Professional Documents

Culture Documents

PDF Astm A240 Compress

Uploaded by

Venkat RamuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF Astm A240 Compress

Uploaded by

Venkat RamuCopyright:

Available Formats

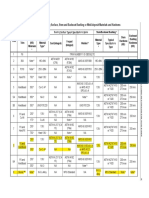

Stainless Steel Selection Guide (Ref. ASTM-A240)

TYPICAL MECHANICAL PROPERTIES

TYPE DESCRIPTION TYPICAL COMPOSITION % FORM Annealed at Room Temperature WEL

WE LD- RELATI

REL TIVE

VE

Tensile Yield Elongation Hardness ABILITY COST

(0.2% Offset) (% in 2”)

Austenitic (Hardenable by cold working only)

304 Low-carbon modification of type 302 for restriction of carbide precipita- 18-20 Cr, 8-10.50 Ni, sheets 84,000 42,000 55 80 Rb A 100

(S30400) tion during

during welding. Chemic

Chemicalal and food processing

processing equipment;

equipment; brew- 0.08 C, 2.0 Mn, 1.0 Si, plates 82,000 35,000 60 149 Bhn 100

ing equipment; cryogenic vessels; gutters; downspouts; flashings. 0.045 P, 0.030 S

304L Extra-low-carbon modification of type 304 for further restriction of car- 18-20 Cr, 8-12 Ni, sheets 81,000 39,000 55 79 Rb A 111

(S30403) bide precipitati

precipitation

on during welding.

welding. Coal hopper linings;

linings; tanks for liquid 0.03 C, 2.0 Mn, 1.0 Si, plates 79,000 33,000 60 143 Bhn 109

fertilizer and tomato paste. 0.045 P, 0.030 S

316 Higher

High er co

corr

rrosi

osion

on re

resi

sist

stan

ance

ce th

than

an tytype

pess 30

302

2 an

andd 30

304;

4; hi

high

gh cr

cree

eep

p 16-18 Cr, 10-14 Ni, sheets 84,000 42,000 50 79 Rb A 148

(S31600) strength.

strength. Chemi

Chemical

cal and pulp handling equipment;

equipment; photographic

photographic equip- 0.08 C, 2.0 Mn, 1.0 Si plates 82,000 36,000 55 149 Bhn 140

ment; brandy vats; fertilizer parts; ketchup cooking kettles; yeast tubs. 0.045 P, 0.030 S, 2.0-3.0 Mo

316L Extra-low-carbon modification of type 316 Welded construction where 16-18 Cr, 10-14 Ni sheets 81,000 42,000 50 79 Rb A 159

(S31603) intergranul

intergranular

ar carbide precipitation

precipitation must be avoided. Type 316 applic

applica-

a- 0.03 C, 2.0 Mn, 1.0 Si plates 81,000 34,000 55 146 Bhn 149

tion requiring extensive welding. 0.045 P, 0.030 S, 2.0-3.0 Mo

321 Stabilized for weldments subject to severe corrosive conditions, and for 17-19 Cr, 9-12 Ni,

(S32100) service

service from 800 to 1600 F.F. Aircra

Aircraft

ft exhaust manifolds;

manifolds; boiler

boiler shells; 0.08 C, 2.0 Mn, 1.0 Si, sheets 90,000 35,000 45 80 Rb A 130

processs equipm

proces equipment;

ent; expansion joints; cabin heaters; fire walls; flexi

flexible

ble 0.045 P, 0.030 S (Ti, 5 X C min) plates 85,000 30,000 55 160 Bhn 128

couplings, pressure vessels.

You might also like

- AstmDocument1 pageAstmجبر البرحNo ratings yet

- OK 61.30 (Inox 308)Document1 pageOK 61.30 (Inox 308)Tiberiu MunteanuNo ratings yet

- ASTM A53 Data SheetDocument3 pagesASTM A53 Data Sheetmarcelomaster88No ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Certificado Tee sch40Document1 pageCertificado Tee sch40benedicto soto mestanzaNo ratings yet

- ASTM A53 Data Sheet PDFDocument3 pagesASTM A53 Data Sheet PDFmarcelomaster88No ratings yet

- Piping UpdatedDocument1 pagePiping UpdatedbalamuruganNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- Datasheet For Steel Grades Special Alloy STS304Document2 pagesDatasheet For Steel Grades Special Alloy STS304Thanakit Srisaeng100% (1)

- Pressure Vessel Design (Faiz Zelin)Document1 pagePressure Vessel Design (Faiz Zelin)arcelitasNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Mechanical SteelDocument1 pageMechanical SteelHaery BrebesNo ratings yet

- P P P P: Ssttaaiin Nlleessss Sstteeeell SS/ /ii B Beeaam MssDocument4 pagesP P P P: Ssttaaiin Nlleessss Sstteeeell SS/ /ii B Beeaam MssPercyNo ratings yet

- Aisi E50100, E52100: 154/amoyDocument6 pagesAisi E50100, E52100: 154/amoyahmad hafizNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- OK 63.30 (Inox 316)Document1 pageOK 63.30 (Inox 316)Tiberiu MunteanuNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Document3 pagesSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNo ratings yet

- Invalved Valve Trim Materials Standard Trim ConfigurationsDocument1 pageInvalved Valve Trim Materials Standard Trim ConfigurationsmanishkapriNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- ASTM A106. Gr. A B C. P235GH P265GH P295GHDocument4 pagesASTM A106. Gr. A B C. P235GH P265GH P295GHOmkar100% (3)

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- Trim Segun API 600Document1 pageTrim Segun API 600Sabas Lopez MartinNo ratings yet

- Literatura Tecnica Aço Inoxidável - Normas e AplicaçõesDocument2 pagesLiteratura Tecnica Aço Inoxidável - Normas e AplicaçõesE7 EMPIRE GIGITALNo ratings yet

- Data Table For Grades Stainless Steels - Special Steels STS304Document3 pagesData Table For Grades Stainless Steels - Special Steels STS304NathanNo ratings yet

- J 403-Aisi 1060Document1 pageJ 403-Aisi 1060Cho thuê chung cư Cầu GiấyNo ratings yet

- Kobelco Welding Handbook 2008 - 1Document2 pagesKobelco Welding Handbook 2008 - 1Hanif SamsiNo ratings yet

- KST 316LDocument1 pageKST 316LtrueavatharNo ratings yet

- CS, LAS N SS Steel Requirements FinalDocument11 pagesCS, LAS N SS Steel Requirements FinalJahanvi BaruiNo ratings yet

- LB-52 Lb-52u: Oh H Vu F Oh H VuDocument1 pageLB-52 Lb-52u: Oh H Vu F Oh H VuMohd Farid OsmanNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul Sebastiam67% (3)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- Sandvik 253MA Data Sheet PDFDocument10 pagesSandvik 253MA Data Sheet PDFTee Klong RungNo ratings yet

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocument10 pagesSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNo ratings yet

- Roll GradeDocument1 pageRoll GradeVicente GarcíaNo ratings yet

- Roll Grade PDFDocument1 pageRoll Grade PDFVicente GarcíaNo ratings yet

- MaterialsDocument1 pageMaterialssubhashaheer524No ratings yet

- Comp of Flanges KochiDocument1 pageComp of Flanges KochiRabindra SutradharNo ratings yet

- European Steel and Alloy Grades: About Us EN 10248-1Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandNo ratings yet

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000No ratings yet

- Material TypeDocument1 pageMaterial Typesalikhashmi2013No ratings yet

- Welding ChartDocument2 pagesWelding ChartVikas DograNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- MaterialsDocument1 pageMaterialsŞhallaw R. QadirNo ratings yet

- Table of Material and Welding Requirement As Per ASME IXDocument1 pageTable of Material and Welding Requirement As Per ASME IXYuvaRaj RNo ratings yet

- MaterialsDocument1 pageMaterialsMd AmazerNo ratings yet

- Material TypeDocument1 pageMaterial TypeapNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- MS150093 01e PDFDocument181 pagesMS150093 01e PDFAntonio MartinNo ratings yet

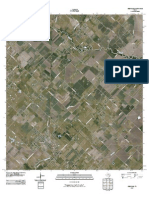

- Topographic Map of NeedvilleDocument1 pageTopographic Map of NeedvilleHistoricalMapsNo ratings yet

- Vale International Pellet Plant PDFDocument2 pagesVale International Pellet Plant PDFSrinivasanNo ratings yet

- Windows 10Document28 pagesWindows 10Vibal PasumbalNo ratings yet

- Electrical Equipment in Hazardous LocationsDocument41 pagesElectrical Equipment in Hazardous LocationsSAYEDNo ratings yet

- Introduction To ICT EthicsDocument8 pagesIntroduction To ICT EthicsJohn Niño FilipinoNo ratings yet

- Summer Training ReportDocument133 pagesSummer Training ReportRitesh Meena100% (3)

- Chapter 5 Hydraulic JumpDocument31 pagesChapter 5 Hydraulic JumpUsman AliNo ratings yet

- Watershed SegmentationDocument19 pagesWatershed SegmentationSan DeepNo ratings yet

- Seipl Profile and CapabilitiesDocument32 pagesSeipl Profile and CapabilitiesAbhishek GuptaNo ratings yet

- Fire Risk Assessment ChecklistDocument10 pagesFire Risk Assessment Checklistm. absiyeNo ratings yet

- MIC DatasheetDocument16 pagesMIC DatasheetArosh Thiwanka LiveraNo ratings yet

- Vi Quick ReferenceDocument1 pageVi Quick ReferenceSneetsher Crispy100% (6)

- Ducon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshDocument3 pagesDucon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshFounTech612No ratings yet

- Aa1a32 02Document3 pagesAa1a32 02MramirezNo ratings yet

- DIAGRAMA - 2007 - NEW YarisDocument1 pageDIAGRAMA - 2007 - NEW YarisLuis M. Valenzuela Arias50% (2)

- Audit QuickstartDocument6 pagesAudit QuickstarthugorduartejNo ratings yet

- Roadworthiness Requirements: Vehicle Standards InformationDocument10 pagesRoadworthiness Requirements: Vehicle Standards Informationstallie001No ratings yet

- BulldogDocument20 pagesBulldogFlorinNo ratings yet

- Estoflex PU800: Moisture Cure Polyurethane, Elastomeric Liquid Applied Seamless Waterproofing MembraneDocument2 pagesEstoflex PU800: Moisture Cure Polyurethane, Elastomeric Liquid Applied Seamless Waterproofing MembraneTony JamesNo ratings yet

- R H R C H E C R: Egenerating The Uman Ight TOA Lean and Ealthy Nvironment in The Ommons EnaissanceDocument229 pagesR H R C H E C R: Egenerating The Uman Ight TOA Lean and Ealthy Nvironment in The Ommons Enaissanceapi-250991215No ratings yet

- MBAM Deployment GuideDocument80 pagesMBAM Deployment GuidePsam Umasankar0% (1)

- Simplified Management With Hitachi Command Suite Application BriefDocument19 pagesSimplified Management With Hitachi Command Suite Application BriefpankajrudrawarNo ratings yet

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDocument8 pagesThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- Acct Statement XX6669 23062023Document66 pagesAcct Statement XX6669 23062023Suraj KoratkarNo ratings yet

- Move All Database Objects From One Tablespace To AnotherDocument2 pagesMove All Database Objects From One Tablespace To AnotherJabras GuppiesNo ratings yet

- Unit - 2 SatcommDocument35 pagesUnit - 2 SatcommVerzeo group projectNo ratings yet

- As 3638-1993 Test Sieving ProceduresDocument7 pagesAs 3638-1993 Test Sieving ProceduresSAI Global - APACNo ratings yet

- 2460 3660 FM Canadian CertificateDocument2 pages2460 3660 FM Canadian Certificateluis hernandezNo ratings yet