Professional Documents

Culture Documents

838 Silicone Adhesive Sealant

Uploaded by

Mario Vargas Vega0 ratings0% found this document useful (0 votes)

44 views3 pagesOriginal Title

838 SILICONE ADHESIVE SEALANT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views3 pages838 Silicone Adhesive Sealant

Uploaded by

Mario Vargas VegaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Technical Data Sheet

DOWSIL™ 838 Silicone Adhesive Sealant

FEATURES One-part, white, non-flowing general purpose adhesive with good

• Non-flowing flame resistance

• Room temperature cure

• High elongation for added stress APPLICATIONS

relief DOWSIL™ 838 Silicone Adhesive Sealant application method: Automated or

• UL 94HB Flammability Rating manual needle dispensing systems

• Sealing openings in modules and housings

BENEFITS • Adding mechanical stability to individual components

• Assembly of components on PWBs

• No mixing required

• Sealing in and around wired and electrical leads

• RT cure, no ovens required

• Yoke assembly

• Faster in-line processing with

optional heat acceleration

• Added reliability can result from

TYPICAL PROPERTIES

Specification Writers: These values are not intended for use in preparing

lower cured stress

specifications.

• Can be considered for uses

Property Unit Result

Extrusion Rate g/min 199.2

Flow Rate - Slump in 0

cm 0.1

Specific Gravity (Cured) 1.02

Tack-Free Time at 25ºC minutes 46

Tensile Strength psi 270

MPa 1.9

kg/cm2 19

Tensile Modulus psi 60

MPa 0.4

kg/cm2 4

Durometer Shore A 31

UL Flammability Classification NA 94 HB

DESCRIPTION as acetone or isopropyl alcohol (IPA) release agents. Small-scale laboratory

Dow one-part moisture cure do not tend to remove oils well, and evaluation of all substrates is

adhesives are generally cured at room any oils remaining on the surface may recommended before production trials

temperature and in an environment of interfere with adhesion. Light surface are made.

30 to 80 percent relative humidity abrasion is recommended whenever

eliminating the need for curing ovens possible, because it promotes good Useful Temperature Ranges

and the associated costs of energy cleaning and increases the surface area For most uses, silicone elastomers

and capital. Greater than 90 percent for bonding. A final surface wipe with should be operational over a

of full physical properties should be acetone or IPA is also useful. Some temperature range of -45 to 200°C (-

attained within 24 to 72 hours and cleaning techniques may provide 49 to 392°F) for long periods of time.

varies according to product. Faster better results than others; users should However, at both the low- and high

manufacturing throughput is achieve determine the best techniques for their temperature ends of the spectrum,

however since the adhesive and particular applications. behavior of the materials and

component can be handled in much performance in particular applications

shorter times of about 10 to 120 Substrate Testing can become more complex and require

minutes depending on the adhesive Due to the wide variety of substrate additional considerations. For low-

selected and the amount of applied. types and differences in substrate temperature performance, thermal

surface conditions, general statements cycling to conditions such as -55°C (-

These adhesives are not typically on adhesion and bond strength are 67°F) may be possible, but

used in highly confined spaces or impossible. To ensure maximum bond performance should be verified for

where a deep section cure is required strength on a particular substrate, 100 your parts or assemblies. Factors that

as they generally cure from the percent cohesive failure of the may influence performance are

exposed surface inward at a rate of adhesive in a lap shear or similar configuration and stress sensitivity of

0.25 inch per seven days. Cure adhesive strength test is desired. This components, cooling rates and hold

progresses from the outer exposed ensures compatibility of the adhesive times, and prior temperature history.

surface and is dependent on the with the substrate being considered. At the high-temperature end, the

moisture in the air. Working time is Also, this test can be used to durability of the cured silicone

generally a few minutes to an hour determine minimum cure time or can elastomer is time and temperature

for these products until a surface skin detect the presence of surface dependent. As expected, the higher the

begins to form. Mild heat below 60°C contaminants such as mold release temperature, the shorter the time the

(140°F) may be used to increase agents, oils, greases and oxide films. material will remain useable.

through -put by accelerating the cure.

Adhesion Solvent

Dow silicone adhesives retain their Dow silicone adhesives are specially Exposure when liquid or vapor solvent

original physical and electrical formulated to provide unprimed or fuel exposure can occur in an

properties over a broad range of adhesion too many reactive metals, application, the silicone adhesive

operating conditions which enhance ceramics and glass, as well as to discussed in this brochure is intended

the reliability of and service life of selected laminates, resins and plastics. only to survive splash or intermittent

PCB system assemblies. The stable However, good adhesion cannot be exposures. It is not suited for

chemistry and versatile processing expected on non-reactive metal continuous solvent or fuel exposure.

options of these adhesives offer substrates or non-reactive plastic Testing should be done to confirm

benefits for a variety of needs from surfaces such as Teflon®, polyethylene performance of the adhesives under

increasing component safety and or polypropylene. Special surface these conditions.

reliability, reducing total cost or treatments such as chemical etching or

increasing the performance envelope plasma treatment can sometimes HANDLING

of devices or modules. provide a reactive surface and promote PRECAUTIONS

adhesion to these types of substrates.

PRODUCT SAFETY

HOW TO USE Dow primers can be used to increase

INFORMATION REQUIRED FOR

the chemical activity on difficult

Preparing Surfaces SAFE USE IS NOT INCLUDED IN

substrates. Poor adhesion may be

All surfaces should be thoroughly THIS DOCUMENT. BEFORE

experienced on plastic or rubber

cleaned and/or degreased with Dow HANDLING, READ PRODUCT

substrates that are highly plasticized,

OS fluids, naphtha, mineral spirits, AND SAFETY DATA SHEETS

because the mobile plasticizers act as

methyl ethyl ketone (MEK) or other AND CONTAINER LABELS FOR

suitable solvent. Solvents such SAFE USE, PHYSICAL AND

UNRESTRICTED – May be shared with anyone

®

™The DOW Diamond and DOWSIL are trademarks of The Dow Chemical Company

Teflon is a registered trademark of E.I Dupont de Nemours and Company.

DOWSIL™ 838 Silicone Adhesive Sealant

© 2017 The Dow Chemical Company. All rights reserved. Form No. 95-1108-01 A

2

HEALTH HAZARD For more information about our

INFORMATION. THE SAFETY materials and capabilities, visit

DATA SHEET IS AVAILABLE ON www.consumer.dow.com.

THE DOW WEBSITE AT

WWW.CONSUMER.DOW.COM, To discuss how we could work

OR FROM YOUR DOW SALES together to meet your specific needs,

APPLICATION ENGINEER, OR go to www.consumer.dow.com for a

DISTRIBUTOR, OR BY CALLING contact close to your location. Dow

DOW CUSTOMER SERVICE. has customer service teams, science

and technology centers, application

USABLE LIFE AND support teams, sales offices, and

STORAGE manufacturing sites around the globe.

DOWSIL 838 Silicone Adhesive

Sealant should be stored at or below at LIMITED WARRANTY

or below room temperature (away INFORMATION – PLEASE

from direct sunlight), maximum 25°C READ CAREFULLY

(77°F) in original, unopened The information contained herein is

containers. offered in good faith and is believed to

Containers should be kept tightly be accurate. However, because

closed with head or air space conditions and methods of use of our

minimized. Partially filled containers products are beyond our control, this

should be purged with dry air or other information should not be used in

gases, such as nitrogen. substitution for customer’s tests to

ensure that our products are safe,

effective, and fully satisfactory for the

LIMITATIONS intended end use. Suggestions of use

This product is neither tested nor

shall not be taken as inducements to

represented as suitable for medical or

infringe any patent.

pharmaceutical uses.

Dow’s sole warranty is that our

HEALTH AND products will meet the sales

ENVIRONMENTAL specifications in effect at the time of

INFORMATION shipment.

To support customers in their product

safety needs, Dow has an extensive Your exclusive remedy for breach of

Product Stewardship organization and such warranty is limited to refund of

a team of product safety and purchase price or replacement of any

regulatory compliance specialists product shown to be other than as

available in each area. warranted.

For further information, please see our TO THE FULLEST EXTENT

website, www.consumer.dow.com or PERMITTED BY APPLICABLE

consult your local Dow representative. LAW, DOW SPECIFICALLY

DISCLAIMS ANY OTHER

HOW CAN WE HELP YOU EXPRESS OR IMPLIED

TODAY? WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR

Tell us about your performance,

MERCHANTABILITY.

design, and manufacturing challenges.

Let us put our silicon-based materials

expertise, application knowledge, and DOW DISCLAIMS LIABILITY

processing experience to work for FOR ANY INCIDENTAL OR

you. CONSEQUENTIAL DAMAGES.

www.consumer.dow.com

®

Trademark of The Dow Chemical Company Form No. 95-1108-01 A

3

You might also like

- Dow Corning 3165Document3 pagesDow Corning 3165Morlin BungkeriNo ratings yet

- DOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsDocument4 pagesDOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsSami LAHMIDINo ratings yet

- Electronics: Dow CorningDocument3 pagesElectronics: Dow CorningWandyy GonçalvesNo ratings yet

- DOWSIL™ 3-1965 Conformal Coating: Features & BenefitsDocument3 pagesDOWSIL™ 3-1965 Conformal Coating: Features & Benefitsquang trinhNo ratings yet

- Technical Data Sheet for 1-Part Silicone Sealant Silcoset 151Document2 pagesTechnical Data Sheet for 1-Part Silicone Sealant Silcoset 151Arun VaideeswaranNo ratings yet

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- DOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingDocument3 pagesDOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingGreat StuffNo ratings yet

- Dow Corning 791 Silicone Weatherproofing Sealant: Product InformationDocument4 pagesDow Corning 791 Silicone Weatherproofing Sealant: Product InformationРоман СередаNo ratings yet

- DOWSIL™ 3-1944 RTV Coating: Features & BenefitsDocument4 pagesDOWSIL™ 3-1944 RTV Coating: Features & Benefitsquang trinhNo ratings yet

- En - Silcoset 151 TDS - 1Document1 pageEn - Silcoset 151 TDS - 1Андрей МошкинNo ratings yet

- Dow CorningDocument2 pagesDow Corningwardoyoclp75No ratings yet

- Epoxy Primer for Corrosion ProtectionDocument2 pagesEpoxy Primer for Corrosion ProtectionsreeNo ratings yet

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- Construction: Dow CorningDocument3 pagesConstruction: Dow Corningsamira bashirvandNo ratings yet

- GAF FlexSeal Sealant Product Data 2176367Document2 pagesGAF FlexSeal Sealant Product Data 2176367FachrurraziNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- MOLYKOTE 44 - MediumDocument2 pagesMOLYKOTE 44 - MediumCesar AlejandroNo ratings yet

- CC-3122 Conformal CoatingDocument3 pagesCC-3122 Conformal Coatingquang trinhNo ratings yet

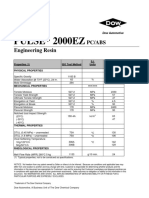

- 2000EZDocument2 pages2000EZAlejandro DelgadoNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- Silcoset 158 Technical Data SheetDocument1 pageSilcoset 158 Technical Data SheetАндрей МошкинNo ratings yet

- Sylgard+527+TDS ENDocument3 pagesSylgard+527+TDS ENMuhammet DemirNo ratings yet

- SEMICOSIL 987 GR en 2021.09.17Document4 pagesSEMICOSIL 987 GR en 2021.09.17Carlos Enriquez ReyesNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Evonik-Amicure PACMDocument5 pagesEvonik-Amicure PACMuzzy2No ratings yet

- Epoxy Undercoat Protects Steel and ConcreteDocument2 pagesEpoxy Undercoat Protects Steel and ConcreteMoin AltafNo ratings yet

- En - Silcoset 153 TDS - 1Document1 pageEn - Silcoset 153 TDS - 1Андрей МошкинNo ratings yet

- Hyperdesmo®-Pb-Mono - enDocument3 pagesHyperdesmo®-Pb-Mono - enMajd M. KhalilNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Hempel Shopprimer 15890ZSDocument2 pagesHempel Shopprimer 15890ZSAnuar SalehNo ratings yet

- Technical Data Sheet Jazeera Selfmastic JI-66009: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Selfmastic JI-66009: Descriptionsalam nazarNo ratings yet

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- Cepsa Circulante 150Document1 pageCepsa Circulante 150RamonNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Jazeera Damp MasticDocument3 pagesJazeera Damp MasticAhmad BougeisNo ratings yet

- Technical Data Sheet for Silcoset 152 1-Part Adhesive SealantDocument1 pageTechnical Data Sheet for Silcoset 152 1-Part Adhesive SealantАндрей МошкинNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- LSR LC-50-2004Document3 pagesLSR LC-50-2004tarot.insights4uNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- LUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CDocument2 pagesLUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CPraveenNo ratings yet

- Loctite Stycast 2651MM Cat 9 TDS 1Document2 pagesLoctite Stycast 2651MM Cat 9 TDS 1steffan.henryNo ratings yet

- Chemlok 217 Adhesive: Lord Technical Data Lord Technical DataDocument2 pagesChemlok 217 Adhesive: Lord Technical Data Lord Technical DataNeeraj BhallaNo ratings yet

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroNo ratings yet

- TDS - Shell Irus DU 46 - EN PDFDocument2 pagesTDS - Shell Irus DU 46 - EN PDFdtcuongNo ratings yet

- Chemask Solder Masking Agent: Product# CM8, CM1Document2 pagesChemask Solder Masking Agent: Product# CM8, CM1Alexsander CamargoNo ratings yet

- Expandable SealDocument2 pagesExpandable Sealmeena nachiyarNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- DOWSIL™ GP Sealant: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ GP Sealant: Features & Benefits ApplicationsSondangNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Vacuum Pump Oil SDS Safety DataDocument21 pagesVacuum Pump Oil SDS Safety DataMario Vargas VegaNo ratings yet

- Microspraying in Perfection!: eco-SPRAYDocument4 pagesMicrospraying in Perfection!: eco-SPRAYMario Vargas VegaNo ratings yet

- Spare Parts List Eco PEN600 ENDocument1 pageSpare Parts List Eco PEN600 ENMario Vargas VegaNo ratings yet

- Dosing Technology: eco-CONTROL EC200-KDocument2 pagesDosing Technology: eco-CONTROL EC200-KMario Vargas VegaNo ratings yet

- Dosing Technology: eco-CONTROL EC200-DUODocument2 pagesDosing Technology: eco-CONTROL EC200-DUOMario Vargas VegaNo ratings yet

- Ecoduo330 EnglDocument2 pagesEcoduo330 EnglMario Vargas VegaNo ratings yet

- Ecoduo330 EnglDocument2 pagesEcoduo330 EnglMario Vargas VegaNo ratings yet

- Microspraying in Perfection!: eco-SPRAYDocument4 pagesMicrospraying in Perfection!: eco-SPRAYMario Vargas VegaNo ratings yet

- LORD DS3298 Thermoset300Document4 pagesLORD DS3298 Thermoset300Mario Vargas VegaNo ratings yet

- Report Information: Global Polyurethane Foam Market Research Report 2017Document12 pagesReport Information: Global Polyurethane Foam Market Research Report 2017Vo HanNo ratings yet

- Technical Data Sheet TemplateDocument2 pagesTechnical Data Sheet TemplateAisha MughalNo ratings yet

- Dow HFDG4201Document3 pagesDow HFDG4201cwqccqNo ratings yet

- 0901 B 80380532 B 2 FDocument2 pages0901 B 80380532 B 2 FKeval VelaniNo ratings yet

- Dow KT 10000 UeDocument2 pagesDow KT 10000 UeLuca GuadagnoNo ratings yet

- The Making of A Megadeal Howard Ungerleider On The Merger of Dow and DupontDocument7 pagesThe Making of A Megadeal Howard Ungerleider On The Merger of Dow and DupontebncloudNo ratings yet

- DOWSIL™ 813C Construction and Concrete Silicone Sealant: Features & BenefitsDocument6 pagesDOWSIL™ 813C Construction and Concrete Silicone Sealant: Features & BenefitsMurali KrishnaNo ratings yet

- 16 Tomczak V MortonDocument3 pages16 Tomczak V MortonAlfonso Miguel LopezNo ratings yet

- Dow ChemicalDocument12 pagesDow Chemicalvenkata muraliNo ratings yet

- 0901 B 803808 Be 983Document6 pages0901 B 803808 Be 983Nikesh ShahNo ratings yet

- Bioban - Dow ChemicalsDocument3 pagesBioban - Dow ChemicalsNanda KishoreNo ratings yet

- Antifoams ChartDocument1 pageAntifoams ChartTariq Khan OtmanzaiNo ratings yet

- Dowsil 790 Silicone Building SealantDocument4 pagesDowsil 790 Silicone Building SealantChris ChanonaNo ratings yet

- Dowsil Sw-8005 c30 Resin WaxDocument3 pagesDowsil Sw-8005 c30 Resin WaxCarolline GregorioNo ratings yet

- Tech Data Sheet IMPAXX™ 700 Energy Absorbing Foam: Product InformationDocument2 pagesTech Data Sheet IMPAXX™ 700 Energy Absorbing Foam: Product InformationAnonymous KjrLUwYSNo ratings yet

- Bhopal Gas Disaster - 25 Years AfterDocument106 pagesBhopal Gas Disaster - 25 Years AfterKannanGKNo ratings yet

- ACUSOL™ OP301 Opacifier: Features & BenefitsDocument4 pagesACUSOL™ OP301 Opacifier: Features & BenefitsDirza PutrawisesaNo ratings yet

- StyrofoamDocument12 pagesStyrofoamOliveraNo ratings yet

- Equipo ProtecticDocument12 pagesEquipo ProtecticRuiz AlfredoNo ratings yet

- Germany Wants Amityowners Extradited Forfinancial FraudDocument32 pagesGermany Wants Amityowners Extradited Forfinancial FrauddksyndcNo ratings yet

- Dowtherm Heat Transfer FluidsDocument16 pagesDowtherm Heat Transfer FluidsUdaya ZorroNo ratings yet

- Kathonlx1 5%TDSDocument9 pagesKathonlx1 5%TDSPablo Manu Gomez VNo ratings yet

- Sealant ComparisonDocument3 pagesSealant Comparisonmercab15No ratings yet

- 901 01901 01 Dow Products For Graphic Arts Market InformationDocument4 pages901 01901 01 Dow Products For Graphic Arts Market InformationJun ChenNo ratings yet

- DOWSIL™ 33 Additive: Features & BenefitsDocument3 pagesDOWSIL™ 33 Additive: Features & BenefitsNiranjan GoriwaleNo ratings yet

- Affinity GA 1950 - SMLDocument3 pagesAffinity GA 1950 - SMLkübraNo ratings yet

- Upendra Baxi, Valiant Victims, Lethal Litigation' in The Statesman (2014)Document34 pagesUpendra Baxi, Valiant Victims, Lethal Litigation' in The Statesman (2014)yoloNo ratings yet

- Amberjet 1500 H PdsDocument3 pagesAmberjet 1500 H Pdsak_thimiriNo ratings yet

- Icis Ott Nov16Document48 pagesIcis Ott Nov16franz_passariniNo ratings yet

- Xiameter 65Document2 pagesXiameter 65santi2100No ratings yet