Professional Documents

Culture Documents

Understanding The What Why How of Strategic Sourcing - Zycus Procurement Blog

Understanding The What Why How of Strategic Sourcing - Zycus Procurement Blog

Uploaded by

BharadwajaChennupati0 ratings0% found this document useful (0 votes)

11 views14 pagesOriginal Title

Understanding-the-What-Why-How-of-Strategic-Sourcing---Zycus-Procurement-Blog

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views14 pagesUnderstanding The What Why How of Strategic Sourcing - Zycus Procurement Blog

Understanding The What Why How of Strategic Sourcing - Zycus Procurement Blog

Uploaded by

BharadwajaChennupatiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 14

Understanding the What,

Why, & How of Strategic

Sourcing

As businesses today continue to harness the power of

globalization to expand performance, the role of

effectively sourcing goods and services from suppliers

has become inevitable. Additionally, procurement is

transforming into a more strategic function that is

aligned to organizational goals and objectives.

Furthermore, issues like economic and political volatility,

technological disruption, etc. have rendered market a

fierce competition. Hence, it is important for

organizations to adopt effective strategic sourcing skills

and processes to maximize their business performance

and efficiency to gain a competitive advantage over their

peers. tweet

What is Strategic Sourcing?

.

Definition

Strategic sourcing refers to the process of identifying the

spend profile of an organization and its supplier base to

ensure their business requirements are aligned with the

suppliers. tweet

The boom in the adoption of strategic sourcing implies that

almost everyone has heard of it. However, being a term that

encompasses a large number of sub-concepts,

understanding strategic sourcing might get complex.

Hence, this article attempts to cover what constitutes

strategic sourcing, how it differs from tactical sourcing, and

its driving forces and processes.

Difference between Tactical Sourcing

and Strategic Sourcing

.

Understanding Strategic Sourcing

Strategic sourcing involves developing a proactive, holistic,

and continuous evaluation and re-evaluation of the sourcing

activities in an organization. Strategic sourcing aims to

achieve the lowest Total Cost of Ownership (TCO) along

with minimal supply chain risk. Hence, it reflects the

organization’s relationship with its sourcing partners as a

loop instead of a one-way process—an in-depth profile of

the suppliers and their core capabilities is developed and

periodically aligned to the sourcing requirements of the

organization. Strategic sourcing views suppliers as crucial

value partners and aims to building sustained, collaborative

relations. The customer-supplier loop is assessed at every

stage of its lifecycle in order to ensure that the needs of the

organizations are continuously and efficiently met. To

accomplish this, strategic sourcing leverages spend

analysis, supplier evaluation, supplier relationship

management, and detailed market research. Strategic

sourcing is, hence, a long-term process and for its

successful implementation, it needs skilled personnel and

relevant technology platforms and tools.

Understanding Tactical Sourcing

In contrast, tactical sourcing involves a short-term and

traditionally reactive approach towards managing the

sourcing activities of an organization. It aims to achieve the

lowest possible cost without considering other factors like

supplier relationship management, supply chain risk

mitigation, etc. Consequently, the focus on building long-

term relationships with suppliers and understanding how

their core capabilities can meet the organization is minimal

as communication with suppliers only occurs when

problems arise. While tactical sourcing can bring gains in

the short-term, it prohibits sustained optimization of its

sourcing activities. Furthermore, compared to strategic

sourcing, tactical sourcing doesn’t necessitate large

investments in advanced technological platforms and

personnel skillsets.

Why do we Need Strategic Sourcing?

.

Outlining 4 Key Benefits of Strategic Sourcing

Now that the concept of strategic sourcing is clearer, it is

important to understand its benefits and why it makes

sense for more organizations to adopt strategic sourcing. A

whitepaper authored by Zycus talks about the various

advantages an organization can leverage by implementing

strategic sourcing:

Increased Level of Cost Savings

The most obvious benefit businesses will experience from

strategic sourcing would be higher levels of cost savings. By

identifying and selecting suppliers that will provide the

highest value at the right pricing will enable an organization

to continuously achieve higher cost savings. This is even

more important as according to Zycus’ Pulse of

Procurement 2018, 54% of top procurement professionals

have recognized cost savings as a key focus area.

Better Alignment of Sourcing and Business

Objectives

Aligning the sourcing activities of a business to its

organizational goals and objectives is at the crux of

strategic sourcing. Better alignment allows the business to

achieve higher business performance with higher efficiency

and minimal supply chain risks.

Optimization of Ideal Suppliers

In order to effectively implement strategic sourcing in your

organization, it is necessary to analyze the suppliers, their

profiles, and core capabilities. Once this is accomplished,

an organization is equipped with information that will allow

them to match their business objectives to their ideal

suppliers. This implies highest value-creation at lowest-

possible cost.

Long-term Relationship Building with Suppliers

Strategic sourcing helps an organization build long-term

relationships with its suppliers. By reinforcing the focus on

the core capabilities of the suppliers and assuring the right

suppliers for the right sourcing objective, strategic sourcing

helps create a synergy between organizations and its

suppliers. Sustained relationship with suppliers also implies

that when the suppliers are valued and considered in

various sourcing decisions; they feel motivated to optimize

their performance to meet the organizations objectives.

How do we Implement Strategic

Sourcing?

..

7-Step Process to Effectively Implement Strategic

Sourcing in your Organization

Understanding the advantages of strategic sourcing brings

us to designing a process to implement strategic sourcing in

an organization. While a single process might not match the

specifications and requirements of every organization, we

can outline a basic structure that can guide the strategic

sourcing process:

Identification and Categorization of Spend Profiles

To initiate the strategic sourcing process, identify the spend

areas existent across all the business areas in the

organization and categorize it on the basis of how

critical/non-critical the spend area is. Categorization will

help prioritize the sourcing activities for each spend area.

If required, other categorization criteria that better suit the

business requirements can also be developed (e.g.:

domestic/international spend, direct/indirect spend). In such

cases, it is important to do a risk analysis of the chosen

spend categories to help prioritize and develop strategies.

Building a Sourcing Strategy

The second step includes building a strategy on how each

categorized spend area will be approached. This involves

identifying the requirements of the business units that

necessitate spending and defining goals, objectives, and

corresponding timelines to fulfill the requirements. This also

necessitates building a communication workflow so that all

stakeholders relevant to the respective sourcing projects

have clear visibility of upcoming updates.

Analysis of the Supplier Market

The third step is to execute an in-depth analysis of the

current and future suppliers to understand and evaluate

relevant supplier profiles. This includes analyzing the

revenue or market share of suppliers to understand their

market standing and industrial performance along with the

risks and opportunities surrounding the supplier market.

Request for Supplier Information and Identification

of Selection Criteria

Once the supplier market research is completed, the fourth

step is to request RFIs/RFPs/RFQs from suppliers. It is

important to communicate the exact requirements of the

organization as well as the end-goals and performance

expectations so that the suppliers have clear understanding

of what the organization needs. This is important so that

they provide an accurate roadmap and develop strategies to

fulfill the business’s objectives.

The submitted information will provide insightful data—the

pricing structure, delivery and warranty provisions,

product/service specifications etc. After the submitted data

is collated, the selection criteria can be identified for

supplier selection.

Selection of Suppliers and Execution of Contracting

Process

After the selection criteria are identified, the fifth step is to

choose the suppliers that can offer the highest level of cost

savings along with delivering quality. After supplier selection

for the relevant spend areas, the contracting process starts

to on-board the suppliers.

Measurement and Periodic Tracking of Supplier

Performance

The process of strategic sourcing doesn’t end at choosing a

supplier. The sixth step is to effectively measure how

suppliers perform vis-à-vis the requirements and objectives

of the organization. It is important to engage in periodic

tracking of supplier performance and identify areas for

improvement. This can significantly help organizations

understand supplier risks and design strategies to mitigate

all possible supply chain disruptions.

Implementation of Supplier Relationship

Management (SRM)

The seventh step is factoring Supplier Relationship

Management (SRM) in the strategic sourcing process which

makes the relationship between the organization and

suppliers a loop instead of a one-way process. SRM

enhances the level of collaboration between an organization

and its suppliers by transforming a mere customer-buyer

relationship into strategic value partners. Both parties

participate in building propositions and innovative strategies

that optimize the sourcing needs of the organization. The

relationships that arise out of such synergized collaboration

are long-term and can be leveraged to further improve

supplier performance. More than just being the final step in

the strategic sourcing process, SRM links suppliers and

organizations in a way that both current and future

requirements are met in the most efficient and value-

maximizing manner.

Factors Driving Automation of Strategic

Sourcing

.

Automation is everywhere and procurement isn’t far behind.

Organizations are adopting eSourcing in order to streamline

their strategic sourcing activities and simplify the

complexities that surround it. A CIPS blog on ‘E-sourcing

can help your organisation collaborate on procurement’ by

Alun Morris talks about how eSourcing not only focuses on

finding the right suppliers for the right sourcing need, but

also enables various business units in an organization to

collaborate on their sourcing activities. This is necessary as

every department will have their unique set of sourcing

requirements. Organizations using eSourcing software

enables ‘end-users to source their own suppliers within the

bounds of necessary procurement and compliance rules.’

The end-users of an organization can easily use eSourcing

tools to gather competitive pricing from available suppliers

vis-à-vis e-tendering and select the right ones.

Here’s a list of key factors driving increased use of

eSourcing:

Enhanced Data Reporting and Increased Visibility

into Sourcing Projects

eSourcing platforms generate useful data regarding spend

activities of an organization, supplier performance, and

supply chain risk evaluation. The data will improve visibility

and also enable holistic assessments of the various on-

going sourcing activities, thereby allowing the organization

to make more informed sourcing decisions.

Robust Management of Key Spend Categories

Automaton of strategic sourcing activities helps identify and

categorize the various spend categories that exist in an

organization across business units. Improving visibility of

spend categories enables an organization to streamline and

control its spend activities.

Supply Chain Risk Assessment

eSourcing enables an organization to identify, evaluate, and

mitigate various risks that impede supply chain thereby

improving compliance. This expedites business

performance, reduces excessive spend due to supply chain

failures, and helps organizations cope with various external

and internal environmental disruptions. As an added bonus

of automating strategic sourcing, Pulse of Procurement

2018 identified Supply Risk Management as one of the key

procurement focus areas.

Higher Level of Accountability while executing

Sourcing Projects

An eSourcing platform showcases the workflow of sourcing

activities and its corresponding stakeholders. It enhances

the level of visibility, accountability, and compliance of all

the relevant stakeholders involved in respective sourcing

projects.

.

In a Nutshell

The attempt of this article is to demystify the various facets

of strategic sourcing—what it stands for and how it differs

from tactical sourcing, the advantages organizations

experience through strategic sourcing; its process and

factors that drive its automation.

Organizations are adopting strategic sourcing to establish a

holistic approach to manage their sourcing requirements

and to build a more proactive approach to the various

supply chain disruptions. By aligning the business goals and

requirements to the right suppliers with the right

capabilities, organizations maximize their performance and

gain a competitive edge over their peers. Furthermore, by

leveraging the power of automation technology for strategic

sourcing, business units are empowered to optimize their

sourcing.

Strategic sourcing is here to stay—it delivers cost savings

without compromising on quality. Are you there yet?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Federal CaseDocument3 pagesFederal CaseSasidharan Ravikumar100% (3)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BMW Supply Chain NowDocument26 pagesBMW Supply Chain Nowapi-239652082100% (4)

- Bunnell Corporation Is A Manufacturer That Uses Job-Order Costing.Document6 pagesBunnell Corporation Is A Manufacturer That Uses Job-Order Costing.laale dijaanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Problem 2Document19 pagesProblem 2Aaliyahkaye JulaoNo ratings yet

- Avion Inc CaseDocument1 pageAvion Inc CaseSasidharan RavikumarNo ratings yet

- Avion Inc CaseDocument1 pageAvion Inc CaseSasidharan RavikumarNo ratings yet

- Samsung PresentationDocument18 pagesSamsung PresentationAnonymous 7TICzzmzomNo ratings yet

- Sasi FMDocument17 pagesSasi FMSasidharan RavikumarNo ratings yet

- ICICI Bank LTD (ICICIBC IN) - StandardizedDocument51 pagesICICI Bank LTD (ICICIBC IN) - StandardizedSasidharan RavikumarNo ratings yet

- Ratio Analysis of ICICI Bank and Lloyds BankDocument12 pagesRatio Analysis of ICICI Bank and Lloyds BankSasidharan RavikumarNo ratings yet

- C3W2 03 Strategic Sourcing A Key Process of Category Management PDFDocument24 pagesC3W2 03 Strategic Sourcing A Key Process of Category Management PDFSasidharan RavikumarNo ratings yet

- C3W1 02 The Strategic Sourcing Process Article PDFDocument5 pagesC3W1 02 The Strategic Sourcing Process Article PDFSasidharan RavikumarNo ratings yet

- Session 6Document18 pagesSession 6Sasidharan RavikumarNo ratings yet

- # 2. Procurement Procedure - StepwiseDocument30 pages# 2. Procurement Procedure - StepwiseSasidharan Ravikumar50% (2)

- RSCM - Course Plan - Jan To May - 2021Document10 pagesRSCM - Course Plan - Jan To May - 2021Nimi AimaNo ratings yet

- Coca Cola FinalDocument5 pagesCoca Cola FinalKAINAT YASEENNo ratings yet

- Managing Product Lines and Brands - 10Document23 pagesManaging Product Lines and Brands - 10jesslynel100% (1)

- Process CostingDocument60 pagesProcess CostingKristine Angeli Gerona De MesaNo ratings yet

- Maverick Integrated Marketing LLP - Company Credentials PDFDocument39 pagesMaverick Integrated Marketing LLP - Company Credentials PDFgaurav_gsn05No ratings yet

- Purchasing - Receiving Options - Oracle SCM TodayDocument4 pagesPurchasing - Receiving Options - Oracle SCM TodayAtiqueNo ratings yet

- BL MasterDocument1 pageBL MasterLidia Meylin Rivero LoayzaNo ratings yet

- What Is Inventory ManagementDocument2 pagesWhat Is Inventory Managementkimola5gNo ratings yet

- A Blockchain Approach To Supply Chain Management (2019)Document10 pagesA Blockchain Approach To Supply Chain Management (2019)Lee Shyh HaurNo ratings yet

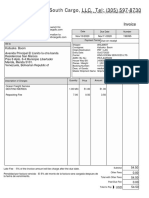

- South Cargo, LLC. Tel: (305) 597-8730: InvoiceDocument1 pageSouth Cargo, LLC. Tel: (305) 597-8730: InvoiceChevyveronaNo ratings yet

- Case Study On Master BudgetDocument8 pagesCase Study On Master BudgetMusaib Ansari100% (1)

- Chapter 1 - Business Functions and Business ProcessesDocument45 pagesChapter 1 - Business Functions and Business ProcessesĐạt PhạmNo ratings yet

- Chapter-2-Answer Cost AccountingDocument18 pagesChapter-2-Answer Cost AccountingJuline Ashley A Carballo100% (1)

- CHECKLIST1Document14 pagesCHECKLIST1Rudro KumarNo ratings yet

- Retail Management Chapter 3 Evaluating RDocument74 pagesRetail Management Chapter 3 Evaluating RMd Ghulam RabbanyNo ratings yet

- C4 - Warehousing ManagementDocument41 pagesC4 - Warehousing ManagementTuyết TrinhNo ratings yet

- Pengetahuan TPM 1Document30 pagesPengetahuan TPM 1bayoepoetroNo ratings yet

- Parker Drilling I Ms ManualDocument34 pagesParker Drilling I Ms ManualMANDY CROTONNo ratings yet

- TOP 20 Resource Software: Enterprise PlanningDocument9 pagesTOP 20 Resource Software: Enterprise PlanningmanojnarainNo ratings yet

- CIT 224 Omega Practice Questions 2021 - 2022 AnsweredDocument18 pagesCIT 224 Omega Practice Questions 2021 - 2022 AnsweredChristopher NakpodiaNo ratings yet

- Value Chain AnalysisDocument14 pagesValue Chain AnalysisVivek Kumar Gupta100% (5)

- Marketing Management: Presented By: Syeda Huma Ali - 22812 Muhammad Umair Ul Haque - 22953Document4 pagesMarketing Management: Presented By: Syeda Huma Ali - 22812 Muhammad Umair Ul Haque - 22953Mubashir HasanNo ratings yet

- Inventory Management MaterialDocument18 pagesInventory Management Material719 Sowmiya. SNo ratings yet

- Conference Schedule: International Conference Agile ManufacturingDocument11 pagesConference Schedule: International Conference Agile ManufacturingSudeep Kumar SinghNo ratings yet

- WalmartDocument10 pagesWalmartAnonymous 1RSbCRE7mJNo ratings yet

- Chapter 01 - INCOTERMS 2000 - 2010 - 2020Document100 pagesChapter 01 - INCOTERMS 2000 - 2010 - 2020Anh NguyễnNo ratings yet