Professional Documents

Culture Documents

Pro-50 50K

Uploaded by

余日中Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pro-50 50K

Uploaded by

余日中Copyright:

Available Formats

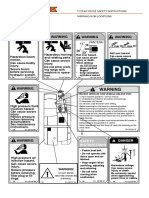

HOW TO USE SOLDERPRO 50 CHANGING TIPS

® 5.1 Be sure the tip has cooled before

REFUELING removal. The catalyst seen through 3.2

SOLDERPRO 50K 2.1 Adaptors are not normaly required 2.2 the exhaust ports of the soldering

Butane

when refilling. tip is very delicate and will not

2.2 To refill, hold refill can as pictured sustain mechanical abuse without

SPECIFICATIONS (fuel transfer is dependent upon serious damage.

w/cap 153 mm (6.0 in) gravity). Observe fuel level in 5.2 The soldering tip is easily removable

Length: w/soldering tip 140 mm (5.5 in)

w/blow torch tip 142 mm (5.6 in)

transparent window and stop allowing the installation of other

Weight (when gas-filled) 60 g filling when 90% FULL. style tips or the replacement of a

Approximate temperature worn tip. After the soldering tip is

Soldering tip 250~500°C (482~1005°F)

Torch 1300°C (2400°F)

cool, simply unscrew it with a

Hot Knife 200~350°C (400~660°F) counterclockwise motion. Pliers

Heat Blower 250~450°C (480~850°F) IGNITION SEQUENCE-1

3.1 may be required to lightly grasp the

Gas container capacity 7 ml 3.1.1 SOLDERING IRON.

tip in order to loosen it. Be careful

Operating Time 30 min Push the ON/OFF adjuster upward

(one gas filling) at mid setting not to overtighten as this could

toward tip to release gas and turn

damage the thread in the cap.

to mid position. Then holding the

IMPORTANT SAFETY unit away from the face and body,

INSTRUCTIONS activate with the flint ignitor or

regular lighter. BUILT IN SAFETY WIRE STAND

6.1 This built in safety

Warnings:

1.1 Unit contains flammable gas wire stand is

( Butane ) under pressure - use designed to hold

IGNITION SEQUENCE-2

with care. the soldering iron 6.1

3.1.2 With the other hand,

1.2 DO NOT expose to heat above still to prevent from

holding it in close

+50°C (120°F) and avoid rolling off.

IGNITOR proximity to the tip, spin

prolonged exposure to the sun. 6.2 For continuous use of the soldering tool,

1.3 DO NOT puncture or incinerate. the spark wheel while

we recommend to use a separate metal

1.4 Excessive gas flow, flare-up, or pointing the stream of

stand, which requires the minimum height

catalyst pulsing red may occur sparks at the exhaust

of 1 - 1.5 inchs from any flat surface.

when the regulator is incorrectly ports. The tip will now

adjusted, i.e., set too high. flame for a few seconds

1.5 DO NOT refill, ignite or use near before starting to glow.

open flame, heater, furnace or The flame will then self-

combustible materials. It is IMPORTANT NOTE:

extinguish.

essential, therefore, to keep unit THIS TOOL HAS BEEN ESPECIALLY DESIGNED

3.2 BLOW TORCH

away from face and body when FOR USE WITH 100% BUTANE GAS. ANY OTHER

igniting. Same as soldering iron

BUTANE-PROPANE MIX OR OTHER FUEL GASES

1.6 KEEP WORK AREA CLEAN. but point stream of sparks

3.1.2A COULD CREATE MUCH HIGHER TEMPERATURES

Cluttered areas and benches invite into the open end of the

AND INDUCE 'FLARE UP' AT THE TIP EXHAUST SLOTS.

injuries. CAP Blow Torch tip.

1.7 KEEP AWAY FROM CHILDREN. All 3.3 HEAT BLOWER

visitors should be kept away from Same as for soldering

work area. iron but point stream of

1.8 STORE WHEN NOT IN USE.

SOLDERING sparks into the open end 3.1.2B

Store in dry, locked cabinet out of TIP BASIC TIPS

of the tip. Wait a short

reach of children.

1.9 Be extremely careful as torch flame CATALYST time for the flame to self

tip temperature is over 1300°C extinguish and to reach 1mm 2mm

(2400°F) operating temperatures.

1.10 Be extremely careful as torch flame 3.4 HOT KNIFE

is almost invisible in daylight or Same as for the soldering

SAFETY WIRE

under strong light. STAND iron tip.

1.11 WEAR SAFETY GLASSES.

1.12 DON'T OVERREACH. Keep proper T-01 T-02 S-05 S-06 S-07

footing and balance at all times. ON / OFF

1.13 STAY ALERT. Watch what you are ADJUSTER ADJUSTMENT

doing. Use common sense. Do not 4.1 The tip temperature can

operate when you are tired. be adjusted by turning

1.14 DO NOT TOUCH the heated tip or the ON / OFF adjuster.

tip barrel of the unit. GAS TANK 4.2 Normally set the ON/OFF

1.15 DO NOT leave unit unattended

adjuster forward to mid

when it is operating or hot.

1.16 ALWAYS BE SURE THE UNIT IS COOL position when soldering

BEFORE STORING. or brazing.

1.17 DO NOT REPLACE CAP WITHOUT SEE 4.3 It is not necessary for the S-08 S-30 S-31 S-32

SWITCHING UNIT OFF AND THROUGH tip to glow bright red to

WINDOW

ENSURING TIP HAS COOLED. achieve satisfactory

1.18 USE ONLY IN WELL VENTILATED soldering temperatures.

AREA. Experience will dictate the

FILLING

1.19 DO NOT attempt to readjust or VALVE adjuster setting required. PATENTS:

repair. Unit is not user serviceable. U.S.PATENT 5,135,389

4.4 Excessive gas flow, flare-

Do ensure flame is extinguished R.O.C PATENT PENDING

before putting down. up or catalyst pulsing red EUROPEAN PATENT PENDING

may occur when the

DESIGNED & MANUFACTURED

• READ ENCLOSED INSTRUCTION MANUAL PRIOR TO USE. regulator is incorrectly BY PRO-IRODA INDUSTRIES, INC.

• BUTANE NOT INCLUDED. adjusted, i.e., set too high.

We love the Earth MADE IN TAIWAN

Pro-Iroda Industries, Inc. Taichung, Taiwan

CMYK

CMYK

geprufte

Sicherhelt

Designers and Manufacturers of

APPLICATIONS

Butane-Powered Tools for Industry! ® ® Professional • Electrical/Electronic

SOLDERPRO 50K

Quality Circuit Repair

• Light Brazing

• Jewellry, Eyeglass

Frame Repair

30W-70W • Model Building

POWER RANGE • Arts and Crafts

• Dental Wax Corrections

PATENTS:

TAIWAN 80040

U.S.PATENT NR. 5,135,389

Butane Powered

5,381,920

CHINA ZL 92 2 33540.0

SOLDERING IRON SPECIFICATIONS

93 2 45052.0 w/cap 153 mm (6.0 in)

Length: w/soldering tip 140 mm (5.5 in)

w/blow torch tip 142 mm (5.6 in)

Weight (when gas-filled) 60 g

Approximate temperature 250~500°C

soldering tip (482~1005°F)

Torch 1300°C (2400°F)

Gas container capacity 7 ml

Operating Time 30 min

(one gas filling) at mid setting

SOLDERING HOT KNIFE BLOW TORCH HEAT BLOWER

H O T N E W P R O - T O O L S F R O M P R O - I R O D A C O R D L E S S B U T A N E P R O D U C T S A T T H E L E A D I N G E D G E .

geprufte

Sicherhelt

APPLICATIONS

® Professional • Electrical/Electronic

SOLDERPRO 50K

Quality Circuit Repair

• Light Brazing

• Jewellry, Eyeglass

Frame Repair

30W-70W • Model Building

POWER RANGE • Arts and Crafts

• Dental Wax Corrections

PATENTS:

TAIWAN 80040

U.S.PATENT NR. 5,135,389

Butane Powered

5,381,920

CHINA ZL 92 2 33540.0

SOLDERING IRON SPECIFICATIONS

93 2 45052.0 w/cap 153 mm (6.0 in)

Length: w/soldering tip 140 mm (5.5 in)

w/blow torch tip 142 mm (5.6 in)

Weight (when gas-filled) 60 g

Approximate temperature 250~500°C

soldering tip (482~1005°F)

Torch 1300°C (2400°F)

Gas container capacity 7 ml

Operating Time 30 min

(one gas filling) at mid setting

SOLDERING HOT KNIFE BLOW TORCH HEAT BLOWER

H O T N E W P R O - T O O L S F R O M P R O - I R O D A C O R D L E S S B U T A N E P R O D U C T S A T T H E L E A D I N G E D G E .

geprufte

Sicherhelt

APPLICATIONS

® Professional • Electrical/Electronic

SOLDERPRO 50K

Quality Circuit Repair

• Light Brazing

• Jewellry, Eyeglass

Frame Repair

30W-70W • Model Building

POWER RANGE • Arts and Crafts

• Dental Wax Corrections

PATENTS:

TAIWAN 80040

U.S.PATENT NR. 5,135,389

Butane Powered

Cordless butane products at the leading edge! 5,381,920 SOLDERING IRON SPECIFICATIONS

www.pro-iroda.com.tw CHINA ZL 92 2 33540.0

w/cap 153 mm (6.0 in)

93 2 45052.0

Length: w/soldering tip 140 mm (5.5 in)

w/blow torch tip 142 mm (5.6 in)

Weight (when gas-filled) 60 g

Approximate temperature 250~500°C

soldering tip (482~1005°F)

CMYK Torch 1300°C (2400°F)

Gas container capacity 7 ml

Operating Time 30 min

(one gas filling) at mid setting

SOLDERING HOT KNIFE BLOW TORCH HEAT BLOWER

H O T N E W P R O - T O O L S F R O M P R O - I R O D A C O R D L E S S B U T A N E P R O D U C T S A T T H E L E A D I N G E D G E .

CMYK

You might also like

- Instruction Manual: Solderpro™Document1 pageInstruction Manual: Solderpro™余日中No ratings yet

- Primus - PowerCook PDFDocument8 pagesPrimus - PowerCook PDFmajoni88No ratings yet

- Fusion Splicer 22S Quick Reference Guide: SM AutoDocument4 pagesFusion Splicer 22S Quick Reference Guide: SM AutoMboa YannickNo ratings yet

- Wiring Instructions For 10, 16 & 20 Function, 92 & 93 Series, FET ReceiversDocument3 pagesWiring Instructions For 10, 16 & 20 Function, 92 & 93 Series, FET ReceiversGerardNo ratings yet

- Vciom 06062 enDocument4 pagesVciom 06062 enJoeNo ratings yet

- 8djhDocument2 pages8djhkiady.andriaNo ratings yet

- JZ990D43501 eDocument6 pagesJZ990D43501 eМаксим ПасичникNo ratings yet

- Quick Reference Guide 12S CDocument4 pagesQuick Reference Guide 12S CChristos MouratidisNo ratings yet

- Ttrucklite Flasher PDFDocument5 pagesTtrucklite Flasher PDFfrank mutaleNo ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- Service RSVP Post Weld Heat TreatDocument2 pagesService RSVP Post Weld Heat Treat1339979No ratings yet

- 907Document15 pages907Made AgusNo ratings yet

- Monitor oil levels in transformers with this compact indicatorDocument2 pagesMonitor oil levels in transformers with this compact indicatorvipulpanchotiyaNo ratings yet

- Rotary Paddle Level Switch DetectionDocument15 pagesRotary Paddle Level Switch DetectionMiguelangel MelendezNo ratings yet

- Actuator Double ActingDocument3 pagesActuator Double Actingandi nainggolanNo ratings yet

- PART NO. 8200: Tune Up Kit For GM Hei V8 DistributorsDocument2 pagesPART NO. 8200: Tune Up Kit For GM Hei V8 DistributorschrispyNo ratings yet

- Fusion Splicer Quick Reference GuideDocument4 pagesFusion Splicer Quick Reference Guideboba78No ratings yet

- L-134 Static TimingDocument17 pagesL-134 Static TimingMax Steffe100% (1)

- Flashlight User Manual: FL2220 FL2210 FL2203Document5 pagesFlashlight User Manual: FL2220 FL2210 FL2203Maury M MarquesNo ratings yet

- For Safe Operation: Description of Error DetectedDocument1 pageFor Safe Operation: Description of Error DetectedAmjad HossenNo ratings yet

- ALS Series: Exd Limit Switch BoxDocument4 pagesALS Series: Exd Limit Switch BoxNabeel MohammedNo ratings yet

- Cooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorDocument5 pagesCooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorAleksander RzeczyckiNo ratings yet

- Enduro 2Document2 pagesEnduro 2Srdjan MalinicNo ratings yet

- PPSK Instruction ManualDocument1 pagePPSK Instruction ManualjoseNo ratings yet

- Deutsch English Français: Gefahr Danger DangerDocument2 pagesDeutsch English Français: Gefahr Danger Dangermat.worst.crNo ratings yet

- INSTRUCTION MANUAL (Air Ejctor Type Vacuum Pump-E)Document8 pagesINSTRUCTION MANUAL (Air Ejctor Type Vacuum Pump-E)Naman BajpaiNo ratings yet

- Splice Operation: SM Auto Auto SM FastDocument4 pagesSplice Operation: SM Auto Auto SM FastNayeemNo ratings yet

- Suzuki GSX-S1000 Heater Grip Installation GuideDocument108 pagesSuzuki GSX-S1000 Heater Grip Installation GuideseowshengNo ratings yet

- Heater Control and AccessoryDocument2 pagesHeater Control and Accessorydmc constructionNo ratings yet

- Electrovalvula Freno RX700Document2 pagesElectrovalvula Freno RX700hectorNo ratings yet

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Replacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)Document1 pageReplacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)navin agarwalNo ratings yet

- Whirlpool Gas Dryer Conversion Kit Instructions W10301479ADocument4 pagesWhirlpool Gas Dryer Conversion Kit Instructions W10301479ASamurai Appliance Repair ManNo ratings yet

- Remove Starter MotorDocument4 pagesRemove Starter MotorEmanuel Theodor RaduNo ratings yet

- Memmet UFP 800Document36 pagesMemmet UFP 800Jeffrine PhilipNo ratings yet

- Water Level Limiter 933 (Instruction of Use)Document2 pagesWater Level Limiter 933 (Instruction of Use)Miraz RahmanNo ratings yet

- Operating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersDocument2 pagesOperating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersMahesh Daxini ThakkerNo ratings yet

- Finepix S5700/ S700: Digital CameraDocument134 pagesFinepix S5700/ S700: Digital CameraIzaias AlexandreNo ratings yet

- User's Manual for Hydraulic BreakersDocument34 pagesUser's Manual for Hydraulic BreakersClaudio VargasNo ratings yet

- GS65 BJ - User Manual R3 FINAL PDFDocument11 pagesGS65 BJ - User Manual R3 FINAL PDFrmendoza85No ratings yet

- Rotary Paddle Level Switch GuideDocument11 pagesRotary Paddle Level Switch GuideMã Hồng PhúcNo ratings yet

- V An de G Raff G Enerator SF-9722Document4 pagesV An de G Raff G Enerator SF-9722JonhGonzálezNo ratings yet

- ISOTIP SolderPro-50-7971-Inside-InstructionsDocument1 pageISOTIP SolderPro-50-7971-Inside-InstructionsGmo HdezNo ratings yet

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- Fujifilm - Finepix - s1500 - Service ManualDocument142 pagesFujifilm - Finepix - s1500 - Service ManualimalettinNo ratings yet

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfNo ratings yet

- 1 (Arrastados) 5Document1 page1 (Arrastados) 5Eduardo TeixeiraNo ratings yet

- 91sr S PDFDocument2 pages91sr S PDFricardoNo ratings yet

- Boss DM-2 Delay: InstructionsDocument8 pagesBoss DM-2 Delay: InstructionscarlazNo ratings yet

- Press SW IndfossDocument2 pagesPress SW IndfossSting DâuNo ratings yet

- Onkyo - C 701 ADocument21 pagesOnkyo - C 701 Anyoman dundunNo ratings yet

- Pantera1100 o 2Document10 pagesPantera1100 o 2Emad Abu SafeihNo ratings yet

- O10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetDocument4 pagesO10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetmaresliviuNo ratings yet

- O10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetDocument4 pagesO10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetmaresliviuNo ratings yet

- O10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetDocument4 pagesO10/O16/O20/O60 Commercial Temperature Controls: Instruction SheetmaresliviuNo ratings yet

- Series Instruction Manual: High-Accuracy Digital Contact SensorDocument16 pagesSeries Instruction Manual: High-Accuracy Digital Contact SensorCzipó BalázsNo ratings yet

- Read and Understand All Instruction, Warning and Danger Labels On The UnitDocument2 pagesRead and Understand All Instruction, Warning and Danger Labels On The United drayceNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Spps Pol-1076Document4 pagesSpps Pol-1076余日中No ratings yet

- PoliceDocument5 pagesPolice余日中No ratings yet

- TC E p68Document14 pagesTC E p68余日中No ratings yet

- E-Procurement System User Manual (For Public Works Contractor)Document8 pagesE-Procurement System User Manual (For Public Works Contractor)余日中No ratings yet

- Application FormDocument1 pageApplication Form余日中No ratings yet

- UserManual PO PDFDocument3 pagesUserManual PO PDFVintonius Raffaele PRIMUSNo ratings yet

- Ip Camera: H SeriesDocument26 pagesIp Camera: H Series余日中No ratings yet

- GF340Document8 pagesGF340余日中No ratings yet

- UserManual Account ActivationDocument6 pagesUserManual Account Activation余日中No ratings yet

- 03 NEUTRIK PG E - SpeakON Connectors - 201907-V20Document20 pages03 NEUTRIK PG E - SpeakON Connectors - 201907-V20余日中No ratings yet

- UserManual Account ActivationDocument6 pagesUserManual Account Activation余日中No ratings yet

- Siptrunk Addition PressreleaseDocument1 pageSiptrunk Addition Pressrelease余日中No ratings yet

- UserManual View Invitation To QuotationDocument13 pagesUserManual View Invitation To QuotationVintonius Raffaele PRIMUSNo ratings yet

- E-Procurement System User Manual (For Public Works Contractor)Document5 pagesE-Procurement System User Manual (For Public Works Contractor)Vintonius Raffaele PRIMUSNo ratings yet

- How To View and Reply Clarificat Ion: E-Procurement SystemDocument5 pagesHow To View and Reply Clarificat Ion: E-Procurement SystemVintonius Raffaele PRIMUSNo ratings yet

- View, submit and track invoices online with e-ProcurementDocument9 pagesView, submit and track invoices online with e-ProcurementVintonius Raffaele PRIMUSNo ratings yet

- UserManual Update Company Details and ContactsDocument22 pagesUserManual Update Company Details and ContactsVintonius Raffaele PRIMUSNo ratings yet

- Siptrunk Addition PressreleaseDocument1 pageSiptrunk Addition Pressrelease余日中No ratings yet

- Stanley Stud Sensor S100Document50 pagesStanley Stud Sensor S100余日中No ratings yet

- UserManual Update Electronic CatalogueDocument10 pagesUserManual Update Electronic CatalogueVintonius Raffaele PRIMUSNo ratings yet

- Repertoire List UpdatedDocument6 pagesRepertoire List Updated余日中No ratings yet

- Rechargeable Laptop Battery User ManualDocument1 pageRechargeable Laptop Battery User ManualVintonius Raffaele PRIMUSNo ratings yet

- UserManual Update Company Details and ContactsDocument22 pagesUserManual Update Company Details and ContactsVintonius Raffaele PRIMUSNo ratings yet

- CO PY: Camera User GuideDocument0 pagesCO PY: Camera User GuideDiogo MartinhoNo ratings yet

- Product Catalogue: - Professional Fastening Technology - Professional Fastening TechnologyDocument180 pagesProduct Catalogue: - Professional Fastening Technology - Professional Fastening Technology余日中No ratings yet

- Solderpro™: Instruction ManualDocument1 pageSolderpro™: Instruction ManualWinton YUNo ratings yet

- Product Data Sheet: Power Tools For Trade & IndustryDocument2 pagesProduct Data Sheet: Power Tools For Trade & Industry余日中No ratings yet

- Downloaded From Manuals Search EngineDocument44 pagesDownloaded From Manuals Search Enginemilton arenaNo ratings yet

- C 20 MY 3 4 SemDocument80 pagesC 20 MY 3 4 SemMatthew SmithNo ratings yet

- Building Model Airplanes From Scratch (PDFDrive)Document262 pagesBuilding Model Airplanes From Scratch (PDFDrive)Aulia Suherlan100% (2)

- KEC - 251 - Electronics - Lab AKTUDocument48 pagesKEC - 251 - Electronics - Lab AKTUimvuuser1No ratings yet

- Philips Tps1.2ela 312278517600Document56 pagesPhilips Tps1.2ela 312278517600Анатоли АнгеловNo ratings yet

- Welding and Joining of Magnesium Alloys: Frank CzerwinskiDocument24 pagesWelding and Joining of Magnesium Alloys: Frank Czerwinskivenkat mechNo ratings yet

- L04a Ad 3122785158810Document96 pagesL04a Ad 3122785158810Вячеслав ЖигалкинNo ratings yet

- TPM Total Productive MaintenanceDocument124 pagesTPM Total Productive MaintenanceKisJanosTamas75% (4)

- Pioneer Deh-24ub 2400ub 2450ub 2490ub crt4745Document63 pagesPioneer Deh-24ub 2400ub 2450ub 2490ub crt4745Ronal Perez100% (1)

- Basic Soldering Lessons 1-9Document27 pagesBasic Soldering Lessons 1-9Edgardo De La CruzNo ratings yet

- 32lf56 Service ManualDocument56 pages32lf56 Service ManualpatoraNo ratings yet

- LG 42ls3400 42ls340y PDFDocument42 pagesLG 42ls3400 42ls340y PDFMaria de Guerrero100% (1)

- R320 3 PDFDocument472 pagesR320 3 PDFazze bouzNo ratings yet

- Pioneer Deh-9450ubDocument74 pagesPioneer Deh-9450ubDimitar MirchevNo ratings yet

- OLED65B6PUDocument95 pagesOLED65B6PUyakaka33No ratings yet

- Service Manual: DSC-W180/W190Document20 pagesService Manual: DSC-W180/W190Jorge Fernando de TivantaNo ratings yet

- JFE Advanced Tin Mill Products TechnologyDocument27 pagesJFE Advanced Tin Mill Products TechnologyGustavo BarreraNo ratings yet

- LG 42LM3450 42LM345S 42LM345T Za LD21B PDFDocument55 pagesLG 42LM3450 42LM345S 42LM345T Za LD21B PDFvanjalujic100% (1)

- LG 49UF7700 Chassis LJ53JDocument119 pagesLG 49UF7700 Chassis LJ53Jleonardogustavoc100% (1)

- Mobile Phone Repairing PDF 2Document81 pagesMobile Phone Repairing PDF 2belacheweshetu222No ratings yet

- Service Manual: Compact Disc ReceiverDocument130 pagesService Manual: Compact Disc Receiverjose luisNo ratings yet

- Fiberglass Reinforcement Extends Fatigue Life of 3D PrintsDocument23 pagesFiberglass Reinforcement Extends Fatigue Life of 3D PrintsGargoyleBardNo ratings yet

- Philips+TPM18 7L+LADocument59 pagesPhilips+TPM18 7L+LAMindSet MarcosNo ratings yet

- Sony HCD Gpx7Document70 pagesSony HCD Gpx7Bila Nicola Florin SorinNo ratings yet

- Ice GuideDocument65 pagesIce GuideDanny BrittonNo ratings yet

- Infineon-MOSFET CoolMOS 600V S7T With Integrated Temparature sensor-ApplicationNotes-v01 00-ENDocument22 pagesInfineon-MOSFET CoolMOS 600V S7T With Integrated Temparature sensor-ApplicationNotes-v01 00-ENDante AlighieriNo ratings yet

- Infineon Board - Assembly - Recommendations General Package v05 - 00 EN PDFDocument43 pagesInfineon Board - Assembly - Recommendations General Package v05 - 00 EN PDFTin NguyenNo ratings yet

- Pma2 6Document9 pagesPma2 6EllyYanaNo ratings yet

- Integrated Circuits Data Sheet for 2 to 6 W Audio Power Amplifier TDA1011Document14 pagesIntegrated Circuits Data Sheet for 2 to 6 W Audio Power Amplifier TDA1011Jose M PeresNo ratings yet

- Uda1334 - Audio DacDocument23 pagesUda1334 - Audio DacRegis DantasNo ratings yet