Professional Documents

Culture Documents

Wartsila o e Ls x82

Uploaded by

Isaac tHe OcEaNSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wartsila o e Ls x82

Uploaded by

Isaac tHe OcEaNSCopyright:

Available Formats

Wärtsilä X82

KEY BENEFITS WÄRTSILÄ X82 RATING FIELD The new engine parameters offer an

•• Compact design with limited engine increased flexibility for selecting the most

width and height, combined with low efficient propeller speed, thus giving

shaft speed minimised daily fuel consumption, by using

•• Extended rating field offering optimum the appropriate propeller diameter for the

propeller speed for different applications

projected ship design and mission profile.

•• Low fuel consumption thanks the

Thanks to the higher engine de-rating

application of FAST injectors

•• Reliability based on many RT-flex82T potential and lower propeller revolutions and

engines in service the utilisation of a larger propeller diameter,

•• Stable operation at low speed due to the application areas have been increased

the superior electronically controlled significantly. Moreover, the unique Wärtsilä

common-rail concept extended layout field (R1+) offers the

possibility to select this engine for container

TYPICAL APPLICATION AREAS

The Wärtsilä X82 engine is perfectly suited

as main engine for VLCC, VLOC as well as for

Panamax container vessels due to its extended

and optimised rating field.

vessels with minimised piston dismantling height.

The application of a waste heat recovery system (WHR) can increase the

efficiency of the fuel input energy by around 10% improving the overall

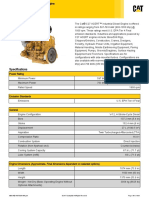

Wärtsilä X82

04.2014 Bock´s Office

IMO Tier II

energy use and reducing the environmental impact. Cylinder bore 820 mm

Piston stroke 3375 mm

OPERATIONAL FEATURES Speed 65–84 rpm

Mean effective pressure at R1/R1+ 21.0/19.0 bar

Wärtsilä’s well proven electronically-controlled common-rail technology

Stroke / bore 4.12

plays a key role in enabling ship owners to reduce fuel costs, mainly

Rated power, principal dimensions and weights

through the flexibility of the fuel injection and exhaust valve operations. A Output in kW at

unique feature of Wärtsilä low-speed electronically controlled engines is Cyl. 76 / 84 rpm 65 rpm Length A

mm

Weight

tonnes

the possibility to control each fuel injector separately. This flexibility results R1 / R1+ R2 / R2+ R3 R4

6 28 500 21 720 24 390 18 600 11 045 805

in lower fuel consumption across the entire operating range, especially at

7 33 250 25 340 28 455 21 700 12 550 910

low and part loads. In addition, different engine tunings are available in 8 38 000 28 960 32 520 24 800 14 055 1 020

order to meet specific customer requirements according to their particular 9 42 750 32 580 36 585 27 900 16 500 1 160

needs (Standard, Delta and Low Load). Other advantages of this technology B C D E

include stable low running speeds down to 15 rpm, smokeless operation, Dimensions 5 320 1 800 12 250 5 400

mm F1 F2 F3 G

and improved control of exhaust emissions. For cylinder lubrication, an

14 820 14 800 13 800 2 700

oil feed rate of 0.6 g/kWh can be achieved. The engines are equipped as

Brake specific fuel consumption (BSFC) in g/kWh

standard with intelligent combustion control (ICC) system enabling further

Full load

fuel savings and balanced working of each cylinder. Rating point R1/R1+ R2/R2+ R3 R4

BMEP, bar 21.0/19.0 16.0/14.5 21.0 16.0

ENVIRONMENTAL COMPLIANCE BSFC Standard Tuning 165/163 158 165 158

The engine is fully compliant with IMO Tier II requirements. The introduction Part load,% of R1/R1+ 85 70 85 70 65

Tuning variant Standard Standard Delta Delta Low-Load

of the EEDI index also put an emphasis on CO2 emissions and total vessel

BSFC 161.4/159.4 161.0/159.0 160.7/158.7 159.5/157.5 156.2/154.5

efficiency. The Wärtsilä X82’s internal engine and propulsion efficiencies,

and the possibility to apply various Power Take Off (PTO) arrangements for

onboard electricity production, make it easy for shipyards to meet these

new requirements. Thanks to Wärtsilä common-rail technology, the engine

E

has no visible smoke at any load. Waste Heat Recovery (WHR) offers further

possibilities for maximising energy efficiency and for reducing emissions.

F2 / F3

F1

TOTAL COST OF OWNERSHIP

D

All areas of lifecycle costs have been taken into account for the Wärtsilä

X82 engine. The selected stroke-to-bore ratio makes the engine compact

C

and has a positive impact on the manufacturing cost. The Wärtsilä X82

is based on the very reliable RT-flex82T engine and its design stand for A B

long maintenance-free operation. It also allows extended Time Between

Overhaul (TBO) as much as 5 years. The service-friendly design will reduce

downtime, maintain vessel operation and cut operating costs. Together with

Condition Based Maintenance (CBM) and service agreements, the overhaul

interval could be even further extended, thus minimising maintenance

costs and maximising the revenue-earning capability of the vessel.

WÄRTSILÄ® is a registered trademark. Copyright © 2014 Wärtsilä Corporation.

WARTSILA.COM

You might also like

- Brochure o e w20Document2 pagesBrochure o e w20Christopher JonatanNo ratings yet

- HVT R2 Hydromechanical Variable TransmissionDocument12 pagesHVT R2 Hydromechanical Variable TransmissionShubham JaruharNo ratings yet

- Dana Rexroth HVT R2 Hydromechanical Variable TransmissionDocument2 pagesDana Rexroth HVT R2 Hydromechanical Variable TransmissionPankaj GargNo ratings yet

- Wartsila 34df LeafletDocument5 pagesWartsila 34df LeafletJaya BharathiNo ratings yet

- Compresor Mobil Atlas Copco XAMS 287 MDDocument4 pagesCompresor Mobil Atlas Copco XAMS 287 MDdicon100% (1)

- D10T2 01Document20 pagesD10T2 01AlbertoNo ratings yet

- Cce WL B Series 821b 921b Brochure 06-09-2009Document28 pagesCce WL B Series 821b 921b Brochure 06-09-2009Renato Evangelista100% (1)

- RPM48R: Two Stage Loader-Mounted Snow BlowerDocument4 pagesRPM48R: Two Stage Loader-Mounted Snow BlowerRevathi PNo ratings yet

- 4008TAG1-2A - 844-924kWm Emission Compliant Epak PN1833 - 3Document2 pages4008TAG1-2A - 844-924kWm Emission Compliant Epak PN1833 - 3Ali Reza PishevarNo ratings yet

- Powerful pedigree for large enginesDocument4 pagesPowerful pedigree for large enginesvanNo ratings yet

- 2051 TPL ADocument4 pages2051 TPL ACurtler PaquibotNo ratings yet

- TDS of Kixx HD1 - 220519Document1 pageTDS of Kixx HD1 - 220519Mohamed IsmailNo ratings yet

- Wärtsilä X62: Fuel Costs/Roundtrip (Kusd)Document2 pagesWärtsilä X62: Fuel Costs/Roundtrip (Kusd)Avery CrosbyNo ratings yet

- Brochure o e w20dfDocument2 pagesBrochure o e w20dfRizki A. RadyantamaNo ratings yet

- D85-18 WH PDFDocument20 pagesD85-18 WH PDFSBNo ratings yet

- SMC Publ-5612 2022 enDocument2 pagesSMC Publ-5612 2022 enSergioNo ratings yet

- Portable Air Compressors Powerful Dependable GlobalDocument4 pagesPortable Air Compressors Powerful Dependable GlobalJamal HabbasNo ratings yet

- Duron XL 15W-40Document4 pagesDuron XL 15W-40CopyMaster2No ratings yet

- Shell Rimula R2 15W-40 Technical Data SheetDocument2 pagesShell Rimula R2 15W-40 Technical Data SheetHUM CIREBON DFLTSNo ratings yet

- Man CatalogueDocument16 pagesMan CatalogueClaudio100% (3)

- Factsheet Industrial Trent 60 Us LowresDocument2 pagesFactsheet Industrial Trent 60 Us LowresAsri GaniNo ratings yet

- Xas 400 CD It4 Xavs 400 CD It4Document2 pagesXas 400 CD It4 Xavs 400 CD It4Sri RamNo ratings yet

- Wartsila 25 The Power To Target Net ZeroDocument8 pagesWartsila 25 The Power To Target Net ZeroAlvin AkbarNo ratings yet

- Shell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsDocument2 pagesShell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsWajahat RasoolNo ratings yet

- MAN High Speed Marine Engines: For Medium Duty ApplicationsDocument4 pagesMAN High Speed Marine Engines: For Medium Duty Applicationsكردن سيدي محمدNo ratings yet

- Page: M-1 of M-4 © 2020 Caterpillar All Rights Reserved MSS-PET-18443098-030 PDFDocument4 pagesPage: M-1 of M-4 © 2020 Caterpillar All Rights Reserved MSS-PET-18443098-030 PDFDerek JohnsonNo ratings yet

- Sauer Danfoss Orbital Motors PDFDocument5 pagesSauer Danfoss Orbital Motors PDFSoledad Navarro LazoNo ratings yet

- Powerful 2832 Series 6X4 Tippers with 240 kW EngineDocument12 pagesPowerful 2832 Series 6X4 Tippers with 240 kW EngineJhamil CruzNo ratings yet

- SS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFDocument5 pagesSS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFANDRES CASASNo ratings yet

- 938g PDFDocument24 pages938g PDFLuis Fernando Vasquez Ramos100% (1)

- New Booster Technical DataDocument1 pageNew Booster Technical DataAmr SherifNo ratings yet

- MAN high speed marine engines for medium duty applicationsDocument4 pagesMAN high speed marine engines for medium duty applicationsJoana Natalia PardedeNo ratings yet

- ENEOS Diesel GRAND LA 10W40 Product InfoDocument2 pagesENEOS Diesel GRAND LA 10W40 Product InfodedysuyetnoNo ratings yet

- Shell Rimula R3 40Document2 pagesShell Rimula R3 40francisNo ratings yet

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Dozer D375A 8 Brochure English EN-D375A-8BR01-0722-V12Document20 pagesDozer D375A 8 Brochure English EN-D375A-8BR01-0722-V12marionabil998No ratings yet

- Rimula All Purpose Disel Engine Oil 20W 40Document2 pagesRimula All Purpose Disel Engine Oil 20W 40HAAWK INTERNATIONAL RAAVINDRA GODENo ratings yet

- Winergy Hybriddrive: The Power Pack For Wind TurbinesDocument2 pagesWinergy Hybriddrive: The Power Pack For Wind Turbinesbenjamin sassardNo ratings yet

- Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-PET-1000000845-009 PDFDocument4 pagesPage: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-PET-1000000845-009 PDFkaran sharmaNo ratings yet

- Shell Rimula R6 M 10W-40Document2 pagesShell Rimula R6 M 10W-40spare parts dubaiNo ratings yet

- Deutz TCD 2015Document2 pagesDeutz TCD 2015Paul GuillaumeNo ratings yet

- Deutz 2015Document2 pagesDeutz 2015mohammad hazbehzadNo ratings yet

- C4.4 IOPU Spec SheetDocument3 pagesC4.4 IOPU Spec SheetFire Suppression SystemNo ratings yet

- MSS Ind 18375269 009Document3 pagesMSS Ind 18375269 009Abaidi RabieNo ratings yet

- 980L Block HandlerDocument2 pages980L Block Handlercorsini999No ratings yet

- D11T/ D11T CD: Track-Type TractorDocument28 pagesD11T/ D11T CD: Track-Type TractordiegoNo ratings yet

- XL/LGP: Track-Type TractorDocument20 pagesXL/LGP: Track-Type TractorTyler LafleurNo ratings yet

- Specifications: SS-9353428-18377762-001 SS Page 1 of 7Document7 pagesSpecifications: SS-9353428-18377762-001 SS Page 1 of 7Su truong vanNo ratings yet

- Shell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & BenefitsDocument2 pagesShell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & Benefitssamsoon80No ratings yet

- DEUTZ - CaracterísticasDocument2 pagesDEUTZ - CaracterísticasIkerNo ratings yet

- Edx10 11Document8 pagesEdx10 11Fernando NapitupuluNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocument4 pagesRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.No ratings yet

- Shell Rimula R3 Turbo 20W-50Document2 pagesShell Rimula R3 Turbo 20W-50Álgøkár Áhmēd100% (1)

- For Mobile Machinery 74.9 - 243 KW - 100 - 325.9 HP at 2100 - 2300 Min - RPM Eu Stage Iiia / Us Epa Tier 3Document2 pagesFor Mobile Machinery 74.9 - 243 KW - 100 - 325.9 HP at 2100 - 2300 Min - RPM Eu Stage Iiia / Us Epa Tier 3citoNo ratings yet

- 2806a-E18tag2 SpecDocument5 pages2806a-E18tag2 SpecbereketNo ratings yet

- Shell Rimula Ultra 5W-30Document2 pagesShell Rimula Ultra 5W-30Aaron ChanNo ratings yet

- 2016 L50 - L80 - L140 - Brochure - GBDocument8 pages2016 L50 - L80 - L140 - Brochure - GBjennlin.changNo ratings yet

- SS-9408177-18375269-020 SS Page 1 of 5: Page: M-1 of M-3 © 2016 Caterpillar All Rights Reserved MSS-IND-18375269-007 PDFDocument5 pagesSS-9408177-18375269-020 SS Page 1 of 5: Page: M-1 of M-3 © 2016 Caterpillar All Rights Reserved MSS-IND-18375269-007 PDFAlfredoNo ratings yet

- Service Network: History of SunflameDocument4 pagesService Network: History of SunflameSebastianEduardoMuñozDiazNo ratings yet

- Kangrim Company Introduction: Boilers, Pressure Vessels, and Cryogenic Insulation ExpertDocument38 pagesKangrim Company Introduction: Boilers, Pressure Vessels, and Cryogenic Insulation ExpertIsaac tHe OcEaNSNo ratings yet

- Hull Cleaning Operation Efficiency in Containing BDocument14 pagesHull Cleaning Operation Efficiency in Containing BIsaac tHe OcEaNSNo ratings yet

- Osd35 0136 067Document208 pagesOsd35 0136 067Samir Mervyn Razvi100% (6)

- BRO MA Marine System Technology 2012 08 EN - tcm11 23607Document23 pagesBRO MA Marine System Technology 2012 08 EN - tcm11 23607roberto luckyNo ratings yet

- HFO Instruction Manual WestfaliaDocument216 pagesHFO Instruction Manual WestfaliaRobin Hillson100% (9)

- Comprehensive Examination For Power and Industrial Plant Engineering A.Y. 2014-2015Document8 pagesComprehensive Examination For Power and Industrial Plant Engineering A.Y. 2014-2015maria katherine pantojaNo ratings yet

- Bifuel CatalogDocument16 pagesBifuel Catalogkarma0034269100% (1)

- IC Engines and Reciprocating Machines Course GuideDocument6 pagesIC Engines and Reciprocating Machines Course GuideEphrem AbabiyaNo ratings yet

- Shell Lubricants ck4 and Fa4 Technical BrochureDocument20 pagesShell Lubricants ck4 and Fa4 Technical BrochureRaden ArdyNo ratings yet

- Engine tightening torque guideDocument9 pagesEngine tightening torque guideBassie100% (1)

- TCS 700 Brochure PDFDocument4 pagesTCS 700 Brochure PDFHerrydroidNo ratings yet

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionDocument4 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloNo ratings yet

- Car Trouble ShootingDocument8 pagesCar Trouble ShootingJoy GudivadaNo ratings yet

- Parts Manual for GS-2669RT, GS-3369RT and GS-4069RT Genie Scissor LiftsDocument330 pagesParts Manual for GS-2669RT, GS-3369RT and GS-4069RT Genie Scissor LiftsPablo Ernesto Veloso ContrerasNo ratings yet

- MP720E42HT: Technical DescriptionsDocument18 pagesMP720E42HT: Technical DescriptionsBroCactusNo ratings yet

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaDocument67 pagesOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILNo ratings yet

- Manage diesel safely undergroundDocument11 pagesManage diesel safely undergroundErwinApriandiNo ratings yet

- 350X2 Manual de ServicioDocument1,154 pages350X2 Manual de ServicioJuan David Gomez Avella100% (1)

- Volvo Penta Inboard Diesel: 570 KW (775 HP) Crankshaft Power Acc. To ISO 8665Document2 pagesVolvo Penta Inboard Diesel: 570 KW (775 HP) Crankshaft Power Acc. To ISO 8665deepakgkdNo ratings yet

- Technical Data: @perkinsDocument2 pagesTechnical Data: @perkinsOGNo ratings yet

- Types of Water HeatersDocument17 pagesTypes of Water HeatersAngelika Lei GaraoNo ratings yet

- Toro-3360-462 User ManualDocument40 pagesToro-3360-462 User ManualJennifer TreanorNo ratings yet

- Vasco Da GamaDocument2 pagesVasco Da GamaghenovaNo ratings yet

- Generating Sets: Standard Genset SpecificationsDocument2 pagesGenerating Sets: Standard Genset SpecificationsSAMINo ratings yet

- Arctic Cat 500 Service ManualDocument253 pagesArctic Cat 500 Service ManualJunkMan1989No ratings yet

- Isx 650 MotorhomesDocument6 pagesIsx 650 Motorhomesmauricio olaya100% (1)

- TUT935 (TRUCK MOUNTED COILED TUBING UNIT) - 2010 Hydra Rig 10x8Document12 pagesTUT935 (TRUCK MOUNTED COILED TUBING UNIT) - 2010 Hydra Rig 10x8Alexander KlmNo ratings yet

- Oil pump specificationDocument2 pagesOil pump specificationmochammad RezaNo ratings yet

- 4 Petrol EngineDocument7 pages4 Petrol Engineayesha amjadNo ratings yet

- 403A-15G2 ElectropaK PN2009Document2 pages403A-15G2 ElectropaK PN2009Md ShNo ratings yet

- Owners Handbook - BUKH DV 36 RMEDocument24 pagesOwners Handbook - BUKH DV 36 RMEVo BuiNo ratings yet

- WSM - Kubota M100,110,126,135GX & 135GX-FS Tractor Workshop ManualDocument1,012 pagesWSM - Kubota M100,110,126,135GX & 135GX-FS Tractor Workshop Manualtgit2892% (13)

- Tejaswi Project Final Draft PDFDocument111 pagesTejaswi Project Final Draft PDFHemasri ChinnuNo ratings yet

- Cm25E Electric Power Generator Set: Features and BenefitsDocument4 pagesCm25E Electric Power Generator Set: Features and BenefitsJose FavaNo ratings yet

- Data Sheets pc750lc 7 Se 7 en (f3b) PDFDocument16 pagesData Sheets pc750lc 7 Se 7 en (f3b) PDFAbood Sameer AlbaghdadiNo ratings yet