Professional Documents

Culture Documents

Safety report analyzes accident causes

Uploaded by

Darius DsouzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety report analyzes accident causes

Uploaded by

Darius DsouzaCopyright:

Available Formats

اﻟﺼﺤﺔ واﻟﺴﻼﻣﺔ واﻟﺒﯿﺌﺔ

ﺗﺬﻛﯿﺮ

To: All Employees Date: April 2012

Preventing accidents is extremely difficult if we don’t understand what causes the accidents. According to W.H. Heinrich

(1931), who developed the so-called domino theory, 88% of all accidents are caused by Unsafe Acts of people, 10% by

Unsafe Conditions and 2% by “acts of God”.

But what does Unsafe really means? It is anything involving or causing danger that is liable to hurt or harm. In the

workplace, unsafe is attributed to an Unsafe Act or Condition. Unsafe Act is an action against the established regulations

which has potential to harm individuals or properties. Unsafe Condition is part of the work environment and physical

condition of machinery and human beings that contributed or could have contributed to an accident.

Unsafe Acts or Practices and Unsafe Working Conditions are two (2) known symptoms leading to an accident. The first

symptom relates to “behaviours”, the second relates to “circumstances” which could permit the occurrence of an accident.

Incidents / accidents are invariably preceded by Unsafe Acts or Unsafe Conditions.

To analyse further, causes of accidents are grouped into “IMMEDIATE” and “CONTRIBUTING”. The immediate causes are the

Unsafe Acts or Practices of the worker and Unsafe Working Conditions. The contributing causes are the management-related

factors, the environment, the physical and mental condition of the worker etc. An accident will result when a combination of

causes will converge.

It is very essential to analyse and assess properly the immediate cause of any type of incident such as near miss / dangerous

occurrence, fire incident etc. For any near miss that someone could benefit by learning from the event should be reported

and investigated as an opportunity to improve safety in the workplace. Near miss is an undesired event that did not result in

an injury or loss, but had the potential to result in undesirable consequences to personnel (injury / illness), and/or to the

assets (damage / loss) or to the neighbouring community and environment, if circumstances had been slightly different.

In order to improve our safety performance, it is mandatory that all incidents shall be transparently reported, recorded and

analysed to identify the Immediate Causes – Unsafe Act and Unsafe Condition.

IMMEDIATE CAUSES

UNSAFE ACTS / PRACTICES (85-96%) UNSAFE WORKING CONDITIONS (4-15%)

Operating equipment without authority Inadequate guards or barriers

Operating at improper speed Inadequate or improper protective

Using defective equipment equipment

Using equipment improperly Defective tools, equipment or materials

Servicing equipment in operation Congestion or restricted action

Making safety devices inoperable Inadequate warning system

Removing safety devices Poor housekeeping; disorderly workplace

Failure to use PPE Hazardous environmental conditions:

gases, dusts, vapors, smokes, fumes

Failure to warn

Fire and explosion hazards

Failure to secure

Noise exposures

Improper loading

Radiation exposures

Improper placement

Temperature extremes

Improper position for task

Inadequate or excessive illumination

Under influence of alcohol/and or drugs

Inadequate ventilation

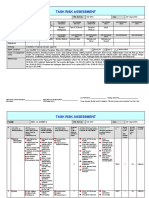

ACCIDENT CAUSES ANALYSIS (2010 vs 2011)

UNSAFE ACTS 2010 2011 UNSAFE CONDITIONS 2010 2011

Others Others

Taking Unsafe Position 37 24 Congested Area 22 9

Adjust. Equip. Improper Illumination

Failure to Secure 8 14 Hazardous Arrangement 7 9

Insecure Grip Slippery Surfaces

PPE Non-Compliance 12 14 Environmental Condition 0 6

Unsafe Lifting Lack of Coordination

Unsafe Lifting 11 8 Lack of Coordination 15 1

PPE Non-Compliance Environmental C.

Insecure Grip 0 5 Slippery Surface 12 2

Failure to Secure Hazardous A.

Adjust. Equip. in Motion 0 5 Improper Illumination 0 1

Taking Unsafe Position Congested Area

Others 15 15 Others 27 6

“Safety is a positive act, practice it and stay intact.”

HseR/04/2012

You might also like

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- Contractor Near-Miss ReportedDocument15 pagesContractor Near-Miss ReportedAyaz AhmadNo ratings yet

- 2 Accident Incident ReportingDocument28 pages2 Accident Incident ReportingBhaskar ShuklaNo ratings yet

- SWP Automotive Parts Washer - AS502Document2 pagesSWP Automotive Parts Washer - AS502Anam AbrarNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaJaafar LagayanNo ratings yet

- Prosedur Work PermitDocument3 pagesProsedur Work Permithse bsjNo ratings yet

- HSE-RA-044 Painting Rev 0Document14 pagesHSE-RA-044 Painting Rev 0عمروNo ratings yet

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- TRAINING MATRIXDocument1 pageTRAINING MATRIXImamNo ratings yet

- Safety Committee Minutes of MeetingDocument4 pagesSafety Committee Minutes of MeetingMichael BejigaNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- Manual Bending Rolls Safe Work ProcedureDocument2 pagesManual Bending Rolls Safe Work Procedurejason cepadaNo ratings yet

- Safety Training Plan ExampleDocument2 pagesSafety Training Plan ExampleBilly Billy100% (1)

- 10 Rules Hand SafetyDocument1 page10 Rules Hand SafetyRoman StreliaievNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- 06-F02 Training Needs AnalysisDocument36 pages06-F02 Training Needs AnalysisSn AhsanNo ratings yet

- Prosedur Work at HighDocument3 pagesProsedur Work at Highhse bsj100% (1)

- JSa For Glass FixingDocument17 pagesJSa For Glass FixingShekh BabulNo ratings yet

- Near Miss Report Format 19-08-22Document1 pageNear Miss Report Format 19-08-22CHETAN WANKHADE100% (1)

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- HSE Coporate Meeting No. 006 Dubia (AutoRecovered)Document5 pagesHSE Coporate Meeting No. 006 Dubia (AutoRecovered)Lawrence adeleke OmisakinNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- Safety Representative Monthly Inspection ReportDocument16 pagesSafety Representative Monthly Inspection ReportanisaanNo ratings yet

- OCP - 15 - GrindingDocument2 pagesOCP - 15 - GrindingNagendra Kumar SinghNo ratings yet

- Facility safety observations and risksDocument327 pagesFacility safety observations and risksSafetyNo ratings yet

- Sop Changing A Toner CartridgeDocument2 pagesSop Changing A Toner CartridgezaheerNo ratings yet

- IM 12 EHS Risk Management ProcedureDocument166 pagesIM 12 EHS Risk Management Procedureharish14586100% (1)

- Cold Work PermitDocument1 pageCold Work PermitherdianNo ratings yet

- Annual Training Calender Eti 12Document1 pageAnnual Training Calender Eti 12anand shankarNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Stop Work Report for Safety InterventionsDocument1 pageStop Work Report for Safety InterventionsRetselisitsoeNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- Risk Assessment For Ceramic & Porcelain Tile WorksDocument6 pagesRisk Assessment For Ceramic & Porcelain Tile WorksFaizan TanveerNo ratings yet

- RJ Oil Chemical Storage Safety ManagementDocument1 pageRJ Oil Chemical Storage Safety ManagementOws AnishNo ratings yet

- Hse Risk Register-RaDocument8 pagesHse Risk Register-RaNiraNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- 04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectDocument5 pages04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectAviects Avie JaroNo ratings yet

- Risk Assessment - Concrete PouringDocument6 pagesRisk Assessment - Concrete Pouringabdullah ashrafNo ratings yet

- List of PPEDocument4 pagesList of PPEBinayNo ratings yet

- OHSE Project HIRA - Fencing Work - R 00Document3 pagesOHSE Project HIRA - Fencing Work - R 00Pankaj SinghNo ratings yet

- Health and Safety Work at HeightDocument4 pagesHealth and Safety Work at Heightalexst48No ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document3 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Wealth OSIOBENo ratings yet

- Mifa Safety Regulations UKDocument2 pagesMifa Safety Regulations UKnqh2009No ratings yet

- Emergency Drill Evacuation ReportDocument6 pagesEmergency Drill Evacuation ReportYunan EdhieNo ratings yet

- IGC III Obsevation ReportDocument5 pagesIGC III Obsevation ReportAbrahamAbraciaNo ratings yet

- Daily HSEReport FormatDocument7 pagesDaily HSEReport Formatsufiyan sskNo ratings yet

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Drill PressDocument2 pages(Your Business Name Here) - Safe Work Procedure Drill PressSafety DeptNo ratings yet

- Risk Assessment - Hot WorkDocument6 pagesRisk Assessment - Hot Workabdullah ashrafNo ratings yet

- SWP Metal Cutting Guillotine AS525Document2 pagesSWP Metal Cutting Guillotine AS525Riddhi SarvaiyaNo ratings yet

- Safety Alert GujaratDocument2 pagesSafety Alert GujaratUnitac HaziiNo ratings yet

- MSDS Cement PDFDocument5 pagesMSDS Cement PDFHendrik SimatupangNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- 05a AccreportDocument1 page05a AccreportMohammed MinhajNo ratings yet

- Concrete Pump Maintenance ChecklistDocument4 pagesConcrete Pump Maintenance ChecklistDarius DsouzaNo ratings yet

- 8) .Tool Box Talk RecordDocument11 pages8) .Tool Box Talk RecordDarius DsouzaNo ratings yet

- Monthly Safety, Health and Environment Report For The Month January 2020)Document9 pagesMonthly Safety, Health and Environment Report For The Month January 2020)Darius DsouzaNo ratings yet

- ARC Accident 21202105021440Document1 pageARC Accident 21202105021440Darius DsouzaNo ratings yet

- 1) Land Incident Investigaton ReportDocument4 pages1) Land Incident Investigaton ReportDarius DsouzaNo ratings yet

- Lifting PlanDocument31 pagesLifting PlanDarius DsouzaNo ratings yet

- Guide To Powder CoatingDocument45 pagesGuide To Powder CoatingSreedhar Patnaik.M100% (3)

- Heat Stress Program - J38Document24 pagesHeat Stress Program - J38Darius DsouzaNo ratings yet

- ERP For Company Covering All SitesDocument7 pagesERP For Company Covering All SitesDarius DsouzaNo ratings yet

- Aspire 001 IGC I Element 1-Foundations - IGC IDocument48 pagesAspire 001 IGC I Element 1-Foundations - IGC IDarius DsouzaNo ratings yet

- 14-Telescopic Forklift Check List Hindi English - Page - 1Document1 page14-Telescopic Forklift Check List Hindi English - Page - 1Darius DsouzaNo ratings yet

- Confined Space Atmospheric TestDocument1 pageConfined Space Atmospheric TestDarius DsouzaNo ratings yet

- Isometric Jum-Tp02 RevdDocument1 pageIsometric Jum-Tp02 RevdDarius DsouzaNo ratings yet

- Combustible DustDocument12 pagesCombustible DustDarius DsouzaNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- Accident Causation ModelDocument16 pagesAccident Causation ModelDarius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaNo ratings yet

- TRA # 102 For Installation of Piping and Pipe SupportsDocument5 pagesTRA # 102 For Installation of Piping and Pipe SupportsDarius DsouzaNo ratings yet

- Lifting Plan Layout1Document1 pageLifting Plan Layout1Darius DsouzaNo ratings yet

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Aspire 001I Element 1 - Foundations in Health and SafetyDocument46 pagesAspire 001I Element 1 - Foundations in Health and SafetyDarius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For ExcavationDocument3 pagesP111-RSME-TRA-007 - TRA For ExcavationDarius DsouzaNo ratings yet

- Valve Station DrawingDocument1 pageValve Station DrawingDarius DsouzaNo ratings yet

- Aspire 006 GC II Element 1-Workplace Hazards and Controls QDocument89 pagesAspire 006 GC II Element 1-Workplace Hazards and Controls QDarius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For ExcavationDocument3 pagesP111-RSME-TRA-007 - TRA For ExcavationDarius DsouzaNo ratings yet

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- Bowel Preparation: Penyusun: Nicholas David Marcellis Pembimbing: Dr. Mangalindung O, SPBDocument18 pagesBowel Preparation: Penyusun: Nicholas David Marcellis Pembimbing: Dr. Mangalindung O, SPBbocah_britpopNo ratings yet

- 20221201151148college Wise P2 BDSDocument17 pages20221201151148college Wise P2 BDSMEGLADONNo ratings yet

- Week 13 CD COURSE TASK 7. Dengue Fever, Filariasis, Malaria and EncephalitisDocument5 pagesWeek 13 CD COURSE TASK 7. Dengue Fever, Filariasis, Malaria and EncephalitisRogelyn PatriarcaNo ratings yet

- Drug StudyDocument34 pagesDrug StudyMarco MoralesNo ratings yet

- Translating Idea Into PolicyDocument64 pagesTranslating Idea Into PolicyBisrat AsfawNo ratings yet

- Effect of Vitamin E On Thrombocytopenia in Dengue FeverDocument5 pagesEffect of Vitamin E On Thrombocytopenia in Dengue FeverBernadeth MeilyNo ratings yet

- Abbott Alinity S FactSheetDocument1 pageAbbott Alinity S FactSheetInayat UllahNo ratings yet

- CCTV CONSENTDocument2 pagesCCTV CONSENTGam SaiiNo ratings yet

- JHA Risk Assesment 1Document6 pagesJHA Risk Assesment 1leonardo GaraisNo ratings yet

- Immunization: For C-1 Med Student DR Muluken JAN/2018Document71 pagesImmunization: For C-1 Med Student DR Muluken JAN/2018Yemata HailuNo ratings yet

- CMC Vellore Guide History Facilities Services Departments MapDocument75 pagesCMC Vellore Guide History Facilities Services Departments MapSanjay Kumar SekhardeoNo ratings yet

- PBS Test Study Guide Unit 3 Outbreaks and Emergencies: Key TermsDocument3 pagesPBS Test Study Guide Unit 3 Outbreaks and Emergencies: Key TermsJude ChartierNo ratings yet

- Evaluation of antibiotic use in children with respiratory infectionsDocument9 pagesEvaluation of antibiotic use in children with respiratory infectionsuda photocopy PerintisNo ratings yet

- Analysis of Nutrients in Traditional South Kalimantan CakesDocument5 pagesAnalysis of Nutrients in Traditional South Kalimantan CakesAzwa SafrinaNo ratings yet

- Immediate vs delayed implant loadingDocument27 pagesImmediate vs delayed implant loadingAhmed GendiaNo ratings yet

- Post Graduate Program in Infectious DiseasesDocument7 pagesPost Graduate Program in Infectious DiseasesRakibk65No ratings yet

- Syllabus - Clinical ImmunologyDocument5 pagesSyllabus - Clinical ImmunologyJonsu1517No ratings yet

- Amelogenesis Imperfecta: Review of Diagnostic Findings and Treatment ConceptsDocument12 pagesAmelogenesis Imperfecta: Review of Diagnostic Findings and Treatment ConceptsBruno M. StrangioNo ratings yet

- Active List Libsong EastDocument71 pagesActive List Libsong EastJohn Reybren MaloganNo ratings yet

- Flagyl Marketing PlanDocument50 pagesFlagyl Marketing Planstring70575% (4)

- Drug Prescribing UpdateDocument1 pageDrug Prescribing UpdateMahmoud EladawyNo ratings yet

- Do Immunisations Reduce The Risk For SIDS? A Meta-AnalysisDocument5 pagesDo Immunisations Reduce The Risk For SIDS? A Meta-AnalysisRoss StalkerNo ratings yet

- Health Companion Policy WordingDocument26 pagesHealth Companion Policy WordingRaj GopalNo ratings yet

- Digital DentistryDocument13 pagesDigital DentistryCesar Augusto Rojas MachucaNo ratings yet

- Dds Curriculum. Jalil June 30Document45 pagesDds Curriculum. Jalil June 30তৌহিদ তপুNo ratings yet

- NLM MedicatingDocument11 pagesNLM MedicatingQuimberly ModequilloNo ratings yet

- Nursing Role and Nursing Care During Pregnancy ComplicationsDocument21 pagesNursing Role and Nursing Care During Pregnancy Complicationsvienny kayeNo ratings yet

- Health Services and Delivery ResearchDocument152 pagesHealth Services and Delivery ResearchThierry UhawenimanaNo ratings yet

- Carboplatin PaclitaxelDocument6 pagesCarboplatin PaclitaxelNida Auliya RahmahNo ratings yet

- DR Philip Swales - GIM 22 MayDocument34 pagesDR Philip Swales - GIM 22 MaySathvika BNo ratings yet