Professional Documents

Culture Documents

ECRL-S4-AW-MS-0023 Construction of In-Situ Box Culvert (Rev 01)

Uploaded by

Fateh Aliya0 ratings0% found this document useful (0 votes)

138 views75 pagesOriginal Title

ECRL-S4-AW-MS-0023 Construction of in-Situ Box Culvert (Rev 01)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

138 views75 pagesECRL-S4-AW-MS-0023 Construction of In-Situ Box Culvert (Rev 01)

Uploaded by

Fateh AliyaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 75

pense

nro

CHINA COMMUNICATIONS CONSTRUCTION

COMPANY

EAST COAST RAIL LINK PROJECT

METHOD STATEMENT

FOR

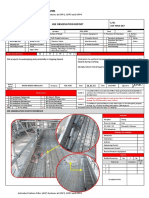

ACTIVITY : CONSTRUCTION OF IN-SITU BOX CULVERT

LOCATION : SECTION 4

Document No |: ECRL-S4-AW-MS-0023

Revision No [201

Date Issued | : 08 JUNE 2020

SC Signature Date:

| PREPARED” | REVIEWED] REVIEWED | REVIEWED | APPROVED

BY BY BY BY BY

(Nw? AO a" Photo’

ran Liang Liu Bo Liu Ziyang Feng

Jianyuan Rongxian

‘Senior ‘Section HSE ‘Chief Infrastructure

Engineer Qaac Manager Engineer Deputy

Manager General

Manager

Gist ewe

“CONSTRUCTION OF CAST IN-SITU Box GRVERT”

‘ECRL-S4—AW-M

DRS-0164, Rev 00)

of Rea ge TRE RD

REVISION HISTORY

00 First Issue ‘22 MAY 2020

01 | Second Issue as Per DRS (ECRL-HSSI-S1-AW- 08 JUNE 2020

Construction of Catt Box Calvert,

ECRL-S4- AW.MS-0023 & Rev. 0

Page 2 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT” _|

SPowse Doosan. ECRL-S4—AWMS-0023

Rovision No. a Rov. Date (08 JUNE 2020

Table of Contents

1.0 SCOPE OF WORK.

1.4 General Description...

1.2 Reference

1.3. Materials........

4.4 Plant and Equipment

1.5 Manpower

1.6 Construction Procedures

2.0 SAFETY AND HEALTH

241 Job Safety & Health Analysis (JSA)..

2.2 _ Information to Personnel

2.3. Emergency Arrangements ..

2.4 Permit Requirements...

2.5 Permit to Work.

3.0 ENVIRONMENTAL ISSUES. 24

3.1 Environmental Aspects, Impacts & Control Measure:

4.0 QUALITY ASSURANCE & QUALITY CONTROL...

4.1 Contractual Requirements.

4.2 Inspection & Testing

43 Follow up & Evaluation

5.0 APPENDICE:

5.1 Construction Sequence Flow

5.2 Job Safety & Health Analysis (JSA).

5.3 Environmental Aspect Impact Register (EAIR)..

5.4 Inspection Test Plan (ITP)

5.5 Quality Control Site Inspection Checklist...

5.6 Work and Activity Commencement Notification .

ATTACHMENT! ERT Organization Chart

ATTACHMENT Il Permit to Work Form

CConstuction of Cast In-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 3 of 36

& “CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No. ECRL-S4—AW-NS-0023,

Revision No. of Rev. Date (08 JUNE 2020

4.0 | SCOPE OF WORK

44

4.2

General Description

This method statement details the methodology to be employed for the

costruction of pre-cast box culvert and Cast in-situ box culvert

The scope or work covered in this method statement include setting out

of the box culvert,temporary works (sheet pile shoring wall and etc.) in

the construction of the box culvert, excavation &backfilling,bedding,the

construction of the box culvert shaft,the construction of inlet and outlet,

of the box culvert,the construction of approach slab(transition

slab),banks protection work and connecting the box culvert to the

proposed drain or existing drain. For movement joint or expansion joints

waterstop shall refer to waterproof and settlement joint refrence

drawing,for location and filling on box culvert shall refer to reference

subgrade construction drawings

Note: Details of the procedures contained herein may be reviewed

periodically and modified based on the actual site requirements.

Reference

1.2.1. The relevant references are as follows’

Contractor to refer the latest drawings for commence the work

No

Description Document Ref. No.

Approved for Construction CD/ECRL1/C/MLISR/SEC2.4/PP000

Drawings of Embankment

Approved Construction Drawing CDIECRLIC/MLICVIRFD/RBC 003

Bridge

(RC Frame Box Culvert )

Approved Construction Drawing CD/ECRLIC/MLICV/RFDIRBC 004

Bridge

(RC Frame Box Culvert )

‘Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 04

Page 4 of 36

=CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No.

ECRL-S4—AW-MS-0023,

Sosa

Revision No Gl

Rev. Date (08 JUNE 2020

4 | Approved Construction Drawing

Bridge

(RC Frame Box Culvert )

CD/ECRLIC/MLICVIRFD/RBC 005

5. | Approved Construction Drawing CD/ECRLIC/MLICV/RFD/VBC 001

Vehicular Box Culvert (Main

Line)

6 | Detail Design for Wing Wall (CD/ECRLICIMLWWIRFD/WW001

7 | Construction Drawing of

Embankment CH 183+500-

231+500

CD/ECRL1/C/MLICV/MLISRISEC2.4/PP000

8 | Subgrade Reference Drawings

CD/ECRL1/C/MUSRIRFD/1

9 | Construction Drawing of

Subgrade CH 221+819 —

CH224+086

CD/ECRL/C/MUSR/SEC2.4/GT007

10 | Construction Drawing of

‘Subgrade CH 215+499-

CH215+567

CD/ECRLC/MUSR/SEC2.4/GT002

11 | Construction Drawing of

Subgrade CH 216+776-

CH216+832

CD/ECRLIC/MLISRISEC2.4/GT002

12 | Construction Drawing of

Subgrade CH 261+438-

216+649

CD/ECRLIC/MUSRISEC2.4/GT003

13 | Technical Specification for

Reinforcement Conorete Works

CD-ECRL-AW-GEN-SPC-0003 (SEC18)

Technical Specification for

14 | Drainage Works

CD-ECRL-AW-GEN-SPC-0002 (SEC04)

15 | Method Statement for Bulk

excavation and Filling works

ECRL-S4-SR-MS-0001

16 | Method Statement for

Reinforcement Concrete Works

ECRL-S4-AW-MS-0008

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 5 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

CDSE [Document No. ECRL-S4—AW-MS-0023

Revision No. oF Rev. Date ‘08 JUNE 2020

17 | Method Statement for Works ECRL-S4-AW-MS-0013

Surface Drainage works

18 | POP Procedure ECRL-CCCC-QA-PQP-0001

19 | MSA Procedure ECRL-CCCC-AW-PRO-0005

20 | RFI Procedure ECRL-CCCC-QA-PRO-0003

21 | General Guidelines of ‘Act 520 (MCO SOP Document 1)

Operations for the Construction

Project in the Period of MCO

22 | Covid-19 Prevention Guidelines ‘Act 520 (MCO SOP Document 2)

for Construction Site

23 | Emergency Response Plan for | ECRL-CCCC-HSE-PLAN-0005

The Outbreak of Novel

Coronavirus Infection

Pneumonia

21 | Occupational Safety and Health Act 514 OSHA 1994

Act (OSHA 1994)

22 | Factory & Machinery Act (FMA Act 319 FMA 1967

1967)

23 | Project Safety and Health Plan ECRL-S4-AW-PLN-0002

24 | Emergency Response Plan ECRL-S4-AW-PLN-0003

25 | SOP for Scaffolding ECRL-CCCC-HSE-SOP-0007

26 | SOP for Site Sanitation and ECRL-CCCC-HSE-SOP-0008

Vector Diseases Control

27 | SOP for Housekeeping ECRL-CCCC-HSE-SOP-0010

28 | SOP for Working at Height ECRL-CCCC-HSE-SOP-0014

29 | SOP for Hand and Power Tools ECRL-CCCC-HSE-SOP-0016

30 | SOP Permit to Works ECRL-CCCC-HSE-SOP-0006

‘Construction of Cast in-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 6 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

bE | Document No ECRL-S#—AW-HS-0023

Revision No. | _ Rev. Date (08 JUNE 2020

31 | SOP Mobile Construction ECRL-CCCC-HSE-SOP-0003

Equipment

1.3 Materials

1.3.1 List of materials requires shall be as follows:

No Type of Material Material Submission Approval

(MSA) Ref No.

1. | Concrete Grade 20 ECRL-S4-BR-MSA-0036

2. | Concrete Grade 40 ECRL-S4-BR-MSA-0001

3. | Conorete Grade 40 ECRL-S4-BR-MSA-0013

4 | Conorete Grade 40 ECRL-S4-BR-MSA-0015

5 | C40 Fine aggregate Concrete TBA

6 | Geotextle ECRL-CCCC-SR-MSA-0006

7 | M10 Cement Mortar TBA

8. | Expansion Bolt (Wall Plug) TBA

M10

9 | Steel Reinforcement (MS 146) | ECRL-CCCC-AW-MSA-0010

(68.4449) Hot rolled

deformed Bar)

10 | Back Sticking Water stop ECRL-CCCC-TUN-MSA-0032

11. | Mid Buried Edge/Edge Water | ECRL-CCCC-TUN-MSA-0033

stop

12 | Polyethylene foam Plastic TBA

Board

13 | PVC Plaster (caulking ECRL-S4-AW-MSA-0052

Material)

14 | Rubber Waterstop TBA

15. | Waterproof Coiled Material TBA

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW-MS-0025 & Rev. OF

Page 7 of 36

INSTRUCTION OF CAST IN-SITU BOX CULVERT” |

coisa [Document Ro. ECRL-S4—AW-MS-0023 |

Revision No. a Rev. Date (08 JUNE 2020 |

16 | (Polyurethane waterproof ECRL-CCCC-AW-MSA-0035

coatings) Bitumen

1.4 Plant and Equipment

1.4.1 List of plant and machineries requires for the execution of

activities:

No | Plant and Machinery Purpose

1, | Backhoe For excavation works

2. | Excavator For excavation works

3. | Mobile Crane

For lifting materials to/from site

4, | Bar bending &

cutting machine

For bending and cutting steel material

during construction

5. | Machine Tamper or

For compaction work purposes

‘Compactor

6. | Air compressor For air supply

7. | Generator For power supply

8. | Robin engine

To supply power to operate machines

and equipment

9. | Water pump

To remove ponding water from

construction site

10. | Vibrating Poker To generate vibrations

11. | Form tie system —_| To connect opposite faces of wall

12. | Survey Equipment _| Used for surveying work purposes

13. | Double Stain Stitch | For construction work purposes

‘Sewing Machine

14, | Pegs and thread —_| For surveying work purposes

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AWAMS-0023 & Rev. 01

Page 8 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

BERR [Desens ECRL-S4—AW-S-0023

elon No. a Rov. Dato | 08 JUNE 2020

Manpower

1.5.1 Responsibility / duty assigned are as follows:

No. | Deseription Type of Brief Roles and Responsibilities

Manpower

1. | Operations Site Engineer / | To do coordination and supervision at site

‘Supervisor

‘Surveyor and | To do survey, measure and marking at site

Chainman

Site Foreman | To organise construction works

Plants and | To handle the plants and machineries at site

Machinery

Operators

Cerpenter__| To organise construction works

Barbender | To do the bar bender & bar cutting works

General Worker | To do the general works at site

2. | Safety, Health | Safety and | To ensure the implementation by the operation

& Environment | Health Officer / | team on Safety and Health procedure were

Supervisor | adhere all the time

Environmental | To ensure the implementation by the operation

Officer team on environment procedures and

requirements were adhere at all time.

3. | Quality Quality | Checking quality of materials and work in

Inspector _| progress.

‘QAQC Engineer | Ensure all work follow the latest document and

‘work in progress inspection

Supervising | Checking quality of materials and work in,

Consultant | progress.

Construction of Cast In-Situ Box Culver,

ECRL-S4- AWMS-0023 & Rev. 1

Page 9 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

coma [Document No. ECRL-S4—AW-MS-0023

Revision No ev. Date | 08 JUNE 2020

1.6 Construction Procedures

4.6.1. Pre-construction

a

Prior to commence of work, site inspection shall be carried

out for risk identification during excavation work, accompany

by SHO team.

Contractor shall submit the layout plan, longitudinal section

plan, cross-section pian or (shop drawing showing survey

details prepared by survey department) and alignment of

box culvert and its surrounding, propose invert level, survey

details and other construction details for Supervising

Consultant approval.

The temporary work involved such as temporary drainage

and etc. Shall be informed to the Supervising Consultant 1

week before the commencement of work.

The method of concreting which covered the fabrication of

reinforcement, erecting of formwork, casting of concrete until

dismantling the formwork shall be refer in the Approved

Method statement for Reinforce Concrete Works with Ref.

No. of (ECRL-S4-AW-MS-0008), and for further details of

concreting refer to CD drawing for Culvert NOTE (G)

‘construction

To comply with CIDB requirement, all workers required go

through Covid-19 screening before start work. This practice

must be complying until further notice or information by

cipB.

To comply with CIDB SOP (General Guidelines of

Operations for the Construction Project in the Period of MCO

‘And Covid-19 Prevention Guidelines for Construction Site).

Implementing hand sanitizer and health monitoring by

temperature screening before start work.

Face mask must be wear all the time and safe social

distancing applied before, during work, during rest time and

after work. Disinfection work execute at all vehicle, toilet

and frequently use facility.

Al screening and disinfection work must be recorded and

keep.

‘Construction of Cat In-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 10 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Pema [Doomenine ECRL-S4—AW-MS-0023

Revision No. oO Rev. Date 08 JUNE 2020

1.6.2 Excavation Work

1.6.2.4

1.6.2.2

1.6.2.3

‘Construction of Cast In-Situ Box Culvert,

ECRLS4- AWMS-0023 & Rev. 01

Setting Out

a. Setting out work shall be carried out in accordance

with the coordinates and reduce levels shown in

approved drawings.

b. The centreline of the box culvert, RHS and LHS

edges will be pegged out, and the offsets of these

pegs will be established.

Open Excavation

a. The method of excavation and filing work was

describe the Approved Method statement for

Bulk Excavation and Filing Work

Ref. No. (ECRL-S4-SR-MS-0001).

b. The detail of the excavation such as the slope

properties and the depth of excavation shall be

referred to the Approved CD Drawing. However,

necessary adjustment may be made depending on

site conditioned prior to the approval of the

‘Supervising Consultant.

Foundation of the Box culvert

a. The type of the foundation for the box culvert can be

refer to the AFC drawing Culvert Found

Schedule and shall be in conjunction with the

n.

approved Construction drawing,

b. Ifthe foundation does not required ground treatment,

further 600mm depth are to be excavated and to be

replaced with aggregate or crusher-run bedding with

Suitable compaction work according to specification.

©. Before the crusher run is lay to the treated ground,

the soft material beneath the culvert bedding shall be

removed.

Page 11 of 36

‘CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No, ECRL-S4—AW-MS-0023

Revision No. oo Rev.Date | 08 JUNE 2020

d. For further details of concreting refer to CD drawing

for Culvert NOTE (G) (construction.) The maximum.

height of wall casting, per lift shall approved by

SC (refer to culvert summary) for individual box

culvert

Crusher Run Bedding

a. The crusher run bedding shall be according to the

‘AFC drawing Bedding, backfill and approach slab for

cast in situ box culvert, together with the AFC

drawing for Culvert Foundation Schedule.

b. The crushers run to be laid and compacted in layers.

‘The compacted thickness for each layer is 300mm or

shall be accordance to the Technical Specification

(Sec 4.10.3.2) or specified in the AFC drawings

1.6.3 Construc

in of the Box Culvert Shaft

1.6.3.1 Setting Out of Box Culvert Alignment

a. Setting out work shall be carried out again to indicate the

level and the alignment of the box culvert as per approved

shop drawing. The AFC drawing for Culvert Schedule

Drawing tabulated the dimensions and invert level of the box

culvert

1.6.3.2 Lean Conerete

a. Lean concrete shall be provided to the construction of the

box culvert shaft. The grade of the lean concrete is G20 or

specified in the Approved Construction Drawing.

1.6.3.3 Reinforcement and Expansion Joint.

Construction of Cast In-Situ Box Culvert,

ECRL-S4 AW-MS-0023 & Rev. 01

Page 12 of 36

> ee

=CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No.

ECRL-S4—AW-MS-0023,

Revision No.

oF

Rev. Dale

(08 JUNE 2020

a. Concrete spacer block are to be provided on the top of the

lean concrete to ensure adequate cover for the

reinforcement.

b. Reinforcement bar for the box culvert shaft shalll be erected

first and shall be referred to the AFC drawing for

Reinforcements details of Box Culvert. Formwork of shaft

will then be erected upon approval from the Supervising

Consultant,

c. The method of erecting the reinforcement shall be referred

Hem 1.6 (1.6.1(d) in this method statement.

d. The detail and the number of the expansion joint provided

shall be referred to Approved construction Drawing and for

Reinforcement details of Box Culvert.

fe. Water stop should be installed as per drawing at

construction joint (CJ), the location be determine by site

actual construction sequence.

{. Mid-Buried waterstop is set along centreline of Frame Slab

at the end of culvert segment in a ring.

g. Back-sticking waterstop is laid outside the culvert structure,

bottom slab, foundation of culvert segment at entrance and

exit (refer to individual Culvert Drawings.)

1.6.3.4 Erecting of Formwork

a. Method describing the erecting and striking of formwork

shall be referred to item 1.6.1. (d) In this method statement.

b. Side formwork of base slab (timber form) with sufficient

timber support shall be erected prior to installation of steel

reinforcement.

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW.MS.0023 & Rev. 01

Page 13 of 36

DEBSER — [Document No. ECRL-S4—AW-MS-0023

=CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

© Revision No. oF "Rev. Date (08 JUNE 2020

c. Tie rod shall be applied to secure the side formwork at

suitable spacing of less than 750mm centre with a pair of

‘50mm dia G.I. pipe or 2"X3" hardwood timber as wales.

1.6.3.5 Concreting of Box Culvert Shaft.

a. Method describing the casting of concrete and the curing of

hardened concrete shall be referred to tem 1.6 (1.6.1(d) in

this method statement.

b. Joint inspection with Supervising Consultant shall be carried

out before concreting to check formwork, reinforcement and

cleanness .Approved Inspection Test Plan and checklist

form as per stated in Sec 4.0 -Quality assurance and Quality

Control shall be complied by the contractor and approved by

Supervising Consultant for records. Upon approval from the

Supervising Consultant, contractor can procesd with

concreting work.

1.6.3.6 Dismantling Formwork

a. Formworks are to be dismantling after the concrete is fully

hardened. The dismantling of formworks shall be carried out

‘on the next working day side or as specified in the Approved

Method Statement for Reinforce concrete Works with Ref.

No. (ECRL-S4-AW-MS-0008).and shall agree by SC

b. The dismantling of formwork should also in conjunction to

Table 18.12.10, Section 18 Technical Specification. The

period between concreting and removal shall be modified

appropriately. (Refer to Sec 18.8.4 and 18.4.9) And shall be

agreed by SC

cc. Water Curing shall be applied as Sec 18. 5. 8 and 18.5.8.1

Curing and protection and Normal curing and protection

4 Construction Phase of the Box Culvert Shaft

1.6.4.1 Construction of Base Slab

a. The base slab shall be constructed first. The base slabs

reinforcement shall be erected after casting of lean concrete.

CConsiuction of Cast In-Situ Box Culvert,

ECRL-S4- AWMS-0025 & Rev. 07

Page 14 of 36

‘CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

ChERSER = [Document No.

ECRL-S4—AW-MS-0023

Revision No.

a L_Rev. Date (08 JUNE 2020

The next activities are erecting of formworks and casting of

conerete.

b. Prior concreting, a joint inspection with the Supervising

Consultant shall be conducted to check on the reinforcement

and formwork.

c. The method of concreting shall be referred to item 1.6.3 in

this method statement after casting of lean concrete.

1.6.4.2 Construction of Side wall, Top Slabs and Corbels

1.6.5

a. Side wall, top slabs and corbels to be constructed after at

least 1 day of concreting the base slab.

b. Walls, top slab and corbels have to be provided when

erecting the reinforcement.

¢. Top dowel bar for the translation slab to be provided when

erecting the reinforcement.

d. Expect for walls and corbels, dismantling of formwork for top

slab shall be conducted or as per stated in Approved Method

‘Statement for Reinforcement Concrete works with Ref. No

(ECRL-S4-AW-MS-0008).

Inlet and outlet Structure

1.6.5.1 Construction of Inlet and Outlet structure

d. The type of inlet and outlet structure for the culvert shall be

referred to the AFC drawing Culvert Schedule.

e. The detail of the inlet and Outlet be in accordance to the

approved shop drawing and shall be in conjunction with AFC

drawing for Typical Details of Wing wall for Drainage Box

Culvert.

f. The method describing the construction of inlet and outlet

structure shall be referred to item 1.6.3 in this method

statement

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AWMS-0023 & Rev. 01

Page 15 of 36

7 “CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

sumgext [Document Re, ECRLSt—AWMS-O0ZS

Revision No TW] Rev. ate | 08 JUNE 2020

1.6.6 Backfilling Work of the Box Culvert

1.6.6.1 Backfilling Work of the Box Culvert

a. The method of backfilling was described in the Approved

method Statement for Bulk excavation and Filling with Ref.

No. (ECRL-S4-SR-MS-0001).

b. The Depth of backfilling shall be carried out in layers,

compacted and tested until the soffit level of the transition

slab. The Soil parameters shall be referred to the approved

construction drawing, for Culvert Note (E)(Backfill and

Compaction) and the filling depth per layer shall refer to

Technical Specification Section 3 Earth Works (Table 3.5

Type of Compaction)

¢. Prior to backfiling all the earth face structure shall applied

by 2 layers of bituminous coating.

1.6.7 Approach /Transition Slab

1.6.7.1 Construction of the Approach slab/Transition

a. The detail of the approach slab shall be referred to the

approved construction drawing and shall be in cooperate

together with Construction drawing for subgrade for backfill

and approach Slab for Cast In-Situ Box Culvert. The method

of concreting which includes form the erection of

reinforcement erection of formwork, of concrete until

striking of formwork shall be referred to item 1.6.3 in this

method statement

1.6.8 Bank Protection Work

1.6.8.1 Construction of Banks Protection Work

a. The setting out to be carried out as per approved shop

drawing, However ,minor adjustment has to be carried out

to suit the actual site condition in order to ensure the smooth

of water into the existing river, existing stream or existing

drain.

b. Excavation work shall be conducted after setting out. The

depth of excavation and slope formation shall be referred to

the AFC drawings for Culverts Inlet Protection Work.

Construction of Cast In-Situ Box Culver,

ECRL-S4- AWMS-0023 & Rev. 01

Page 16 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

SOBRE [Document Ro. ECRL-S4—AW-MS-0023

_ Revision No. of [_ Fev. Date (08 JUNE 2020

c. 100mm thick of sand bedding shall be laid, or per specified

In approved construction drawing.

The filter fabric is then to be provided on the top of the sand

bedding. The detail of the filter fabric shall be referred to the

approved construction drawing.

Rubble pitching work shall be laid after the filter fabric

layering is complete. The properties of the rubble pitching

stone shall be referred to the approved construction

drawing.

1.6.9 Joining the Box Culvert to the Proposed Drain/Existing Drain

1.6.9.1.

Connection the Box Culvert to the Proposed / Existing

Drain

a. Firstly, excavation the earth connecting to the outlet of

the box culvert to the existing drain.

b. At the next step another permanent earth drain to be

constructed to connect the inlet of the box culvert to

the existing drain.

c. After that, the flow of existing drain will be diverted into

the box culvert inlet through permanent earth drain by

either using the sheet piles or build an embankment

or any that suits the site condition.

d. After successfully diverting the flow from the existing

drain into the proposed box culvert, the existing drain

will be backfilled in layered and compacted.

‘Construction of Cast In-Situ Box Culver.

ECRL-S4- AW-MS-0023 & Rev. 01

Page 17 of 36

ES

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No. ECRL-S4—AW-MS-0023

Revision No. oF Rev.Date_ | 08 JUNE2020__|

2.0 SAFETY AND HEALTH

2.41 Job Safety & Health Analysis (JSA)

a

ii,

vi

vii

vil

All personal shall receive CCCC ECRL Section 4 HSE

Induction Program,

All personal shall have valid CIDB green card.

All HSE issues in every work location will be coordinated by

the Safety Officer/Site Safety Supervisor.

All personal shall be provided with and shall use appropriate

personal protective equipment (PPE) (e.g. safety helmet,

safety goggle, face shields, dust masks, safety shoes, hand

gloves, etc.)

All tools and equipment shall be checked daily by qualified

person prior to use,

Any damaged equipment or tools shall not to use. They shall

be tagged, removed from site and replaced by equipment and

tools in proper condition

Any work must follow closely with approved JHA.

‘Obtain CCCC ECRL Section 4 approval prior to execute work

Ensure housekeeping conducted daily.

Due to Covid-19, control measure must be done to

ensuring safe and health working environment at

workplace:

All workers to go through Covid-19 screening (implement

until further notice or information by CIDB).

To inform KKM if found positive workers on the Covid-19

screening, To inform KKM on the workers which have

symptoms of Covid-19,

Use face mask and hand sanitizer prior start of work.

Brief workers on the safe method of work during toolbox (1-

meter gap).

Do health monitoring by temperature screening before start

work.

Safe social distance more then 1-meter before work, during

work, during rest hour and after work.

Disinfection work execute at all vehicle, toilet and

frequently use facility.

All screening and disinfection work must be recorded and

keep.

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 18 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

cpBsseae [Document No. ECRL-S4—AW-MS-0023

evn No a Rev. Dato | 08 JUNE 2020

2.2 Information to Personnel

Construction Industry Development Board (CIDB)

CCCC ECRL Section 4 shall ensure all employees and it’s to have 2

valid CIDB card when working in the CCC ECRL Section 4 project site.

This CIDB training Is conducted by competent trainer.

CCC ECRL Section 4 HSE Induction Program

Upon receipt of valid CIDB card and prior to start WORK in the CCC

ECRL Section 4 project site, all employees including SUB

CONTRACTOR employees shall attend a HSE Induction program to be

conducted by the CCC ECRL Section 4, This HSE induction program

shall be done at site in CCC ECRL Main Office/ site. Each employee

and who has attended and passed the HSE Induction program will be

issued with a sticker to indicate that he has completed the HSE

Induction Program. Only then, WORK is allowed to commence at site.

Abbriefing based on the control measures detailed in the job safely and

health analysis is required for all work activity and all personnel involved

in the work have been given a pre-task briefing in a language that can

be understood by all persons involved. Detail the person responsible for

providing this briefing and the way in which records will be maintained.

2.3. Emergency Arrangements

In order to minimize casualties, property losses and social impacts

caused by safety accidents, the project department worked out

contingency plans. After the accident, emergency deployment should

be started immediately, and accidents should be dealt with in time so

as to prevent the loss of accidents from expanding.

1) Emergency on Covid-19

If workers or staff found with Covid-19 symptoms, send to the

nearest Klinik Kesihatan for screening and immediate treatment,

depending on Doctor Advice.

Report to the Project Manager and SHO.

Preventive measures: Before sending the personal to Klinik

Kesihatan, the vehicle must be disinfecting and all personal use

hand sanitizer. Safe social distancing must be applied inside

vehicle. All people inside vehicle must wear face mask. Avoid close

contact to each other. After finished al the procedure, all personal

must wash hands and take bath. The vehicle must be disinfecting

Report to the HQ CCC ECRL as soon as possible.

lf someone in the project is found positive Covid-19, other members

Who to be in closed contact should be observed and receive medical

observation for at least 14 days.

‘Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW.MS-0023 & Rev. 01

Page 19 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

cbepsi@ = [Document No. ECRL-S4—AW-MS-0023,

Revision No. om Rev. Dale (08 JUNE 2020

2) Construction in Thunderstorm

Local rainfall, rainy season construction more prone to lightning,

heavy rain, wind weather, construction equipment, personnel

damage.

Preventive measures: before hoisting operation, to know the

weather in advance, not suitable for operation of the weather

(thunderstorm weather, wind speed up to 6) to carry out lifting

operations and piling work is strictly prohibited. In the construction

process such as sudden strong wind or heavy rain, steel pipe piles

or steel should be immediately put back, and fixed, until the weather

conditions improved, check the spreader may continue to work.

3) Matters needing attentions under the influence of tide

In the waters of the construction range, a proper distance vertical

draft, observe the tidal changes. Through local JPS and water

conservancy irrigation Bureau, the river management department

issued the water construction announcement ahead of time,

reminding the passing vessels safe passage.

4) Operations nearby sea or river

The personnel fell into the water and drowned.

Water construction personnel life jacket, traffic and other lifesaving

boat facilities shall be complete and effective. Steel pipe piles,

operations platform erection process must be designated in

dangerous zone, danger zone strictly prohibited,

5) Accident

If occurs an accident on construction site, employees shall:

= Assess the situation: do not put yourself in danger;

- Make the area safe, and do not try to move the casualty;

= Look for a first aid responder;

- First aid responder should;

- Assess the victim: Check for consciousness, bleeding,

breathing, heart;

~ Call - or send somebody to call - the site nurse.

- Explain the location, cause of accident, number and state of

victims.

= Look for a first aid box and material that first aid responder /

rescuer will need;

- First aid responder should provide first aid car

= Send someone near road / access to guide the ambulance /

paramedic staff;

- Report to immediate supervisor and Safety Head.

Construction of Ces In-Situ Box Quiver,

ECRL-S4- AW.MS.0025 & Rev. 01

Page 20 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

pms [Document No, ECRL-S4—AW.ME-0023

Reviion No, OH Rev. Date [08 JUNE 2020

6) Fire

Ifa fire occurs, employees shall

Alert personnel in the immediate area;

If no personal risk is involved remove injured person from

immediate danger,

Call Supervisor or Safety Head who will assess if Fire Dept.

must be called;

If no personal risk is involved and fire is still small, try to

extinguish it with a fire blanket, fire extinguisher or other

available means;

If in doubt, or if fire is not controllable evacuate quickly and

calmly;

Proceed to designated Assembly Point following evacuation

routes;

Report to immediate supervisor and Safety Head

7) Pollution spillage or leakage

In the event of pollutant spillage or leakage no matter what size,

employees shall:

Try to stop the spill source, e.g. close the valve, if possible;

Notify personnel in the immediate area of the spill;

Attend to any persons that may have been contaminated

Contaminated clothing must be removed immediately and

appropriate first aid applied;

if a volatile flammable material is spilled, control any

possible sources of ignition and ventilate the area;

Wear appropriate PPE (Safety goggles, chemical suits or

approved coveralls, rubber, vinyl gloves, rubber boots) for

the material spilled and avoid breathing any vapor from the

spill

Use appropriate spill control material to first contain and

absorb the spill according to procedures previously obtained

from the SDS;

When the spilled materials have been absorbed, use a brush

and scoop to place materials in an appropriate container.

‘Store the container in a ventilated area;

Decontaminate the surface where the spill occurred before

allowing normal work activities to resume in the area;

Report to immediate supervisor and Safety Head

8) Contamination of groundwater

In case of accidental pollutant spillage or leakage, groundwater

can be contaminated and pollutant can be release to the water

body through dewatering process.

ECRL-S4- AW.MS-0023 & Rev. O1

In the event of contamination of groundwater during dewatering,

employees shall:

CConstrycton of Cast In-Situ Box Culvert,

Page 21 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

‘Document No.

ECRL-S4—AW-MS-0023

RevisionNo. | 04

Rev. Dato

(08 JUNE 2020

- Follow instructions for controlling pollutant spillage or

leakage (NOTES ON GROUNDWATER CONTROL)

- Protect the outlet point with absorbent mats in order to

contain

- Report to immediate supervisor and Safety Head

9) Subsequent medical treatment

~ _ If frst aid care provided on site by first aid responders or

medical staffs are not sufficient, subsequent medical

treatments will be required. These treatments will have to

be done by external facilities.

- The transportation of the wounded persons to the nearest

Hospital shall be done by the ambulance or by site

vehicles such as minivan, regular car and pickup truck.

- Anurse should escort the casualty to the hospital in order

to gather the medical diagnostics and report properly to

CCC ECRL management.

NO. PHONE

POSITION NAME

NUMBER

1 | Group leader Yongjun Zhou 0173265086 |

2 | Deputy leader Qifeng Cai 0122816581

3 | Deputy leader Rongxian Feng | 01125692586

4 | Deputy leader Ziyang Liu (0172508359

5 | Deputy leader Xianquan Yang 0179672371

6 | Deputy leader Chungui Ye 01127580471

7 | Deputy leader Kai Yuan 01127580486

8 | Member Bo Liu (0179718934

‘9 | Member Dongfan Zeng (0179241269

10 | Member Jianyuan Liang 0179718415

11 [Member Mah Kok Weng 0127265181

12 | Member Mohd Kamarul 0104077116

13 | Member Puvaneswaran 0164404689

14 | Member Kamil Helmi 0145345900

15 | Member Fathul 0137434634

16 | Member Suriani 0182704990

Construction of Cast In-Situ Box Cuvert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 22 of 36

ome [oasomennes [ESR AWN

Revision No. oF Rov. Date (08 JUNE 2020

NO. UNIT PHONE

NUMBER

1 | Management 0175877669

2 | Chinese Consulate in Malaysia (00603-42513555

3 | Paka Fire Department 09-8274444

4 | Paka Police Station 09-8271222

3 | Health Bureau (09-8422100

6 | Dungun Fire Department 09-8484444

7 ~~ | Dungun Hospital 09-8483333

8 | Dungun Police Station (09-8482222

9 | Department of Environment Kuala| 09-6247135

Terengganu

10 | Department of Wildlife (PERHILITAN) | _ 09-8423262

Dungun

24 — Permit Requirements

Alll permits to work required for this specific work activity along with the

name of the person responsible for obtaining each permit are as follows:

Description Authority | Responsible | Contact Details

Personnel (Mobile No)

‘Traffic Management Plan JKR Zamri 142842216

Approval for operation and workers’ MITI/CIDB Ziyang liu 0172508359

movement during MCO.

2.5 Permit to Work

PTW is a written document authorizing person to carry out the

work concern, warning of possible hazard and spelling out

precautions needed for the job to be done safely

No.

Description

Responsible Personnel

Construction of Cast n-Situ Box Culver,

ECRL-S4- AWMS-0023 & Rev. Of

Page 23 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

> cote [Document No. ECRL-S4—AW-MS-0023

Revision No. ot L_Rev. Dato (08 JUNE 2020

1. | Excavation Permit Permit Requestor/Supervisor/Foreman

2. | Lifting Permit Permit Requestor/Supervisor/Foreman

3. | Permit to Work Permit Requestor/Supervisor/Foreman

(Night/Weekend/Public

Holiday)

4. | Transportation Permit | Permit Requestor/Supervisor/Foreman

3.0 ENVIRONMENTAL ISSUES

34

Environmental Aspects, Impacts & Control Measures

1) Strictly comply with the requirements of the safety education

meeting, formulate relevant management system and strictly abide

by.

2) Implementation traffic control as per approved Traffic Management

Plan (TMP)

3) The vehicles/machineries that loaded with raw materials is properly

covered with canvas

4) Construction machinery and equipment should be regularly

checked and maintenance to prevent oil leakage to avoid polluting

‘the water environment.

5) Water bowser should regularly operation especially during dry days

6) Ensure cleanliness of public road by provision of wash trough and/or

public road cleaning using manpower/machinery

7) Prepare secondary containment/bund/drip tray for bar bending and

bar cutting machinery

8) Covered the bar bending and bar cutting machinery with canvas

after use (if working area not roofed)

9) Avoid placement of machinery/vehicles near public sensitive area

(if applicable).

10) Water runoff from site activity should channeled into erosion and

sediment control (ESC) before discharge i.e silt trap, sedimentation

pond

11) Construct earth drain and silt trap/retention pond before/concurrent

of work start

12) Sprinkle water to reduce dust emission during crunching excess

concrete (if necessary)

13) To inform Public Relation Department if any Public Report/Protes/

Local Authorities Notice/Fine/Stop Work Order arise

14)To install hoarding and/or noise barrier at working area near

residential/neighboring Area (if necessary)

Construction of Cast inSitu Box Cuvert,

ECRL-S4- AWHMS-0023 & Rev. 01

Page 24 of 36

® “CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No ECRL-S4—AW-MS-0023

Revision No. ui Rev. Date | 08 JUNE 2020

18) Optimize the amount used for usage of diesel/lubricant oil/ raw

materials to reduce the amount of sources depletion

16) Sprinkle water during crushing activity ( if any)

17) Excess concrete can be used for temporary work (if any)

18) Stockpile for crusher run should be collect at a designated area (if

any)

19) Ensure to clean on-site sanitation, clean and tidy site, and do a good

job in site civilized construction

20)No open burning allowed at site

21)Necessary wildlife management is planned and properly carried

before/concurrent with work activities as per Wildlife Management

Plan

22) Wildlife Department specialist arrangements for wildlife monitoring

and management for any case of wildlife sighting/wildlife-human

conflic/wildiife attack in site

The all environmental aspects related to the construction of In-Situ Box Culvert has

been identify and its control measures are as follows:

Adlivities | — Significant Mitigation measures

Impacts

Vehicle and} Traffic Impact ‘TWVehicle/Machinery Mobilization complete with

Machinery Traffic Control

Mobilization

Air Quality

1) The vehiclesimachineries that loaded with raw

materials is properly covered with canvas

2) Water bowser regular operation especiall

during dry days

3) Ensure cleanliness of public road by provision)

of wash trough andfor public road cleaning using

manpowerlmachinery

Usage of

Bendit

par Bencing| soit and Water 1) Prepare secondary containment/bund/dri

Quality tray for

ar Cutting ‘ i

chine bar bending and bar cutting machinery

2) Covered the bar bending and bar cuttin

machinery with canvas after use (if working are

Construction of Cast In-Situ Box Cuver,

ECRLS4- AWMS-

0023 & Rev. OF

Page 25 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

eam Document No.

ECRL-S4—AW-MS-0023,

Revision No.

a Rev. Date (08 JUNE 2020

not roofed)Traffic Management Plan to addres:

the issue of traffic disruption

Noise Quality

‘Avoid placement near public sensitive area.

‘Air Quality

‘Avoid placement near public sensitive area

Water Quality

excavation

id

ckfilling

rk.

‘Turbid water runoff from site activity

channeled into erosion and sediment control

(ESC) before discharge

1) Construct earth drain and silt trap/retention,

pond before of work start

2) Issue Site Inspection Report (SIRVWarning

Notice/Non-Conformance Report (NCR

Air Quality

Total Suspended

article)

Noise Quality

Dust Emission without Dust Control

1) Management Report, Reminder and Penalty

System

2) Sprinkle water to reduce dust emission (if

necessary)

Public Report/Protest/ Local Authorities

lotice/Fine/Stop Work Order

}) To inform Public Retation Department

2) To arrange immediate rectification

8) To dismiss/stop work until rectification done

{Generation of Noi:

1) Hoarding and Noise Barrier Installation at

Residential/Neighboring Area

2) Avoid working activity during sensitive hours

nsitive Area (ESA)

pero at Sensitive Hour at Environment

Construction of Cast in-Situ Box Cuivert,

ECRL-S4- AW-MS-0023 & Rev. 01

Page 26 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

COEBEM [Document No. ECRL-S4—AW-MS-0023

Revision No. a Rev. Dato (08 JUNE 2020

) Public Engagement

22) Work Schedule

Local Authorities Notice/Fine/Stop Work Order

) To inform Public Relation Department

2) To arrange immediate action

}) To dismiss/stop work until proper action taken

Conereling Depletion of

Resources

Air Quality

jsage of Diesel/Lubricant Oil/ Raw Materials

) Optimize the Amount Used

22) Avoid Resource Wastage

Used of excess concrete

) Sprinkle water during crushing activity (if any)

) Excess concrete can be used for temporary

rk

) Collect at a designated area or ROW

Formwork | Local Authorities Used of formwork

Dismantle | Concern/Sensitivty|

) Housekeeping

2) Wood reuse for other structure

) Dispose into RORO Bin

#4) No open burning

5) Management report, reminder and NCR as

any open burning at site were prohibited

Work Site

jin Forest or}

Forest

Corridor

'Wildlife Disturbance

roperly carried before/concurrent with work

ren wildlife management is planned and

ivities as per Wildlife Management Plan

}) Awareness training is provided for the workers

\2) Wildlife Department specialist arrangements for

ildlife monitoring and management

pete Sighting/Wildlife-Human

‘onflict/Wildlife Attack in site or

1) Wildlife Department Response Team and

Emergency Response Team (ERT) is

activated

Refer to Section 5.3 for specific environmental aspect impact register.

Construction of Cast In-Situ Box Culver,

ECRL-S4- AWMS-0028 & Rev. 01

Page 27 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Document No. ECRL-S4—AW-MS-0023

Revision No. oF Rev. Date | 08 JUNE 2020

4.0 QUALITY ASSURANCE & QUALITY CONTROL

4.1 Contractual Requirements

1, IFC drawings, Technical Specifications, technical document submissions

and shall be implemented in accordance with submitted comprehensive

Project Quality Plan (PQP)

2. The Contractor shall make necessary arrangements for the relevant utility

and authority representatives to be present during the relocations of

existing utility services, jointing of new to existing utility services,

inspection of works, inspection of materials and testing and hand-over of

the new utility services.

42 Inspection & Testing

= Referto the attached Appendix 5.4 Inspection and Testing Plan

4.3 Follow up & Evaluation

1. The work shall be carried out using the inspection form/ checklist attached

in Appendix 5.5 and ensure the finishing quality of work shall be

acceptable by Supervising Consultant.

2. Should there is any Non-conformity of work issued, we will respond within

‘seven (7) days. Root cause shall be determined, correction of work shall

be taken immediately if possible and corrective action shall be taken

accordingly within agree date, Our objective is to limit the repeat

occurrence of major NCR to a maximum two (2) times. All NCR shall be

closed within the agreed completion date

‘Construction of Cast In-Situ 80x Culver,

ECRLS4- AWMS-0023 & Rev. 01

Page 28 of 36

(om

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

zi [Document No.

ECRL-S4—AW-MS-0023

Revision No.

ou

Rev.Dale_ | 08 JUNE 2020

5.0 APPENDICES

5A

5.2

5.3

54

5.5

5.6

Construction Sequence Flow

Job Safety & Health Analysis (JSA)

Environmental Aspect Impact Register (EAIR)

Inspection Test Plan (ITP)

Quality Control Sit

Inspection Checklist

Work and Activity Commencement Notification

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW.MS-0023 & Rev. 01

Page 29 of 36

coms [Document No. ECRL-S4—AW-MS.0023

& [___ “CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

Rovision No. ot Rev. Date] _ 08 JUNE 2020

Appendix 5.1

Construction Sequence

(In flow chart)

FOR CONSTRUCTION OF IN-SITUBOX

CULVERT

‘Constustion of Cast in Stu Box Culvert,

ECRL-S+ AW.MS-0025 & Rev. 01

Page 30 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

ECRL-S4—AW-MS-0023

SDB [Document No

Revision No

ou i

Rev. Date ‘08 JUNE 2020

Construction Sequence Flow

EXCAVATE TO

BEDDING LEVEL

|

‘SET-OUT CULVERT POSITION

LAY, SPREAD

BEDDING 600mm.

ALLACTIVITY

NEED SC/QAQC

INSPECTION

REINFORCEMENT

PRE-CAST BOX

CULVERT

INSTALLATION LEAN CONCRETE

CAST BASE/SHAFT &

‘WALL UNTIL KICKER

‘WATERPOOF/WATERSTOP

‘Works

INSPECTION T

WING WALL CAST WALL AND

CONSTRUCTION ROOF SLAB

BACKFILL TO

REQUIRED LEVEL

J

REINFORCEMENT

INSPECTION

CAST APPROACH SLAB

J

FINAL INSPECTION

AS-BUILT SURVEY

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AW.MIS-0023 & Rev. 01

Page 31 of 36

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT”

‘Document No. ECRL-S4—AW-MS-0023

Revision No. 0 _ | Rev. Dato | _ 08 JUNE 2020

Appendix 5.2

Job Safety & Health Analysis

(JSA)

FOR “CONSTRUCTION OF IN-SITU BOX

CULVERT”

Construction of Cast In-Situ Box Culvert,

ECRL-S4- AWMS-0023 & Rev. 04

Page 32 of 36

sar aa pa

reroupen [runt | “ruren

| ST

aqeres

ws ‘Aunt A208 1

mre *) s . (auesp) Avoutypew

Joyerado aouayadwop (91| Aq pausnsa 10 xpnNs ET

-mus woponnsven 0p :

co" 2eng aurepIng “aigetene Lid / vind (5

1900 800 "LN wonsedsul AOUIYDEN (>

noversuy | 3d » lor > Buydaayasnou (e

= -waashs Appna (z sures

“popinoud ease 3s0y (7 ssons1e0H +1

“ays e uojsiadns pasor> (0 JaypeaM 10H ZT

>pnuysajem Aq yonuos yang (q

‘ays uo onuos ayes,

suspueweye | yiipy vi} oz z

reumeu poe voesuen

‘ebems ueeo0

‘ant A

wea p08

pue hayes iu

LST 305 VASO ‘uononpuiasH (| uno. Aadays t1| eos uonevedaud aus | 1

NIM NIFONT . . FONTOUAIN /3NLLNOY

‘Nvna in 3k puoqpes

? 10:0N zu vat

mie jr enon oe

= NIdSISV INVA CHOW ‘UaAIND XOg Jo UONINYSUOD :GOr 4O NOLLAIISIG asH

:A@ O3UVdSEd | :430/A10

€TjOT ade aed

ozo INATZ | Biep anss1 , en

To uojay) TOMLNOD NSIY CNV LNAINS3SSV SIH ‘NOLLWIIJLINAG! GuvZvH | Beer

£7200-SW-MV-PS-1893 | “ON WO4

roeesoinurinees | sen] onamanpipanayudinyan | moiety

mew | + non

sft ARTS Re Toa TGS TT =

versa | Pere consem pur gods ies | Arann Ann

| RT Tas Tee

ada

uwipy

Som 1eye pUE

4noy 3894 Buysnp jor Buynp

‘quom asoyaq Jaqourt wou

‘40w aouersip je 0s ayes -

“u0m 1e3s as0}0q

Sujuaains axmevadway

oa) s z 4q 3uoyuou

210M Jo Y3e9s sOUd saztiues

uey pue ysew 298) as -

“6T-pIAoD Jo swordwiAs

aad

uwpy

‘aAeY YOIUM S12 YOM

43 wo yyy WOJUI O4

“Bujuaans 6T-pIn0D

or

. . {aa

‘Aq uonewoyus so aon0u

seyuuny jnun juauraydusy)

‘Buluaanns 6t-pIn0D

{yoy 08 0} si34s0m ty

ada

uwoy

wonamasul 20M (si

v z z (rsew sng 008 Ayes

‘3804 Mayes 2H PACH) add (Lt

(hequow / wsoy /

soynbsou /2yeus)

puezey je2:8oj01g 9°

‘nu

uo siayior ayu}

‘Bupeaids

sma jo ¥sns

(yeasqno

uunp) 10m sod

paiidde sazniues puey

ou / ysew aoe) ynoyim

Bupyom / saau-T ueUE

$52] 29ueIsip [e805 $°T

“qe=y

on page 2]u014) +

sn pT

€Tj0 7 a8eg aed

ee erar| TOULNOD ¥SIY CNV LNJINSSSSY NSIY ‘NOLLVDHLLN3GI GYVZVH

£200-SIN-MV-9S-1893 ‘ON WO,

remeawe/svon | wm] +

Sa 3

was

Spon ven wae ape T

* ‘sts voendo

ok ea ‘mid (4 Bupuog / suom sega: |

Ss ss OHS eam ae uy ° e © punosBuapun Jevayew Surjpuer

‘oouais, | puemnpsamses uy

st 80 me aunoid_( uoneyersui soy ious | €

wpe

2 als z “(ysewasna ‘ioog Mayes

youtg ‘89p Ayes eH preH) add (c nouns

omer “Buidea495NOH (TH ssornbsow / 3yeUs)

was ara (04 Sere eo

os “papinosd ease ysay Taeies

‘5555 ‘ons “oie ames

“aauaua or s z ‘Bupuup wuayns Aiding (; eee eh

Aq paysnuo 40 yon ZZ

o| 2 e ‘nf Anos

ue hays oes iiespue diy una jo no

prey punoiB Aiaddist' | Bunaas oj yom Aanins |_z

-daoy pue popioas

29 snus om woR>asUSP

pure veo wy =

‘aloe asn Apuenbos,

ue 903 optan ye

ciroava yom UORDOWITA -

£130 € o8ed ‘aed

ea eam TOWLNOD NSIY CNY LNAWSASSY ISI ‘NOLLVOISILNaGI GUVZVH Soe0

EZOO-SW-Mv-7S-1493 | “ON WHOS

: rsesymtinajtanes | man | isenetpimres saint | enon |

Srey

‘eats ps manera HOON NBR Fe RRR ° oe pasaeaamonsocngou evan | Aan

=| waar tet | “nese —e SERENATA a

Sorte nepe Rema ony nue sR RN RN [Sita i fee | a | —e | ~ Ba ins ov oom | —

eit eno een nan NN PR : rumsreion | onan | ‘ome nnemypeeotunjenig | _Amunnn

ar cam | ae | ewe [Cie

ORO rr “aaa

] ]

aad

oupy ol] s z Lu

eyoour8u roa 4

1o1eneox9

LSE

reuossajo1g “9Ieu! “ules

3a z| z fy ueya 210u uonencoxg - ‘ssansie9H 1

ad ‘weld uoneneax3 - HSE

:uonansisul oN (s) aw

sae “soreiado aouaieduie9 (y 1

uwipy oO s z “uonpadsu: ArauyseW (E1 ‘Assuiypew.

(1SeW 13Na “I00g KBJES | Aq paysna 10 YONG ve

aa ‘9500 Mayes ‘YeH PueH) 3a (2

ulwpy ‘Buydaayasnoy (1! "walqosd

a eye z waishs Appng (oy, BUHe2y 20ND

-seuensuyo | uuaeursug | apnoid ease 1s0y_ ( z

sean cain “ais ve vojsiuadns pasory(

i, ‘24s vo jonuoa 2yjesL

: o | s z ;peou ay9nd ;

usoudua Aqseau uoneeisul 10} AL ( punos@i=pun yaim

“ssa2oe ajes as (q__eIUOD lenuaIOd TE

fimmonl wes eae uonesado aia 1e

7 revstew pue wessuen sa8eulis'g apeoiuea Mayes ( “Aunluy sau

£1 j0y ated [aaa

Seon eary| TOULNOD SIX GNY LNJINSASSV ISI ‘NOLLWOIILLNAGI GYZWH

E200-SW-MV-PS-1u93 | “ON WI0s

aan

sos senr/muees | eo

eae aainpuotayvsden | moa

"ag |

os

‘s8'985 ‘OHS

‘sauldu3

‘aovensujo

sayeaysan pue asu3y

‘as pue wee

revere puevodsuen

‘aaei035‘uonesodo

‘auunp yaeoy

ue Aas ounsu

21 'ST295 wHs0

or

wey

3

uyoouug

add

uwpy

3

upsourua

add

wey

3

upesutug

sovesado aouajadwop (c'

‘uonsadsul AlouiNeW (9)

“PiseW asa oog Aes

‘son Ayes "10H pIEH) aad (5

“Buidaayasnoy (11

-uiarshs Appng (¢

papinoud ease soy (2

“auls 1 uolswsodns paso (1

‘aus uo

ou a11gnd

‘Aqseau uoreneoxa 40} dL

“yuan

‘aya Bulyouag pue uid

“ypu

sea T Buped Ai

/ Suppers jeuarew oN

mop 08 01 ssaaze ayes sis

“yuan auf jo apa 1e

soBeudis g apeouueg Arayes

“spom 1e3s 0} sold Buyaug

‘Mud

19 punos@uapun

oy Ayanne Sundog

nuos 24je41. (0

(

(

Ryees

“hanfar Apog +

cuonencoxa yo a8pa au

e984 Woy 124 9°

4

‘389035 189H,

‘Avouiysews

‘Aq paysnua 10 yonns by

asdeoo yea Ey

waiqoud

Buyeay 1uo.y +

asjou 0) asodx3 2"

puno.@sapun yim

ppeWUO9 leNUAIO Ty

‘Buqyppeg

Pueuoreresx3 |

£450 Sa8e4

‘aBed

0z0z ANZ | arep ans)

10

UOISIABY

€Z00-SW-MV-7S-1493 | “ON WHOS

TOULNOS YSIY CNV LNSINSASSY SIX ‘NOLLVD!

ILNAQI GYVZVH

5 iran | eno | 5 tga anny ingen | wmiy

or a [aaa

vt elt e | ‘jouer | us. yeomuous ine 10

soresedo aouaraduioy (¢Y_ WWD YIM 39209 75

“ajgeene La / vind (Z ~ANEIES

7 wonedsu ArouNDEW (T saunfur Apog 1

i 7) 8 . ‘uidaayasnon (Ot 108

-warshs Appna (¢_Bunyt ove pue axem £°5

“popirosd eore 108 (

xa z | ot z ‘ys uosadns paso wwaigoxd

wey als uo jonuo> yes Supeoy a1u0.4)

us pue we -peod Aqieou jt di

revseu poe vodsuen mop 08 01 ssanne aes paraidwoo

eesiraeey| 344 als z ‘saBeulls apedtiieg Aiayes Jesu) lomutioy

puehajesarmue | UUPY : 92.0400 deo ata

45195 WHS /2i22U09 wear yo Buker | §

|

3aa

umpy

: os z !

usu 24 astopus 0} (3d) s2au8u3

reuojssajo4g “oraus “Ayeres

fy ues 210u1 uoneneox3 - “Aanfuy Apa 1

uelg voneneoea soreneaxo

L wonannsui om (B40 Bua ‘palddoL cy

€Tj0g9 a8eg aed

Seen o uosry| TOULNOD YSIY GN LNAINSASSY ¥SIY ‘NOLLWOI4ILN3C! GUWZWH

€ZOO-SW-MV-PS-1HD3_ “ON WHOS

saponins yom

uyetanajianes | yer | ot sip denny uedeyain | ania noe

ca agp RE OD

Tena

OO

Raed

‘Aintusofew

oe, cunssoud vy

t or oyanp uossoidx3 “1

wweouses “quauedwo> @urkiy

aed on 198811100 40) 02d: padewep

owpy “pourou Bu 1

uoysyjo0 / auly2eus

Ag ysrup / nas £°S

sea -sunyan woes (

up or porate ams (8

aoveinsujo (seus

1snq ‘sanoj8 uoNto9 ‘Bnyd xe |__PUNOAB argeasun 9's |

‘anoj8 saqany ‘1009 Ayes

3a z “s9n Auayes ‘IeH pAeH) add (SI quires

upy “(hiauy>ew) 50251004

(2si0n) vs Joyeredg qwereduio3 tr sayeanroy S's

£101 a8e¢ ‘Bed

ozoz ant | ep anssy

To] uosnay] TOXLNOD 4SIY GNV LNJINSASSY SIH ‘NOILVOISILNIGI GY¥ZVH

€200-SW-MW-¥S-TH93 | “ON WHOS

#2560

—ee s Agee arden Ae ou s pifend ma Maanp Auoenbess vediey umn | wren souRy

n i= ma

—— 1 7 ae Trento

— aes ro Tae one

aaa iano

‘(auen) saunfuy Apog 1

aad st s € soyeradg aouaredwod (€1 a

vupy (uaunpew) ues Buuinp 1e08

vosiag aouaraduion (21 je pueaeme'9

sae varqewene wid (t

* 8 9 z € sauNpeW (01 ‘Aunt s9uy +

“65 'sss ‘OHS uyeeulsu3, ‘Budaayasnoy (¢ aurypew Bunin>

wee mene { 32 paezey Bupynd Z°9

via) Axaurypeus 505 pep “sayen

sous 0

ed upp wapyns Meng (

aispuewedie | — 34g “aus e uoisiuadns paso;> Aun(uys28u13 *1

revorew puevodsuen | yuupy 3 z e ‘umop 08 0} $sa20¢ ay

‘ate vote “saBeulis apenuieg hes

pue ayer ain “Suom es 0} oud Buyaug /reuayew Buypuey

0151395 M50 ud _(H__ Buunp aujog out T'9 9

“paye 21uouem3

aa ‘ued peg 1

ol} oz z

wing ones.

gum y2ewu09 oF's

£1 j0g adeg aged

0202 INN Z | aep anss} 4 samen sewrwnan WO

To] uosmey) TOULNOD ASIY GNV LNAINSASSY SIX ‘NOILVIISLLNIGI GYVZVH Baan

€200-SW-MV-¥S-THOA | “ON UO

jgnes | wn | poeaana samp nomagasenn | von touy

Teton

‘ueWsqueG

/uewsey yum jonuo> ayjea),

pueAyesainsua | UMP

peo} papuadsns

Jepun Bunom Te

21 'St295 ¥HSO “vonronpul 3SH

‘auyjae. -

“uew)eusis -

40} a9eds wuarsyjns~ |

sadosd-

1d Buy -

uonsmnsuy om (rd

‘a8eso1s Syuey sopUho

uwpy z z z

Suyinp uonisod Apoa $'9

“aoejd uj saysinunxe ony (gi

-lunyay wepyyns

payidde ayeid ars (9

ad y lor ‘parrediio> aneyins (5)

uwiey (sew 35nq ‘sano

” one ‘ynus se3 / nid sea wes

= smaanes eos soni

‘95205 v8 ‘159A M25 2H ple) 34d (67 Jaygeom 20H »'9

£1406 adeg ‘aBeg |

020z ANN Z | a1ep anss) 4 we

To | wosnay) TOULNOD HSH CNY LNAWSASSY ¥SIY ‘NOLLVDISLLNSGI GUYZVH | Z3c Reich

€200-SW-MV-¥S-1894 | “ON WuOs |

[= ez00-sw-mv-ps-T9a | “ON WHOS

: seesnosisines| no | ivcneninetnnony tn | wea

Seta een ener Sr = 7

Panos mri oi oe

poron00 seqo1 Bupnao

as, eld < >yBloy ve BupoM Buynp

tured payooy sad, -uonea

Suny | upsonjequayavaino

pueuonejeisu auunp — | sono yam soewvan 9

Somat} aya 2un395- “Fareed

“powiaw Bu sodo14- sunt kpo

sas als . “ats Arena paBewep

oe, 091001 Arouwoew +1

Bump 40m jo porous wots /auiyoeus

285 3p Uo s19410m jU8- jacene once

orem 0m (1 =

“sauntut Ap09

se deus se98 uy

Fc o | s z somo)

an 2uno9s Buin 3008

Suny 203 ue 22090 9c

vomeeneua | aaa {oven} o1eedosueraduoy (e] Aunt seu 4

snurrrtvoneraes | up ad £

ecg setente | oy ageene na / wna (2 qwlod would

ore vonmadsui AUDEN (1

ren BuideoxasnoH (0 ‘nf Ap08

a st vonersey wuoishsAppng_( veges

eon) ne pepwosdeoies3y (qd Bupnnoid eyes “I

a dat aysveuojsnodns pos09 ies pue din

er 10 or ate wea ]

(z0z NTT | BIeP an551 c Scenh

To] uosmey] MOULNOD ASIN GNV LNAINSASSY ¥SIY ‘NOLLVDISILNIG!I GYvZVH | Basen

Mo : wonsimrtaens| pono | om

Sasa omen po oN NN RP 7 a onan

Te sg | — woe | —

WaRsAS Appa

“¥oq]00 ‘pay 2]uouo83 “1

uwipy z z z ‘Buunp 10m Jo poyyaut Hom Burystuy

pue sajsuen Yo

Suunp uorisod Apoa y's

sversap | ela : (4sew asng ‘sano sone

uwipy uowen ‘yn e3/ nid ses |

Sauuion ngs || suum ee

2s 344tonum py “as0n AiapeS ‘VEH PIeH) add SS PENNE

‘SS‘S85 ‘OHS sone uonzad:

‘saauu3 penn | aug zl x ‘Buidaayasnoy ‘tures

wwe warshs Appng “ssansyeoH “1

“papwnosd ease soy J2YIEIM 10H 7°S-

“saiem

Bupuup uarsuins Aiddns (

‘ayse uoisiasadns poser) (

a, z} or |e ss 3/3

so8euais 9 apeoiueg Mayes ( “infu 398045 +

oe eee vom ues 0 oud 3uyou8 ( 2a4sues 3901 vojpeyosd veg

2150295 ¥HS0 Aid (1 _Suunp quod youd t's | 10} yom BuyoUd ataany |g

€TjO TT aseg adeg

020z 3NNFZ | ep anss) 4

To} uossy] TOULNOD YSIY CNV LNSINSISSY NSIY ‘NOLLVDISILNIG! GYVZVH

£700-SW-MV-PS-1893 | “ON W404

: ssmmpsun tam | yo | somaena ane tetay tion | sues oun

eeuesciu aa =

2 Te

Ze aa

ad

wey uiod ‘Aunty Apog *}

3 or 5 z ‘Aquiasse xe qunoo peay aya wuaiey

upaouaus ‘uo sosiasadns 03 Bulioday - wos 399fqo Bune ¥°6

‘wiaishs Appng - hi

*x0q]003 SuLunp (443)

Ue|g asuodsoy Aouadiaw3,

ao} s z Uo sioyoM Jou - ArouureW

Uonsnnsu 0m (€1 1 / aunpew

(seu sna ‘anoIB uowteD Aauysnn /Yonns £6

‘ssausey Apog "00g Aajes

‘asen Arajes "eH pueH) Idd (2!

2s

‘55°595 0Ns sae

‘eau wt

“a8 : s | 2 €

uysoua worsks Appng_{ ‘Asnfut AOR

papiaosd ease 1soy weypuedus

ujod Aiquiasse

AouaBiawe payeuaisaq (q TeUsIeUW Jo onansasqo

“yewsyueg / punos® Arodaus 76

[vewBey wpm josru09 ayes (

“soBeufis apeouseg AajeS |

a ‘ainpanoud

ssoubug | + z fousdiawe uo 90m

‘owpy 1veIs 01 oud BuyaUIG xoqjOoL |

ue hays ais mid ( “Aint Apoa

ee Moo wuorompulssn_ Uf wBeuuortesr's| ano puehousBiws | 6

€TJ0 ZT a8ed ageg

WNIOIOYWZWH | Bercy &

0207 INNS Z | aep anss) ‘

To wosmey) TOULNOD SIY ONY LNAWSaSSY YSIY ‘NOLLYDI

ZOOS MV-PS"THD3 | “ON WHOS

. symeerana sae | you ute mane sane undanis | mana ouy

‘nace waumans | tn ‘pobimeempucuegaoutainymin | Awan

= aa he ye | — a ap aS STS ET 7am

H Rat pon [ SR ae Nay wp ep ag | oa

* rrartrpeeas | a umm mi seqprnanesuees | Amann SHA

“aaa Tae a

ass roo

14 3e Buppiom 8

AouaBsaw3 ayeansy -

€1 50 €t a8ed

TOULNOD SIH GNY LNAINSASSW SIH ‘NOLLYOILLNAGI GUVZVH | Brace

“CONSTRUCTION OF CAST IN-SITU BOX CULVERT” _

BBE [peamenne ECRL-StAW-MS-0023

Revision No. 4 Rev.Date | 08 JUNE 2020

Appendix 5.3

Environmental Aspect Impact

Register (EAIR)

FOR “CONSTRUCTION OF IN-SITU BOX

CULVERT”

Construction of Cast In-Situ Box Culvert,

ECRL-S¢- AWMS-0023 & Rev. 01

Page 33 of 36

sft

ue VORA wei WAWSTETEH UAL

yodey yueproyjueprouy (j | _ J96eueWy s 1

‘ein eon Aoupen | ONUOBSSS 6

ue sepsyequeplooy Ber umd i eee 1

Cn) vel wsuiodeuey

bale u posted se ana sya swraueo tt | OALOS pesuiauen | S088

josuog ayers now | ,/SS5,, 6 ele

UOREZMIGOW AsoUjYoeW/OI>I4OA : Boe S

renueg yeas ona : ile

MONeZIIGOW AseUIYDeW/O}O posiwedns '

2210 womdas (| Ra

28e1en09 eipewy ssenuAsuotgny 16907 04 | 1) onuGu5 6 zie voneziqow

Pevodeupraenyjureiduiog aman : Aaueveurg | 02 ‘Arauysen pur aye”

TYON) Hoday eoueWOjU05-UON/eOHON

Suwenviuis) vodey uonoedsy ays anssi(| | [SSEUEN. x

epioxd | oaatdns , a

Jou a1 Jonuog vojeenua eng: mwlowny fayen 9 ops sng

fuysn Suue9p peo! axgnd oypue yénaa use

so uopinaid fq peos and Jo ssouIueop ans (2

step Mp | o3/OWL

Sup Ayepods0 uopeedo 161 sesnog aia | osWoons . bs

‘SBAUBD YIM PasENod Ayedoud S| sjeLO}eL

nea ym pepeo| Jey SeHEUIyDeW/SEAIYAA OUI (| |

oresturg send : WON

(Aoue6s0w3 ‘yeusougy ‘jewoN) eBseyo a yrduiy podsy

‘SeNSeEWY |01jUOD [1 nesedo ‘uj uosi9g Feywewuosjaug jeyuewuoNAauz ‘souanbas dor /Ayanoy

queoyubis | Bue ysia

74

N3MNIC OM7 | : Ad GAAONdd

(3H ONVM | : AG GSM3IAZY JAIATND XOF AO NOLLONALSNOD : sor JO NOLdds30

rs AOSNA 19 INVINS HOON | : Ad GFNvdaad ‘TADA & NOLLIAS : NOLLW9OT

0202/90/20 Siva

40 ON ABH

£200-SW-MV-PS-1H9A | : jaa b 3DVHOWd

N31SIDIY LOVdWI ONV L93dSV TWLNSWNOUIANS:

bo: ey YALSIDIY LOVdWI ONY LOAdSV TWLNSIWNOMIANS Boca

L axan

s/2

BeqeTOITE UOOS Sey TTEPOLIA

uod uoquoiaydes its pue UeI ued Aynooe (2

(ON) vodey eouewoywog-uonveonen | seBevenVOa

Sywenn(uis) vodex uooedauy as anes (y | _osinodns es

‘28ve48Ip e1ojeq (9g) losuoo | 2ou6U3 ag oun

uewpes pue uo}sor9 oyu porjeuuet you seop

; Sieuiou Aen 221600 am pM, 40m,

pe oye wou youn sem un: euouy isvatemies | —cumprees bus uopexrora

od uonuoraydes is pue UIP ques Yorusu0d (L | oa

‘Bueyosip e1ojeq (983) | Hosinledns z\o

eyo | ssoul6u3 ons

‘AyARDe ey'8 WoNy ound Joye PIgIN "JULON

UORS

arse pompous Aeiodw pojooysjo eoveseld (© | co

WINES HO edd (2 |p SESjae ely Aen

voqueraig o6eds 10 0 abesn aunsua (| {Lon ns 212M DUE HOS

(Guyyeo Jo fequejed) uoneiedo AieuyoeH

Suming 289 pue Supuog weg :jewuougy

sunny) sol 24

ou waze Bupom 1) asn Jaye senueo im Atouoeus

Buna ea poe Supa sea 98 PaN29 (2 | 9503 ng L Ayer deus

‘vouypew Buna Jeq pue Buypusq seq | Ao SS y 20}8\4 pue 10S, 0

4 Kea duprpunqnuewneiuen Kiepuooes eredota (b

tuonexedo uoew Sumng 228

‘Asounyoew Buming 168 pue Buipuea 2eg * euLON pue Bupuog seg jo ebesn,

TopCEUT

9612614 2nos04 PION ‘oo

posh ynoiy a4 az1uAd0 (F | oct ‘ meee

loweouar ; osivodng y | seuonedea

wo weaygnyeseia yo aBesn :euson | ,HOeeINS

oa

ave angisues oyand seeu wuowoerd proay (L | nootniodng z | + | Ayeno eon | uoneroue9 estan

2810N Jo uoneioue9 :eULON | /s6UN6U3 o1s

oa

ae ansues agnd Je9u ywowoneld plory (I | posiiedng z\ + Aen 9 vores g enous

UWo}SSIW3 @yOUNS : eULON | n90U1U3 ors

((uess200n s)) vonequowoysu =

Lo :uorsiaey ‘YBLSIOTY LOVdWNI ONY LO3dS¥ TWINAWNOUIANA eam eemcme

s/t

‘|1S8M PeINDEYOS AlerodwWe | Pejooy Jo BOUESsAL,

oaneoubua ea

ous

bends JouNN 10 weDHaMYIOseIG = poswvedns sounpoyieg,

abeiseqy saunosey prony (2

posn nowy eu oxtundo (| “eae US ‘yy

NO WeSLqQN"yI9S0\q Jo aBesy) : /eULION uogeiedg)

UORES Aauupen

‘1sena pompauos Assodua4 pojooy jo oouesold (© | ue eoUeA

ends 1 aS ooace's | noouua ous vs

Uonuenaid Bends ‘emsua (|

wopesedg posnvechs Ayer

Asouryoew pue 9j2149A Bupyeoy: jeuougy 2590n4 9UE HOS

uogsedsu| e6e4207,

uonesedg Axouyyor @

HOM

‘WoW UORDETOCGIT A Sumyyoeg pue uopeneoxg

uonoe eye|peuut pour OL(Z | YdueGeuew

qwauedeg uogeioy oyang wo ior 103 $s

posvuedng

do}s,eulsjeon0N sonuoMny [2907 : ‘utenatt

‘ampatos won (z

qweweBebug ofan (1 | HaMaseuenn slz ‘Auten 9s10N pvopnicg

(vga) eary onnisues yuewuomaug | ng "

Je oy ennsueg 18 uonuyea :eurougy oowect

“nou ennisues Buunp Rinne Bungom prony (z

cotyBasnowdenenopne| | ©3?2008H3 cls

28 uoqeyeisu ouog 290N pUe BUPIEOH (| pope Sag

25}0N Jo uonBsoUe : eWLON

‘BUop UOREDITIG! un Hon CsI O1 Ce

Uoneoyroos ajepouuy aBuee of (2 | HaHeBeusy (ope

quewyedeg UOREICY a1}GNd WOIUt O| (| ‘3SHIO3 ¢ z pepuedsng Je10 |) ‘vojss}uig 18M

J9p10 110m dos/ouly/eonON sennotny | pospvedns ‘en ay

12007 pseioianuoden oygn : Aovo6s0Wg

‘Thiesseoou

4 wows yanp eonpos 0 o70M apiuuds (z | soBeueWyoR (opquect

lwoisks | _poswiadng + | » | pepuadsng io) | uojsswia sna

‘yeuog pur Jopuoy ‘pode wawebeuey (1 | Hoouibua aus ‘AED atv

JOAUOS ISNG IoUYM UO|sswy ISNQ : jeUUoUgy

10 :uorsiney NaLSISaY LOVvdINI ONY LO3dSV TWLNSIWNOUIANS ‘—romenomn

as60

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Acf-Mra-067 - UcDocument1 pageAcf-Mra-067 - UcFateh AliyaNo ratings yet

- 1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementDocument16 pages1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementFateh AliyaNo ratings yet

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Acf-Mra-068 - UcDocument1 pageAcf-Mra-068 - UcFateh AliyaNo ratings yet

- Ruang Terkurung Icop 2010 PDFDocument82 pagesRuang Terkurung Icop 2010 PDFFateh AliyaNo ratings yet

- Ruang Terkurung Icop 2010 PDFDocument82 pagesRuang Terkurung Icop 2010 PDFFateh AliyaNo ratings yet

- ECRL-S4-AW-MS-0023 Construction of In-Situ Box Culvert (Rev 01)Document75 pagesECRL-S4-AW-MS-0023 Construction of In-Situ Box Culvert (Rev 01)Fateh AliyaNo ratings yet

- Construction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05Document126 pagesConstruction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05Fateh Aliya100% (1)

- Perintah Khas KPDocument1 pagePerintah Khas KPSham AranNo ratings yet

- ENG ICOP CHC (Amendment) Part 1 2019Document66 pagesENG ICOP CHC (Amendment) Part 1 2019Fateh AliyaNo ratings yet

- ECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Document74 pagesECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Fateh Aliya0% (1)

- Acf-Mra-069 - UcDocument1 pageAcf-Mra-069 - UcFateh AliyaNo ratings yet

- Acf-Mra-066 - SCDocument1 pageAcf-Mra-066 - SCFateh AliyaNo ratings yet

- MRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestDocument1 pageMRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestFateh AliyaNo ratings yet

- Description of NCR at Bridge 3Document7 pagesDescription of NCR at Bridge 3Fateh AliyaNo ratings yet

- Acf-Mra-065 - SCDocument1 pageAcf-Mra-065 - SCFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- GHSSE-HS-ME-2018-1012-114 Memo Safety Sign Color CodingDocument1 pageGHSSE-HS-ME-2018-1012-114 Memo Safety Sign Color CodingFateh AliyaNo ratings yet

- Acf-Mra-062 - SCDocument1 pageAcf-Mra-062 - SCFateh AliyaNo ratings yet

- Hirard - DrivingDocument2 pagesHirard - DrivingFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- MMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Document1 pageMMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Fateh AliyaNo ratings yet

- Piling SOP - Rev 00 PDFDocument20 pagesPiling SOP - Rev 00 PDFFateh AliyaNo ratings yet

- Piling SOP - Rev 00 PDFDocument20 pagesPiling SOP - Rev 00 PDFFateh AliyaNo ratings yet