Professional Documents

Culture Documents

Paint Adhesion Tests (Part I Test Method A or X-Cut)

Uploaded by

Bvel2019Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paint Adhesion Tests (Part I Test Method A or X-Cut)

Uploaded by

Bvel2019Copyright:

Available Formats

Paint adhesion tests (Part I: Test Method A or X-Cut) https://translate.googleusercontent.com/translate_c?act=url&depth=1&h...

Paint adhesion tests (Part I: Test Method A or X-Cut)

Views: 8634 Posted by Rezazadeh Published on Sunday, 13 April 1391 19:02 Categories: Building Inspection Description

Apply paint to ensure proper adhesion of paint on the metal surface should be applied to surfaces to be tested. Different methods are used to study the adhesion of paint to the surface is the most

common testing method with a knife (Knife Test), test adhesive tape (Tape Test) and Pull-Off Test requirements.

In this paper, scotch tape test adhesion is one of the most common tests in accordance with ASTM D 3359-09 standard is described. (The first part of this paper is to evaluate the test method A or

X-Cut.)

In this method by applying and removing adhesive tape (Pressure Sensitive) on or scissor cuts made to the film, the adhesive coating on the surface of the metal films is examined.

NOTE: To measure the adhesion of paint to soft surfaces (such as wood, plastic or metal) refer to the ISO 2409 standard.

To perform this test, the method or methods A and B exist. A further test for job sites (job sites) and Test Method B is more suitable laboratories. The test method B for films with a thickness of 5 mils or

Color incoherence 125 µm is not used.

Test Method A (X-Cut):

In this method, an X-shaped cuts in the film on the metal surface caused by the pressure-sensitive adhesive tape is applied on cuts and on the back have. Adhesion is evaluated qualitatively on a scale of 0 to 5.

Test Method B (Cross-Cut):

A network model with 6 or 11 slots in each direction on the film, created and Scotch on the network and then applying the adhesive it will be removed based on a comparison and the interpretation of evaluation.

Equipment required for the test method A:

1. Cutting tools: razor-sharp scalpel, knife or any other means won. Note that the edges of the blade must be good condition and appropriately.

2. Cutting Ruler: Ruler of steel (or hard metal) with smooth edges to ensure a straight cut

3. Scotch Transparent half an inch wide and 25 mm,

Note: Scotch Common name for this Prmasl 99 (Permacel 99) are available in the market with the same name.

1. Delete: you can delete it at the end of a pencil is used.

2. Light: a light source to ensure that the cuts made to the film has been Flzkshydh level, will be required.

Method:

Select a surface that is free of flaws and rust have minimal surface defects. Make sure the surface is clean and dry. Note that high temperatures and high relative humidity (especially in sites) affect the adhesive film.

Editor's Note: The D 3359 adhesion test time required for temperature and humidity conditions exist.

Cut a length of approximately 1.5 inches (40 mm) on each pass through the middle, making films create and the acute angle between 30 to 45 degrees. DO NOT use the ruler tool and move in a fixed order.

Cut the gap to the visible light reflected from the metal surface inspected to make sure that the film coating completely penetrated. If the surface were visible, cut in another place to create a new X session.

Note: The cutting should be done in one step is not correct and deepen the previous gaps and affecting adhesion.

Two separate rounds of scotch tape and a piece of 3-inch (75 mm) from it.

Put glue in the middle of the intersection point of the cuts and then cutting it with your finger and rub with the eraser end of a pencil stuck it over the surface.

The color of the transparent tape is a useful indicator to make sure the glue is sticking well to the surface.

After a period of time of 90 ± 30 seconds, apply glue, tape quickly from the surface do. So far as may be added without shaking his hand and onto the bar when digging angle is 180 degrees.

Now the location of the X-cut separation of the coating from the metal surface by using the following scale to your search:

5A: without any separation

4A: a small detachment or separation cuts along or in place of their

3A: separation of rough and cut along the incision to 1.6 mm on the other side

2A: separation of rough and cut along the greater cuts to 3.2 mm on the other side

1A: X-cut separation in most areas of Zyrnvar

0A: separation away from the X

To ensure the adherence of other places to shop in other places the surface, repeat the test.

Finally, clean the cutting tool. Number of tests with the results reported.

1 of 1 9/11/2014 8:19 AM

You might also like

- F 941 - 99 - RJK0MQ - PDFDocument3 pagesF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNo ratings yet

- Astm d3330Document2 pagesAstm d3330Asep Achmad RamdhaniNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- NACE SP0188-2024 Discontinuity (Holiday) Testing of New Protective Coatings on Conductive SubstratesDocument17 pagesNACE SP0188-2024 Discontinuity (Holiday) Testing of New Protective Coatings on Conductive Substratesahugandkiss77071100% (1)

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 pagesSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- C Tape Datasheet PDFDocument2 pagesC Tape Datasheet PDFIftikhar Ahmed KhalidNo ratings yet

- Comparison Table of Standard Sieve SeriesDocument3 pagesComparison Table of Standard Sieve SeriesAlexander HillNo ratings yet

- HEMPEL'S URETHANE 5595U High Gloss Protective CoatingDocument2 pagesHEMPEL'S URETHANE 5595U High Gloss Protective CoatingFreddy Carl FredricksenNo ratings yet

- High Voltage Porosity2Document14 pagesHigh Voltage Porosity2Alejandro EstremadoyroNo ratings yet

- 131 - 1.9.1.2-85T - 316 Stainless SteelDocument4 pages131 - 1.9.1.2-85T - 316 Stainless SteelFtg WwfdfNo ratings yet

- Asme SB466Document9 pagesAsme SB466Stéphane LevasseurNo ratings yet

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDocument4 pagesHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNo ratings yet

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- High Carbon Steel Shot GritDocument2 pagesHigh Carbon Steel Shot Gritabdulaziz mohammedNo ratings yet

- Holiday Detector Voltage SettingsDocument1 pageHoliday Detector Voltage Settingsrizviabbas2012No ratings yet

- Comparison of SSPC PA2 and ISO-19840 - DFT Verification Method and Acceptance CriteriaDocument5 pagesComparison of SSPC PA2 and ISO-19840 - DFT Verification Method and Acceptance Criteriarajali18No ratings yet

- NDE-Penetrant TestDocument2 pagesNDE-Penetrant TestCandy KendeeNo ratings yet

- Se 797Document7 pagesSe 797donaldoguerreroNo ratings yet

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- 136.4.2 Visual ExaminationDocument1 page136.4.2 Visual ExaminationrohimNo ratings yet

- G10 PDFDocument3 pagesG10 PDFSameer Sa100% (1)

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- Flash Report #01: Industry & Facilities DivisionDocument4 pagesFlash Report #01: Industry & Facilities DivisionEduard GadzhievNo ratings yet

- Sa 435 (Ed 2013)Document4 pagesSa 435 (Ed 2013)Mohd Idris MohiuddinNo ratings yet

- Datasheet Wear PadDocument3 pagesDatasheet Wear PadGILBERTO YOSHIDANo ratings yet

- Unibar Shopprimer LV: BarilDocument2 pagesUnibar Shopprimer LV: BarilFlori SmăduNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- PTFEDocument1 pagePTFEIkhsan LyNo ratings yet

- Astm E797Document7 pagesAstm E797Jimmy MárquezNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Liquid Penetrant Testing Procedure - IDocument2 pagesLiquid Penetrant Testing Procedure - IManivannanMudhaliarNo ratings yet

- Fibre Reinforced Plastics 124Document6 pagesFibre Reinforced Plastics 124RajaramNo ratings yet

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDocument22 pagesSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- 1 E-1742Document15 pages1 E-1742punitg_2No ratings yet

- App10 Fundamentals of ConnectionsDocument23 pagesApp10 Fundamentals of ConnectionsjdmacbookNo ratings yet

- Factors and Areas Prone to Corrosion in Amphibious AircraftDocument10 pagesFactors and Areas Prone to Corrosion in Amphibious AircraftIranthaShalindaJayawardanaNo ratings yet

- Astm E-570-09 RFL Steel TubeDocument7 pagesAstm E-570-09 RFL Steel TubempusNo ratings yet

- Coast Guard Piping RegulationsDocument71 pagesCoast Guard Piping Regulationspkitchen25No ratings yet

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- Vignesh NDT CVDocument2 pagesVignesh NDT CVShanmuga NavaneethanNo ratings yet

- Evaluation of AISI 4140 Steel Repair Without Post-WeldDocument8 pagesEvaluation of AISI 4140 Steel Repair Without Post-WeldVidaurriNo ratings yet

- Zinc Rich Anticorrosive Primer PDFDocument53 pagesZinc Rich Anticorrosive Primer PDFDhruv SevakNo ratings yet

- E 1254 - 03 Rteyntq - PDFDocument3 pagesE 1254 - 03 Rteyntq - PDFMarceloNo ratings yet

- Cold Pilger Rolling - Part Two - KEY To METALS ArticleDocument2 pagesCold Pilger Rolling - Part Two - KEY To METALS Articlekumarpankaj030No ratings yet

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocument4 pagesAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonNo ratings yet

- WPS_Review_Guidelines_2007Document27 pagesWPS_Review_Guidelines_2007Bvel2019No ratings yet

- SSPC-QP3 InitialApp 0718Document29 pagesSSPC-QP3 InitialApp 0718Bvel2019No ratings yet

- Abrasive Steel Shots PDF Technical AspectsDocument12 pagesAbrasive Steel Shots PDF Technical AspectsBvel2019No ratings yet

- comparing-the-reliability-of-structural-steel-welds-using-ultrasonic-fatigue-testingDocument2 pagescomparing-the-reliability-of-structural-steel-welds-using-ultrasonic-fatigue-testingBvel2019No ratings yet

- Paint - Consumption CalculationDocument1 pagePaint - Consumption CalculationBvel2019No ratings yet

- En Metalwork ChippingDocument5 pagesEn Metalwork ChippingBvel2019No ratings yet

- Techniques To Improve Small Hole Cut Quality On Carbon Steel With A CNC Plasma SystemDocument16 pagesTechniques To Improve Small Hole Cut Quality On Carbon Steel With A CNC Plasma SystemLogicIndustriesLLCNo ratings yet

- En Metalwork Centring Drilling and Counterboring Countersinking Vocational TrainingDocument14 pagesEn Metalwork Centring Drilling and Counterboring Countersinking Vocational Trainingbluesky_1976No ratings yet

- En Metalwork Cutting by Milling Vocational Training PDFDocument20 pagesEn Metalwork Cutting by Milling Vocational Training PDFpedjaNo ratings yet

- Packing InspectionDocument2 pagesPacking InspectionBvel2019No ratings yet

- Machinist Course - Metal Properties, Characteristics, Uses, and CodesDocument98 pagesMachinist Course - Metal Properties, Characteristics, Uses, and Codesmerlinson1100% (5)

- En Metalwork Annealing Hardening Tempering Vocational Training PDFDocument18 pagesEn Metalwork Annealing Hardening Tempering Vocational Training PDFKevin AlexanderNo ratings yet

- Skill Development and Traini NG Programmes of Central GovernmnetsDocument10 pagesSkill Development and Traini NG Programmes of Central GovernmnetscapziaNo ratings yet

- Calibration BookletDocument12 pagesCalibration BookletGeorge Manuel50% (2)

- Galvanizing InspectionDocument1 pageGalvanizing InspectionBvel2019No ratings yet

- OIML R 35-1: Nternational EcommendationDocument40 pagesOIML R 35-1: Nternational EcommendationJulian MeloNo ratings yet

- Coloring Page Template PrintingDocument1 pageColoring Page Template PrintingBvel2019No ratings yet

- HydroponicsDocument45 pagesHydroponicsRavindra Kumara100% (15)

- Difference Between Code Standard and SpecificationDocument1 pageDifference Between Code Standard and SpecificationBvel2019No ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- Tamilnadu +2 Chemistry Question Paper 2018Document15 pagesTamilnadu +2 Chemistry Question Paper 2018Bvel2019No ratings yet

- Capsicum - Economics - 4000Document1 pageCapsicum - Economics - 4000Bvel2019No ratings yet

- Maximizing Area and Minimizing Costs with CalculusDocument18 pagesMaximizing Area and Minimizing Costs with Calculusanon_218576188No ratings yet

- Manual Bot With Relay CircuitDocument4 pagesManual Bot With Relay CircuitKarishma MishraNo ratings yet

- Principles of Marketing - Product, Service and Experience DifferencesDocument26 pagesPrinciples of Marketing - Product, Service and Experience DifferencesVivien Leigh LopezNo ratings yet

- Caelus TT - Caelus Product TrainingDocument93 pagesCaelus TT - Caelus Product TrainingYader Daniel Ortiz CerdaNo ratings yet

- SE 276B Syllabus Winter 2018Document2 pagesSE 276B Syllabus Winter 2018Manu VegaNo ratings yet

- Fundamentals of Wind EnergyDocument24 pagesFundamentals of Wind EnergyMas3odNo ratings yet

- Packaging Materials and Handling Technique: Dr. Ranjeet SinghDocument48 pagesPackaging Materials and Handling Technique: Dr. Ranjeet Singharon demagiba100% (1)

- Bronchiolitis A Practical Approach For The General RadiologistDocument42 pagesBronchiolitis A Practical Approach For The General RadiologistTara NareswariNo ratings yet

- Angle of Depression Lesson for Grade 9 MathDocument6 pagesAngle of Depression Lesson for Grade 9 MathPatrick Guerra100% (1)

- Theoretical Development of The Brooks-Corey CapillDocument7 pagesTheoretical Development of The Brooks-Corey CapillDiana Vanessa PedrazaNo ratings yet

- Aula 4 - Wooten - Organizational FieldsDocument28 pagesAula 4 - Wooten - Organizational FieldsferreiraccarolinaNo ratings yet

- Water Spray Nozzle: Fire Fighting Equipment Data SheetDocument7 pagesWater Spray Nozzle: Fire Fighting Equipment Data SheetJosef MadronaNo ratings yet

- 07 - Structural Organisation in AnimalsDocument31 pages07 - Structural Organisation in AnimalsKamala Kannan XANo ratings yet

- Digital control engineering lecture on z-transform and samplingDocument13 pagesDigital control engineering lecture on z-transform and samplingjin kazamaNo ratings yet

- Fitness RX For Women - December 2013Document124 pagesFitness RX For Women - December 2013renrmrm100% (2)

- Image Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)Document7 pagesImage Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)ManiNo ratings yet

- Worthy - Elevation WorshipDocument1 pageWorthy - Elevation WorshipSabine J.100% (1)

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabeNo ratings yet

- Simply Supported Beam ReactionsDocument4 pagesSimply Supported Beam ReactionsRushi TutorNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- Slovakia C1 TestDocument7 pagesSlovakia C1 TestĐăng LêNo ratings yet

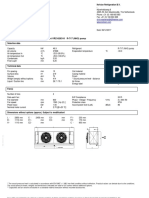

- GSL DIP Phase - 1 Cooler 45kWDocument1 pageGSL DIP Phase - 1 Cooler 45kWMuhasin PallikkalNo ratings yet

- Booklet English 2016Document17 pagesBooklet English 2016Noranita ZakariaNo ratings yet

- Eliminating False Detection: Sensing Guide Pulse Level SensorDocument16 pagesEliminating False Detection: Sensing Guide Pulse Level SensorRafael MirandaNo ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- Idioms and Phrases MCQs - English Grammar For Competitive ExamsDocument6 pagesIdioms and Phrases MCQs - English Grammar For Competitive ExamsgeologistlakhanNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Negative Compressibility and PVT Extrapolation WarningsDocument17 pagesNegative Compressibility and PVT Extrapolation WarningsMarcelo SaezNo ratings yet

- Bernard BTB MIG GunsDocument8 pagesBernard BTB MIG GunsEdwin Mauricio Gallego OsorioNo ratings yet

- 9th Mole Concept and Problems Based On PDFDocument2 pages9th Mole Concept and Problems Based On PDFMintu KhanNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreFrom EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreRating: 4.5 out of 5 stars4.5/5 (3)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Siren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetFrom EverandSiren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetRating: 5 out of 5 stars5/5 (3)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- More than a Granny: 20 Versatile Crochet Square Patterns US VersionFrom EverandMore than a Granny: 20 Versatile Crochet Square Patterns US VersionRating: 1.5 out of 5 stars1.5/5 (2)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Design 555 Doilies Vintage Crochet Pattern eBookFrom EverandDesign 555 Doilies Vintage Crochet Pattern eBookRating: 2.5 out of 5 stars2.5/5 (2)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)