Professional Documents

Culture Documents

Industrial Generator Set Accessories: Sound Level 1 Enclosure Standard Features

Uploaded by

GohoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Generator Set Accessories: Sound Level 1 Enclosure Standard Features

Uploaded by

GohoCopyright:

Available Formats

Industrial Generator Set Accessories

Sound Enclosure and

Subbase Fuel Tank Package

Applicable to the following models:

KD800 - KD2500 (includes KD1250-A,

KD1250-4, KD2500-4)

Sound Level 1 Enclosure Standard Features

D Internal silencers with flexible exhaust connectors and

exhaust elbows.

D Mounts to lift base and optional subbase fuel tank.

D Aluminum construction with six large, hinged,

removable doors for easy maintenance.

D Fade-, scratch-, and corrosion-resistant Kohlerr

Level 1 Sound Enclosure with Lift Base Power Armort automotive-grade textured finish.

D Lockable, flush-mounted door latches.

D Air inlet louvers to reduce rain and snow entry.

D Sloped roof to reduce the buildup of moisture and

debris.

D Acoustic insulation that meets UL 94 HF1 flammability

classification.

D Sound level 1 enclosure is designed

to 150 mph (241 kph) wind load rating.

D Sound level 1 enclosure uses internal silencers,

acoustic insulation and acoustic-lined air inlet hoods.

Sound Level 2 Enclosure Standard Features

D Includes all of the sound level 1 enclosure features with

the addition of up to 51 mm (2 in.) acoustic insulation

material, intake sound baffles, secondary silencers,

Level 2 Sound Enclosure with Subbase Fuel Tank and vertical air discharge with rain caps.

(shown with optional spill containment) D Vertical outlet hood with 90 degree angles to redirect

air and reduce noise.

D Sound level 2 enclosure is certified to 186 mph

(299 kph) wind load rating for KD800- 2500 models.

Enclosure and Subbase Fuel Tank Combinations Subbase Fuel Tank Features

Four enclosure configurations are available with the subbase fuel D The fuel tank has a Power Armor Plust textured

tanks: epoxy-based rubberized coating.

d Sound Enclosure Level 1 D The above-ground rectangular secondary containment

d Sound Enclosure Level 1, AQMD Ready tank mounts directly to the generator set, below the

d Sound Enclosure Level 2 generator set skid (subbase).

D Both the inner and outer tanks have UL-listed

d Sound Enclosure Level 2, AQMD Ready

emergency relief vents.

D Flexible fuel lines are provided with subbase fuel tank

Available Approvals and Listings selection.

D The containment tank’s construction protects against

- UL 2200 Listing fuel leaks or ruptures. The inner (primary) tank is

- UL142 Listing (fuel tanks) sealed inside the outer (secondary) tank. The outer

- CSA Approval tank contains the fuel if the inner tank leaks or ruptures.

- IBC Seismic Certification D The above ground secondary containment subbase

- California OSHPD Approval (KD800- KD1750 models) fuel tank meets UL 142 requirements.

- cUL Listing (fuel tanks only) D State tanks with varying capacities are available.

- Hurricane Rated Enclosure - Available on aluminum Florida Dept. of Environmental Protection (FDEP) File

Sound Level 2 enclosures, KD800- KD1750 models No. EQ-634 approved.

(Impact rated for Large Missile Level E and Wind

load rated per Florida Building Code, tested to

TAS201- 94, TAS202- 94 and TAS203- 94 standards)

NOTE: Some models may have limited third-party approvals; see

your local distributor for details.

G6-154 10/20q Page 1

Aluminum Sound Enclosures

Fade, scratch, and Acoustic insulation meets Radiator ducted to enclosure air Enclosed insulated exhaust Sloped roof

corrosion resistant UL 94 HF1 flammability outlet prevents air recirculation silencers for improved safety reduces water

polyurethane finish classification and repels within the enclosure and noise reduction. accumulation

moisture

Air inlet lined with

acoustic insulation

Horizontal exhaust

and cooling air

discharge

Air inlet louvers reduce

rain and snow entry

Door hold-backs provide

positive door positioning Recessed and lockable Air outlet internal plenum

during wind gusts door handles minimize lined with acoustic

potential damage insulation

Hinged and removable doors Rubber sealed access doors

on both sides of the enclosure prevent water infiltration and

for easy maintenance minimize noise

Note: Sample sound level 1 (SL1) enclosure shown; other models are similar.

Enclosure ships assembled on lifting base. ADV- 8927

Level 1 Sound Enclosure Features

D Heavy-duty formed panels, solid construction. D Interchangeable modular panel construction. Allows

Preassembled package offering corrosion resistant, dent complete serviceability or replacement without compromising

resilient structure mounting directly to lift base or fuel tank. enclosure design.

D Polyurethane enamel paint. Superior finish, durability, and D Bolted panels facilitate service, future modification upgrades,

appearance. or field replacement.

D The enclosure has a sloped roof to reduce the buildup of D Cooling/combustion air intake. Fixed air intake louvers.

moisture and debris.

D Sound-attenuating design using critical silencers. Acoustic

D Internal exhaust silencers offering maximum component life insulation UL 94 HF1 listed for flame resistance.

and operator safety.

D Horizontal air discharge. Sound level 1 (SL1) enclosures use

NOTE: Installing an additional length of exhaust tail pipe may a horizontal design that directs exhaust and cooling air out

increase backpressure levels. Please refer to the generator set the end of the enclosure.

spec sheet for the maximum backpressure value.

D Service access. Multiple personnel doors for easy access to

generator set control and servicing of the fuel fill, fuel gauge,

oil fill, and battery.

G6-154 10/20q Page 2

Aluminum Sound Enclosures

Fade, scratch, and Acoustic insulation meets UL 94 90 degree vertical air outlet

corrosion resistant HF1 flammability classification Radiator ducted to enclosure air redirects air to reduce noise

polyurethane finish and repels moisture outlet prevents air recirculation (SL2 enclosure only)

within the enclosure Enclosed insulated exhaust

Air inlet lined with silencers for improved safety

acoustic insulation and noise reduction. Silencers

include rain

caps

Sloped roof

reduces water

accumulation

Air inlet louvers reduce

rain and snow entry

Door hold-backs provide

positive door positioning Air outlet internal plenum

during wind gusts Rubber sealed access doors lined with acoustic

Recessed and lockable

door handles minimize prevent water infiltration and insulation

potential damage minimize noise

Hinged and removable doors

on both sides of the enclosure

for easy maintenance

Note: Sample sound level 2 (SL2) enclosure shown; other models are similar.

Enclosure ships assembled on lifting base. ADV- 8927

Level 2 Sound Enclosure Features

D Heavy-duty formed panels, solid construction. D Interchangeable modular panel construction. Allows

Preassembled package offering corrosion resistant, dent complete serviceability or replacement without compromising

resilient structure mounting directly to lift base or fuel tank. enclosure design.

D Polyurethane enamel paint. Superior finish, durability, and D Bolted panels facilitate service, future modification upgrades,

appearance. or field replacement.

D The enclosure has a sloped roof to reduce the buildup of D Cooling/combustion air intake. Fixed air intake louvers.

moisture and debris.

D Sound-attenuating design using additional secondary

D Internal exhaust silencers offering maximum component life silencers and up to 51 mm (2 inches) of added acoustic

and operator safety. insulation, UL 94 HF1 listed for flame resistance.

D Service access. Multiple personnel doors on both sides for D Vertical air discharge. Sound level 2 (SL2) models use a

easy access to generator set control and servicing of the fuel vertical air discharge design that redirects exhaust and

fill, fuel gauge, oil fill, and battery. cooling air up and above the enclosure to reduce noise.

G6-154 10/20q Page 3

Aluminum Sound Enclosure Options

Top view of SL2 enclosure, shown with roof removed for illustration only:

LED light

LED lights DC lights

Enclosure heater Exhaust ventilation fan

LED light

Side view of SL2 enclosure, shown with side panels removed for illustration only:

Fixed air intake louver/baffle

assembly, both sides

Enclosure heater

Spill

containment

Fuel tank

alarm panel

Motorized damper Load center Emergency 3-way switch Motorized or gravity

stop switch with GFCI, qty. 2 discharge damper

3-way switch with GFCI, qty. 2

Note: Sample sound level 2 (SL2) enclosure shown; other models are similar. ADV-8919-5

G6-154 10/20q Page 4

Tier 4 Aluminum Sound Enclosure

KD2500-4, Side view of SL2 enclosure, shown with side panels removed for illustration only:

Outlet pipe Selective catalytic reduction (SCR)

Exhaust collector

Exhaust flange

Flexible exhaust

Load center

Remote monitor display

DEF fill location DEF tank

Fluid dosing system

DEF tank

Service access panels, both sides

and front

Note: Sample sound level 2 (SL2) enclosure shown; other models are similar. ADV-9179-2

Tier 4, Level 2 Sound Enclosure Features

D Availabe on KD1250- 4 and KD2500- 4 D Diesel fuel state tank is standard

d KD1250- 4

D Tier 4 options only available with sound level 2 enclosures. - State tank, 5863 L (1549 gal.) or 11205 L (2960 gal.)

D Includes all of the sound level 1 and 2 enclosure features - DEF tank capacity,

with the addition of DEF tank, SCR, and exhaust collector. * 620 L (164 gal.) with 5863 L (1549 gal.) state tank

* 1241 L (328 gal.) with 11205 L (2960 gal.) state tank

D Remote monitor display

d KD2500- 4

D Locates DEF tanks and lines - State tank, 14130 L (3733 gal.)

- DEF tank capacity, 1241 L (328 gal.)

D Correctly sizes DEF and diesel tanks

D Service box for control and filter mounting

D Platforms not included

G6-154 10/20q Page 5

Aluminum Sound Enclosure Options

Basic Electrical Package (BEP) Stepdown Transformers. 100 amp BEP required, 60 Hz only.

KD1250- 2500 only. *

Distribution Panel/Load Center. Prewired AC power

distribution of all factory-installed features including block - Single-phase, 120/240 V *

heater, two GFCI-protected internal 120-volt service - Three-phase, 120/208 V *

receptacles, internal lighting, and commercial grade wall

switches. Single-phase or three-phase load center powered by Disconnect Switches. Disconnect switch for stepdown

building source power and protected by a main circuit breaker, transformer. 60 Hz only. *

rated for 100, 125, or 200 amps as noted, with capacity and

circuit positions for future expansion. AC power distribution - Single-phase *

installed in accordance with NEC and all wiring within EMT thin - Three-phase *

wall conduit. LED AC lights located within UL-listed fixtures

designed for wet locations. Enclosure Heater

- BEP, single-phase, 120/208, 60 Hz or 120/240 VAC, 60 Hz. Heater, 3.7/5 kW Ceiling Mounted. Electrical utility heater

Includes 100 amp electrical panel, two 3-way switches, four prewired to load center internal to enclosure. Rated at

LED lights, and two GFCI receptacles. * 17100 Btu. Includes adjustable louvers offering down flow and

- BEP, three-phase, 120/208, 60 Hz or 120/240VAC, 60 Hz. horizontal air tuning, built-in thermostat with automatic fan

Includes 125 amp electrical panel, two 3-way switches, four delay controls.

LED lights, and two GFCI receptacles.

- BEP, 200 amp, single-phase, 120/208, 60 Hz or 120/240 - Heater kit with 1 heater, single/three phase,

VAC, 60 Hz. Includes 200 amp electrical panel, two 3-way 208/240 VAC, 60 Hz. BEP required.

switches, four LED lights, and two GFCI receptacles. * - Heater kit with 2 heaters, for KD1250- 2500 only,

- BEP, 200 amp, three-phase, 120/208, 60 Hz or single/three phase, 208/240 VAC, 60 Hz. 200 amp BEP

120/240VAC, 60 Hz. Includes 200 amp electrical panel, two required.

3-way switches, four LED lights, and two GFCI receptacles.

Exhaust Fan

DC Light Package - Exhaust Ventilation Fan. Mounted inside the enclosure.

DC Light Package (DLP). Prewired, internal DC light package BEP required.

offering an economical alternative light source within the

enclosure, as a complement to the BEP or a source of light Motorized Inlet Louvers. 60 Hz only; BEP required.

when AC power is not available. Battery drain limited with fuse

- Aluminum construction

protection and controlled through a 0- 60 minute, spring-wound,

no-hold timer. - Insulated aluminum construction

Available in LED. - Galvanized construction

Motorized Outlet Louvers. 60 Hz only; BEP required.

Electrical Accessories

- Aluminum construction

Wiring Kits. Electrical wiring for accessories. BEP required. - Insulated aluminum construction

- Alternator heater wiring (KD1250- 2500 only) - Galvanized construction

- Block heater wiring, single-phase *

Gravity Air Outlet

- Block heater wiring, three-phase

- Battery charger wiring - Aluminum construction

- Wire DEF tank heater [

- Wire power supply (Tier 4 system heaters) w

Emergency Stop Switch

- Generator set emergency stop switch, qty. 1.

* Not available options with Tier 4 generator set enclosures.

[ Only available on enclosed Tier 4 generator set enclosures.

w Only available on open or enclosed Tier 4 generator sets.

G6-154 10/20q Page 6

Subbase Fuel Tank

Emergency tank Electrical stub-up Fuel basin Fuel level gauge Additional fittings Check valve with dip Dip tube

relief vents areas open to bottom switch with sender for optional tube assembly assembly

accessories

2 in. NPTF for

optional fuel level

switch

2 in. normal

vent with riser

Fuel fill with lockable cap Fuel level gauge,

and 203 mm (8 in.) riser mechanical

Note: Sample model shown, other models are similar. ADV-8927

Subbase Fuel Tank Standard Features Fuel Fill Options

- Fill pipe extension to within 152 mm (6 in.) of bottom of fuel

D Extended operation. State tanks with various capacities for tank

multiple hour requirements.

- 18.9 L (5 gallon) spill containment

D UL listed. Secondary containment generator set base tank

meeting UL 142 requirements. - 18.9 L (5 gallon) spill containment with 95% shutoff

D NFPA compliant. Designed to comply with the installation - 18.9 L (5 gallon) spill containment fill to within 152 mm

standards of NFPA 30 and NFPA 37. (6 in.) of bottom of fuel tank

D Integral external lift lugs. Enables crane with spreader-bar - 18.9 L (5 gallon) spill containment, OSHPD/IBC

lifting of the complete package (empty tank, mounted - 18.9 L (5 gallon) spill containment with 95% shutoff,

generator set, and enclosure) to ensure safety. OSHPD/IBC

D Emergency pressure relief vents. Vents ensure adequate - 28.4 L (7.5 gallon) spill containment, Florida Dept. of

venting of inner and outer tank under extreme pressure Environmental Protection (FDEP) File No. EQ-345 approved

and/or emergency conditions. - 28.4 L (7.5 gallon) spill containment with 95% shutoff,

D Normal vent with cap. Vent is raised above lockable fuel fill. Florida Dept. of Environmental Protection (FDEP) File No.

D Fuel level gauge with sender. EQ-345/EQ-257 approved

D Mechanical fuel level gauge.

High Fuel Level Switch

D Leak detection switch. Annunciates a contained primary tank

fuel leak condition at generator set control. - High fuel level switch, 24V

D Electrical stub-up area open to bottom. - High fuel level switch, 24V, Florida Dept. of Environmental

D Additional 2 in. NPT fittings for optional accessories. Protection (FDEP) File No. EQ-682 approved

- Fuel tank panel, 3 alarm, 24 V

Subbase Fuel Tank Options - Fuel tank panel, 3 alarm, 24 V, Florida Dept. of

Environmental Protection (FDEP) File No. EQ-682 approved

Bottom Clearance

Normal Vent Options

- I-beams, provide 102 mm (4 in.) of ground clearance

(not available with OSHPD or IBC seismic certification) - 3.7 m (12 ft.) above grade (without spill containment)

- 3.7 m (12 ft.) above grade (with spill containment)

Emergency Vent Options

- 127 mm (5 in.), IBC Freestanding Stairs

- 152.4 mm (6 in.), IBC KD800- 1000 12 hr. tank only - Stairs only, single door access

- Stairs with platform, single door access

Fuel in Basin Options

- Stairs with catwalk, 2 door access, door length only

- Fuel in basin switch, Florida Dept. of Environmental - Stairs with catwalk, 2 door access, full length of enclosure

Protection (FDEP) File No. EQ-682 approved

- 100% engine fluid containment Tank Marking Options

- Decal, Combustible Liquids - Keep Fire Away (qty. 2)

Fuel Supply Options

- Decal, NFPA 704 identification (qty. 2)

- Fire safety valve (installed on fuel supply line)

- Decal, tank number and safe fuel fill height (qty. 2)

- Ball valve (installed on fuel supply line)

G6-154 10/20q Page 7

Enclosure and Subbase Fuel Tank Specifications

Est. Fuel Supply Sound Pressure

Fuel Tank Hours at 60 Hz Max. Dimensions, mm (in.) Fuel Tank Level at 60 Hz

Capacity, with Full Load Max. Weight, [ Height, with Full Load,

L (gal.) (nominal ) Length Width w Height kg (lb.) mm (in.) dB(A) ]

KD800 SL1 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 6582 (259) 3350 (132) 10184 (22452) —

3475 (918) 12 3706 (146) 13772 (30362) 356 (14.0)

6621 (1749) 24 7309 (288) 2616 (103) 3934 (155) 14252 (31421) 584 (23.0) 90

10573 (2793) 48 4264 (168) 14831 (32698) 914 (36.0)

15740 (4158) 72 9144 (360) 4366 (172) 16242 (35808) 1016 (40.0)

KD800 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 7707 (303) 3350 (132) 10587 (23340) —

3475 (918) 12 3706 (146) 14175 (31250) 356 (14.0)

6621 (1749) 24 8434 (332) 2616 (103) 3934 (155) 14655 (32309) 584 (23.0) 75

10573 (2793) 48 4290 (169) 15234 (33586) 915 (36.0)

15740 (4158) 72 9144 (360) 4366 (172) 16645 (36696) 1016 (40.0)

KD900 SL1 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 6582 (259) 3350 (132) 10497 (23343) —

3475 (918) 12 3706 (146) 14085 (31253) 356 (14.0)

7309 (288)

6621 (1749) 24 2616 (103) 3934 (155) 14565 (32312) 584 (23.0) 91

12969 (3426) 48 8400 (331) 4293 (169) 16348 (36243) 940 (37.0)

19381 (5120) 72 11050 (435) 4369 (172) 17527 (38840) 1016 (40.0)

KD900 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 7707 (303) 3350 (132) 10900 (24231) —

3475 (918) 12 3706 (146) 14488 (32141) 356 (14.0)

6621 (1749) 24 8434 (332) 2616 (103) 3934 (155) 14968 (33200) 584 (23.0) 75

12969 (3426) 48 4290 (169) 16751 (37131) 940 (37.0)

19381 (5120) 72 11050 (435) 4366 (172) 17930 (39728) 1016 (40.0)

KD1000 SL1 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 6582 (259) 3350 (132) 10810 (23833) —

3475 (918) 12 3706 (146) 14398 (31743) 356 (14.0)

7309 (288)

6621 (1749) 24 2616 (103) 3934 (155) 14878 (32802) 584 (23.0) 92

12969 (3426) 48 8400 (331) 4290 (169) 16661 (36733) 940 (37.0)

19381 (5120) 72 11050 (435) 4366 (172) 17840 (39330) 1016 (40.0)

KD1000 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 7707 (303) 3353 (132) 11213 (24721) —

3475 (918) 12 3706 (146) 14801 (32631) 356 (14.0)

6621 (1749) 24 8434 (332) 2616 (103) 3934 (155) 15281 (33690) 584 (23.0) 76

12969 (3426) 48 4290 (169) 17064 (37621) 940 (37.0)

19381 (5120) 72 11050 (435) 4366 (172) 18243 (40218) 1016 (40.0)

KD1250/1500 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 8831 (348) 3579 (141) 17116 (37748) —

5863 (1549) 18/15 3960 (156) 22326 (49234) 381 (15.0)

9860 (2605) 30/25 9594 (378) 4138 (163) 22808 (50296) 559 (22.0)

3033 (119) 93

11204 (2960) 34/28 4214 (166) 22973 (50661) 635 (25.0)

19214 (5076) 58/48 4468 (176) 25277 (55741) 889 (35.0)

11113 (438)

21985 (5808) 66/55 4570 (180) 25684 (56637) 991 (39.0)

KD1250/1500 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 10420 (410) 3579 (141) 18031 (39764) —

5863 (1549) 18/15 3960 (156) 23241 (51250) 381 (15.0)

9860 (2605) 30/25 4138 (163) 23723 (52312) 559 (22.0)

3033 (119) 79

11204 (2960) 34/28 11147 (439) 4214 (166) 23888 (52677) 635 (25.0)

19214 (5076) 58/48 4468 (176) 26192 (57757) 889 (35.0)

21985 (5808) 66/55 4570 (180) 26599 (58653) 991 (39.0)

* Data in table is for reference only. Height includes enclosure, lift base, and tank (if equipped). Refer to your authorized Kohler distributor for enclosure

and subbase fuel tank specification details.

[ Max. weight includes the generator set (wet) with the largest alternator option, enclosure, silencers, lift base, and tank (no fuel).

] Log average sound pressure level of 8 measured positions around the perimeter of the unit at a distance of 7 m (23 ft.). Refer to TIB-114 for

details. Enclosed generator set sound data for some models was not available at time of print.

w An additional 940 mm (37 inches) of clearance on each side for opening and closing the access doors is recommended.

NOTE: If the Est. Fuel Supply Hours column shows more than one number, the numbers represent each model in that range.

G6-154 10/20q Page 8

Enclosure and Subbase Fuel Tank Specifications, continued

Est. Fuel Supply Sound Pressure

Fuel Tank Hours at 60 Hz Max. Dimensions, mm (in.) Fuel Tank Level at 60 Hz

Capacity, with Full Load Max. Weight, [ Height, with Full Load,

L (gal.) (nominal ) Length Width w Height kg (lb.) mm (in.) dB(A) ]

KD1250-4 SL2 Sound Enclosure with State Code Subbase Fuel Tank z:

5863 (1549) 17 4640 (183) 22507 (49619) 381 (15.0)

11147 (439) 3033 (119) 75

11204 (2960) 33 4894 (193) 23731 (52318) 635 (25.0)

KD1250-A/1350 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 8831 (348) 3579 (141) 17116 (37748) —

5863 (1549) 18/17 3960 (156) 22326 (49234) 381 (15.0)

9860 (2605) 30/29 9594 (378) 4138 (163) 22808 (50296) 559 (22.0)

3033 (119) 93

11204 (2960) 34/32 4214 (166) 22973 (50661) 635 (25.0)

19214 (5076) 58/56 4468 (176) 25277 (55741) 889 (35.0)

11113 (438)

21985 (5808) 67/64 4570 (180) 25684 (56637) 991 (39.0)

KD1250-A/1350 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 10420 (410) 3579 (141) 18031 (39764) —

5863 (1549) 18/17 3960 (156) 23241 (51250) 381 (15.0)

9860 (2605) 30/29 4138 (163) 23723 (52312) 559 (22.0)

3033 (119) 76

11204 (2960) 34/32 11147 (439) 4214 (166) 23888 (52677) 635 (25.0)

19214 (5076) 58/56 4468 (176) 26192 (57757) 889 (35.0)

21985 (5808) 67/64 4570 (180) 26599 (58653) 991 (39.0)

KD1600 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 8831 (348) 3579 (141) 17343 (38248) —

5863 (1549) 14 3960 (156) 22553 (49734) 381 (15.0)

9860 (2605) 23 9594 (378) 4138 (163) 23035 (50796) 559 (22.0)

3033 (119) 94

11204 (2960) 26 4214 (166) 23200 (51161) 635 (25.0)

19214 (5076) 45 4468 (176) 25504 (56241) 889 (35.0)

11113 (438)

21985 (5808) 52 4570 (180) 25911 (57137) 991 (39.0)

KD1600 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 10420 (410) 3579 (141) 18258 (40264) —

5863 (1549) 14 3960 (156) 23468 (51750) 381 (15.0)

9860 (2605) 23 4138 (163) 23950 (52812) 559 (22.0)

3033 (119) 79

11204 (2960) 26 11147 (439) 4214 (166) 24115 (53177) 635 (25.0)

19214 (5076) 45 4468 (176) 26419 (58257) 889 (35.0)

21985 (5808) 52 4570 (180) 26826 (59153) 991 (39.0)

KD1750 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 8831 (348) 3579 (141) 17343 (38248) —

5863 (1549) 13 3960 (156) 22553 (49734) 381 (15.0)

9860 (2605) 21 9594 (378) 4138 (163) 23035 (50796) 559 (22.0)

3033 (119) 95

11204 (2960) 24 4214 (166) 23200 (51161) 635 (25.0)

19214 (5076) 42 4468 (176) 25504 (56241) 889 (35.0)

11113 (438)

21985 (5808) 48 4570 (180) 25911 (57137) 991 (39.0)

KD1750 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 10420 (410) 3579 (141) 18258 (40264) —

5863 (1549) 13 3960 (156) 23468 (51750) 381 (15.0)

9860 (2605) 21 4138 (163) 23950 (52812) 559 (22.0)

3033 (119) 79

11204 (2960) 24 11147 (439) 4214 (166) 24115 (53177) 635 (25.0)

19214 (5076) 42 4468 (176) 26419 (58257) 889 (35.0)

21985 (5808) 48 4570 (180) 26826 (59153) 991 (39.0)

* Data in table is for reference only. Height includes enclosure, lift base, and tank (if equipped). Refer to your authorized Kohler distributor for enclosure

and subbase fuel tank specification details.

z Tier 4 generator enclosure height includes the fuel tank and enclosure up to the exhaust flange. The height does not include the SCR, or the SCR

inlet and outlet pipes.

: Tier 4 generator enclosure weight includes the DEF tank but does not include the SCR or the SCR inlet and outlet pipes.

[ Max. weight includes the generator set (wet) with the largest alternator option, enclosure, silencers, lift base, and tank (no fuel).

] Log average sound pressure level of 8 measured positions around the perimeter of the unit at a distance of 7 m (23 ft.). Refer to TIB-114 for

details. Enclosed generator set sound data for some models was not available at time of print.

w An additional 940 mm (37 inches) of clearance on each side for opening and closing the access doors is recommended.

NOTE: If the Est. Fuel Supply Hours column shows more than one number, the numbers represent each model in that range.

G6-154 10/20q Page 9

Enclosure and Subbase Fuel Tank Specifications, continued

Est. Fuel Supply Sound Pressure

Fuel Tank Hours at 60 Hz Max. Dimensions, mm (in.) Fuel Tank Level at 60 Hz

Capacity, with Full Load Max. Weight, [ Height, with Full Load,

L (gal.) (nominal ) Length Width w Height kg (lb.) mm (in.) dB(A) ]

KD2000/2250/2500 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 10774 (424) 4141 (163) 33073 (72909) —

8577 (2266) 15/14/13 4522 (178) 40485 (89252) 381 (15)

3488 (137) 90

14130 (3733) 25/22/22 11465 (451) 4700 (185) 41216 (90861) 559 (22)

16451 (4346) 29/26/25 4776 (188) 41497 (91483) 635 (25)

KD2000/2250/2500 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 12766 (503) 4141 (163) 35121 (77426) —

8577 (2266) 15/14/13 4522 (178) 42533 (93766) 381 (15)

3488 (137) 78

14130 (3733) 25/22/22 13491 (531) 4700 (185) 43264 (95378) 559 (22)

16451 (4346) 29/26/25 4776 (188) 43545 (95997) 635 (25)

KD2500-4 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank Y;

14130 (3733) 21 13491 (531) 3488 (137) 4907 (193) 43583 (96084) 559 (22) 78

* Data in table is for reference only. Height includes enclosure, lift base, and tank (if equipped). Refer to your authorized Kohler distributor for enclosure

and sub-base fuel tank specification details.

Y Tier 4 generator enclosure height includes the lift base, tank, and enclosure up to the exhaust flange. The height does not include the exhaust

collector, SCR, or the SCR inlet and outlet pipes.

; Tier 4 generator enclosure weight includes the DEF tank but does not include the exhaust collector, SCR, or SCR inlet and outlet pipes.

[ Max. weight includes the generator set (wet) with the largest alternator option, enclosure, silencers, lift base, and tank (no fuel).

] Log average sound pressure level of 8 measured positions around the perimeter of the unit at a distance of 7 m (23 ft.). Refer to TIB-114 for

details. Enclosed generator set sound data for some models was not available at time of print.

w An additional 940 mm (37 inches) of clearance on each side for opening and closing the access doors is recommended.

NOTE: If the Est. Fuel Supply Hours column shows more than one number, the numbers represent each model in that range.

G6-154 10/20q Page 10

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

Enclosure and Subbase Fuel Tank Specifications, continued

Est. Fuel Supply Sound Pressure

Fuel Tank Hours at 60 Hz Max. Dimensions, mm (in.) Fuel Tank Level at 60 Hz

Capacity, with Full Load Max. Weight, [ Height, with Full Load,

L (gal.) (nominal ) Length Width w Height kg (lb.) mm (in.) dB(A) ]

KD2000/2250/2500 SL1 Sound Enclosure with Internal Silencers and State Code Subbase Fuel Tank *

Lifting Base 0 10774 (424) 4141 (163) 33073 (72909) —

8577 (2266) 15/14/13 4522 (178) 40485 (89252) 381 (15)

3488 (137) 90

14130 (3733) 25/22/22 11465 (451) 4700 (185) 41216 (90861) 559 (22)

16451 (4346) 29/26/25 4776 (188) 41497 (91483) 635 (25)

KD2000/2250/2500 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank *

Lifting Base 0 12766 (503) 4141 (163) 35121 (77426) —

8577 (2266) 15/14/13 4522 (178) 42533 (93766) 381 (15)

3488 (137) 78

14130 (3733) 25/22/22 13491 (531) 4700 (185) 43264 (95378) 559 (22)

16451 (4346) 29/26/25 4776 (188) 43545 (95997) 635 (25)

KD2500-4 SL2 Sound Enclosure with Internal Silencer and State Code Subbase Fuel Tank Y;

14130 (3733) 21 13491 (531) 3488 (137) 4907 (193) 43583 (96084) 559 (22) 78

* Data in table is for reference only. Height includes enclosure, lift base, and tank (if equipped). Refer to your authorized Kohler distributor for enclosure

and sub-base fuel tank specification details.

YTier 4 generator enclosure height includes the lift base, tank, and enclosure up to the exhaust flange. The height does not include the exhaust

collector, SCR, or the SCR inlet and outlet pipes.

;Tier 4 generator enclosure weight includes the DEF tank but does not include the exhaust collector, SCR, or SCR inlet and outlet pipes.

[ Max. weight includes the generator set (wet) with the largest alternator option, enclosure, silencers, lift base, and tank (no fuel).

] Log average sound pressure level of 8 measured positions around the perimeter of the unit at a distance of 7 m (23 ft.). Refer to TIB-114 for

details. Enclosed generator set sound data for some models was not available at time of print.

w An additional 940 mm (37 inches) of clearance on each side for opening and closing the access doors is recommended.

NOTE: If the Est. Fuel Supply Hours column shows more than one number, the numbers represent each model in that range.

DISTRIBUTED BY:

Availability is subject to change without notice. Kohler Co. reserves the

right to change the design or specifications without notice and without any

obligation or liability whatsoever. Contact your local Kohlerr generator

set distributor for availability. 2016 Kohler Co. All rights reserved.

G6-154 10/20q Page 11

You might also like

- KD800-2500 G6154Document10 pagesKD800-2500 G6154Leo Van Ezel ArcayNo ratings yet

- 15-60reozk G6141Document8 pages15-60reozk G6141fishhunter180% (1)

- Industrial Generator Set Accessories: Sound Level 1 Enclosure Standard FeaturesDocument12 pagesIndustrial Generator Set Accessories: Sound Level 1 Enclosure Standard Featuresy.cruzNo ratings yet

- Industrial Generator Set Accessories: Aluminum Enclosure and Subbase Fuel Tank PackageDocument10 pagesIndustrial Generator Set Accessories: Aluminum Enclosure and Subbase Fuel Tank PackageDoan DaiNo ratings yet

- 40-300REOZJ - G6099 Enclosure Specification SheetDocument8 pages40-300REOZJ - G6099 Enclosure Specification SheetĐoàn Trung HậuNo ratings yet

- Model:: Residential GasDocument4 pagesModel:: Residential Gasapelectric100% (1)

- XC21-AC-Engineering Data-10-2010Document36 pagesXC21-AC-Engineering Data-10-2010kman548No ratings yet

- Steel Enclosures - Weather Protective and Sound Attenuated 10-500 KW GensetsDocument10 pagesSteel Enclosures - Weather Protective and Sound Attenuated 10-500 KW GensetsIgnacio TabuadaNo ratings yet

- ILED Aquarius CIRCLE H Helideck Lighting System Specification SheetDocument4 pagesILED Aquarius CIRCLE H Helideck Lighting System Specification Sheetbakien-canNo ratings yet

- g6099 250kw Spec Sheet KohlerDocument8 pagesg6099 250kw Spec Sheet Kohlerwilliam000111No ratings yet

- Datasheet 10reozdcDocument4 pagesDatasheet 10reozdcWilliam AlvaradoNo ratings yet

- Series E Environmental Coils: Coils and Electronic ControlsDocument18 pagesSeries E Environmental Coils: Coils and Electronic ControlsMMM-MMMNo ratings yet

- Accs r407c CatalogueDocument16 pagesAccs r407c CatalogueMohd FirdhausNo ratings yet

- ACCS R407C 50Hz - MS0316C 1213 CatalogDocument16 pagesACCS R407C 50Hz - MS0316C 1213 CatalogPratikno SajaNo ratings yet

- Blast Resistance, Bullet Resistant & Fire Rated Door: Engineering Metal ProductsDocument2 pagesBlast Resistance, Bullet Resistant & Fire Rated Door: Engineering Metal ProductsAbu AlAnda Gate for metal industries and Equipment.No ratings yet

- Rectangular Attenuators and Splitters: Type DS DKDocument12 pagesRectangular Attenuators and Splitters: Type DS DKSandeepNo ratings yet

- Series E Environmental Coils: Coils and Electronic ControlsDocument18 pagesSeries E Environmental Coils: Coils and Electronic ControlsSayed Ibrahim GhanemNo ratings yet

- Dunnair Premium Range Rooftop Packaged Soft Copy 1 Feb PDFDocument12 pagesDunnair Premium Range Rooftop Packaged Soft Copy 1 Feb PDFSalaar AnsarNo ratings yet

- Crouse Hinds Ace10 Variable Frequency Drive Catalog PageDocument5 pagesCrouse Hinds Ace10 Variable Frequency Drive Catalog PageSaeid MalekizadehNo ratings yet

- LxemDocument10 pagesLxemtgghareebNo ratings yet

- 14resa (L) Spec Sheet 2019Document6 pages14resa (L) Spec Sheet 2019angelNo ratings yet

- Inert Gas PRD Leaflet ENDocument2 pagesInert Gas PRD Leaflet ENlasmar abdelfattahNo ratings yet

- Ab ATLANTIC BLOWERSDocument16 pagesAb ATLANTIC BLOWERSFernando VásconezNo ratings yet

- 20RES Spec Sheet g4172Document4 pages20RES Spec Sheet g4172apelectricNo ratings yet

- G4-276 (7-18b) 48RCLB (KG6208) SpecDocument4 pagesG4-276 (7-18b) 48RCLB (KG6208) SpecService Brags & Hayes, Inc.No ratings yet

- Kohler 20resl 14resl SpecificationsDocument4 pagesKohler 20resl 14resl SpecificationsapelectricNo ratings yet

- ACHX A 5SR R134a 50Hz - MS0499B 0316 - Cs - NpyDocument24 pagesACHX A 5SR R134a 50Hz - MS0499B 0316 - Cs - NpyMARCOSNo ratings yet

- Brochure XK (EN)Document10 pagesBrochure XK (EN)ASrpinNo ratings yet

- 3 400 1 PDFDocument18 pages3 400 1 PDFmasakpNo ratings yet

- Product Data Sheet Insulated Roof & Wall PanelsDocument6 pagesProduct Data Sheet Insulated Roof & Wall PanelsTomek BudaNo ratings yet

- JDN Air Hoists ProfiDocument8 pagesJDN Air Hoists ProfiRichard EVNo ratings yet

- Cat TD Silent 1300 2000 en Fid5660Document12 pagesCat TD Silent 1300 2000 en Fid5660Jhon DiazNo ratings yet

- Product Data Sheet Insulated Roof & Wall PanelsDocument6 pagesProduct Data Sheet Insulated Roof & Wall PanelsmuathNo ratings yet

- Firelight / Firelight DUO / Firelight DUO RN: Natural Smoke and Day To Day VentilatorDocument2 pagesFirelight / Firelight DUO / Firelight DUO RN: Natural Smoke and Day To Day VentilatorJoshuaCheongChuenKitNo ratings yet

- HDT ConcreteCement Brochure 05-lrDocument8 pagesHDT ConcreteCement Brochure 05-lrDhroov SharmaNo ratings yet

- Fire Resistant Systems: Architectural Aluminium Glazing SystemsDocument6 pagesFire Resistant Systems: Architectural Aluminium Glazing SystemsSantosh PatilNo ratings yet

- Grupo Electrogeno Kohler 14 20RESADocument6 pagesGrupo Electrogeno Kohler 14 20RESAUrs SantellanNo ratings yet

- 20rca (L) Spec Sheet 2019Document4 pages20rca (L) Spec Sheet 2019angelNo ratings yet

- CC-JD HT Fan CatalogueDocument2 pagesCC-JD HT Fan CatalogueFaizal MohammedNo ratings yet

- Wide-Lite F Series Floodlight Bulletin 1988Document4 pagesWide-Lite F Series Floodlight Bulletin 1988Alan MastersNo ratings yet

- G4-277 (7-18b) 60RCLA (KG6208) SpecDocument4 pagesG4-277 (7-18b) 60RCLA (KG6208) SpecService Brags & Hayes, Inc.No ratings yet

- SMUL-SAGLDocument9 pagesSMUL-SAGLProject AsyadacNo ratings yet

- Ward Product SelectorDocument32 pagesWard Product SelectorvgchgchgcNo ratings yet

- Technical D-313 Datasheet ENDocument2 pagesTechnical D-313 Datasheet ENnikola.markovicNo ratings yet

- Code - Master 2 HID Factory Sealed Floodlights: Marine (Outside Type) - ExplosionproofDocument8 pagesCode - Master 2 HID Factory Sealed Floodlights: Marine (Outside Type) - ExplosionproofLuis Guillermo BenitezNo ratings yet

- BM (D) X52-g Series Explosion-Proof Illumination (Power) Distribution Box (IIC, TD)Document2 pagesBM (D) X52-g Series Explosion-Proof Illumination (Power) Distribution Box (IIC, TD)Agus ErtigaNo ratings yet

- ACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Document20 pagesACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Eduardo Luis SouzaNo ratings yet

- Airlite Natural VentilatorDocument2 pagesAirlite Natural VentilatorsasNo ratings yet

- Lehe5419 09Document2 pagesLehe5419 09nanthu7090No ratings yet

- Hardrock Dual Density Range: High Performance Acoustic Insulation Boards For Warm at RoofsDocument8 pagesHardrock Dual Density Range: High Performance Acoustic Insulation Boards For Warm at RoofsNarendra Reddy BhumaNo ratings yet

- Fleetrite: The Rite Parts, Right NowDocument12 pagesFleetrite: The Rite Parts, Right NowEdinson BolivarNo ratings yet

- Q SPK Ad-Dwl SpecsDocument2 pagesQ SPK Ad-Dwl SpecsprasanthNo ratings yet

- Models:: Multi-Fuel LPG/Natural GasDocument6 pagesModels:: Multi-Fuel LPG/Natural GasJoe SmithNo ratings yet

- Technical D-313 CLEANROOM Datasheet ENDocument2 pagesTechnical D-313 CLEANROOM Datasheet ENnikola.markovicNo ratings yet

- Switch Rack Assemblies PDFDocument9 pagesSwitch Rack Assemblies PDFGILMER CORREANo ratings yet

- Pressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)Document6 pagesPressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)KOMATSU SHOVELNo ratings yet

- Equipment 210915 Catalog 4f170684Document12 pagesEquipment 210915 Catalog 4f170684Ruby Jane LuchingNo ratings yet

- Storage RequirementsDocument5 pagesStorage RequirementsPrabin SNo ratings yet

- ACP BroucherDocument3 pagesACP BroucherMohammed AhmedNo ratings yet

- Cummins PowerHour - ParallelingTopologies1Document41 pagesCummins PowerHour - ParallelingTopologies1GohoNo ratings yet

- AGN071 - Load Sharing With Quadrature LoopDocument5 pagesAGN071 - Load Sharing With Quadrature LoopQuang PhamNo ratings yet

- Generator Sound Pressure Level CalculationsDocument4 pagesGenerator Sound Pressure Level CalculationsSaeed KazemiNo ratings yet

- Level II Generator SetDocument4 pagesLevel II Generator SetBing UrbinaNo ratings yet

- SS 97-2016 - PreviewDocument21 pagesSS 97-2016 - PreviewGohoNo ratings yet

- Fire Rated Brochure 4hrsDocument1 pageFire Rated Brochure 4hrsGohoNo ratings yet

- SS 551-2009 - PreviewDocument12 pagesSS 551-2009 - PreviewRichard LeongNo ratings yet

- CT Sat Calculator (PSRC)Document345 pagesCT Sat Calculator (PSRC)Ezequiel Juarez BenítezNo ratings yet

- Assessment Test For Applicants For An Electrician's TestDocument7 pagesAssessment Test For Applicants For An Electrician's TestZhu Qi WangNo ratings yet

- Megger InsulationtesterDocument67 pagesMegger InsulationtesterNh Chuminda YapaNo ratings yet

- Cool Fire Manual 45M620N2UK 01 PDFDocument198 pagesCool Fire Manual 45M620N2UK 01 PDFPaun MihaiNo ratings yet

- Classification of Books Using Python and FlaskDocument5 pagesClassification of Books Using Python and FlaskIJRASETPublicationsNo ratings yet

- Data Network Unit 6 - UCDocument15 pagesData Network Unit 6 - UCANISHA DONDENo ratings yet

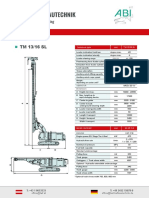

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNo ratings yet

- I Pmtea 2020 HandoutDocument94 pagesI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- Roles and Responsibilities of An InstructorDocument4 pagesRoles and Responsibilities of An InstructorMohanlal SainiNo ratings yet

- Crisis of The World Split Apart: Solzhenitsyn On The WestDocument52 pagesCrisis of The World Split Apart: Solzhenitsyn On The WestdodnkaNo ratings yet

- Coal Bottom Ash As Sand Replacement in ConcreteDocument9 pagesCoal Bottom Ash As Sand Replacement in ConcretexxqNo ratings yet

- Electrical Engineering Lab Vica AnDocument6 pagesElectrical Engineering Lab Vica Anabdulnaveed50% (2)

- Republic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasDocument6 pagesRepublic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasJOHN MC RAE RACINESNo ratings yet

- 32 Hyderabad HITEC City BisleriDocument23 pages32 Hyderabad HITEC City BisleriSridhar ViswanathanNo ratings yet

- Maha Vedha DikshaDocument1 pageMaha Vedha DikshaBallakrishnen SubramaniamNo ratings yet

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocument11 pagesA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Daily Lesson Log Quarter 1 Week 1Document5 pagesDaily Lesson Log Quarter 1 Week 1John Patrick Famadulan100% (1)

- Just in Time and TQMDocument8 pagesJust in Time and TQMBhramadhathNo ratings yet

- The Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObserverDocument1 pageThe Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObservermarceNo ratings yet

- Table of Specification 1st QDocument5 pagesTable of Specification 1st QVIRGILIO JR FABINo ratings yet

- Brosur YSIO X.preeDocument20 pagesBrosur YSIO X.preeRadiologi RSUD KilisuciNo ratings yet

- Nutrition 2022 PIRDocument22 pagesNutrition 2022 PIRAlmira LacasaNo ratings yet

- Past Simple Vs Past ContinuousDocument3 pagesPast Simple Vs Past ContinuousNatalia SalinasNo ratings yet

- Paper 1 AnalysisDocument2 pagesPaper 1 AnalysisNamanNo ratings yet

- Green Dot ExtractDocument25 pagesGreen Dot ExtractAllen & UnwinNo ratings yet

- Digital Electronics Chapter 5Document30 pagesDigital Electronics Chapter 5Pious TraderNo ratings yet

- Introducing The Thinkcentre M70A. A Desktop You DefineDocument3 pagesIntroducing The Thinkcentre M70A. A Desktop You DefineSiti RohayatiNo ratings yet

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDocument10 pagesAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNo ratings yet

- Twin PregnancyDocument73 pagesTwin Pregnancykrishna mandalNo ratings yet

- BSH 7005-15Document129 pagesBSH 7005-15Mark InnesNo ratings yet

- Paul Spicker - The Welfare State A General TheoryDocument162 pagesPaul Spicker - The Welfare State A General TheoryTista ArumNo ratings yet

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Document4 pagesLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PNo ratings yet

- Analytics Designer - Comment Deletion - SAP CommunityDocument6 pagesAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASNo ratings yet