Professional Documents

Culture Documents

United States Patent 19: Allentown, Pa. Feed Dinitrotoluene Is Water Washed To Remove HNO3 To

Uploaded by

Rafi Theda Prabawa0 ratings0% found this document useful (0 votes)

6 views5 pagesx

Original Title

Us 4224249

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentx

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views5 pagesUnited States Patent 19: Allentown, Pa. Feed Dinitrotoluene Is Water Washed To Remove HNO3 To

Uploaded by

Rafi Theda Prabawax

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

United States Patent 19 11 4,224,249

Kunz et al. (45) Sep. 23, 1980

54 TOLUENE DIAMINE FROM NON-WASHED Attorney, Agent, or Firm-Russell L. Brewer; E. Eugene

DNITROTOBLUENE Innis

57 ABSTRACT

75 Inventors: Nance D. Kunz, Bethlehem; Thomas This invention relates to an improvement in a process

A. Johnson, Orefield; Barton

Milligan, Coplay, all of Pa. for preparing toluene diamine. The improvement re

sides in a process which is capable of permitting reduc

73 Assignee: Air Products and Chemicals, Inc., tion of dinitrotoluene to toluene diamine without prior

Allentown, Pa. alkaline treatment for removal of nitrocresols in the

21 Appl. No.: 38,976

dinitrotoluene. In carrying out the improvement the

feed dinitrotoluene is water washed to remove HNO3 to

22 Filed: May 14, 1979 a level below 6000 ppm, and the catalytic conversion of

dinitrotoluene to toluene diamine is done continuously.

51. Int. Cl. ....................... C07C 85/11; CO7C 85/26 Dinitrotoluene is charged to a reaction vessel contain

52 U.S. C. .................................... 260/580; 260/582; ing a liquid carrier and reduced with hydrogen at con

260/689; 260/705 stant pressure, the dinitrotoluene being added at a rate

58) Field of Search ................................ 260/580, 582 to maintain a concentration of dinitrotoluene of 0.0001

to 25% by weight of the total reactor contents while the

56) References Cited hydrogenation catalyst is maintained at a level from

U.S. PATENT DOCUMENTS about 0.1 to 3% based on the weight of reactor con

tents.

3,546,296 12/1970 Gobron et al. ...................... 260/580

Primary Examiner-John Doll 5 Claims, No Drawings

4,224,249 2

1.

lytic hydrogenation of dinitrotoluene. The improve

TOLUENE DAMNE FROM NON-WASHED ment resides in the ability to utilize a crude dinitrotol

DNITROTOLUENE uene feedstock prepared by the mixed H2SO4/HNO3

acid nitration of toluene which has not been subjected

BACKGROUND OF THE INVENTION to alkaline treatment as a reactant. The improvement in

1. Field of the Invention the basic process of preparing toluene diamine by react

This invention relates to a process for producing withnon-alkaline

ing treated crude dinitrotoluene feedstock

toluene diamine from an impure dinitrotoluene reactant. lyst comprises: the presence of a hydrogenation cata

hydrogen in

2. Description of the Prior Art (a) water washing the crude feedstock to reduce the

U.S. Pat. No. 2,131,734 is typical of the early pro 10 acid concentration in the feedstock to less than 6,000

cesses for the liquid phase hydrogenation of dinitrotol

uene to toluene diamine. Typically, the hydrogenation ppm, if above;

(b) continuously introducing dinitrotoluene and hy

was carried out in the presence of nickel supported on a

silica substrate and in the presence of a small amount of drogen to a reactor vessel,

an alkaline substance such as caustic soda. Typical 15 (c) maintaining a concentration of dinitrotoluene

amounts of catalysts were 0.5-2% catalyst metal by from about 0.0001 to 25% by weight;

weight of the dinitrotoluene. Temperatures were from (d) maintaining a hydrogenation catalyst concentra

80 to 140 C. and pressures were from 200 to 500 tion of about 0.1 to 20% by weight of liquid reaction

pounds per square inch. mass; and

U.S. Pat. No. 2,976,320 represented an improvement (e) utilizing a hydrogenation catalyst containing a

over the early liquid phase hydrogenation processes of metal selected from the group consisting of nickel, co

dinitrotoluene. In that process, the temperature of reac balt, chromium and iron.

tion was reduced to less than 100° C. to prevent hazards Several advantages are associated with the improve

due to the instability of the dinitrotoluene. Low temper 25 ment of this invention, and these advantages include:

ature hydrogenation was accomplished by first reduc an ability to hydrogenate dinitrotoluene without

ing the nitrocresol content in the feed and then using a prior alkaline treatment for reducing alleged catalyst

palladium or platinum catalyst to effect hydrogenation. poisoning nitrocresols and nitrophenols;

It was reported that nitrophenols or nitrocresols, which an ability to eliminate alkaline treatment of dinitroto

are normally present in commercial dinitrotoluenes, are 30 uene without adversely effecting hydrogenation condi

catalyst poisons and decomposition accelerators, and tions, thus saving on the expense of chemicals;

that by limiting the concentration to less than 500 ppm, an ability to reduce the problems associated with

and preferably 200 ppm, a dinitrotoluene could be hy environmental disposal of nitrocresol and nitrophenol

drogenated safely at low temperatures. One of the typi salts as associated with the prior art by virtue of the

cal ways of removing the nitrocresols and nitrophenols

was by washing the crude dinitro product, obtained by 35 elimination

an ability

of the alkaline treatment; and

to hydrogenate non-alkaline washed dini

separation from the spent nitration acid, with dilute trotoluene without noticeable loss of catalyst life or

aqueous alkali (e.g., sodium carbonate solution). The product, toluene diamine purity.

product then was water washed.

U.S. Pat. No. 3,093,685 discloses a liquid phase pro DESCRIPTION OF THE PREFERRED

cess for reducing dinitrotoluene to toluene diamine with EMBOOMENTS

the improvement residing in carrying out the reduction Dinitrotoluene which is used as a reactant in the

in the presence of water of reaction with no other sol present process is produced conventionally by nitrating

vent or diluent being added.

U.S. Pat. No. 3,356,728 differs from the patents previ toluene using the mixed acid technique. In this process,

ously cited in that it relates to a continuous process for sulfuric acid,isand

45 the toluene reacted with a mixture of nitric acid,

water under conditions effective for

reducing dinitrotoluene to toluene diamine. It was dis producing dinitrotoluene. Conventionally, the crude

closed that various operating problems such as poor

catalyst life and operating hazards due to the instability adinitrotoluene is removed from the reactor, passed into

phase separator and the product. separated from the

of the dinitrotoluene could be minimized by using the 50 aqueous

continuous process wherein the catalyst was present in product isacid phase. Further purification of the crude.

effected by washing with water to remove

about 2 to 25% by weight of the slurry with extremely

low concentrations of dinitrotoluene as the reactant. contaminant acid material followed by treatment with

The level of nitro compound was maintained at 0.15 an alkali, e.g. sodium carbonate to reduce the level of

pound equivalents nitro groups per pound of catalyst. nitrocresols and nitrophenols (nitrophenolic material) in

Temperatures of 100-140 C. and pressures of 55 the dinitrotoluene product. As noted in the prior art, the

100-2000 psig, preferably 200-500 psig hydrogen were primary purpose of the alkaline treatment was to re

move the nitrocresols and nitrophenols as these compo

used. Raney nickel catalyst was used in the hydrogena nents were believed to reduce catalyst life during the

tion procedure. reduction of the dinitrotoluene to toluene diamine.

U.S. Pat. No. 3,546,296 relates to another continuous

process for producing toluene diamine by the reduction 60 The process of this invention can tolerate crude dini

of dinitrotoluene utilizing specific reactor equipment. trotoluene which has not been treated with alkaline

Again, the concentration of dinitrotoluene in terms of material as a reactant and even permit concentrations of

the catalyst is extremely low so as to reduce operating nitrocresols and nitrophenols to at least a level of 1200

hazard. parts per million (ppm). Under the batch processes,

65 these concentrations of nitrocresols and nitrophenols

SUMMARY OF THE INVENTION could not be tolerated as evidenced by U.S. Pat. No.

This invention relates to an improvement in a contin 2,976,320. Although not intending to be bound by the

uous process for preparing toluene diamine by the cata ory, it is speculated that the batch hydrogenation pro

4,224,249

3 4.

cess was not sensitive to nitrocresols and nitrophenols The following examples are provided to illustrate the

as reported but rather was sensitive to acid. This belief invention and all the parts and percentages are by

is based on information from the continuous process of weight unless otherwise specified.

this invention which shows an acid concentration of

above 6,000 ppm seriously diminishes catalyst life and 5 EXAMPLE 1.

increases tar while the reaction appears relatively insen The hydrogenation of dinitrotoluene was conducted

sitive to nitrophenolic material. In the prior art the in several runs to determine the effectiveness of the

alkaline treatment not only removed both nitrocresols process. The reactor used was a stirred one liter Parr

and nitrophenols but also the acid, and apparently based 316 stainless steel autoclave. The dinitrotoluene was

on the improved results obtained it was perhaps 10 charged to the autoclave on a semi-continuous (pulse)

wrongly concluded that catalyst life was sensitive to basis with the product being removed from the auto

nitrocresols, etc. rather than acid. Based on experimen clave in corresponding intermittent relationships so that

tal data water washing of the contaminated dinitrotol a constant volume of 500 milliliters was maintained in

uene is all that is necessary in the continuous process if the autoclave. The crude dinitrotoluene fed to the reac

the acid concentration is above 6,000 ppm. Water wash- 15 tor had the following general analysis and was obtained

ing is usually conducted so the acid level is 2,500 ppm from a commercial production unit after it had been

or below. washed with water (WW DNT) but not being exposed

The temperatures and pressures utilized in the pro to sodium carbonate treatment. The control was both

cess remain unchanged from the prior art and, for exam water washed and carbonate treated.

ple, such temperatures are generally from about 50 to 20

200 C. but preferably at a temperature of from about Dinitrotoluene 99.0%

90° to 130 C. Hydrogen pressures of 25-2000 psig can Nitrophenolic material 0.080%

be utilized, but generally the pressures are from about Nitric Acid 1200 ppm

100-250 psig. Balance approximately 1%

The hydrogenation of dinitrotoluene is carried out in 25

the presence of a hydrogenation catalyst. Any of the First the autoclave was charged with 500 ml of a

various non-precious metal catalysts which have been mixture of 60% toluene diamine and 40% water by

disclosed in the prior art promoting this reaction may be weight containing about 0.4% by weight pyrophoric

employed. These catalysts may be pelleted, granular, or Raney nickel catalyst having a particle size of from 1 to

powdered, although the powdered form having a parti 30 350 microns. Then the contents were heated in the

cle size of from 1-350 microns is preferred. Metals that

can be used for forming the catalyst are nickel, nickel autoclave to a temperature of 130° C. and then the

autoclave was pressurized with hydrogen. Although

promoted by cobalt, chromium, molybdenum and iron. the operation was a semi-batch mode because of inter

Raney nickel type catalysts are the preferred catalysts mittent feed and intermittent removal of product the

since in the continuous process they are relatively insen 35 operation was deemed continuous because the auto

sitive to nitrophenolic material. The hydrogenation clave remained at substantially constant volume and the

catalyst metals may be present on a support such as pulse rate was relatively rapid. The dinitrotoluene was

kieselguhr, silica, silica-alumina, and alumina although fed to the reactor at a rate of 1.45 gms/minute which

in the preferred case the Raney nickel type catalysts are translates to turnover numbers of 43.6 parts DNT re

unsupported.

The proportion of hydrogenation catalyst utilized in duced per hour per part catalyst and a maximum con

the reaction is quite low, e.g. from about 0.10 to 20% centration of about 0.3% DNT. The average reaction

time allowed for the dinitrotoluene was about 1-1.5

preferably from about 0.1 to 3%. When the concentra minutes even though the reduction takes place almost

tion of catalyst exceeds about 2% by weight little im instantly.

provement is realized. When the catalyst level falls 45

Table 1 represents two runs, one as a control wherein

below about 0.1% by weight there is insufficient cata the dinitrotoluene had been exposed to sodium carbon

lyst to effect rapid hydrogenation of the dinitrotoluene ate treatment with the result that practically no nitro

and long residence times are required. phenolic material or acid was present (control) and the

The proportion of dinitrotoluene is maintained in a other using

proportion of 0.0001 to 25% by weight of the reaction 50 material hadthe feed above wherein the nitrophenolic

mixture. Preferred results utilize a concentration of acid due to waterbeen

not removed but only the residual

washing (WWDNT). Results are as

0.01-3%.

follows in Table 1. Catalyst concentration, pressures

and other variables are given.

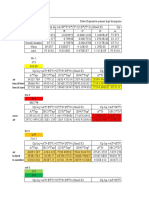

TABLE 1.

Run #1 Run #2

Control WWDNT

Temperature (C.) 130 130

Pressure (psig) 160 160

Catalyst Conc. (wt.%) 4(a) 4(a)

Operating mode incremental feed() incremental feed

Vapor phase H2 Concentration (%) 100 100

Catalyst Feed Mode batch batch

- - gmol H2 1.37 x 10-4 9.34 X 10-5

Initial Activity

(min) (gm cat) (cm)

Tar generation (%) 0.2-1.3% 0.1-2%

Turnover part DNT 43.62 43.62

hr. part cat.

Catalyst life-partPNT- 1975 1885 (minimum)(c)

part cat

4,224,249 6

TABLE 1-continued

Run #1 Run #2

Control WWDNT

Deactivation rate initial rate

-0086%. gn initial rate

DNT reduced

-009.1% gm DNT reduced

97,

Material balance closure (%) 94.7

(2 gms of catalyst in 500 gm reaction mass

With pulse-in, pulse out systems autoclave liquid volume was maintained at 500 ml.

Experiment terminated at this point; exhausted dinitrotoluene feed stock.

The results show that water washed dinitrotoluene

could be hydrogenated without an adverse effect on

catalyst life or rate of reaction. The catalyst perfor -continued

mance in Run 2 was substantially the same as Run 1 and FEED Compositions

it was lower only because of an exhausted feedstock. 15 Run #3 Run #4

Tar generation was slightly higher in Run 2. This value Control WWDNT

Feed

may not represent any greater loss of material since tar Analysis/Sample DNT Feed

generation in Run 1 does not include the nitrophenolic Oxalate (ppm) 0.2

2.47 0.4

170 44

material removed by alkali treatment. Acetate (ppm)

20

. . . . EXAMPLE 2. The results are given in Table 2. . . .

The procedure of Example 1 was repeated except The results in terms of catalyst activity and reaction

that different feed and higher catalyst concentrations rate for both the control and the water washed dini

were used. The feed analyzed as follows for the alkaline trotoluene appeared to be similar. Slightly higher tar

treated dinitrotoluene feed and the water washed dini 25 generation with the water washed dinitrotoluene, was

trotoluene feed. noted. It is also noted the reaction is relatively insensi

TABLE 2. tive to nitrophenolic material as the concentration was

about 700 ppm. Table 3 below represents analysis of the

Run i3 Run i4

Control WWDNT percentage tar versus the grams of dinitrotoluene re

Temperature ("C.) 130 130 duced per gram of catalyst.

Pressure (psig) 160 60 TABLE 3

Catalyst Conc, (wt.%) 1.7(a) 1.7(a)

Operating mode incremental feed() incremental Tar Analyses (wt %)

feed(b) Run #3 Run #4

Vapor phase 35 Gms. DNT % Reaction Control WWDNT

H2 Concentration (%) 100 100 Reduced Per Mass Produced DNT DNT

Catalyst Feed Mode batch batch Gm. Catalyst From Feed % Tar (ppm) % Tar (ppm)

Initial Activity 3.67 x 10-5 3.67 x 10-5 0. 0. 0.42 5.0 0.482 5.0

gmol H2 59.5 5.9 1.02 5.0 0.888 5.0

(min) (gm cat) (cm) 6,8 76.4 1.28 50 0.99 5.0

Tar generation (%)() .4-1.28% 48-1.75% 40 175.3 88.6 1108 5.0 1.30 5.0

Turnover part DNT 2.03 21.03 233.2 94.4 1.27 5.0 1.54 5.0

hr, part cat. 289.1 97.24 0.904 5.0 1.66 5.0

Material balance 95.5 96.8 300.2 97.7 1,28 5.0 1.75 5.0

closure (%)

(a8.5 grams catalyst in 500gm. reaction mass

(with pulse-in, pulse-out systems autoclave liquid volume was maintained at 500 45 Table 3 shows that the tar concentration is slightly

ml. higher for the water washed dinitrotoluene feedstock

particularly at higher levels of dinitrotoluene reduced

per gram of catalyst. Even so the percent tar produced

FEED Compositions is relatively insignificant in terms of the benefit gained,

Run if3 Run #4 50 i.e. the ability to eliminate the alkaline treatment of

Control WWDNT dinitrotoluene and associated high chemical cost. Also,

Analysis/Sample DNT Feed Feed the process eliminates the environmental problems asso

Water (ppm) 4400 4800 100 ciated with the alkaline treatment.

Freezing pt. ("C.) 56.2.1 57.1 0.1

Acidity (ppm as H2SO4) 3000 - 200 55

EXAMPLE 3

Alkalinity (ppm as KOH) Nil Ni The procedure of Example 1 was repeated in order to

Cresols (ppm) 8 1 700 - 0

2,4,6 TNT (ppm) 730 - 40 100 + 30 determine the sensitivity of the process to acid concen

nitrobenzene (wt.%) 0.01 0.02 tration. The DNT feedstock used was product DNT

o-nitrotoluene (wt.%) 0.02 0.01 (control) spiked with nitric acid to an acid concentra

m-nitrotoluene (wt.%) 0.01 '0.01

p-nitrotoluene (wt.%) 0.02 0.01 60 tion of 10,000 ppm. The 10,000 ppm level was used as it

2,6 Dinitrotoluene (wt.%) 19.4 17.73 approximates the acid concentration of crude DNT

2,5 Dinitrotoluene (wt.%) 0.75 0.68 prior to water washing. In carrying out the test the

2,4 Dinitrotoluene (wt.%) 75.44 77.17 spiked DNT was continuously added to a reactor con

3,5 Dinitrotoluene (wt.%) 0.03 0.03

2,3 Dinitrotoluene (wt.%) 1,62 1.47 taining 40% H2O and 60% toluene diamine. During the

3,4 Dinitrotoluene (wt.%) 2.46 2.23 65 addition the acid concentration was monitored. The

Normalized isomer ratio 2,472,6

Nitrate (ppm)

79.7/20.2

0.3

81.3/18.7

092 - 20

hydrogenation was compared with water washed

Nitrite (ppm) 0.3507 60 - 8 DNT.

Sulfate (ppm) 0.69 0.26 230 - 50 The results are in Table 4.

7

4,224,249

8

TABLE 4 stock without alkaline treatment with hydrogen which

Product DNT with

comprises:

WW DNT 10,000 ppm HNO3 (a) water washing the crude feedstock to reduce the

Initial Acitivity acid concentration in the feedstock to less than

(mol H2/min. g cat. cm) 3.67 x 105 6.0 x 10-5 5 6000 ppm;

Final Activity

(mol H2/min. g cat. cm) 3.67 x 10- 2.03 x 10-5

(b) continuously introducing dinitrotoluene and hy

Tar Generation (Wt. 7%) 1.7 4 at 6000 ppm drogen to a reaction vessel;

HNO3 (c) maintaining the concentration of dinitrotoluene in

10-30 above 6000

O

a range from about 0.0001 to 25% by weight;

Catalyst Life

ppm HNO3 (d) maintaining a hydrogenation catalyst concentra

gm DNT/gm cat. 800 220 tion of from about 0.1 to 20% based on the weight

Nitrobody in reactor 5 5 below 6000 ppm of reactor contents; and

(ppm) HNO3 (e) utilizing a hydrogenation catalyst containing a

5500 above 6000 ppm

HNO3 15

metal selected from a group consisting of molybde

num, nickel, cobalt, chromium, iron and mixtures

thereof,

Final catalyst activity of the product DNT corrected 2. The process of claim 1 wherein said dinitrotoluene

for difference in volume to the activity of the WW concentration maintained in the reactor is from 0.01 to

DNT was 1.24x 10-5(mole H2/mingm cat cm). At 6000 ppm 20

3% by weight.

HNO3, based on feed concentration, the catalyst activ 3. The process of claim 2 wherein said catalyst level

ity had diminished by about , and shortly after the is maintained from 0.1 to 3%.

catalyst completely failed. 4. The process of claim 3 wherein said metal catalyst

What is claimed is: is Raney nickel.

1. In a process for preparing toluene diamine which 25 5. The process of claim 4 wherein the crude dini

comprises reacting dinitrotoluene with hydrogen in the trotoluene feedstock is water washed to the extent that

presence of a hydrogenation catalyst, the improvement the acid concentration issk notk above 2500 ppm.

for permitting reaction of the crude dinitrotoluene feed k s t

30

35

45

50

55

60

65

You might also like

- Nitrification and Denitrification in the Activated Sludge ProcessFrom EverandNitrification and Denitrification in the Activated Sludge ProcessNo ratings yet

- Toluenediamine PDFDocument15 pagesToluenediamine PDFAmalia RizkaNo ratings yet

- Us 3607021Document4 pagesUs 3607021haviedNo ratings yet

- United States Patent Office: Preparation of Affo Itrile by HydroDocument5 pagesUnited States Patent Office: Preparation of Affo Itrile by HydroAgnes Anggi SimanjuntakNo ratings yet

- Physiology and Kinetics of Autotrophic Denitrification by Thiobacillus DenitrificansDocument7 pagesPhysiology and Kinetics of Autotrophic Denitrification by Thiobacillus DenitrificansPatrick Antony Bent BowieNo ratings yet

- (IDP-C) Reduce Water Consumption in NT Plant.: Team ID (3XZXC87)Document15 pages(IDP-C) Reduce Water Consumption in NT Plant.: Team ID (3XZXC87)nirajkulkarni09No ratings yet

- Nitroglycerin manufacturing process and propertiesDocument5 pagesNitroglycerin manufacturing process and propertiesNana NannaNo ratings yet

- 1 s2.0 S0141391000000306 MainDocument4 pages1 s2.0 S0141391000000306 MainMuhammad AdeelNo ratings yet

- BCSJ 41 2508Document7 pagesBCSJ 41 2508JULIA REESE REYESNo ratings yet

- 1 s2.0 S0926860X98000210 MainDocument11 pages1 s2.0 S0926860X98000210 MainOwen KhosashiNo ratings yet

- US3870756 (Sudah)Document4 pagesUS3870756 (Sudah)aris_nurhidayatNo ratings yet

- United States Patent Office: Patented Sept. 27, 1966Document6 pagesUnited States Patent Office: Patented Sept. 27, 1966Aminatu JuriahNo ratings yet

- Eudes Lorençon, Diego C.B. Alves, Klaus Krambrock, Erick S. Ávila, Rodrigo R. Resende, Andre S. Ferlauto, Rochel M. LagoDocument9 pagesEudes Lorençon, Diego C.B. Alves, Klaus Krambrock, Erick S. Ávila, Rodrigo R. Resende, Andre S. Ferlauto, Rochel M. Lagohameed66No ratings yet

- Articulo - Sintesis de Tribencil EstañoDocument9 pagesArticulo - Sintesis de Tribencil EstañoFreider CaicedoNo ratings yet

- Project On NitrobenzeneDocument65 pagesProject On NitrobenzeneAmit Khosla80% (10)

- Liquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsDocument6 pagesLiquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsIJARP PublicationsNo ratings yet

- US patent describes dehydrogenation process using improved catalystDocument5 pagesUS patent describes dehydrogenation process using improved catalystandiNo ratings yet

- Method of Preparation of Triethanolamina Borate Us2785192Document3 pagesMethod of Preparation of Triethanolamina Borate Us2785192ROMAY MERECIASNo ratings yet

- United States Patent (19) : Hu Et AlDocument4 pagesUnited States Patent (19) : Hu Et AlSepti WidyaNo ratings yet

- Resume NanofibersDocument6 pagesResume NanofibersMarindia BorbaNo ratings yet

- Nitro Benzene Sai PDFDocument65 pagesNitro Benzene Sai PDFDeepak Pandey100% (1)

- Syrene Production by Dow Process RTDocument22 pagesSyrene Production by Dow Process RTAnonymous Ksq1dyPRhNo ratings yet

- Us 6288289Document16 pagesUs 6288289ade sefliaNo ratings yet

- Acryllonitrile UllmannDocument10 pagesAcryllonitrile UllmannZek ZhangNo ratings yet

- JM 7 39 1988Document2 pagesJM 7 39 1988blink scientificNo ratings yet

- Pce-Ii Unit-VDocument25 pagesPce-Ii Unit-Vanil kumarNo ratings yet

- Project ON NitrobenzeneDocument65 pagesProject ON NitrobenzeneRomil GandhiNo ratings yet

- Project ON NitrobenzeneDocument65 pagesProject ON NitrobenzeneRomil GandhiNo ratings yet

- IIT Guwahati Green Chemistry Mid-Semester ExamDocument8 pagesIIT Guwahati Green Chemistry Mid-Semester ExamBhavik2002No ratings yet

- 1 Bài Nghiên C UDocument9 pages1 Bài Nghiên C UTHỊ HÀ NGUYỄNNo ratings yet

- Chapter-2: Materials and MethodsDocument13 pagesChapter-2: Materials and Methodsdalton2003No ratings yet

- Chemosphere: Hui Wang, Hui-Long Wang, Wen-Feng JiangDocument7 pagesChemosphere: Hui Wang, Hui-Long Wang, Wen-Feng JiangZaharia MariusNo ratings yet

- United States PatentDocument4 pagesUnited States Patentwiam wiamNo ratings yet

- Aniline From Nitrobenzene 1Document11 pagesAniline From Nitrobenzene 1Neha MiracleNo ratings yet

- 2003 - H.K.Singh - Photocatalysed Degradation of A Herbicide Derivative, Bromacil, in Aqueous Suspensions of Titanium Dioxide PDFDocument6 pages2003 - H.K.Singh - Photocatalysed Degradation of A Herbicide Derivative, Bromacil, in Aqueous Suspensions of Titanium Dioxide PDFpablocolindresNo ratings yet

- Chitosan HydrochlorideDocument4 pagesChitosan Hydrochloridedivya tailorNo ratings yet

- Continuous removal of hydrogen peroxide using immobilised catalaseDocument7 pagesContinuous removal of hydrogen peroxide using immobilised catalaseRIVALDO MARSEL TNo ratings yet

- SOP AMBL 104A HardnessDocument5 pagesSOP AMBL 104A HardnessRamiAdelNo ratings yet

- Anju Ramakrishnan Thomas, Ajesh P. Suresh, Eringathodi Srinivasan, AlagarDocument2 pagesAnju Ramakrishnan Thomas, Ajesh P. Suresh, Eringathodi Srinivasan, AlagarDavid OcampoNo ratings yet

- United States Patent (19) : Correia Et AlDocument3 pagesUnited States Patent (19) : Correia Et AlVatsal KardaniNo ratings yet

- Patent Benzil KloridaDocument3 pagesPatent Benzil KloridaShochib Al FatihNo ratings yet

- Piric Acid PatentDocument2 pagesPiric Acid PatentOmar valdesNo ratings yet

- United States Patent (19) : Piccolo Et Al. 56 References CitedDocument8 pagesUnited States Patent (19) : Piccolo Et Al. 56 References Citednazanin timasiNo ratings yet

- Dehydration of Butanediol into Methyl Ethyl Ketone Using Solid Acid CatalystDocument9 pagesDehydration of Butanediol into Methyl Ethyl Ketone Using Solid Acid CatalysthidayahNo ratings yet

- Composition and Method For Sweetening HydrocarbonsDocument8 pagesComposition and Method For Sweetening HydrocarbonsIveth RomeroNo ratings yet

- pNO DPADocument4 pagespNO DPATri DoNo ratings yet

- Vol-1, Issue-5Document8 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- US4668495Document5 pagesUS4668495Chemist Ahmed FoudaNo ratings yet

- A Convenient Preparation of Volatile Acid ChloridesDocument4 pagesA Convenient Preparation of Volatile Acid ChloridesScott SwartzNo ratings yet

- Inhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aDocument8 pagesInhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aJohnSmithNo ratings yet

- Elsevier Sequoia S. A., Lausanne A Kaddmiai Kiad6, BudapestDocument8 pagesElsevier Sequoia S. A., Lausanne A Kaddmiai Kiad6, Budapestgonzalo7cornejo7ramiNo ratings yet

- Influence of Steaming Pressure On Steam Explosion Pretreatment of Lespedeza Stalks (Lespedeza Cyrtobotrya) - II. Characteristics of Degraded LigninDocument9 pagesInfluence of Steaming Pressure On Steam Explosion Pretreatment of Lespedeza Stalks (Lespedeza Cyrtobotrya) - II. Characteristics of Degraded Ligninnuljmal_535260430No ratings yet

- Us 4945186Document3 pagesUs 4945186J Venkat RamanNo ratings yet

- Increasing The Hydrophobicity of Filter Medium ParDocument14 pagesIncreasing The Hydrophobicity of Filter Medium ParDoua AbdouNo ratings yet

- US4094913Document4 pagesUS4094913Ranjana MadabushiNo ratings yet

- A Review Chemistry of PETN and Its ManufDocument9 pagesA Review Chemistry of PETN and Its ManufOmar valdesNo ratings yet

- Bor 3Document8 pagesBor 3petru apopeiNo ratings yet

- Hydrazine Formate ReductionsDocument3 pagesHydrazine Formate ReductionsPedro Mendonca100% (1)

- Ejurnal PDFDocument8 pagesEjurnal PDFdeby fiestaNo ratings yet

- Revised Version Decomposition of 2,4,6-Trinitrotoluene and Other Industrial Pollutants Using Pigment Derivatives and Visible LightDocument12 pagesRevised Version Decomposition of 2,4,6-Trinitrotoluene and Other Industrial Pollutants Using Pigment Derivatives and Visible LightBenjamin LukasNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 4Document74 pagesLampiran Pusri Rafi Theda Prabawa 4Rafi Theda PrabawaNo ratings yet

- The Rock MusicDocument7 pagesThe Rock MusicRafi Theda PrabawaNo ratings yet

- Rafi Theda Prabawa (121150069)Document1 pageRafi Theda Prabawa (121150069)Rafi Theda PrabawaNo ratings yet

- Rafi Theda 121150069Document7 pagesRafi Theda 121150069Rafi Theda PrabawaNo ratings yet

- Rafi Theda Prabawa (121150069)Document1 pageRafi Theda Prabawa (121150069)Rafi Theda PrabawaNo ratings yet

- Nama: Rafi Theda Prabawa Kelas: 9.7 No - Absen: 19Document3 pagesNama: Rafi Theda Prabawa Kelas: 9.7 No - Absen: 19Rafi Theda PrabawaNo ratings yet

- Nama: Rafi Theda Prabawa: Make Your Own BaksoDocument3 pagesNama: Rafi Theda Prabawa: Make Your Own BaksoRafi Theda PrabawaNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 5Document75 pagesLampiran Pusri Rafi Theda Prabawa 5Rafi Theda PrabawaNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 5Document75 pagesLampiran Pusri Rafi Theda Prabawa 5Rafi Theda PrabawaNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 1Document74 pagesLampiran Pusri Rafi Theda Prabawa 1Rafi Theda PrabawaNo ratings yet

- Rafi Theda Prabawa (121150069)Document1 pageRafi Theda Prabawa (121150069)Rafi Theda PrabawaNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 4Document74 pagesLampiran Pusri Rafi Theda Prabawa 4Rafi Theda PrabawaNo ratings yet

- Rafi Theda 121150069Document7 pagesRafi Theda 121150069Rafi Theda PrabawaNo ratings yet

- Rafi Theda PrabawaDocument1 pageRafi Theda PrabawaRafi Theda PrabawaNo ratings yet

- Us 1794057Document2 pagesUs 1794057Rafi Theda PrabawaNo ratings yet

- Lampiran Pusri Rafi Theda Prabawa 2Document73 pagesLampiran Pusri Rafi Theda Prabawa 2Rafi Theda PrabawaNo ratings yet

- Shiva R Kar 2005Document8 pagesShiva R Kar 2005Rafi Theda PrabawaNo ratings yet

- Us 7371903Document4 pagesUs 7371903Rafi Theda PrabawaNo ratings yet

- Aliran Fluida EksponensialDocument4 pagesAliran Fluida EksponensialRafi Theda PrabawaNo ratings yet

- Tugas Pap Rafi Theda Prabawa 121150069Document5 pagesTugas Pap Rafi Theda Prabawa 121150069Rafi Theda PrabawaNo ratings yet

- Sna Uwa Ert 1987Document7 pagesSna Uwa Ert 1987Rafi Theda PrabawaNo ratings yet

- BukuDocument4 pagesBukuRafi Theda PrabawaNo ratings yet

- Tugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Document2 pagesTugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Rafi Theda PrabawaNo ratings yet

- Tugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Document2 pagesTugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Rafi Theda PrabawaNo ratings yet

- Tugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Document2 pagesTugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Rafi Theda PrabawaNo ratings yet

- Tugas Mekanika Fluida - Pertemuan 13 - 121150069 - Rafi Theda PrabawaDocument3 pagesTugas Mekanika Fluida - Pertemuan 13 - 121150069 - Rafi Theda PrabawaRafi Theda PrabawaNo ratings yet

- NM CicelDocument144 pagesNM CicelRafi Theda PrabawaNo ratings yet

- Tugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Document2 pagesTugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Rafi Theda PrabawaNo ratings yet

- Tugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Document2 pagesTugas: Jurusan Teknik Kimia Fakultas Teknik Industri Universitas Pembangunan Nasional "Veteran" Yogyakarta 2020Rafi Theda PrabawaNo ratings yet

- SOR Qns AllDocument17 pagesSOR Qns AllPROgamer GTNo ratings yet

- CBSE Chemistry Class 11 (Mid Term Exam Model Paper)Document3 pagesCBSE Chemistry Class 11 (Mid Term Exam Model Paper)RounakNo ratings yet

- Topik 7 Kertas 1Document39 pagesTopik 7 Kertas 1faggotisyourmomNo ratings yet

- 114c ProposalDocument174 pages114c ProposalDimension LessNo ratings yet

- Erni-Mineralogy Simplified 1885Document442 pagesErni-Mineralogy Simplified 1885RonLaytonNo ratings yet

- Service Bulletin # 2Document13 pagesService Bulletin # 2fahadullahNo ratings yet

- Chemistry Project On Green Chemistry: Bio-Diesel and Bio-PetrolDocument18 pagesChemistry Project On Green Chemistry: Bio-Diesel and Bio-PetrolFerry Sofat82% (17)

- Cladding Degradation - ANL-WIS-MD-000008 REV 01Document126 pagesCladding Degradation - ANL-WIS-MD-000008 REV 01Артём ОстаповNo ratings yet

- Chemsheets As 008 (Amount of Substance)Document36 pagesChemsheets As 008 (Amount of Substance)takashi_leeNo ratings yet

- Chapter 9 Review Questions-KeyDocument3 pagesChapter 9 Review Questions-Keyapi-269764684No ratings yet

- Hydrogen in Material SelectionDocument5 pagesHydrogen in Material SelectionrajaNo ratings yet

- Diamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellDocument4 pagesDiamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellnguyenthanhhopNo ratings yet

- WBSSC LDC LDA 2016 Model Paper SET 1 (WWW - Examkadarrnahi.tk)Document7 pagesWBSSC LDC LDA 2016 Model Paper SET 1 (WWW - Examkadarrnahi.tk)Nisar HussainNo ratings yet

- H +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: QuestionsDocument98 pagesH +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: Questionsakky81No ratings yet

- Chemistry STPM Sem 3 MSAB Pre-Trial AnswerDocument2 pagesChemistry STPM Sem 3 MSAB Pre-Trial AnswerKenneth Chan100% (2)

- 2013 NJC H1 Chemistry Paper 1 Questions and AnswersDocument14 pages2013 NJC H1 Chemistry Paper 1 Questions and AnswersChow Kim WanNo ratings yet

- Butt CrackDocument33 pagesButt CrackElgen CabanagNo ratings yet

- Phoenix - Human Reliability Analysis of An Oil Refinery Operation Using The Phnoenix HRA MethodologyDocument8 pagesPhoenix - Human Reliability Analysis of An Oil Refinery Operation Using The Phnoenix HRA MethodologysteveNo ratings yet

- Semiconductor Fabircation FacilitiesDocument38 pagesSemiconductor Fabircation Facilitiesdg ds100% (2)

- BL Skill CH 3 Notes and TFDocument5 pagesBL Skill CH 3 Notes and TFapi-329922192No ratings yet

- Drug Design: Drug Structure & Pharmacological ActivityDocument55 pagesDrug Design: Drug Structure & Pharmacological ActivityMominul IslamNo ratings yet

- Molarity, Molality, Normality and Percentage ConcentrationDocument6 pagesMolarity, Molality, Normality and Percentage ConcentrationSami FlimbanNo ratings yet

- Anders Møller - FattyAcids Molecular Weights and Conversion FactorsDocument7 pagesAnders Møller - FattyAcids Molecular Weights and Conversion FactorsKellenchNo ratings yet

- 2.1 Energetics TestDocument8 pages2.1 Energetics TestLordie DlaNo ratings yet

- Report 06 2012Document47 pagesReport 06 2012Gabriel DiazNo ratings yet

- Advanced Solid Catalysts For Renewable Energy ProductionDocument11 pagesAdvanced Solid Catalysts For Renewable Energy ProductionOnggy Aries SekaNo ratings yet

- Paper 2 November 2001Document4 pagesPaper 2 November 2001MSH50% (4)

- Coordinate Bonding BasicsDocument12 pagesCoordinate Bonding BasicsVipul GuptaNo ratings yet

- Gas Cylinders RulesDocument9 pagesGas Cylinders Ruleshani_shaabanNo ratings yet

- Chemistry Lab# 4 (Completed)Document4 pagesChemistry Lab# 4 (Completed)tahjsalmon100% (1)