Professional Documents

Culture Documents

Smith Ichiyen Articulo

Uploaded by

IAm JosueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smith Ichiyen Articulo

Uploaded by

IAm JosueCopyright:

Available Formats

• COMPUTER APPLICATIONS AND PROCESS CONTROL

Computer Adjustment of Metallurgical Balances

H. W. SMITH and N. ICHIYEN, makes possible the on-line computation of metallurgi-

Department of Electrical Engineering, cal balances. Finally, the application of steady-state

University of Toronto,

Toronto, Ont. process modelsu·21 for flotation circuit analysis and

optimization requires, as a first step, the computation

of complete and accurate internal metallurgical bal-

ABSTRACT ances from experimental data.

This paper describes a numerical procedure for

A convenient method for the calculation of metallurgical computing mass balances which minimizes special-

balances, based on statistical treatment of all available

data, is presented. An error analysis is included. Examples purpose programming effort and computer storage

show the advantages of the method, and also that such requirements, and which is suitable for both labora-

balances are less precise than might be supposed. tory and plant (including on-line) use. An error

analysis is included.

INTRODUCTION

THE COMPUTATION of metallurgical balances from im- PROBLEM, STATEMENT

precise analytical data is a frequently occurring prob-

lem in flotation plants. In mill practice, very approxi- Consider a flotation circuit in which streams 1, .. . ,

mate methods have normally been used, due to the n have metallurgical compositions given by the com-

computational difficulty of more accurate statistical position vectors

methods. With the steadily growing availability to

mill staff of computer facilities, more accurate meth-

[

ods are now feasible. In addition, the growing use

of on-line X-ray analysis and control computers now C·*

l =

~fl]

•

ctn

for metallurgical species i = 1, ... , m. In addition,

there will be a vector of mass flows within the cir-

cuit

wT J

w* = [ ~;

H. W. SMITH N. M. JCBIYEN

to be determined from the mass balance equations

HAROLD W. SMITH, a native of Toronto, holds degrees for the circuit

from the University of Toronto (B.A.Sc., 1950) and

M.I.T. (Sc.D., instrumentation and control, 1961). He f; (c( , w*) = 0, i = 1, .. • , m.

served in the Royal Canadian Navy (1945-1966), resigning

to join the University of Toronto, where he is currently

Professor of Electrical Engineering. His research in- However, the data available are not the true composi-

terests include the application of modelling, control and tion vectors c:, but rather the measured composition

estimation theory to the improved control of metallurgical vectors

processes. In addition to his university appointment, he is

a consultant to Falconbridge Nickel Mines Ltd., and a Ci = cf + e;

consulting partner in Urwick, Currie and Partners Ltd.,

Toronto. where Eis a vector of sampling and measurement errors.

NORMAN M. ICHIYEN, a native of Montreal, Quebec,

graduated from McGill University in Montreal with a The adjustment problem is thus to determine esti-

Bachelor of Electrical Engineering in 1970. In 1973, he

received an M.A.Sc. in Electrical Engineering from the

mates c1, i = 1, ... , m, and w,

which satisfy the mass

University of Toronto. His thesis work involved simula- balance equations

tion of a complex zinc flotation circuit. His supervisor was

Professor H. W. Smith. He is currently with Atomic

Energy of Canada Limited. f; <2. w) = o

PAPER SUBMITTED: in November of 1972; revised and which are in some sense the " best" estimates of

manuscript received on June 29, 1973. c7 and w* respectively.

KEYWORDS: Computers, Process control, Flotation, On the assumption that sampling and measurement

Mass balance, Metallurgical balances, Statistical methods, errors are Gaussian and unbiased, the maximum like-

Flotation. lihood estimate of c,, w is that which minimizes the

objective function

(CIM) Bulletin for September, 1973 97

J

00

~ (Ci - 'M"j 1 (Ci -

4. Using a direct search program, hill-climb on w

=

i=l

C; ) Ci)

to find a minimum over w

of J, repeating steps 2 and

where 3 at each iteration. A suitable method is that of Rosen-

brockr•i , which consists of stages having one one-di-

M, = E (e;d ) mensional minimization for each element of At w.

(i.e. the covariance matrix of sampling and measure- the end of each stage, the directions of search are

ment error ) and the prime denotes the transpose of a rotated, although still remaining orthogonal, so that

vector or matrix. the first search in the next stage is in the direction

found to be most successfu·l in the previous stage. The

'Briefly stated, therefore, the problem is: minimize

the objective function search terminates when the minimum is located to a

pre-specified accuracy:x·

J = ~ (c, -

1

C;) 'M-;- 1 (C, - ci)

This method permits the use of a standard pro-

i=l .. . - - - - gram; only the program to evaluate B (w ) is specific

to each application, and this program is very simple.

subject to the mass balance constraints The search method suggested is easily programmed,

f; ([;, ~) = 0. a"ud is effective in the ill-conditioned problems which

occur when recycle streams are large.

METHOD OF SOLUTION

COMPUTATIONAL EXAMPLES

The problem as stated is a standard problem in

First consider a flotation circuit having the con-

nonlinear least-squares analysis, and may be solved

figuration 8hown in Figure 1. Grab samples were

by first-order (Gauss-Newton ) or second-order (New-

taken from the eight process streams indicated, and

ton-Raphson ) gradient methodsm. However, the com-

putation of the gradient requires significant addi- analyzed to yield the data shown in the first column in

Table 1. The three mass flows indicated in Figure 1

tional programming which is specific to the circuit

configuration under study. This is undesirable in cir- are to be estimated, together with the corrected values

of the twentycfour analyses.

cuit optimization studies because of the programming

effort involved when many configurations may be

studied. In on-line applications, computer storage is

usually at a premium, and the additional storage re-

quirements of gradient methods are unattractive. For @ ___!!1:.

these reasons, the following direct search method is

proposed:

mi®~®

R S

1. Express the mass balance equations in the form

w~

B (w)c; = 0.

2. For some initial estimate of compute the ad- w,

justment to the composition vector which minimizes

J for that value of w

and satisfies the mass balance 3 w,c ®

equations; this is found, by standard minimum vari-

a nce techniques [3J , to be

oci = - M ,B'(BM,B')- 1Bci. FIGURE 1 - Zinc Circu it .

3 . Form

c, = C; + OCi

''' FORTRAN and APL versions of this algorithm may be

:and evaluate J (w ) . obtained from the authors at reproduction cost.

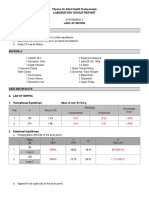

TABLE 1 - Balance for Circuit of Figure I

Experimental Analysis Adjusted Analysis Per Cent Adjustment

Stream Cu Zn Fe Cu Zn Fe Cu Zn Fe

1 0.163 3.93 11.57 0.170 3.85 12.34 4.17 - 1.87 6.59

2 0.447 11.63 12.79 0.462 11.73 13.56 3.29 0.83 6.02

3 0.466 8.11 14.35 0.406 8.72 13.45 -12.83 7.48 -6.22

4 0.140 0.49 13.09 0.136 0.49 12.18 - 2.76 0.12 - 6.94

5 0.960 34.64 14.37 0.964 38.85 14.48 0.43 12.16 0.77

6 0.657 52.07 14.67 0.649 51.70 14.56 - 1.20 - 0.71 -0.73

7 1.020 42.73 14.66 1.009 37.01 14.47 - 1.06 - 13.39 - 1.30

8 0.440 · U.86 13.75 0.472 10.75 13.77 7.38 - 9.39 0.11

I

Mass flows (with 503 probable error):

w1= .06563 ± .00783; w2= 3.781 ± o.738; wa = o.5238 ± o.1346.

98 The Canadian Mtliiug and Metallurgical

Four mass balance equations must be satisfied for @)

each of the three circuit sections - one each for the CD UNIT ® COPPER

@ ZINC

rougher, cleaner and scavenger, and one for the total CELLS FLOTATION FLOTATION

circuit. These are:

l. Circuit: ® WI \J)

w3

2. Scavenger: ® W2

FIGURE 2 - Flotation Circuit.

3. Cleaner :

W3C5 - W1C6 - (w a - W1)C1 = 0

4. Rougher:

TABLE 2 - Balance for Circuit of Figure 2

(1 - W1 + W2 +~w3) C2 - (1 - W1 + W2)C3 - W3C5 = 0

It is easily verified that the values of w obtained Experi menta I Adjusted Per Cent

by solving the first three equations are far from sa- Analysis Analysis Adjustment

tisfying the fourth, and that the results obtained from

the sets of copper, zinc and iron analyses are com-

Stream Cu Zn Cu Zn Cu Zn

pletely inconsistent.

From the mass balance equations, by inspection, ----

1 1.93 3.81 1.91 4.61 -1.02 20.94

2 0.45 4.92 0.45 4.58 0.01 - 6.82

1 0 0 - (1-wi) 3 0.13 5.36 0.13 4.38 -3.78 - 18.26

4 0.09 0.41 0.09 0.41 2.45 - 0.09

B (w) = 0 0 -(1-wi) 5 19.86 7.09 20.04 6.91 0.91 - 2.55

6 21.44 4.95 21.45 4.92 0.03 - 0.51

0 0 0 0 7 0.51 52.10 0.52 51.59 l.17 - 0.98

0

Mass flows (with 503 probable error):

wI = .06954 ± .00232; W2 = .08964 ± .00261;

0 0 wa= .07066 ± .00668.

0 0

As a second example, consider a metallurgical bal-

-(wa-W1) 0 ance over an entire plant, based on X-ray data. The

plant is shown in Figure 2 and the data in Table 2.

-W3 0 0 0

The mass balance equations are:

1. Unit cells

In this case, no reliable data were at hand regarding

C1 - (1 - W1 ) C2 - W1C5 = 0

the precision of sampling and analysis. It was assumed

that the relative precision of each measurement was 2. Copper section

identical and that errors were uncorrelated . On these C1 - (1 - W2 ) C3 - W2C6 = 0

assumptions, except for a scale factor,

3. Zinc section

M i = diag[c; 1 , ... , cr.,] (1 - W2)C3 - (l - W2 - W3) C4 - W3C7 = 0

A starting value for w

was obtained by solving the from which the B(w) matrix is found. In this parti-

first three zinc mass balance equations ; this yielded cular case, the precision of the different X-ray mea-

surements was approximately known from calibra-

,v, = .067, w2 = .459, wa = -.058. tion experiments, and the M matrices were based on

these data. A starting value of was found from w

The value of ;.,a is nonsensical, and was replaced by standard two-product formulas:

w 3 = 0.1, a guess based on experience. The direct

search program converged in four stages to the solu-

tion

w, = o.70, w2 = 0.091, w3= o.096.

The direct search program converged in five stages

iv, = o.06563 w2= 3.781 wa = o.5238 to the solution

and to the corrected analyses given in the second col-

ume of Table 1. The third column gives the per cent iv, = o.06954, w2 = o.08964, wa = o.07066,

change in the original analysis. The r.m.s. sampling

and analytical error may be approximated by the and the adjusted analyses are shown in Table 2. It

standard deviation of the corrections, which is will be noted that three zinc analyses have very large

adjustments. As noted in the report from which the

a = 6.56% . data for this example were takenm, it was later dis-

covered t hat some analyses had X-ray calibration

This value is not unreasonable in practice. errors which were unknown at the time.

(CIM) Bulletin for September, 1973 9S

ERROR ANALYS IS SENSITIVITY OF SOLUTIONS

In fitting models to analytical data, it is frequently For the first example given above, the covariance

des irable to find not only the estimate, of mass w, matrix was computed and found to be

flows in a circuit, but also an estimate of its probable

error. This is particularly true when large recycle

streams exist, as mass flow estimates are then very

sensitive to data errors. A linear estimate of the E [(~*-~ ) ~*-~)'] =

.000135 .000644 - .000027

.000644 1.197 .1039

J

[

probable error may be found in the following way. -.000027 .1039 .0398

If the mass balance equations are perturbed, the per-

turbation equations are found to be This yields the standard deviations

Ai(c,) ow + B (w) oci = o i = l, ... , m.

0

w 1 = 0.01161, aW2 = 1.094, 0

wa = 0.1995,

B (w) is the matrix previously defined, and A, (c,) whiCh are large in comparison with the estimates.

is the matrix of coefficients obtained by writing the Further, although errors in W1 are nearly independent

mass balance equations in the form of those in W2 and wa,

errors in these last two quanti-

ties are strongly correlated (correlation coefficient

A;(c;) w ~ = b (c;) , i = 1, .•• ,m. 0.50). It must be recognized that estimates of mass

flows in large recycle streams are subject to signifi-

Then a perturbation in the data, 8c1, yields a mass cant error even when sampling and measurement er-

flow perturbation rors are relatively small.

Under these conditions, it is essential to use all

ow= -AtB oc; available data, weighted according to precision, and,

where in on-line applications, to use time averaging of X-ray

analytical data to reduce random error in the data.

At = (A:Ai)- 1A:

the pseudo-inverse of A/ 61 • The covariance matrix

E[owow'J = At B E[Oc,oc;J (AtB)'. CONCLUSIONS

If, now, the expectation on the right-hand side is The numerical method proposed offers a convenient

replaced by the measurement covariance matrix, the method of obtaining the best estimate of metallurgical

covariance matrix of w

is obtained; balances, based on proper statistical treatment of the

available data. The error analysis presented allows

E[(w* - w) (w* -w)'] = AtBM, (AtB)'. estimation of the precision of such balances; in gen-

eral, this precision is lower than is usually supposed.

To use all the experimental data, the m sets of equa-

tions must be combined. It is easily verified that this

is done by forming

A' = [A; M ... A,:.] ACKNOWLEDGMENTS

B 0 0 The authors are grateful to the management and

mill staff of the Lake Dufault Division, Falconbridge

B= I 0 B 0 Copper Ltd., for allowing plant access and providing

analytical services in gathering the data for one of

the examples used. The work reported was supported

0 0 B in part by National Research Council Grant A-4165.

M1 0 . 0

M =I 0 M2 0 REFERENCES

(1) King, R. P., Model for the Design and Control of

Flotation Plants, 10th Annual Symposium on the

Application of Computer Methods in the Mineral hi-

0 0 Mrn dustry, Johannesburg, R.S.A., April 1972.

(2) Loveday, B. K., and .Marchant, G. R., Simulation of

Multicomponent Flotation Plants, as for (1).

and finding (3) Deutsch, R., Estimation Theory, Ch. 6 (Prentice-Hall,

Inc., Englewood Cliffs, N.J., 1965).

E[ (w*-w) (w*-w)'J = A+BM(A+B)' (4) Rosenbrock, H. H., An Automatic Method of Finding

the Greatest or Least Value of a Function, Computer

If more precise data concerning measurement error J., 3, pp. 175-184, October 1960.

covariance are not at hand, the M1 matrices may be (5) Smith, H. W., and Lewis, C. L., Computer Control

Experiments at Lake Dufault, CIM Bulletin, 62, W ·

approximated by 109-115, February 1969.

(6) Penrose, R. A., A Generalized Inverse for Matrices,

Mi ~ a 2 diag [c ..... C; n].

2

Proc. Cambridge Phil. Soc., 51, pp. 406-413, 1955.

100 The Canadian Minin2 and Metallurgical

You might also like

- La Ex CSAT PYQ SolvedDocument254 pagesLa Ex CSAT PYQ SolvedSiddharth WorkNo ratings yet

- JKSim Float IMPCDocument6 pagesJKSim Float IMPCCristian AlvayaiNo ratings yet

- Gen Math 1ST Quarter ExamDocument6 pagesGen Math 1ST Quarter ExamGladzangel LoricabvNo ratings yet

- MATH1081 Topic2 LectureNotesDocument37 pagesMATH1081 Topic2 LectureNotesyizzyNo ratings yet

- ANEXO 7 Drop Weight TestDocument20 pagesANEXO 7 Drop Weight TestFrancisco Avalos100% (2)

- CYTEC Solutions Newsletter 3-12 V2 PROOFDocument40 pagesCYTEC Solutions Newsletter 3-12 V2 PROOFLela SepulvedaNo ratings yet

- Optimization of Flotation Circuits by Modelling AnDocument12 pagesOptimization of Flotation Circuits by Modelling AnDiego Alonso Diaz CayllahuaNo ratings yet

- Metsim Print 2018 PDFDocument1 pageMetsim Print 2018 PDFWalter Andrés OrqueraNo ratings yet

- 01 - Chapter 1Document37 pages01 - Chapter 1Eko Idris Hutagaol100% (1)

- Goldver Mining Company: Design of A Silver Cyanidation Plant With Pre-Concentration Using Dense Medium SeparationDocument92 pagesGoldver Mining Company: Design of A Silver Cyanidation Plant With Pre-Concentration Using Dense Medium Separationmaikol Moscoso PinoNo ratings yet

- MiMining Eng Handbook 2009 Flotation Fundamentals PDFDocument30 pagesMiMining Eng Handbook 2009 Flotation Fundamentals PDFAlagu RamNo ratings yet

- Laboratory Flotation Testing An Essential Tool For Ore CharacterisationDocument19 pagesLaboratory Flotation Testing An Essential Tool For Ore CharacterisationNataniel LinaresNo ratings yet

- Metsimmetallurg Y: The Extractiveprocess SimulatorDocument80 pagesMetsimmetallurg Y: The Extractiveprocess SimulatorjahanradsNo ratings yet

- Of Ore And: Simulated Processing CoalDocument28 pagesOf Ore And: Simulated Processing CoalJeromeNo ratings yet

- Cytec Solutions 2013Document52 pagesCytec Solutions 2013Jersson Daniel Davila RuizNo ratings yet

- Yianatos (2007)Document13 pagesYianatos (2007)Nicolas PerezNo ratings yet

- Written ReportDocument16 pagesWritten ReportJamel Cayabyab50% (2)

- Knelson - Recent Innovations in Gravity TechnologyDocument22 pagesKnelson - Recent Innovations in Gravity TechnologyJuan Carlos Quintuna EspinNo ratings yet

- Designing Crushers With A Multi-Objective Evolutionary AlgorithmDocument8 pagesDesigning Crushers With A Multi-Objective Evolutionary AlgorithmRavi Shanker VNo ratings yet

- Selective Flotation of Enargite From Copper Sulphides in Tampakan DepositDocument10 pagesSelective Flotation of Enargite From Copper Sulphides in Tampakan DepositW ZuoNo ratings yet

- Pilot Plant Testing Methods - BPRDocument17 pagesPilot Plant Testing Methods - BPRravibelavadiNo ratings yet

- Grind Size Vs FloatationDocument24 pagesGrind Size Vs FloatationKrishnadas GopalakrishnanNo ratings yet

- How To Taking SamplingsDocument27 pagesHow To Taking SamplingsJason CarterNo ratings yet

- Mass Balancing McGill PDFDocument20 pagesMass Balancing McGill PDFDiego Alejandro Lira EspinozaNo ratings yet

- Jksimmet v6 ManualDocument425 pagesJksimmet v6 Manualkselvan_1100% (1)

- Lix 84-I Ti Evh 0129Document2 pagesLix 84-I Ti Evh 0129Tacachiri Chocamani Jaime100% (1)

- SimSXCu Full Version 2.0Document345 pagesSimSXCu Full Version 2.0joseph kafumbila50% (4)

- Metsim Balance de MasaDocument10 pagesMetsim Balance de MasaOsterlin Mayhua CapchaNo ratings yet

- DENVER Mineral CharacteristicsDocument8 pagesDENVER Mineral CharacteristicsTsakalakis G. Konstantinos100% (1)

- Ok TC FlotationDocument4 pagesOk TC FlotationWilliam SalcedoNo ratings yet

- A Model For Flotation Processes, AMINPRO, August 2007Document16 pagesA Model For Flotation Processes, AMINPRO, August 2007JFSFNo ratings yet

- Scale Up in Froth Flotation. A State of The Art Eview. Mesa2019Document13 pagesScale Up in Froth Flotation. A State of The Art Eview. Mesa2019Enoque MatheNo ratings yet

- JKSimMet V6 - 1 ManualDocument426 pagesJKSimMet V6 - 1 ManualLuis Luna Cruz100% (3)

- Efecto Del Contenido de Pirita en La Flotacion PDFDocument10 pagesEfecto Del Contenido de Pirita en La Flotacion PDFMatias Garcia LabrañaNo ratings yet

- The Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsDocument15 pagesThe Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsLennonNo ratings yet

- Bringing Split Flotation To Reality - The Cannington ExperienceDocument8 pagesBringing Split Flotation To Reality - The Cannington Experienceseansara1100% (1)

- METSIM Brochure2 2009 PDFDocument40 pagesMETSIM Brochure2 2009 PDFjaja_5430% (1)

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- A New Method For Flotation Rate CharacterizationDocument6 pagesA New Method For Flotation Rate CharacterizationPrasanta Kumar BaskeyNo ratings yet

- Evaluation of The Blue Cube MQi Slurry AnalyserDocument15 pagesEvaluation of The Blue Cube MQi Slurry Analysermushava nyoka100% (1)

- Flotation Frothers: Review of Their Classifications, Properties and PreparationDocument20 pagesFlotation Frothers: Review of Their Classifications, Properties and PreparationJAn JAnNo ratings yet

- Simulación ChancadoDocument12 pagesSimulación ChancadoPedro Aquino AquinoNo ratings yet

- Design Considerations For Merrill-Crowe PlantsDocument5 pagesDesign Considerations For Merrill-Crowe PlantsLuis Miguel La Torre100% (1)

- Nageswararao 4 PDFDocument6 pagesNageswararao 4 PDFrodrigoNo ratings yet

- Control of Pulp Levels in Flotation CellsDocument10 pagesControl of Pulp Levels in Flotation CellsmineralmadnessNo ratings yet

- BILCO 3 Brochure GBDocument7 pagesBILCO 3 Brochure GBMgn SanNo ratings yet

- Structural Properties of Clays and Their Effect On The Recovery of Copper Sulphides by Flotation, Lina UribeDocument24 pagesStructural Properties of Clays and Their Effect On The Recovery of Copper Sulphides by Flotation, Lina UribeNicolas MirandaNo ratings yet

- Jksimmet: James Didovich 2014Document42 pagesJksimmet: James Didovich 2014InformationEmissary100% (1)

- Industrial Use of Nitrogen in Flotation of MolybdeniteDocument4 pagesIndustrial Use of Nitrogen in Flotation of MolybdenitedanisaNo ratings yet

- CMB SP 85 1 3 2eMATBAL PDFDocument73 pagesCMB SP 85 1 3 2eMATBAL PDFROOSMEL EDWINNo ratings yet

- Luis VenteDocument15 pagesLuis VenteEdwar Villavicencio JaimesNo ratings yet

- Large Scale Mixer Settlers DesignDocument8 pagesLarge Scale Mixer Settlers DesignRodrigo GarcíaNo ratings yet

- Luis MagneDocument19 pagesLuis Magnerichard gutierrezNo ratings yet

- Aminpro-FK Test - EnglishDocument10 pagesAminpro-FK Test - EnglishpeilinlanNo ratings yet

- Spence Anglo Pilot - Scope OnlyDocument9 pagesSpence Anglo Pilot - Scope OnlyLuis Gutiérrez AlvarezNo ratings yet

- Tesis de Jinghong Ling de Knelson PDFDocument277 pagesTesis de Jinghong Ling de Knelson PDFRobertoCortesNuñezNo ratings yet

- A Strategy For The Identification of Optimal Flotation CircuitsDocument12 pagesA Strategy For The Identification of Optimal Flotation CircuitsNataniel LinaresNo ratings yet

- Contact Cell Info - Gen PDFDocument10 pagesContact Cell Info - Gen PDFsnarf273No ratings yet

- Computer Application To The Piping Analysis Requirements of ASME Section III, Subscribe NB-3600Document12 pagesComputer Application To The Piping Analysis Requirements of ASME Section III, Subscribe NB-3600sateesh chandNo ratings yet

- Cumulative Fatigue Damage Under Random LoadsDocument11 pagesCumulative Fatigue Damage Under Random LoadsMuhammad FaizNo ratings yet

- Overcurrent and Earth Fault Protection Systems Assessment: Hossein - Askarian@eng - Monash.edu - AuDocument0 pagesOvercurrent and Earth Fault Protection Systems Assessment: Hossein - Askarian@eng - Monash.edu - AuAnonymous 9VcxlFErfNo ratings yet

- PhysRevA 109 032408Document14 pagesPhysRevA 109 032408oscar.negrete.sNo ratings yet

- Line-Line Short Circuit of Synchronous Machine Illustration of Computer-Aided Machine AnalysisDocument8 pagesLine-Line Short Circuit of Synchronous Machine Illustration of Computer-Aided Machine Analysisdhirajbharat20No ratings yet

- Rui Wang2011Document7 pagesRui Wang2011Algerian AissaouiNo ratings yet

- General ChemistryDocument101 pagesGeneral ChemistryNohelia Fer GavNo ratings yet

- Math 202-102 Sec: 21 Solution Quiz 2Document2 pagesMath 202-102 Sec: 21 Solution Quiz 2AndreaMunozNo ratings yet

- Unit 11: Complex Numbers Chapter 12.1, 12.2, 12.3, 12.4, 12.5, 12.6Document10 pagesUnit 11: Complex Numbers Chapter 12.1, 12.2, 12.3, 12.4, 12.5, 12.6Rob GchukNo ratings yet

- 1 Month GRE Study ScheduleDocument68 pages1 Month GRE Study ScheduleFahd Khan SuraniNo ratings yet

- Introduction To ANSYS 10 0 Introduction To ANSYS 10.0: Training Manual Training ManualDocument4 pagesIntroduction To ANSYS 10 0 Introduction To ANSYS 10.0: Training Manual Training ManualmohsenNo ratings yet

- Simplex MethodDocument19 pagesSimplex MethodNandini GuptaNo ratings yet

- Introduction To MATLAB: Ashraf Al-Rimawi Matlab 12-12-2008Document32 pagesIntroduction To MATLAB: Ashraf Al-Rimawi Matlab 12-12-2008Sura DaraghmehNo ratings yet

- Ukuran Asosiasi Dalam Epidemiologi: Putri Handayani, M. KKKDocument28 pagesUkuran Asosiasi Dalam Epidemiologi: Putri Handayani, M. KKKNHLNo ratings yet

- Frequencydistributionworksheet 15 RevisedDocument4 pagesFrequencydistributionworksheet 15 RevisedJA HmiNo ratings yet

- Homework 6 Absolute Value InequalitiesDocument7 pagesHomework 6 Absolute Value Inequalitiesh47ws5eq100% (1)

- Bacon Design of CitiespdfDocument18 pagesBacon Design of CitiespdfYounes AlamiNo ratings yet

- LPPDocument2 pagesLPPSayli JadhavNo ratings yet

- Gopertz Growth Curve, Linear Co-EfficientDocument17 pagesGopertz Growth Curve, Linear Co-EfficientAmal DattaNo ratings yet

- SS Midterm 1 S09 SolDocument6 pagesSS Midterm 1 S09 SolPurushotham Prasad KNo ratings yet

- The Latest On Quantitative Sampling Theory: Liberation, Shape and Granulometric FactorsDocument20 pagesThe Latest On Quantitative Sampling Theory: Liberation, Shape and Granulometric FactorsLuis Katsumoto Huere AnayaNo ratings yet

- Diary EntriesDocument3 pagesDiary EntriesPatricia OliverNo ratings yet

- Phase Equilibria and Thermodynamic Properties of TheDocument8 pagesPhase Equilibria and Thermodynamic Properties of TheAlvaro JaraNo ratings yet

- Method Statement for Electrical Resistivity TestDocument18 pagesMethod Statement for Electrical Resistivity TestIkhwan MuhammadNo ratings yet

- Laboratory Group Report: Physics For Allied Health ProfessionalsDocument2 pagesLaboratory Group Report: Physics For Allied Health ProfessionalsJeremiah AmanteNo ratings yet

- EEE248 CNG232 Lab2 3 Spring2012Document10 pagesEEE248 CNG232 Lab2 3 Spring2012Aziz Nihat GürsoyNo ratings yet

- EBP Project Table of Evidence TOE 2022-1Document3 pagesEBP Project Table of Evidence TOE 2022-1simon jordan1005No ratings yet

- List of Books For GATE ECE 2016: Engineering MathematicsDocument2 pagesList of Books For GATE ECE 2016: Engineering MathematicsSharath MunduriNo ratings yet

- To Finance: by George BlazenkoDocument45 pagesTo Finance: by George BlazenkoMoktar Tall ManNo ratings yet

- SemaphoresDocument10 pagesSemaphoresMuhammad MakkiNo ratings yet

- Personal Social Repaso ADE 2016Document24 pagesPersonal Social Repaso ADE 2016dieg028No ratings yet

- Delta Function and Heaviside FunctionDocument5 pagesDelta Function and Heaviside FunctionRajat AroraNo ratings yet