Professional Documents

Culture Documents

Silcoset 158 Technical Data Sheet

Uploaded by

Андрей Мошкин0 ratings0% found this document useful (0 votes)

10 views1 pageThis document provides information on Silcoset 158, a one-part high temperature thixotropic adhesive sealant. It cures at room temperature upon exposure to atmospheric moisture to form a flexible rubber seal. Key features include resistance to chemicals and solvents with flexibility from -60 to 300 degrees Celsius. It has good adhesion to many substrates and remains flexible over a wide temperature range.

Original Description:

Original Title

EN_SILCOSET 158 TDS_1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on Silcoset 158, a one-part high temperature thixotropic adhesive sealant. It cures at room temperature upon exposure to atmospheric moisture to form a flexible rubber seal. Key features include resistance to chemicals and solvents with flexibility from -60 to 300 degrees Celsius. It has good adhesion to many substrates and remains flexible over a wide temperature range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageSilcoset 158 Technical Data Sheet

Uploaded by

Андрей МошкинThis document provides information on Silcoset 158, a one-part high temperature thixotropic adhesive sealant. It cures at room temperature upon exposure to atmospheric moisture to form a flexible rubber seal. Key features include resistance to chemicals and solvents with flexibility from -60 to 300 degrees Celsius. It has good adhesion to many substrates and remains flexible over a wide temperature range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Technical Data Sheet

Silcoset 158 (RTV 1008A)

1 Part high temperature thixotropic adhesive sealant

Introduction

Property Test Method Value

Silcoset 158 is a ready-to-use adhesive sealant, which reacts with

atmospheric moisture to form a resilient rubber, which remains Uncured Product

flexible over a very wide temperature range. Colour: Black

Appearance: Black paste

Silcoset 158 liberates a very small amount of acetic acid during Tack Free Time: 4 minutes *

cure which gives rise to the familiar “vinegar” odour, which quickly 3mm Cure Through: 7 hours*

dissipates after cure. Extrusion Rate: 270g / minute

Viscosity mPas

These high specification sealants are ideal for a myriad of * measured at 23+/-2°C and 65% relative humidity.

engineering applications from production work to fast, effective

maintenance and on-the-spot repairs. They are applied directly Cured Elastomer

from the cartridge and cure at room temperature. Under typical (after 7 days cure at 23+/-2°C and 65% relative humidity)

ambient conditions they develop a tack free surface in Tensile Strength: BS903 Part A2 2.30 MPa

approximately 15 minutes and cure within 24 hours. Elongation at Break : BS903 Part A2 290 %

Youngs Modulus: 0.7 MPa

Modulus at 100% Strain: BS903 Part A2 0.94 MPa

Key Features Tear Strength: BS903 Part A3 5.5 kN/m

Hardness: ASTM D 2240-95 38° Shore A

¾ Good electrical insulation Specific Gravity: BS 903 Part A1 1.07

¾ Resistance to chemicals and solvents Linear Shrinkage: 0.8%

¾ Flexible from -60 to + 300°C Thermal Conductivity: 0.2 W/mK

¾ Excellent bonding to a wide range of substrates Coefficient of Thermal

Expansion:

Use and Cure Information Volumetric 924 ppm / °C

How to Use Linear 308 ppm / °C

Min. Service Temperature: -60 °C

Silcoset 158 is ready for use. If supplied in cartridges it can be Max. Service Temperature: AFS 1540B 300 °C

applied using either manual or pneumatic dispensers.

It can also be applied from bulk containers using conventional drum Electrical Properties

dispensing equipment

Volume Resistivity: ASTM D-257 1E+16Ω.cm

Application and Cure Surface Resistivity: ASTM D-257 3.57E+15Ω

Dielectric Strength: ASTM D-149 18 kV/mm

All surfaces to which the adhesive is to be applied should be clean, Dielectric Constant at 1MHz: ASTM D-150 3

dry and free from grease, dirt, and loose material. Dissipation Factor at 1MHz: ASTM D-150 2.5E-3

Priming of surfaces is not normally required.

If being employed as an adhesive, it should be applied to one clean Adhesion Testing

surface and the other clean surface brought into contact with it

within 5 minutes. Good unprimed adhesion to many substrates including glass

For optimum bond strength the thickness of the sealant joint is 1 to stainless steel, aluminium and most plastics.

2mm. Customers are advised to carry out their own tests on clean,

Joints should be left undisturbed for at least 24 hours, but degreased substrates to ensure satisfactory adhesion is achieved.

preferably longer to effect sufficient depth of cure. Full cure

requires 7 days. All values are typical and should not be accepted as a specification.

“For pneumatic dispensing of 310 ml cartridges, the Health and Safety - Material Safety Data Sheets available on

recommended pressure is 2.25 to 3.45 bar (40 to 50 psi).

request.

Dispensing pressure above the recommended limits may lead

to gas bypassing the piston, causing spluttering at the nozzle

and poor bead quality”

Packages - 310 ml cartridges. Arrangements can be made to

supply in bulk containers.

Storage and Shelf Life – Expected to be 24 months in original,

unopened containers below 40°C.

Revision Date: 12/12/2005

The information and recommendations in this publication are to the best of our knowledge reliable. However nothing herein is to be construed as a

warranty or representation. Users should make their own tests to determine the applicability of such information or the suitability of any products for their

own particular purposes. Statements concerning the use of the products described herein are not to be construed as recommending the infringement of

any patent and no liability for infringement arising out of any such use is to be assumed.

ACC Silicones Ltd, Amber House, Treco S.R.L., Via Romagna N.8,

Showground Road, Bridgwater, Somerset, UK 20098 Sesto Ulteriano (MI), Italia.

Tel. +44(0)1278 411400 Fax. +44(0)1278 411444 Tel. 39/02/9880913 Fax. +39/02/98280413

www.acc-silicones.com

You might also like

- En - Silcoset 151 TDS - 1Document1 pageEn - Silcoset 151 TDS - 1Андрей МошкинNo ratings yet

- Technical Data Sheet for Silcoset 152 1-Part Adhesive SealantDocument1 pageTechnical Data Sheet for Silcoset 152 1-Part Adhesive SealantАндрей МошкинNo ratings yet

- En - Silcoset 153 TDS - 1Document1 pageEn - Silcoset 153 TDS - 1Андрей МошкинNo ratings yet

- Technical Data Sheet for 1-Part Silicone Sealant Silcoset 151Document2 pagesTechnical Data Sheet for 1-Part Silicone Sealant Silcoset 151Arun VaideeswaranNo ratings yet

- Flexseal PU440 TDSDocument2 pagesFlexseal PU440 TDSkumaraguruNo ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Terostat Ms 939-EnDocument2 pagesTerostat Ms 939-EnZoli PoliNo ratings yet

- TI FURADUR DBK 323 enDocument5 pagesTI FURADUR DBK 323 endris.elmouteaNo ratings yet

- Humiseal 1A33 Conformal Coating English TdsDocument2 pagesHumiseal 1A33 Conformal Coating English TdsLee HitchensNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- EMCEKRETE 90 DS - Updated-Dec 2022Document3 pagesEMCEKRETE 90 DS - Updated-Dec 2022Suvajit BisaiNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Tds 8330 2partsDocument2 pagesTds 8330 2partsgrasia77No ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- Zinc Anode 304 MZV Protects Steel Against Severe CorrosionDocument2 pagesZinc Anode 304 MZV Protects Steel Against Severe CorrosionMANIMARAN QCNo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Vetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantDocument2 pagesVetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantSHAIK ASIMUDDINNo ratings yet

- MCU-INSULAT 230 EnglishDocument2 pagesMCU-INSULAT 230 Englishduongbk24 luu quang duongNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- 838 Silicone Adhesive SealantDocument3 pages838 Silicone Adhesive SealantMario Vargas VegaNo ratings yet

- Plascoat Ppa 571: Performance Polymer Alloy CoatingDocument2 pagesPlascoat Ppa 571: Performance Polymer Alloy CoatingEidrish ShaikhNo ratings yet

- Asian Paints Smartcare Waterproofing MembraneDocument2 pagesAsian Paints Smartcare Waterproofing Membraneহিমুরাজ রিয়াজNo ratings yet

- PPA 571 EsDocument4 pagesPPA 571 EsRohit Sangwan0% (1)

- Dow Corning 791 Silicone Weatherproofing Sealant: Product InformationDocument4 pagesDow Corning 791 Silicone Weatherproofing Sealant: Product InformationРоман СередаNo ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetBenjaminNo ratings yet

- Stycast 1266 EpoxyDocument3 pagesStycast 1266 EpoxyAlex22222No ratings yet

- Ceramic Coating Product Data SheetDocument3 pagesCeramic Coating Product Data SheetANIBALLOPEZVEGANo ratings yet

- PC 1752 - Asian Bituminous CoatingsDocument3 pagesPC 1752 - Asian Bituminous CoatingsRamesh BabuNo ratings yet

- Construction: Dow CorningDocument3 pagesConstruction: Dow Corningsamira bashirvandNo ratings yet

- SUP10HT MasterbondDocument2 pagesSUP10HT MasterbondShai KvetnyNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Masterseal M 811 TdsDocument4 pagesMasterseal M 811 TdsAdityaVikramVermaNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Simarine Acrylic Coating Data SheetDocument2 pagesSimarine Acrylic Coating Data SheetPerseroan MustikaNo ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- Scotch® 130C Linerless Rubber Splicing Tape: Data SheetDocument2 pagesScotch® 130C Linerless Rubber Splicing Tape: Data Sheetismail mijasNo ratings yet

- Weberrep 360 FFR-KSA 01Document2 pagesWeberrep 360 FFR-KSA 01moizm53No ratings yet

- Sigmazinc 109 HS: Description Principal CharacteristicsDocument4 pagesSigmazinc 109 HS: Description Principal CharacteristicsАлексейNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Dow Corning 785 Technical DatasheetDocument4 pagesDow Corning 785 Technical DatasheetShuvenduNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- MOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01Document2 pagesMOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01pmf engineering limitedNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- Technical Data Sheet for Barrier 80 S Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 S Zinc Epoxy PrimerHung Mai VanNo ratings yet

- FT AislantesFV Ducwrap CTDocument2 pagesFT AislantesFV Ducwrap CTRODOLFONo ratings yet

- NovaGuard 840Document5 pagesNovaGuard 840sehmediaNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- PPC04-PolyGuard™-Anti-Fog-TDS-WEBDocument3 pagesPPC04-PolyGuard™-Anti-Fog-TDS-WEBnox633159No ratings yet

- Aquasmart PBDocument3 pagesAquasmart PBmeena nachiyarNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetАндрей МошкинNo ratings yet

- Scotchcal™ Graphic Film: Series 50Document4 pagesScotchcal™ Graphic Film: Series 50Андрей МошкинNo ratings yet

- Material Safety Data SheetDocument6 pagesMaterial Safety Data SheetАндрей МошкинNo ratings yet

- 102 MSDSDocument13 pages102 MSDSАндрей МошкинNo ratings yet

- 3M EC2216AB Grey MSDS - Image.MarkedDocument28 pages3M EC2216AB Grey MSDS - Image.MarkedАндрей МошкинNo ratings yet

- Aerodur C21 100 UVRDocument3 pagesAerodur C21 100 UVRАндрей МошкинNo ratings yet

- Замена AeroShell Grease 33MS на ASG 64Document1 pageЗамена AeroShell Grease 33MS на ASG 64Андрей МошкинNo ratings yet

- AEROSIL® 200: Hydrophilic Fumed SilicaDocument2 pagesAEROSIL® 200: Hydrophilic Fumed SilicaJose E BatistaNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetАндрей МошкинNo ratings yet

- Airseal 2 - ENDocument1 pageAirseal 2 - ENАндрей МошкинNo ratings yet

- Aerodex WB: Interior Cabin CoatingDocument5 pagesAerodex WB: Interior Cabin CoatingАндрей МошкинNo ratings yet

- 69 Electrical Tape - OEMDocument2 pages69 Electrical Tape - OEMАндрей МошкинNo ratings yet

- Glass Cloth Tape: Technical DataDocument2 pagesGlass Cloth Tape: Technical DataАндрей МошкинNo ratings yet

- 3M™ Scotch-Weld™ 3524 B A FSTDocument3 pages3M™ Scotch-Weld™ 3524 B A FSTАндрей МошкинNo ratings yet

- Citrus Base Cleaner (Aerosol) : Technical Data October, 2004Document2 pagesCitrus Base Cleaner (Aerosol) : Technical Data October, 2004Aritonang SuryaNo ratings yet

- 3M Spray 77Document3 pages3M Spray 77Cipri CroitorNo ratings yet

- Tape 27 para Alta TemperaturaDocument3 pagesTape 27 para Alta TemperaturaralvaradoarayaNo ratings yet

- 3M Yapes 8672 8694 8663 8693Document2 pages3M Yapes 8672 8694 8663 8693Андрей МошкинNo ratings yet

- 1 Scoth Weld 1300 L TdsDocument4 pages1 Scoth Weld 1300 L TdspokleNo ratings yet

- Precision Aerospace FastenersDocument4 pagesPrecision Aerospace FastenersАндрей МошкинNo ratings yet

- 3M Scotch Weld Epoxy Adhesive 2214Document8 pages3M Scotch Weld Epoxy Adhesive 2214Андрей МошкинNo ratings yet

- Unit IV Measurement of Non-Electrical ParametersDocument17 pagesUnit IV Measurement of Non-Electrical ParametersAleesha100% (6)

- Theory of Solutions DPP-2 (Questions) PDFDocument4 pagesTheory of Solutions DPP-2 (Questions) PDFHarshjeetNo ratings yet

- Envelope Bearing Analysis: Theory and Practice: IEEE Aerospace Conference Proceedings April 2005Document10 pagesEnvelope Bearing Analysis: Theory and Practice: IEEE Aerospace Conference Proceedings April 2005Felipe Andres Figueroa VidelaNo ratings yet

- Allied DC Portable Aspirator User ManualDocument9 pagesAllied DC Portable Aspirator User ManualmiguelNo ratings yet

- Manual eDocument220 pagesManual ejfilipeoliveira1979No ratings yet

- Flight Planning Speed SelectionDocument21 pagesFlight Planning Speed Selectionoswaldo venegas100% (1)

- Solenoid Key Release Unit - SRUE: Installation InstructionsDocument2 pagesSolenoid Key Release Unit - SRUE: Installation InstructionsEva SuárezNo ratings yet

- Cont. Eva.Document2 pagesCont. Eva.Rainwin TamayoNo ratings yet

- Dokumen - Pub Renewable Energy Systems 1536104418 9781536104417Document282 pagesDokumen - Pub Renewable Energy Systems 1536104418 9781536104417Tacko KanouteNo ratings yet

- 3M 2890-2890A Data Sheet 2012Document2 pages3M 2890-2890A Data Sheet 2012Michael TadrosNo ratings yet

- Linear Low Density Polyethylene Resin Special CharacteristicsDocument1 pageLinear Low Density Polyethylene Resin Special CharacteristicsFahad MohamedNo ratings yet

- Gruppe Spot II LED FloodlightDocument2 pagesGruppe Spot II LED FloodlightManju BargaveeNo ratings yet

- Lecture - Notes - Chemistry - Final - 10232018 PDFDocument130 pagesLecture - Notes - Chemistry - Final - 10232018 PDFAlvin DeliroNo ratings yet

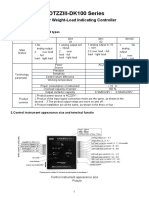

- PESA CARGA DTZZIII-DK100系列说明书英文Document6 pagesPESA CARGA DTZZIII-DK100系列说明书英文NelsonEnrriqueInfante100% (2)

- Manitowoc Ice Makers Service ManualDocument172 pagesManitowoc Ice Makers Service ManualJason PaschkeNo ratings yet

- Envir Otect Power Cable Install ManualDocument49 pagesEnvir Otect Power Cable Install ManualRashi MrBRDNo ratings yet

- Steam Ejector CalculationsDocument7 pagesSteam Ejector Calculationshoangvubui4632No ratings yet

- Sciencedirect Paper Received - Libdl - IrDocument7 pagesSciencedirect Paper Received - Libdl - IrSadegh AhmadiNo ratings yet

- Edexcel AS PhysicsDocument172 pagesEdexcel AS PhysicsNishchay Bhatt93% (14)

- Horizontal Rectangular Steam Sterilizer, LI - RADocument2 pagesHorizontal Rectangular Steam Sterilizer, LI - RALodha International LLPNo ratings yet

- 798 - Third Party Testing of HYSD Reinforcement F 500 DSteelDocument1 page798 - Third Party Testing of HYSD Reinforcement F 500 DSteelp.v.n. lakshmanNo ratings yet

- YCIV MANUAL 201.23-nm2 PDFDocument338 pagesYCIV MANUAL 201.23-nm2 PDFJoel Avena100% (1)

- WP HIAC Detection and Control in WFI and PW Systems USDocument0 pagesWP HIAC Detection and Control in WFI and PW Systems USboddarambabuNo ratings yet

- Cell Phone Battery Flashlight DIY: Build a Bright LED Light Using Old Phone BatteriesDocument6 pagesCell Phone Battery Flashlight DIY: Build a Bright LED Light Using Old Phone Batteriesnita_alecsandruNo ratings yet

- 2021 - JEE Advanced Booster Test - 2 - PaperDocument20 pages2021 - JEE Advanced Booster Test - 2 - PapervikasNo ratings yet

- Maths CoursesiitbDocument136 pagesMaths Coursesiitbbilguunbaatar.dNo ratings yet

- How To Fix A Washing Machine: 9 Common Problems: Attempting RepairsDocument6 pagesHow To Fix A Washing Machine: 9 Common Problems: Attempting RepairsLouieGonzalesNo ratings yet

- Module-2 Energy Systems & AnalysisDocument46 pagesModule-2 Energy Systems & Analysisrushi C SNo ratings yet

- TC XXX 9999023615Document1 pageTC XXX 9999023615Jean RaminhoNo ratings yet

- Ch08 Giancoli7e LectureOutlineDocument33 pagesCh08 Giancoli7e LectureOutlineMuhammad Firman PriatnaNo ratings yet