Professional Documents

Culture Documents

Compressed Air Type Surge Vessels: Data Unit Details

Uploaded by

Thiru AnanthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressed Air Type Surge Vessels: Data Unit Details

Uploaded by

Thiru AnanthCopyright:

Available Formats

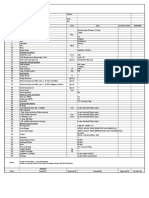

Compressed Air Type Surge Vessels

1 Name of Manufacturer

2 Place of Surge Vessel fabrication (Country)

3 Place of Surge Vessel FAT (Country and Town)

4 Name of local Agent/Supplier

5 Phone/Fax No. of local Agent/Supplier

6

7 DATA UNIT DETAILS

8 Location of Installation - Outdoor

9 Design Standard I Code - ASME VIII Div 1 code (Latest)

10 Type of Vessel - Horizontal / Vertical

11 Quantity/ Area Nos Refer Table on Sheet no. 2

12 Third Party Inspection by - Refer Section 3 of Vol.2 book 5 of 9.

13 Type of Support (Vertical/ Horizontal) - VTP

14 Material of construction - Refer the Volume 2 Book 2 of 9

15 Corrosion Allowance mm Refer the Volume 2 Book 2 of 9

16 Design Pressure barg Refer Note 18 on Sheet no. 2

17 Design Temperature °C Refer Note 18 on Sheet no. 2

18 Workinq pressure barg Refer Note 18 on Sheet no. 2

19 Vessel Volume m3 Refer Note 18 on Sheet no. 2

20 Operating air volume m3 Refer Note 18 on Sheet no. 2

21 Vessel Dimensions (inside diameter / tan to tan height) mm VTP

22 Wall Thickness (Head/Shell) mm VTP

23 Connections - Refer the Volume 2 Book 2 of 9

24 Main Appurtenances details - VTP

25 Ladder (yes/no) - yes

26 Access platform (yes/no) - VTP

27 Internal lining -

Refer Section 7. Cl. 6.2 & 15 of Volume 2 Book 5

Material -

Volume 2 Book 2 of 9.

Refer Section 7 Cl. 6.2 & 15 of Volume 2

Thickness mm

Book 5 Volume 2 Book 2 of 9.

28 Name of organisation issuing the Non Toxicity Certificate - VTP

29 External coating -

Refer Section 7. Cl. 6.2 & Section 15 of Volume 2

Material -

Book 5 Volume 2 Book 2 of 9.

Refer Section 7. Cl. 6.2 & Section 15 of Volume 2

Thickness mm

Book 5 Volume 2 Book 2 of 9.

30 Accessories - VTP

31 Hydrostatic Test Report (yes I no) - Yes

32 Hydrostatic test pressure bar Refer Note 20 of Sheet No.2

33 Weight of Vessel

Empty kg VTP

Full of water kg VTP

34 General Arrangement Drawings No.s - VTP

35 Delivery period weeks VTP

Notes

1 For detailed design requirements please refer tender document vol 2 Book 2 of 9 -Volume 2 Book 5 of 9

2 Please refer Attachment 05 for reference for a typical scheme for surge system along with compressors.

3 Vendor shall provide tentative GA drawing with foundation details, Cross sectional drawings and catalogues along with the offer for

separataly areawise

VTP - Vendor to provide

Compressed Air Type Surge Vessels

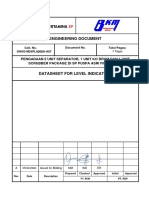

Scope of work

Notes

1 Surge Vessels design shall meet the requirements of Section 7 Volume 2 Book 5 of 9, attached Specifications as below :

tender specifications as per below:

a) Surge Vessels shall be designed, fabricated as per minimum requirements mentioned in ASME Sec.VIII Division1 design code (Latest Edition) and Section 7 CL. 2.

Surge vessel shall be fitted with Nozzles; Manholes; Corrosion protection; Pipe support clips; Ladders with cage; Platforms and walkways;Lifting and lowering accessories; Anchoring accessories;

2 Brackets for lightning protection; Earthing bosses; Nameplates and brackets.

3 All wind and earthquake calculations shall be made in accordance with the ASCE 7 Standard. It shall be assumed that two loads will not occur simultaneously.

4 All nozzles shall be provided with flanges and shall be arranged that the pipe connections are possible. The stub length for all stub pieces shall be at least 200 mm, measured

from the vessel wall to the sealing surface of flange.

5 Heads of surge vessels shall be one-piece torispherical or ellipsoidal heads with an integral straight flange of 75 mm minimum.

6 Materials shall be supplied with material certificate type 3.1 for pressure containing parts, and type 2.2 for structural material in accordance

with EN 10204.

7 All procedures for manufacturing (including welder qualification, welding, weld repair, post weld heat treatment) and quality control, as well as manufacturing time schedule,

shall be subject to approval by the Engineer or its representative prior to fabrication of surge vessels.

8 Inspection, testing, and repairs shall be in accordance with the applicable sections of the basic code and the approved Inspection and Test Plan.

(Refer Section 7 Manual Volume 2 Book 5 of 9.

9 All Nozzle flanges shall be confirm to ASME B16.5 for size upto 24" and ASME B16.47 for size above 24"

10 Vendor to Furnish deliverables after contract of awad as per Clause no. 9 of Section 7 Volume 2 Book 5 of 9,

11 Wherever VTP is mentioned it means " Vendor to provide".

12 Painting of the equipment shall be inline with painting specification (Refer attachment 06: Vol-2- book 5- sec15- painting of piping,

equipment and structural steel work)

13 Internal Painting and external Painting of the equipment shall be inline with painting specification (Refer Sec 5 Clause 22 - “Painting Supervision, Inspection and Tests”as

mentioned in the Volume 2 Book 5 of 9

14 Vendor scope of supply shall include list of start-up and commissioning spares for vessels

15 Vendor to ensure that flange finishes and machined surfaces shall be protected from damage during shipping, storage and installation. The entire gasket surface of flanges shall

be greased and covered with heavy-duty plastic flange protectors, bolted or steel-strapped wood, wood fiber or metal covers. coated flange and cover.

Where wood or metal covers are used, a plastic sheet shall be placed between the

16 The surge vessels shall be permanently tagged with stainless steel nameplate, securely attached on the bracket welded to the shell.

17 Nozzles with blind flanges shall be provided with Gasket, Bolts and nuts and Man holes shall be provided with Blind Flange and

Davit assembly.

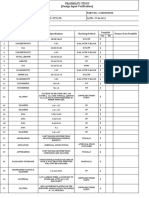

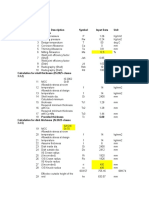

Design Working Operating Air

18 Area Quantity Design Pressure Temperature Pressure Vessel Volume Volume

Nos barg C° barg m3 m3

1 1W+1S 20/FV 18 55

40% of vessel

2 1W+1S 22/FV 55 19.5 55 volume

3 2W+1S 21/FV 19 55

19 As per TET-SS-5031 Rev.1.1 of Volume 2 book 2 of 9 , The surge vessel shall be made of steel plates Gr 70 according to ASTM A 516 standard and shall be normalised.

20 Hydrotest of the surge vessel shall be performed as per the Section 7 of Volume 2 Book 5 of 9 whichever is governing.

21 Vendor to consider & provide the spare parts & consumables list phase wise as per below :

(Commission phase + 3 Months trial Run before system taking over + 4 years after taking over .)

22 For Air compressor details refer attachment 06 attached with this RFQ & accordingly vendor to submit the offer for the entire package.

You might also like

- Bottorff, Steve - A Primer On Knife SharpeningDocument42 pagesBottorff, Steve - A Primer On Knife Sharpeningpauloadriano100% (2)

- All Soil Test ReportDocument35 pagesAll Soil Test ReportSoundar Pachiappan100% (1)

- Specification For Fire Water HydrantDocument5 pagesSpecification For Fire Water HydrantThiru AnanthNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- SMAW Written ExamDocument2 pagesSMAW Written ExamNell Sabas AdolfoNo ratings yet

- (Fifth Revision) : Amendment No. 2 April 2022 TO Is 4984: 2016 Polyethylene Pipes For Water Supply - SpecificationDocument7 pages(Fifth Revision) : Amendment No. 2 April 2022 TO Is 4984: 2016 Polyethylene Pipes For Water Supply - Specificationnarendar.180% (5)

- Datasheet For Pressure Gauge - Process DataDocument8 pagesDatasheet For Pressure Gauge - Process DataLai HuynhNo ratings yet

- Specification For Injection QuillDocument4 pagesSpecification For Injection QuillThiru AnanthNo ratings yet

- Knife Grinding JigDocument13 pagesKnife Grinding JigZarcano FariasNo ratings yet

- Datasheet For Pressure Transmitter - Process DataDocument4 pagesDatasheet For Pressure Transmitter - Process DataLai HuynhNo ratings yet

- Flange Excel NewDocument26 pagesFlange Excel NewvikasNo ratings yet

- SAGA Catalogue MegapowerDocument16 pagesSAGA Catalogue Megapowerarchery100% (2)

- Pipe DesignDocument1 pagePipe DesignShreevardhan KhoatNo ratings yet

- Core 1Document78 pagesCore 1Robert BanagaNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- Check Valve DatasheetDocument4 pagesCheck Valve DatasheetSeptian FirdausNo ratings yet

- PT Pressure TransmitterDocument1 pagePT Pressure TransmitterAr RahmanNo ratings yet

- Stack Fabrication: NIOEC-SP-20-04Document8 pagesStack Fabrication: NIOEC-SP-20-04Ak OraNo ratings yet

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFDocument9 pagesDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFaerfansNo ratings yet

- Sump DesignDocument4 pagesSump DesignThiru AnanthNo ratings yet

- FD ISA Form S20.50 Rev 1 - OriginalDocument1 pageFD ISA Form S20.50 Rev 1 - OriginalRaphael AndradeNo ratings yet

- Application Guide For Ucrete: April 2018Document64 pagesApplication Guide For Ucrete: April 2018Moath AlhajiriNo ratings yet

- DS Pressure SwitchDocument5 pagesDS Pressure SwitchnathaNo ratings yet

- ParCat w2400Document122 pagesParCat w2400IgorKKKNo ratings yet

- PieroDocument6 pagesPierojguerrerosperuNo ratings yet

- Job Information: Job No Sheet No RevDocument2 pagesJob Information: Job No Sheet No RevJedidiahClementNo ratings yet

- Data Sheet For Magnetic Type Level GaugeDocument5 pagesData Sheet For Magnetic Type Level GaugeJaya RamNo ratings yet

- Job Information: Job No Sheet No RevDocument9 pagesJob Information: Job No Sheet No RevAldvin LibresNo ratings yet

- 02 Datasheet Pressure TransmitterDocument2 pages02 Datasheet Pressure TransmitterFadlila MuhammadNo ratings yet

- Data Sheet For Pressure Safety Valve: Document No.: MMR-DS-60-012-A4 3 of 6 Rev.: 3 Date: 4-Aug-22Document4 pagesData Sheet For Pressure Safety Valve: Document No.: MMR-DS-60-012-A4 3 of 6 Rev.: 3 Date: 4-Aug-22nathaNo ratings yet

- Ds DpsDocument1 pageDs DpsNilesh ChavanNo ratings yet

- Douglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Document6 pagesDouglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Luis Omar AmundarayNo ratings yet

- Body Design FeasibilityDocument4 pagesBody Design FeasibilityPrakash kumarTripathiNo ratings yet

- Aluminium Profile Type 2 - EditedDocument1 pageAluminium Profile Type 2 - EditedJessica Issa JuliaNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- Manual de Partes Ricoh MP161Document214 pagesManual de Partes Ricoh MP161Julio JonesNo ratings yet

- DS For Level SwitchDocument7 pagesDS For Level SwitchnathaNo ratings yet

- Metro PDFDocument295 pagesMetro PDFrupadhyaayNo ratings yet

- ReporteDocument16 pagesReporteJefferson Jesus Perez SilvaNo ratings yet

- C18W10 - Drawing Issue Sheet 008Document6 pagesC18W10 - Drawing Issue Sheet 008Chung Him Joe ChanNo ratings yet

- Datasheet For Level Gauge - IfbDocument51 pagesDatasheet For Level Gauge - Ifbfathan fathullahNo ratings yet

- 1pf2gf - Pgf-Int-Gp-Re10213Document20 pages1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingNo ratings yet

- Extruded Rubber Products: Purpose and ScopeDocument16 pagesExtruded Rubber Products: Purpose and ScopeSunil NairNo ratings yet

- Test VRF AermecDocument5 pagesTest VRF Aermecemanuel92No ratings yet

- Pzem 33H224 3 Pumps 10 HPDocument4 pagesPzem 33H224 3 Pumps 10 HPRutchelle BrunoNo ratings yet

- EN3553 Hydrospeicher-Nachschaltung KatalogversionDocument8 pagesEN3553 Hydrospeicher-Nachschaltung KatalogversionsivakumarNo ratings yet

- A Window Size 750mm X 450mm High Clear Glass No 48: Menyiapkan Kk3 Pauh, Perlis ADD.1/D2/25Document1 pageA Window Size 750mm X 450mm High Clear Glass No 48: Menyiapkan Kk3 Pauh, Perlis ADD.1/D2/25ANS HVAC SDN BHDNo ratings yet

- HD RFT Mty Ope 003Document5 pagesHD RFT Mty Ope 003Anonymous AtAGVssJNo ratings yet

- Datasheet For Side Entry MixerDocument4 pagesDatasheet For Side Entry Mixervinoj chandranNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- Pc3 Clamp DrawingDocument4 pagesPc3 Clamp DrawingSujin SujiNo ratings yet

- Pc3 Clamp DrawingDocument4 pagesPc3 Clamp DrawingSujin SujiNo ratings yet

- PEL-TP-00-INS-DS-0XX Datasheet Temperature Control Valve Rev 0Document2 pagesPEL-TP-00-INS-DS-0XX Datasheet Temperature Control Valve Rev 0Adhya RazanNo ratings yet

- Reporte EdificioDocument16 pagesReporte EdificioJefferson Jesus Perez SilvaNo ratings yet

- GD Labs: Comcolor SeriesDocument10 pagesGD Labs: Comcolor SeriesMarlos BonillaNo ratings yet

- Supplementary Communication Sheet: (Document/Drawing Information) With Regard To Ring ForgingDocument2 pagesSupplementary Communication Sheet: (Document/Drawing Information) With Regard To Ring ForgingpkguptaqaqcNo ratings yet

- COSASCO Fittings - RBS-RBSA SBBV WIDocument45 pagesCOSASCO Fittings - RBS-RBSA SBBV WIAhmad KhNo ratings yet

- (Fifth Revision) : Amendment No. 2 April 2022 TO Is 4984: 2016 Polyethylene Pipes For Water Supply - SpecificationDocument7 pages(Fifth Revision) : Amendment No. 2 April 2022 TO Is 4984: 2016 Polyethylene Pipes For Water Supply - Specificationvinit kumarNo ratings yet

- BOQ LANDSCAPE Final June 2013 - LCTDocument50 pagesBOQ LANDSCAPE Final June 2013 - LCTAhmad SaadeldinNo ratings yet

- 72400726-DS-002 Rev 0Document8 pages72400726-DS-002 Rev 0prabakaran365No ratings yet

- 6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01Document9 pages6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01balajiNo ratings yet

- Machine Guarding 2019Document4 pagesMachine Guarding 2019alyssaNo ratings yet

- Tapa Piston Dibujo v1Document1 pageTapa Piston Dibujo v1Jose santiago Bernal foreroNo ratings yet

- DS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feDocument1 pageDS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feFernando RomeroNo ratings yet

- EPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 ApprovedDocument15 pagesEPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 Approvedboy telerNo ratings yet

- Parts Catalog RicoH VT1730Document157 pagesParts Catalog RicoH VT1730AgostinhoNo ratings yet

- Semiconducting III–V Compounds: International Series of Monographs on SemiconductorsFrom EverandSemiconducting III–V Compounds: International Series of Monographs on SemiconductorsNo ratings yet

- GRE Piping Design Data - 10 InchDocument2 pagesGRE Piping Design Data - 10 InchThiru AnanthNo ratings yet

- Power Plant-Part - 2 of 1Document10 pagesPower Plant-Part - 2 of 1Thiru AnanthNo ratings yet

- Specification For Fire Water MonitorsDocument6 pagesSpecification For Fire Water MonitorsThiru AnanthNo ratings yet

- Fire SystemsDocument5 pagesFire SystemsThiru AnanthNo ratings yet

- Appendix-A2 (Piping Design Data)Document2 pagesAppendix-A2 (Piping Design Data)Thiru AnanthNo ratings yet

- Fire Pump SpecificationDocument5 pagesFire Pump SpecificationThiru AnanthNo ratings yet

- Chilled Water Distribution SystemDocument5 pagesChilled Water Distribution SystemThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument1 pageS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Hazen-Williams EquationDocument1 pageHazen-Williams EquationThiru AnanthNo ratings yet

- Transport and Main Roads MRTS78 Fabrication of Structural SteelworkDocument35 pagesTransport and Main Roads MRTS78 Fabrication of Structural SteelworkVitoNo ratings yet

- Lab 7 PipingDocument6 pagesLab 7 PipingAtif AbbasNo ratings yet

- PVM Ms 4750 CDocument30 pagesPVM Ms 4750 CabdelillahNo ratings yet

- Electrodeposited Coatings On Threaded Fasteners (Metric) : Standard Specification ForDocument9 pagesElectrodeposited Coatings On Threaded Fasteners (Metric) : Standard Specification ForsanthakumarNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- SHOP Power ToolsDocument70 pagesSHOP Power ToolsBbNo ratings yet

- Alfileres Fancy Headpins For JL - 0Document9 pagesAlfileres Fancy Headpins For JL - 0Anonymous TvdkFvkE1No ratings yet

- Pan Oston Install Manual Belted Check Lanes 2020Document49 pagesPan Oston Install Manual Belted Check Lanes 2020HEMANTH P ANo ratings yet

- Concept MapDocument8 pagesConcept MapJohn Mark Gallano CanayonNo ratings yet

- Product Catalogue - Grinding Equipment - LOWDocument32 pagesProduct Catalogue - Grinding Equipment - LOWEmrah MertyürekNo ratings yet

- Me8793 Process Planning and Cost EstimationDocument30 pagesMe8793 Process Planning and Cost EstimationVenkadesh Arumugam (Esaikaathalan)No ratings yet

- Salient Features of Exise ActDocument7 pagesSalient Features of Exise ActYogesh Patil0% (1)

- Machine LatheDocument4 pagesMachine LatheKirubel MulugetaNo ratings yet

- A Tool, A Privilege, and A Responsibility: The KnifeDocument5 pagesA Tool, A Privilege, and A Responsibility: The KnifeFabio ViolaNo ratings yet

- Main Product Pipe Fittings: Hebei Xinqi Pipeline Equipment Co.,LtdDocument21 pagesMain Product Pipe Fittings: Hebei Xinqi Pipeline Equipment Co.,Ltdmechanical 1No ratings yet

- Evolution of Money in The PhilippinesDocument9 pagesEvolution of Money in The PhilippinesJulie Bless M. Parcon0% (1)

- Crossette Productivity Tools: Tool Tip..Document11 pagesCrossette Productivity Tools: Tool Tip..Olindo D'AndreaNo ratings yet

- More Information : An Introduction To The Most Common Workshop ToolsDocument3 pagesMore Information : An Introduction To The Most Common Workshop ToolsAvy BatraNo ratings yet

- PDS Pro Struct 617 October 2017 Replaces April 2010Document1 pagePDS Pro Struct 617 October 2017 Replaces April 2010Amar Babu ChNo ratings yet

- JI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDocument2 pagesJI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDamar Wardhana100% (1)

- Die Basics 101 - Part XIII - The FabricatorDocument5 pagesDie Basics 101 - Part XIII - The FabricatorSIMONENo ratings yet

- ShippingDocument248 pagesShippingLarah BuhaweNo ratings yet

- Ptfe Coated Studs, Bolts and NutsDocument1 pagePtfe Coated Studs, Bolts and Nutssabari ramasamyNo ratings yet

- Instrument Construction ProcedureDocument24 pagesInstrument Construction ProcedureDaengkulle Firmansyah PuteraNo ratings yet