered and tightened with an

internal wing nut (3/4 in.). These plugs must remain

firmly in place at all times unless the opening is used

for wiring.

Service Bulletin 17-3048

© 10/2010 Page 1 of 2

Service Bulletin No. 17-3048

INSTALLING PDB COVER When the cover is properly installed, plugs are

properly in place and NEMA 4 connectors, fittings and

Be sure to properly reinstall the PDB cover any time grommets are used for wiring, the PDB is watertight

that it has been removed (see Figure 2) for wiring or under reasonable conditions.

troubleshooting using the internal LEDs. DO NOT

leave the cover off when work is not actively being NOTICE

done. This includes indoors or overnight. When

reinstalling the cover, all six latches must properly Use caution when pressure-washing the engine. Do

engage the cover and the latch screws must be tight. not spray the high-pressure water stream directly at

the cover gasket, at any plug or wiring connector on

the PDB or at any engine-mounted electronics, as

water entry may occur and component damage may

result.

Figure 2

1 - Cover Latch and Screw

Service Bulletin 17-3048

Page 2 of 2 © 10/2010

You might also like

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Waukesha Gas Engines: WarningDocument3 pagesWaukesha Gas Engines: WarningdfmolinaNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 538-220 - Thomas Coupling ManualDocument10 pages538-220 - Thomas Coupling ManualFelipeNo ratings yet

- DDEControllerDocument13 pagesDDEControllercataNo ratings yet

- Waukesha Gas Engines: GE Power & Water Distributed PowerDocument4 pagesWaukesha Gas Engines: GE Power & Water Distributed PowerdfmolinaNo ratings yet

- Westell Cellpak: - Installation GuideDocument6 pagesWestell Cellpak: - Installation GuideKendric ShahidNo ratings yet

- Quick Connection Terminal Block QTCDocument4 pagesQuick Connection Terminal Block QTCOualid ZaouichNo ratings yet

- TEC021 01 IngDocument8 pagesTEC021 01 IngNoufal HarrachiNo ratings yet

- p220 en Inb43Document10 pagesp220 en Inb43Sambit MohapatraNo ratings yet

- SRBC Operating-Instr 2021-10e 8141246g1Document2 pagesSRBC Operating-Instr 2021-10e 8141246g1hamdani sceNo ratings yet

- Technical Specification For Plastic-Insulated Low Voltage CablesDocument9 pagesTechnical Specification For Plastic-Insulated Low Voltage CablesrasoolNo ratings yet

- Hager KldsDocument4 pagesHager KldsZzzdddNo ratings yet

- A5CS 11.00 Rev ECN 3035 - 170 270 370webDocument9 pagesA5CS 11.00 Rev ECN 3035 - 170 270 370webEmilNo ratings yet

- Models: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualDocument19 pagesModels: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualHoàng Điệp NguyễnNo ratings yet

- N Fbfdme8rg Reva EngDocument4 pagesN Fbfdme8rg Reva EngsaomillerNo ratings yet

- T4.2 Conn RJ45 BlindadoDocument9 pagesT4.2 Conn RJ45 BlindadoandrysbotabanNo ratings yet

- Installation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionDocument8 pagesInstallation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionPrabu KhayanganNo ratings yet

- SD5R 3Document12 pagesSD5R 3Abel OliveiraNo ratings yet

- BOGEN Centrala Interfon ADP1mDocument8 pagesBOGEN Centrala Interfon ADP1mValentinNo ratings yet

- New Terminal Connector Kit HD20 Series: Part No. 1908900Document1 pageNew Terminal Connector Kit HD20 Series: Part No. 1908900RIZA BAKIRNo ratings yet

- Magnetics - SMT Transformers For Ultrasonic SnesorsDocument5 pagesMagnetics - SMT Transformers For Ultrasonic SnesorslykaonasNo ratings yet

- Cat ConnectorsDocument85 pagesCat ConnectorsBishoo ShenoudaNo ratings yet

- Install BoardsDocument46 pagesInstall BoardskarlikrleNo ratings yet

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- LPN2 Unheated Sanitation SubmittalsDocument2 pagesLPN2 Unheated Sanitation SubmittalsGabriel Ortiz MNo ratings yet

- Solenoid Plug With Economy Circuit Type MSD 4 ECO Solenoid Plug With Economy Circuit Type MSD 4 ECODocument10 pagesSolenoid Plug With Economy Circuit Type MSD 4 ECO Solenoid Plug With Economy Circuit Type MSD 4 ECOli geneNo ratings yet

- POINT I/O 4 Channel High Density Current Input Modules: Installation InstructionsDocument24 pagesPOINT I/O 4 Channel High Density Current Input Modules: Installation InstructionsGILBERTNo ratings yet

- Mitsubishi MAC-397IF-EDocument14 pagesMitsubishi MAC-397IF-ENiki NaidenovNo ratings yet

- Conectores Electricos Marca Deutsch DT MaquinariaDocument16 pagesConectores Electricos Marca Deutsch DT Maquinariahector0% (1)

- OFDB-1 Installation ManualDocument9 pagesOFDB-1 Installation ManualPuneet SharmaNo ratings yet

- Cat Guia de Medicion de AislamientoDocument28 pagesCat Guia de Medicion de AislamientoMiguel SoteloNo ratings yet

- Sealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsDocument2 pagesSealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsjohnnysNo ratings yet

- Burny 2.8 ManualDocument474 pagesBurny 2.8 ManualDimas Zamora100% (3)

- Littelfuse PDM EPC DatasheetDocument2 pagesLittelfuse PDM EPC DatasheetRudi WernikNo ratings yet

- 2XX-IP: Ethernet Interface OptionDocument12 pages2XX-IP: Ethernet Interface OptionDidik SudarsonoNo ratings yet

- E 65 32 27 PDFDocument4 pagesE 65 32 27 PDFDhuvi LuvioNo ratings yet

- Amorblock 16point ethernetIP Module ManualDocument24 pagesAmorblock 16point ethernetIP Module ManualKhiêm Nguyễn TrườngNo ratings yet

- Tripp Lite Owners Manual 753312Document36 pagesTripp Lite Owners Manual 753312Joe CanchicaNo ratings yet

- Bekomat-33U F Uc Manual English-Us 2014 08Document36 pagesBekomat-33U F Uc Manual English-Us 2014 08Inviernos al SolNo ratings yet

- 2 NBD116200 Fiber Distribution HubDocument3 pages2 NBD116200 Fiber Distribution HubMaylen RivasNo ratings yet

- Im Um ccm30Document30 pagesIm Um ccm30Necko VejzaNo ratings yet

- Bm32 Uc Manual en-USA 2011 06Document28 pagesBm32 Uc Manual en-USA 2011 06bortel2No ratings yet

- Abs Wabco Manutec3Document12 pagesAbs Wabco Manutec3Bom_Jovi_681No ratings yet

- Product Bulletin No.: TDS-02-14 Release Top Drive Drilling SystemDocument2 pagesProduct Bulletin No.: TDS-02-14 Release Top Drive Drilling SystemcarlosorizabaNo ratings yet

- WEG SSW 07 SSW 08 Kit Modbus Rtu Rs 232 0899.5539 Guia de Instalacao Portugues BRDocument12 pagesWEG SSW 07 SSW 08 Kit Modbus Rtu Rs 232 0899.5539 Guia de Instalacao Portugues BRjcnespoliNo ratings yet

- RJ45 AMP PonchadoDocument9 pagesRJ45 AMP PonchadoMauroNo ratings yet

- Rosemount 228 Toroidal Conductivity Sensors: 00825-0100-3228, Rev AA May 2020Document40 pagesRosemount 228 Toroidal Conductivity Sensors: 00825-0100-3228, Rev AA May 2020zerocool86No ratings yet

- Quick Start Guide Rosemount 3051 Pressure Transmitter Rosemount 3051cf DP Flow Meters Wirelesshart Protocol en 89800Document28 pagesQuick Start Guide Rosemount 3051 Pressure Transmitter Rosemount 3051cf DP Flow Meters Wirelesshart Protocol en 89800dikastaloneNo ratings yet

- DT Series Technical Manual: IndustrialDocument16 pagesDT Series Technical Manual: IndustrialSamir FerreiraNo ratings yet

- Submersible Pressure TransducerDocument16 pagesSubmersible Pressure TransducerAnonymous AsIbqUNo ratings yet

- CPVC Sprinkler Head Adapter FittingDocument2 pagesCPVC Sprinkler Head Adapter FittingValentin A.No ratings yet

- Abb Protecta and Mini Center PDFDocument18 pagesAbb Protecta and Mini Center PDFahmed abbasNo ratings yet

- Quick Start Guide - Ecotower 2 370124.103 r1.1Document16 pagesQuick Start Guide - Ecotower 2 370124.103 r1.1Junior EspinalNo ratings yet

- AMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationDocument9 pagesAMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationАндрей9No ratings yet

- EG 15-6-1.1 Installation of Field Instrumentation: ScopeDocument6 pagesEG 15-6-1.1 Installation of Field Instrumentation: Scopeamin100% (1)

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- Diebold Nixdorf BEETLE Multi Interface HubDocument36 pagesDiebold Nixdorf BEETLE Multi Interface HubOferty Firm / SklepówNo ratings yet

- 9a2 KartDocument12 pages9a2 Kartabuzer1981No ratings yet

- Frialen Ai FriatecDocument32 pagesFrialen Ai FriatecOscar MoralNo ratings yet

- Geometry and Topology Optimization of Geodesic Domes Using Charged System SearchDocument16 pagesGeometry and Topology Optimization of Geodesic Domes Using Charged System SearchdfmolinaNo ratings yet

- Dynamic Space Frame StructuresDocument96 pagesDynamic Space Frame StructuresdfmolinaNo ratings yet

- Patternsonthe Spherical SurfaceDocument11 pagesPatternsonthe Spherical SurfacedfmolinaNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument4 pagesService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffecteddfmolinaNo ratings yet

- Optimal Truck Scheduling Mathematical Modeling and Solution by The Column Generation Principle - CompressDocument120 pagesOptimal Truck Scheduling Mathematical Modeling and Solution by The Column Generation Principle - CompressdfmolinaNo ratings yet

- Space and Geometry DissertationDocument60 pagesSpace and Geometry DissertationdfmolinaNo ratings yet

- Demaine E., O'Rourke J. Geometric Folding Algorithms. Linkages, Origami, Cup SDocument486 pagesDemaine E., O'Rourke J. Geometric Folding Algorithms. Linkages, Origami, Cup SKarmen MiseNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument1 pageService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffecteddfmolinaNo ratings yet

- Waukesha Gas Engines: GE Water & Distributed PowerDocument23 pagesWaukesha Gas Engines: GE Water & Distributed PowerdfmolinaNo ratings yet

- Waukesha Gas Engines: GE Power & WaterDocument10 pagesWaukesha Gas Engines: GE Power & WaterdfmolinaNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument1 pageService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffecteddfmolinaNo ratings yet

- TDSH TDSB Partes 2001Document56 pagesTDSH TDSB Partes 2001dfmolinaNo ratings yet

- Rotary Screw Compressor Units: Service Parts ListDocument56 pagesRotary Screw Compressor Units: Service Parts Listdfmolina100% (1)

- Manual TDSH 163 FrickDocument58 pagesManual TDSH 163 FrickHernan Guerra100% (2)

- Rwbii 60 - 480 IomDocument56 pagesRwbii 60 - 480 Iomdfmolina100% (1)

- Frick Vibration Guidelines FOR Service PersonnelDocument6 pagesFrick Vibration Guidelines FOR Service PersonneldfmolinaNo ratings yet

- QUANTUM OperationDocument84 pagesQUANTUM OperationdfmolinaNo ratings yet

- QUANTUM MantenimientoDocument82 pagesQUANTUM MantenimientodfmolinaNo ratings yet

- Ibbotson Sbbi: Stocks, Bonds, Bills, and Inflation 1926-2019Document2 pagesIbbotson Sbbi: Stocks, Bonds, Bills, and Inflation 1926-2019Bastián EnrichNo ratings yet

- Gardner Denver PZ-11revF3Document66 pagesGardner Denver PZ-11revF3Luciano GarridoNo ratings yet

- Unit Process 009Document15 pagesUnit Process 009Talha ImtiazNo ratings yet

- Missouri Courts Appellate PracticeDocument27 pagesMissouri Courts Appellate PracticeGeneNo ratings yet

- 23 Things You Should Know About Excel Pivot Tables - Exceljet PDFDocument21 pages23 Things You Should Know About Excel Pivot Tables - Exceljet PDFRishavKrishna0% (1)

- Cic Tips Part 1&2Document27 pagesCic Tips Part 1&2Yousef AlalawiNo ratings yet

- Brochure Ref 670Document4 pagesBrochure Ref 670veerabossNo ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- Loading N Unloading of Tanker PDFDocument36 pagesLoading N Unloading of Tanker PDFKirtishbose ChowdhuryNo ratings yet

- Javascript Applications Nodejs React MongodbDocument452 pagesJavascript Applications Nodejs React MongodbFrancisco Miguel Estrada PastorNo ratings yet

- State Immunity Cases With Case DigestsDocument37 pagesState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Document3 pagesAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNo ratings yet

- P 1 0000 06 (2000) - EngDocument34 pagesP 1 0000 06 (2000) - EngTomas CruzNo ratings yet

- Amerisolar AS 7M144 HC Module Specification - CompressedDocument2 pagesAmerisolar AS 7M144 HC Module Specification - CompressedMarcus AlbaniNo ratings yet

- IPO Ordinance 2005Document13 pagesIPO Ordinance 2005Altaf SheikhNo ratings yet

- 06-Apache SparkDocument75 pages06-Apache SparkTarike ZewudeNo ratings yet

- BMA Recital Hall Booking FormDocument2 pagesBMA Recital Hall Booking FormPaul Michael BakerNo ratings yet

- X-17 Manual Jofra PDFDocument124 pagesX-17 Manual Jofra PDFBlanca Y. Ramirez CruzNo ratings yet

- Dissertation On Indian Constitutional LawDocument6 pagesDissertation On Indian Constitutional LawCustomPaperWritingAnnArbor100% (1)

- 3125 Vitalogic 4000 PDFDocument444 pages3125 Vitalogic 4000 PDFvlaimirNo ratings yet

- Aluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyDocument2 pagesAluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyJoachim MausolfNo ratings yet

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDocument75 pagesInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspNo ratings yet

- Ss 7 Unit 2 and 3 French and British in North AmericaDocument147 pagesSs 7 Unit 2 and 3 French and British in North Americaapi-530453982No ratings yet

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument58 pagesSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiNo ratings yet

- Jerome4 Sample Chap08Document58 pagesJerome4 Sample Chap08Basil Babym100% (7)

- 5 Star Hotels in Portugal Leads 1Document9 pages5 Star Hotels in Portugal Leads 1Zahed IqbalNo ratings yet

- CoDocument80 pagesCogdayanand4uNo ratings yet

- CSEC Jan 2011 Paper 1Document8 pagesCSEC Jan 2011 Paper 1R.D. KhanNo ratings yet

- Daraman vs. DENRDocument2 pagesDaraman vs. DENRJeng GacalNo ratings yet

- ST JohnDocument20 pagesST JohnNa PeaceNo ratings yet