Professional Documents

Culture Documents

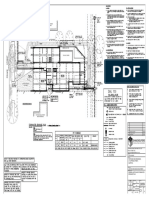

BSC A0 - Drawing 1 Sbc-Model

Uploaded by

Melvin John ThomasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BSC A0 - Drawing 1 Sbc-Model

Uploaded by

Melvin John ThomasCopyright:

Available Formats

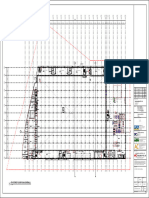

APPROVED BY

37 37 33 33

W W W W W W W W W W W W W W W W W W W W

RS RS

13 7 OPEN 22

8 9 10 20 26

PANEL

20 20 20 20 20 20 20 20 24 36 35

21

WASH AREA

W 2500X3500

W

20 20 20 20 27 27 27 27 27 27

15 15

1 1 TABLE 27 27 27 27 27 27

11 STORE 20 20 20 20 20 20 21a

A 2500X3500

SHEET COATING LAB

BOTTTAN MANUFACTURING SECTION

A

W 22700X25000

4700X3920 RS2 W

OPEN 20 20 20 20 20

WATER TREATMENT PIT

RS4 23 27 27 27 27 27 27

1 12

1 31 25 25 28

TOOL ROOM CASTING PLANT 27 27 27 27 27

2500X3500 21000X15000 31 29

CONTROL OFFICE

4700X3800

APPLICANT SEAL & SIGNATURE

W 31 W

2 RS4 OPEN

2 RACK

31 30 30 30 30 30 30 30 30

STORE

W 2

TABLE POLISHING SECTIN W

2

TABLE

TABLE

31 31 31 31 31 31 31 31 31 31 31 31 31 31

RS3

WATER TREATMENT PIT

RS2 30a 30a 30 30 30 30 30 30

V V

1 1 TABLE

V V 32

14 15 16 34

17 18 19

W

TABLE

30 30 30 30 30 30 30 30

W

PREPARED BY

2 2

W W

TABLE

2 2

YASHMIT HUMAN RESOURCE MANAGEMENT SERVICES

HANGER MANUFACTURING SECTION TABLE 30 30 30 30 30 30 30 30

#5/10, 16TH CROSS LAKKASANDRA, BANGALORE - 560030

38

MOBILE NO - 9591205867

W W

3 3

SCHEDULE TO SITE PLAN

WATER TREATMENT PIT

A - MAIN FACTORY

W

3 3 W B - STORE ROOMS , OFFICE, CANTEEN,

STORE TOILETS

4 RAW MATERIAL STORE

4 18500X15000 C - PUMP HOUSE

4

W1 D - SOUND PROOF M/C

4

W

SCHEDULE OF OPENINGS

RS

ROLLING WINDOWS

W TABLE

PANEL BOARD PANEL BOARD

TABLE 6

39 SHUTTERS

W1

5 5

6

W1 - 1800X1500

W

RS RS

RS - 3000X4200 W2 -900X1500

W W W W W W W W W W W W W W W W W W W

RS1- 2400X2400

RS2- 1800X2400 VENTILATORS

GROUND FLOOR PLAN RS3- 1200X2400 V - 1800X600

RS4- 900X2400

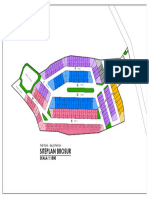

PLAN SHOWING THE FACTORY BUILDING AND MACHINERY

LAYOUT FOR:

M/S, BANGALORE SALES CORPORATION

PLOT NO,175 &,176 BOMMASANDRA JIGANI LINK ROAD,

40

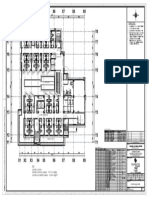

C C C 41 C C WATER

C JIGANI INDUSTRIAL AREA, HENNAGARA POST.

42 TANK

3150X3000

40 ANEKAL TALUK, BANGALORE-562106

OPEN TERRACE

40 3150X3000 SCHEDULE OF MACHINERY

UP DN SL. NO. DESCRIPTION QTY. HP KW

1 INJECTION MOULDING M/C-318 8 120.00 60.0

A STORE A

24400X15000 2 INJECTION MOULDING M/C-218 8 120.00 64.0

FIRST FLOOR PLAN-C SECOND FLOOR PLAN-C

BELOW GROUND FLOOR

3 INJECTION MOULDING M/C-168 4 48.00 24.0

UP

GROUND FLOOR PLAN-C 4 INJECTION MOULDING M/C-128 4 40.00 12.0

5 CHILLER 2 10.00 -

6 PNEUMATIC PRINT MASTER 2 - -

7 ARC WELDING MACHINE 1 - 8.0

900

M S PLATFORM

8 TURNING MACHINE 1 3.00 -

9 AIR COMPRESSOR 1 5.5 -

3000

10 AIR DRYER 1 - 0.5

HAND RAIL

11 DRILLING MACHINE 1 2.0 -

12 SURFACE GRINDING M/C 1 2.0 -

3000

CC FLOORING

13 DRILLING MACHINE 1 0.75 -

ELEVATION

GL GL MEZZANINE FLOOR PLAN-M 14 COLOUR MIXER 1 4.0 -

SECTION-CC

ABOVE CASTING PLANT 15

16

MIXER

HOPPER DRYER

3

1

6.0

-

-

10.0

17 CRUSHER 1 - 4.0

18 CRUSHER 1 10.0 -

19 CRUSHER 1 20.0 -

20 CASTING DRUM 24 - 36.0

21 GRINDING MACHINE 1 - 1.5

A C SHEET

M S SECTION

21a PUNCH GRINDING MACHINE 1 0.5 -

22 AIR COMPRESSOR 1 2.0 -

23 MARY M/C 1 2.0 -

3400

M S COLUMN 24 HYDRO M/C 1 3.0 -

25 PUNCHING MACHINE 2 3.0 -

BBM

LINTEL 26 BENCH GRINDER 1 0.5 -

3500

3000

27 BUTTON DESIGNING M/C 23 - 115.0

CC FLOORING CC PLINTH 28 TOOL GRINDING M/C 1 0.5 -

SSM 29 TOOL DESIGNING M/C 1 0.25 -

30 BUTTON POLISHING M/C 32 48.0 -

SECTION-AA 30a HYDRO M/C 2 0.5 -

31 BUTTON SORTING M/C 15 15.0 -

32 JARATI M/C 11 1.0 -

33 DUST COLLECTOR M/C 2 30.0 -

34 WATER TREATMENT PUMP 2 4.0 -

35 SEEP POND BORD 1 - -

36 CHILLER PLANT 1 3 -

37 COMPRESSOR 2 10 -

38 HYDRO MACHINE 1 5 -

39 ACETONE CLEAN M/C 1 - -

40 PUMP HOUSE 3 9 -

41 COOLING TOWER 1 10 -

42 COOLING TOWER 1 3 -

43 D G MACHINE 1 - 360

TOTAL 502.00 695.0

EAST ELEVATION NOTE :-

1. ALL DIMENSIONS ARE FEET & INCHES

2. FIRE EXTINGUISHER, FIRST AID BOX AND DRINKING

WATER ARE AVAILABLE AT THE PREMISES.

3. FHP-FIRE HYDRANT POINT.

4. AREA / MACHINES TO BE APPROVED.

SCALE :- 1:130, 1:260.

You might also like

- Project Title Owner Sheet Content Sheet No. As Built Plan Mr. Francisco L. Yohanon Electrical Designer Ronald P. PeñaDocument1 pageProject Title Owner Sheet Content Sheet No. As Built Plan Mr. Francisco L. Yohanon Electrical Designer Ronald P. PeñaKpii ReyesNo ratings yet

- Substation Details: X-226390.3291:Y-361071.7341 X-226383.5753:Y-361059.2430Document1 pageSubstation Details: X-226390.3291:Y-361071.7341 X-226383.5753:Y-361059.2430NAHEEMA KPNo ratings yet

- Enlistment Vendor ListDocument24 pagesEnlistment Vendor ListMahir PambharNo ratings yet

- Electrical Wiring: DN 32 DN 32Document1 pageElectrical Wiring: DN 32 DN 32juring bitolaNo ratings yet

- BESWMC Resolution 2022Document4 pagesBESWMC Resolution 2022Blgu LucogNo ratings yet

- Legend: Plumbing Notes:: Water Line Isometric Sanitary & Drainage Line IsometricDocument1 pageLegend: Plumbing Notes:: Water Line Isometric Sanitary & Drainage Line Isometric62296bucoNo ratings yet

- Sag 011 5267 DSN PW CD PK24.476 Ol SG2 100 03Document1 pageSag 011 5267 DSN PW CD PK24.476 Ol SG2 100 03Sanjay SwamiNo ratings yet

- Building 2 ProposedDocument1 pageBuilding 2 ProposedpnkjinamdarNo ratings yet

- Appartment Plan (Competition) PDFDocument1 pageAppartment Plan (Competition) PDFmiteshNo ratings yet

- FP-03 - All Home Cdo - 070317 PDFDocument1 pageFP-03 - All Home Cdo - 070317 PDFLowentan LaxamanaNo ratings yet

- DR Stamped (9 20 2022)Document6 pagesDR Stamped (9 20 2022)Horan HoranNo ratings yet

- Section and Elevation 23-02-24 RV 03Document1 pageSection and Elevation 23-02-24 RV 03krhimanshu0505No ratings yet

- LVL - Lok-500 v1.13 SchematicDocument1 pageLVL - Lok-500 v1.13 SchematiccrackintheshatNo ratings yet

- A07Document1 pageA07Alteina CoradoNo ratings yet

- CD-fp-04 - 4th Storey Floor Plan (Overall)Document1 pageCD-fp-04 - 4th Storey Floor Plan (Overall)balajiNo ratings yet

- Yaramahmoud 196Document5 pagesYaramahmoud 196Yara MahmoudNo ratings yet

- The New Cairo Mall: Cairo Company For Housing &developmentDocument1 pageThe New Cairo Mall: Cairo Company For Housing &developmentMahmud MaherNo ratings yet

- Chariots of Fire - Piano 2Document4 pagesChariots of Fire - Piano 2EFRAIN SANDRO CANUL SANTIAGONo ratings yet

- 24 MP 0202.03 MP0202.03Document1 page24 MP 0202.03 MP0202.03ISH-QUENo ratings yet

- Adventure A2Document1 pageAdventure A2bakuleshNo ratings yet

- Approved: Plot Limit Plot LimitDocument24 pagesApproved: Plot Limit Plot LimitMUBASHIRNo ratings yet

- UntitledDocument11 pagesUntitledRAUL MANUEL ESPINOZA RETAMOZONo ratings yet

- Base Tin Shed: SCALE 0.040 Isometric ViewDocument1 pageBase Tin Shed: SCALE 0.040 Isometric ViewSujeet KumarNo ratings yet

- WBSL-Site-Plan - Warner Brothers UKDocument1 pageWBSL-Site-Plan - Warner Brothers UKAamod GargNo ratings yet

- EEP000093-12102310-2-ST-ARR-0408 - Rev 0Document1 pageEEP000093-12102310-2-ST-ARR-0408 - Rev 0Simran singhNo ratings yet

- SBSP - Pukra 2a Rwy 17rDocument1 pageSBSP - Pukra 2a Rwy 17rVinicius LinsNo ratings yet

- Em-2006-Mep-Eom-Mt-Sd-Plb-110-2 FF Plan-02 Enlarged Water Supply LayoutDocument1 pageEm-2006-Mep-Eom-Mt-Sd-Plb-110-2 FF Plan-02 Enlarged Water Supply LayoutshreeNo ratings yet

- M BD1 1SVDPN Ckea Edr 145007 - 002Document1 pageM BD1 1SVDPN Ckea Edr 145007 - 002Awais NaeemNo ratings yet

- Sbpa - Rnav Korgu 2a - Puksa 2a Rwy 11 - Sid - 20220908Document1 pageSbpa - Rnav Korgu 2a - Puksa 2a Rwy 11 - Sid - 20220908Joelma MilaniNo ratings yet

- Raft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Document1 pageRaft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Omer HayatNo ratings yet

- Power Schematic DiagramDocument2 pagesPower Schematic Diagrambarber1No ratings yet

- Hotaru - Bass TromboneDocument2 pagesHotaru - Bass TromboneWilliam SouzaNo ratings yet

- Karbala Refinery ProjectDocument5 pagesKarbala Refinery Projectعلاء حسينNo ratings yet

- 1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Document1 page1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Mohd AkkiNo ratings yet

- LEVEL - 108.85 Level 6 Total Area - 1747.121 SQM Level 6 Carpet Area - 13340.5 SQFTDocument1 pageLEVEL - 108.85 Level 6 Total Area - 1747.121 SQM Level 6 Carpet Area - 13340.5 SQFTsivagaaneshNo ratings yet

- SBGR - Rnav Romib 4a - Sumra 4a Rwy 27l - 27r - Sid - 20200326 PDFDocument2 pagesSBGR - Rnav Romib 4a - Sumra 4a Rwy 27l - 27r - Sid - 20200326 PDFSädös da LysNo ratings yet

- Schematic Diagram of A Board: Micon, Y/C Jungle Power Supply, HVDocument4 pagesSchematic Diagram of A Board: Micon, Y/C Jungle Power Supply, HVibisible2.3No ratings yet

- Shedule OF Doors & WindowsDocument1 pageShedule OF Doors & WindowseddieNo ratings yet

- Road CuttingDocument1 pageRoad CuttingRavikumar DalmiaNo ratings yet

- 564 Sample Villa - Ground Floor LayoutDocument1 page564 Sample Villa - Ground Floor Layoutalbarajeel consultantsNo ratings yet

- Floor Plan - 9100 - 48 - BASEMENT (PIPING) - Layout1Document1 pageFloor Plan - 9100 - 48 - BASEMENT (PIPING) - Layout1Rachel FloresNo ratings yet

- Up Town Cairo Z3: Ground Floor Plan N5 Second Floor Plan N13Document1 pageUp Town Cairo Z3: Ground Floor Plan N5 Second Floor Plan N13anas and moaz mohamedNo ratings yet

- KingsofConvenience24 25EirikguitarSheetMusicDocument4 pagesKingsofConvenience24 25EirikguitarSheetMusicAnderson Reis ViolãoNo ratings yet

- Site PlaneDocument1 pageSite PlaneindonesiabosheNo ratings yet

- Pipestem Resort State Park Pipestem Resort State Park: Mckeever Lodge Mountain Creek Lodge Mckeever LodgeDocument2 pagesPipestem Resort State Park Pipestem Resort State Park: Mckeever Lodge Mountain Creek Lodge Mckeever LodgeZane CorbinNo ratings yet

- SENR6037Document2 pagesSENR6037Cecilia Gomez.contrerasNo ratings yet

- HDLinkedDocument29 pagesHDLinkedTony Peña VieraNo ratings yet

- EEP000093-12102310-2-ST-ARR-0406 - Rev 0Document1 pageEEP000093-12102310-2-ST-ARR-0406 - Rev 0Simran singhNo ratings yet

- Earthing & Lightning Protection Layout - Ground Floor Plan - Part GDocument1 pageEarthing & Lightning Protection Layout - Ground Floor Plan - Part GAwais NaeemNo ratings yet

- Al Mirar La Cruz TrombonDocument2 pagesAl Mirar La Cruz TrombonJOEL MARCELO MONZON MITANo ratings yet

- 34P Shackelford 23059 - C1-2 Rev A For BPDocument2 pages34P Shackelford 23059 - C1-2 Rev A For BPv8y5h76h9sNo ratings yet

- KANA-BOON - Silhouette (Vicky)Document4 pagesKANA-BOON - Silhouette (Vicky)Victoria Ferrer CañedoNo ratings yet

- Reative Roverbs Nterprises: Second Floor Comfort Room DetailsDocument1 pageReative Roverbs Nterprises: Second Floor Comfort Room Detailswilfred corralNo ratings yet

- C13960ecdc01 BDocument2 pagesC13960ecdc01 Bxuanloc214No ratings yet

- Hitachi Cdh-Le32smart17Document2 pagesHitachi Cdh-Le32smart17Juan PerondiniNo ratings yet

- Chassis TH2983A Diagrama PDFDocument1 pageChassis TH2983A Diagrama PDFWilmer PerezNo ratings yet

- Service Manual: TV-21ST3 TV-20ST5 TV-14ST5Document6 pagesService Manual: TV-21ST3 TV-20ST5 TV-14ST5André LeftNo ratings yet

- Arqui Casa2 2022Document6 pagesArqui Casa2 2022darwinNo ratings yet

- D-448 To D-450 CopingRebar P1-P15 GrpADocument3 pagesD-448 To D-450 CopingRebar P1-P15 GrpAChristian MendozaNo ratings yet

- Tra DCV SDG Id Gen 20010 - Typical Wall & Ceiling DetailsDocument1 pageTra DCV SDG Id Gen 20010 - Typical Wall & Ceiling DetailsErtugrulsurucuNo ratings yet

- Sepl Replace Mezz-InchDocument1 pageSepl Replace Mezz-InchMelvin John ThomasNo ratings yet

- Sepl Replace Mezz-InchDocument1 pageSepl Replace Mezz-InchMelvin John ThomasNo ratings yet

- Medium Duty RacksDocument1 pageMedium Duty RacksMelvin John ThomasNo ratings yet

- Medium Duty RacksDocument1 pageMedium Duty RacksMelvin John ThomasNo ratings yet

- BSC A0 - Drawing 1 Sbc-ModelDocument1 pageBSC A0 - Drawing 1 Sbc-ModelMelvin John ThomasNo ratings yet

- BSC A0 - Drawing 1 Sbc-ModelDocument1 pageBSC A0 - Drawing 1 Sbc-ModelMelvin John ThomasNo ratings yet

- Waste Foundry Sand in Concrete: International Research Journal of Engineering and Technology (IRJET)Document5 pagesWaste Foundry Sand in Concrete: International Research Journal of Engineering and Technology (IRJET)Janak RaazzNo ratings yet

- Chater 5Document9 pagesChater 5Shania LiwanagNo ratings yet

- Jetter Engine Corporation Casting Department Cost of Production Report For February Materials Labor Started in Process This Period Quantity ScheduleDocument9 pagesJetter Engine Corporation Casting Department Cost of Production Report For February Materials Labor Started in Process This Period Quantity SchedulePricilla PutriNo ratings yet

- Astm A743 A743m - 12Document6 pagesAstm A743 A743m - 12Joshua ZantoyNo ratings yet

- Superior Idler Catalog JECDocument86 pagesSuperior Idler Catalog JECkrlos_SW2009No ratings yet

- Homework 2Document11 pagesHomework 2michaquedasilvaNo ratings yet

- Various Advantages and Disadvantages of Waste Incineration - Conserve Energy FutureDocument1 pageVarious Advantages and Disadvantages of Waste Incineration - Conserve Energy FutureKumar SeerattanNo ratings yet

- Decorative Nickel PlatingDocument17 pagesDecorative Nickel PlatingKhaledAhmedNo ratings yet

- TR2 Ingles T... Trabajo FinalDocument12 pagesTR2 Ingles T... Trabajo FinalAngelo OchoaNo ratings yet

- Technical Spec BoilerDocument13 pagesTechnical Spec Boilermochamad RasjidNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Fundamentals Packaging EngDocument12 pagesFundamentals Packaging EngPerum HNHNo ratings yet

- 05 - Kit-Liner-P-Robot - 001 - MIG-MAG Robot Welding TorchDocument8 pages05 - Kit-Liner-P-Robot - 001 - MIG-MAG Robot Welding Torchalecandro_90No ratings yet

- Presto Geocell - GeogridDocument2 pagesPresto Geocell - GeogridLIMITLESSNo ratings yet

- Company Profile ALC 250723Document26 pagesCompany Profile ALC 250723Lâm Quốc TrâmNo ratings yet

- Testing of Heating and Cooling Process of ADI CastDocument5 pagesTesting of Heating and Cooling Process of ADI CastSaloni MaggoNo ratings yet

- Carbon Fiber Reinforced Polymer For Cable Structures-A ReviewDocument22 pagesCarbon Fiber Reinforced Polymer For Cable Structures-A ReviewERICK RCHNo ratings yet

- Gold Mat - ColourchartmetalsDocument4 pagesGold Mat - Colourchartmetalsiklem79No ratings yet

- ME306 Advanced Manufacturing Technology, September 2020Document2 pagesME306 Advanced Manufacturing Technology, September 2020samnoon muadNo ratings yet

- Machine Spec 1 - Interlocking BrickDocument5 pagesMachine Spec 1 - Interlocking BrickZafry TahirNo ratings yet

- Embrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationDocument5 pagesEmbrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationGustavo FelipeNo ratings yet

- Injection Molding: 2.810 Fall 2002 Professor Tim GutowskiDocument42 pagesInjection Molding: 2.810 Fall 2002 Professor Tim GutowskiSree Raj100% (1)

- MillingDocument76 pagesMillingAbduljebar SemuNo ratings yet

- Ae2253 LPDocument2 pagesAe2253 LPசுஜித் குமார்No ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- Review and Related LiteratureDocument11 pagesReview and Related LiteraturebevNo ratings yet

- CPM Formwork FinalDocument17 pagesCPM Formwork FinalPrathikNo ratings yet

- CWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)Document17 pagesCWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNo ratings yet