Professional Documents

Culture Documents

Vocab:: Slightly Wet, Often in A Way That Is Unpleasant The Cottage Was Cold and Damp

Uploaded by

Milk Giang Mỹ0 ratings0% found this document useful (0 votes)

22 views2 pagesOriginal Title

Task 1 P.21 Barron

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views2 pagesVocab:: Slightly Wet, Often in A Way That Is Unpleasant The Cottage Was Cold and Damp

Uploaded by

Milk Giang MỹCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

My essay:

The diagram indicates the process of how

wood pellets are produced, including 7

steps, started with the transportation of

sawdust from sawmill to packing and

selling of finished pellets.

At the first stage, employees transport

sawdust remaining from cutting wood in

the sawmill to manufacturing place. After

that, with a hammer mill, sawdust is

pounded into fibres with uniform length

before fibres are dampened with steam.

Following this step, wet fibres are forced

to go through holes in a pellet machine to

form into pellets. Now, pellets are ready

to be cooled and undergo some more

steps before being sold.

Once the pollets are cooled, they are

vaccumed to remove the loose dust

loose dust is vacuumed off so that the

pellets can be clean as much as possible.

The final steps is to pack pellets into 40

pound bags, which weigh 18 kilo for

selling them. Wood pellets which are

produced by this 7-step process can be

used suitably in either pellet stoves or

pellet furnaces.

What I learn from this Writing:

Including some more machines

used to made the pellets so that

the examiners can know how

many machines are involved in this

process.

Vocab:

Damp (a): slightly wet, often in a way that

is unpleasant

The cottage was cold and damp.

Model essay from Barron Book:

Wood pellets are a type of fuel used for

heading buidings. They are made from

sawdust. The manufacturing process takes

several steps and uses several different

types of machines.

The first machine that is used is the

hammer mill. When the sawdust arrives

from the sawmill, it is put into the

hammer mill. There, the sawdust is

hammered into fibres. The fibres are all

the same length. The fibres are then

dampened with steam, and they are ready

for the next machine. It is called the pellet

machine. This machine forms the damp

fibres into pellets by forcing them through

holes.

After the pellets come out of the machine,

they are cooled. The cool pellets are

vaccumed to remove the loose dust.

Finally, the finished pellets are packed

into 18-kilo (40pound) bags. They are then

ready for sale. They can be burned in

either a pellet stove or a pellet furnace to

heat any kind of buiding.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

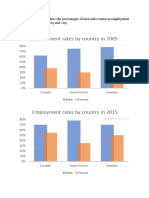

- The Bar Charts Below Show The Percentages of Men and Women in Employment in Three Countries in 2005 and 2015Document2 pagesThe Bar Charts Below Show The Percentages of Men and Women in Employment in Three Countries in 2005 and 2015Milk Giang MỹNo ratings yet

- Cause and Effect Essay Outline SampleDocument1 pageCause and Effect Essay Outline SampleMilk Giang MỹNo ratings yet

- Cause and Effect Essay Outline Examples: Example 1 - Causes and Effects of BullyingDocument2 pagesCause and Effect Essay Outline Examples: Example 1 - Causes and Effects of BullyingMilk Giang MỹNo ratings yet

- The Bar Chart Below Illustrates Five Different Industries' Percentage Share of Brazil's Economy in 2009 and 2019 With A Forecast For 2029Document2 pagesThe Bar Chart Below Illustrates Five Different Industries' Percentage Share of Brazil's Economy in 2009 and 2019 With A Forecast For 2029Milk Giang MỹNo ratings yet

- 251 296Document46 pages251 296Milk Giang MỹNo ratings yet

- Dì ghẻ: Cám Bụt: Bụt: Tấm: BụtDocument2 pagesDì ghẻ: Cám Bụt: Bụt: Tấm: BụtMilk Giang MỹNo ratings yet

- Kỹ năng viết lại câu - Key PDFDocument79 pagesKỹ năng viết lại câu - Key PDFMilk Giang MỹNo ratings yet

- Phrasal Verb Organiser PDFDocument145 pagesPhrasal Verb Organiser PDFMilk Giang MỹNo ratings yet

- Good Morning Ladies and GentlemenDocument4 pagesGood Morning Ladies and GentlemenMilk Giang MỹNo ratings yet

- Tests Movers 2 Book PDFDocument70 pagesTests Movers 2 Book PDFMilk Giang MỹNo ratings yet

- CATPHCM2020Document4 pagesCATPHCM2020Milk Giang Mỹ100% (1)

- Tự học đột phá kỹ năng viết lại câu Tiếng Anh PDFDocument142 pagesTự học đột phá kỹ năng viết lại câu Tiếng Anh PDFMilk Giang MỹNo ratings yet

- Phrasal Verb Organiser PDFDocument145 pagesPhrasal Verb Organiser PDFMilk Giang Mỹ100% (1)

- Lê H NG Phong: Trư NG THPT ChuyênDocument10 pagesLê H NG Phong: Trư NG THPT ChuyênMilk Giang MỹNo ratings yet