Professional Documents

Culture Documents

01.gad For MNB at CH 7+612

Uploaded by

jibeesh cmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01.gad For MNB at CH 7+612

Uploaded by

jibeesh cmCopyright:

Available Formats

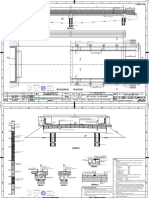

CHANGANASSERY ALAPPUZHA CHANGANASSERY ALAPPUZHA

A1 A2

24000 (SK)

300mm THK. RCC 22692 (SQ) 6000

APPROACH SLAB WEARING COAT

RCC HAND RAIL APPROACH SLAB

100mm THK. PCC

SB ROW

ROW

ROW N

FRL ROW

ROW

ROW

SB

ROW

ROW

ROW

ROW

ROW SB

BRID

WAY

GE BH

ROW ROW

ROW SB ROW

ROW ROW

Z X ROW

ROW SB ROW

PRECAST PSC BEAM

ROW ROW

ROW

ROW

ROW

SB

HFL

ROW

ROW

1.340 ROW

ROW

MINOR BRIDGE

ROW

7+612

1x24

19°

1200Ø PILE

GABION WALL

SECTION A-A

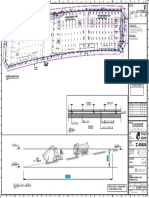

FRL 4.040 4.115 4.097 BH- 32 (CH 7/680)

OGL. -0.245 -0.882 -0.245 0.00m RL=3.583

COLUMN TOP LEVEL 2.062 2.119

FILLED SOIL

PILE BOTTOM LVL. -45.245 -45.245 0.80m N=2

CHAINAGE 7+600 7+612 7+624

SILTY CLAY

(D/GREY)

A1 A2

SLAB TO CARRY UTILITIES

RCC HAND RAIL B

24000 (SK) 17.80m N=1

22692 (SQ)

5000

UTILITY

SILTY CLAY WITH

DECK

1200

DRAINAGE SPOUT (TYP.) SHELL DUST

375

(D/GREY)

2.0%

FOOT

PATH

1750

23.00m N=2

GABION WALL

SILTY CLAY WITH

SHELL DUST

100HIGH x 300WIDE SLOT (D/GREY)

FOR DRAINAGE HOLE IN

KERB KERB

19°

6000

APPROACH

SLAB 30.60m N=16

SAND CLAY

(GREY)

2.5%

32.40m N=26

10000

10500

14000

76

SILTY CLAYEY SAND

105

WITH GRAVEL

(Y/GREY)

2.5%

A A

35.70m N=25

SAND WITH SILTY

CLAY

(Y/GREY)

KERB

39.80m N>100

FOOT

PATH

1750

2.0%

MEDIUM SAND

(GREY)

UTILITY

375

800

DECK

RCC HAND RAIL

B

SLAB TO CARRY UTILITIES 47.00m N>100

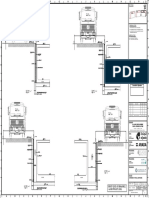

HALF BOTTOM PLAN HALF TOP PLAN

14000 (SQ)

14807 (SK)

1200 (SQ) 1750 (SQ) 10500 (SQ) 1750 (SQ) 800 (SQ)

1269 (SK) 1851 (SK) 11105(SK) 1851 (SK) 846 (SK)

UTILITY FOOT PATH PROPOSED CARRIAGEWAY FOOT PATH UTILITY

DECK DECK

375 (SQ) 375 (SQ)

397 (SK) GAP BETWEEN PRECAST BEAMS 397 (SK)

TOP PORTION TO BE SEALED

RCC WEARING COAT WITH SEALANT (POLY SULPHIDE SEALANT)

HAND RAIL

150mm MIN. CAST-IN-SITU DECK SLAB

100HIGH x 300WIDE SLOT FOR C

KERB FRL DRAINAGE HOLE IN KERB

2.0% 2.0%

2.5% 2.5%

150

50

1.5

C 1

CLOSELY SPACED PRECAST PSC BEAM

DRAINAGE SPOUT

1200Ø PILE

HYDRAULICS PARTICULARS

DISCHARGE 67.537 CUMECS

HFL 1.34 m

SCOUR LEVEL -1.298 m

SECTION B-B

NOTES :

1. All dimensions are in mm and levels are in meter unless noted

otherwise.

2. No dimension shall be scaled from the drawing. Only written

dimension shall be followed.

3. Grade of concrete in various components shall be as under.

Deck slab -M40

Precast beam -M45

A1 Pile cap -M40

C

L OF ABUTMENT Abutment & Pier Pile -M35

WEARING COAT RCC Handrail -M35

150mm MIN. CAST-IN-SITU Leveling Course -M15

DECK SLAB

350 20mm COMPRESSIBLE KERB Approach slab -M30

150

100HIGH x 300WIDE SLOT FOR WEARING COAT 4. The Reinforcement Steel is HYSD bars of grade Fe-500D

FILLER BOARD

ELASTOMERIC DRAINAGE HOLE IN KERB

300 WEARING COAT confirming to IS:1786-2008.

CONCRETE

300 300

5. Clear cover to outermost reinforcement shall be follow

650

APPROACH APPROACH SLAB

PAVEMENT Superstructure - 50mm

310

2 LAYER FELT

350 PAPER Abutment Pile - 75mm

1150

6. Type -1 wearing coat consisting of bituminous concrete 50mm thick

1000

900

CLOSELY SPACED

300

PRECAST BEAM 325 300 325

laid in single layer as per MORTH 5th revision CL. 2702.1 shall be

100mm THK. PCC provide.

300

DETAIL-Z 7. This drawing shall be read in conjunction with relevant highway

1200

DECK SLAB drawing. FRL Camber and section shown in the drawing shall be

BEAM verified with corresponding approved drawing of highway before

1500 (SQ) SECTION C-C

1586 (SK) execution. In case of any discrepancy, it shall be brought to the

notice of "Engineer" for necessary modification in the drawing.

DETAIL-X 8. Design is based on IRC-6:2017 Loading standards.

CONSTRUCTION SEQUENCE : 9. The structure is designed for live load combination as per table 6A

1. Piles will be bored & concreted at the abutment and pier location. of IRC-6:2017.

2. Pier cap will be casted at abutment & pier location. 10. Structure is designed for seismic zone III.

3. The superstructure consists of pre-cast beams that is casted in 11. Protection work will be provided as per site requirement and details

the casting yard. Beams will be launched on the pier / abutment will be provided seperately.

caps. 12. Exposure condition for design is 'SEVERE'.

4. The deck slab and diaphragm are casted together for one 13. Permanent steel liner plate around pile shall be provided up to the

continuous group of spans. scour depth for each location.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Si Report - Perambra Bypass FinalDocument16 pagesSi Report - Perambra Bypass Finaljibeesh cmNo ratings yet

- 4090 Tower PILE (1) ModelDocument1 page4090 Tower PILE (1) Modeljibeesh cmNo ratings yet

- BORE HOLE LOCATIONS FOR CARITHAS ROB-29-11-2022 (1) - ModelDocument1 pageBORE HOLE LOCATIONS FOR CARITHAS ROB-29-11-2022 (1) - Modeljibeesh cmNo ratings yet

- Alappuzha GeologyDocument53 pagesAlappuzha Geologyjibeesh cmNo ratings yet

- Sub Surface Profile-ModelDocument1 pageSub Surface Profile-Modeljibeesh cmNo ratings yet

- Report Kerala r0Document38 pagesReport Kerala r0jibeesh cmNo ratings yet

- Soil Details-1Document29 pagesSoil Details-1jibeesh cmNo ratings yet

- Sample Soil Report - DubaiDocument135 pagesSample Soil Report - Dubaijibeesh cmNo ratings yet

- A1 N Value CorrectionDocument2 pagesA1 N Value Correctionjibeesh cmNo ratings yet

- 01.gad For MNB at Ch.4+611Document2 pages01.gad For MNB at Ch.4+611jibeesh cmNo ratings yet

- 01.gad For MNB at Ch.3+180Document2 pages01.gad For MNB at Ch.3+180jibeesh cmNo ratings yet

- Meteorology - Rain Measures - Specification: Indian StandardDocument8 pagesMeteorology - Rain Measures - Specification: Indian Standardjibeesh cmNo ratings yet

- 17 - 020 - Structural - Drawings1624265747318-20 Al Qouz ProjectDocument1 page17 - 020 - Structural - Drawings1624265747318-20 Al Qouz Projectjibeesh cmNo ratings yet

- 01.gad For MNB at Ch.4+611Document2 pages01.gad For MNB at Ch.4+611jibeesh cmNo ratings yet

- 01.gad For MNB at Ch.1+832Document2 pages01.gad For MNB at Ch.1+832jibeesh cmNo ratings yet

- ST501 Shoring Layout and DetailsDocument1 pageST501 Shoring Layout and Detailsjibeesh cmNo ratings yet

- Aac-222-Cvl-Gen-004 - 00 - Shoring LayoutDocument1 pageAac-222-Cvl-Gen-004 - 00 - Shoring Layoutjibeesh cmNo ratings yet

- Aac-222-Cvl-Gen-005 - 00 - Shoring Typical SectionsDocument1 pageAac-222-Cvl-Gen-005 - 00 - Shoring Typical Sectionsjibeesh cmNo ratings yet

- Soil ReportDocument9 pagesSoil Reportjibeesh cmNo ratings yet

- A-100 Setting Out PlanDocument1 pageA-100 Setting Out Planjibeesh cmNo ratings yet

- S-101 Shoring Layout & DetailsDocument1 pageS-101 Shoring Layout & Detailsjibeesh cmNo ratings yet

- ST502 Shoring DetailsDocument1 pageST502 Shoring Detailsjibeesh cmNo ratings yet

- Neighbor'S Plot - : Sheet No Rev No R0Document1 pageNeighbor'S Plot - : Sheet No Rev No R0jibeesh cmNo ratings yet

- A-101 Basement Floor PlanDocument1 pageA-101 Basement Floor Planjibeesh cmNo ratings yet

- A B C D E F G H: 01 Piling ArrangementsDocument4 pagesA B C D E F G H: 01 Piling Arrangementsjibeesh cmNo ratings yet

- Settlement CalculationDocument3 pagesSettlement Calculationjibeesh cm100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- OKFlux 1062Document1 pageOKFlux 1062jpvtvNo ratings yet

- Pip Stc01015Document45 pagesPip Stc01015Kriztopher UrrutiaNo ratings yet

- TermostatDocument4 pagesTermostatnairam2003No ratings yet

- Wire CoatingDocument11 pagesWire Coatinglalalola12345No ratings yet

- Iso 15733 2015 en PDFDocument6 pagesIso 15733 2015 en PDFponorNo ratings yet

- Textbook of Heat Transfer Sukhatme S PDocument122 pagesTextbook of Heat Transfer Sukhatme S PSamer HouzaynNo ratings yet

- Pavement Condition Evaluation ManualDocument27 pagesPavement Condition Evaluation ManualcrojastNo ratings yet

- Value Engineering vs. Alternate Designs in Bridge BiddingDocument7 pagesValue Engineering vs. Alternate Designs in Bridge BiddingAniket WaghmareNo ratings yet

- 03 Eq-Datalist H341 Rev-2Document61 pages03 Eq-Datalist H341 Rev-2marius raduNo ratings yet

- Thermoplastic Polymers PDFDocument17 pagesThermoplastic Polymers PDFSontosidad, Febie Jynn A.No ratings yet

- Concrete & Steel Calculation Sheet of 220 KV MonopolesDocument2 pagesConcrete & Steel Calculation Sheet of 220 KV MonopolesVikas GuptaNo ratings yet

- PDF - Induction Hadening Machine-1Document14 pagesPDF - Induction Hadening Machine-1smartxdigital marketNo ratings yet

- CitiCorp Center Building Structural AnalysisDocument14 pagesCitiCorp Center Building Structural AnalysisJonathan Hopkins89% (9)

- Bill of Quantities (Boq)Document22 pagesBill of Quantities (Boq)DADADADGGGNo ratings yet

- Data Sheet TRDocument5 pagesData Sheet TRRajaDurai RamakrishnanNo ratings yet

- Schreder The Reference in LightingDocument20 pagesSchreder The Reference in LightingCornel SimocNo ratings yet

- Page 0027Document1 pagePage 0027Matteo BaldassariNo ratings yet

- Construction ScheduleDocument13 pagesConstruction ScheduleBilal Ahmed BarbhuiyaNo ratings yet

- Composite Material AssignmentDocument11 pagesComposite Material AssignmentBhaskarjyaNo ratings yet

- Inspection Electrical Storage Check ListDocument2 pagesInspection Electrical Storage Check ListZaini AchmadNo ratings yet

- Y22-007 Straight Centrifugal Fan CatalogDocument4 pagesY22-007 Straight Centrifugal Fan CatalogdennyNo ratings yet

- 1 Piece(s) 6 X 10 Douglas Fir-Larch No. 1: PassedDocument1 page1 Piece(s) 6 X 10 Douglas Fir-Larch No. 1: PassednaveenthirumalNo ratings yet

- EEE3 Lec13 - Electrical System DesignDocument84 pagesEEE3 Lec13 - Electrical System Designjakob2011No ratings yet

- Ladle Heating FurnaceDocument34 pagesLadle Heating FurnaceAnusha Rao100% (5)

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 3Document75 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 3Percy Romero Murillo100% (1)

- SKAA 2032 - Part 3Document65 pagesSKAA 2032 - Part 3Jason DouglasNo ratings yet

- J. Y. Richard Liew, Yuichi Nishida - Design Guide For Semi-Rigid Composite Joints and beams-SSSS (Singapore Structural Steel Society) (2021)Document136 pagesJ. Y. Richard Liew, Yuichi Nishida - Design Guide For Semi-Rigid Composite Joints and beams-SSSS (Singapore Structural Steel Society) (2021)tmaNo ratings yet

- Effect of Area Ratio On Flow Separation in Annular Diffuser PDFDocument9 pagesEffect of Area Ratio On Flow Separation in Annular Diffuser PDFArun GuptaNo ratings yet

- 2016 DEKS Product Catalogue SmallDocument71 pages2016 DEKS Product Catalogue SmallKedar BhideNo ratings yet