Professional Documents

Culture Documents

Compressor - Mando Project

Uploaded by

Kamalesh Kumar0 ratings0% found this document useful (0 votes)

12 views7 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views7 pagesCompressor - Mando Project

Uploaded by

Kamalesh KumarCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 7

A AIR COMPRESSOR SYSTEM

Supply, Erection, Testing and Commissioning of Air Cooled

Air compressor of Stationary, oil injected, screw

compressor driven by energy efficent motor of suitable

power rating with direct digital control. The compressor

units shall be enclosed inside a well sound insulator body

work to reduce the noise level considerably. The unit is

equipped with an automatic regulator to regulate the

1 operation of the compressor within the programmable

limits. The unit shall be Inbuilt after cooler. Rate shall be

inclusive of Microprocessor / PLC based control panel for

automatic operation of compressors including the

scheduling, sequencing, run time balacing, holiday mode,

power supply 415±10%V etc with RS 485 connectivity for

third party BMS system. The compressor capacity as

follows:

2400 m³/hr @ 8.5 Bar at compressor outlet - Indicative

Nos 2

motor rating: 300 kW

Supply, Erection, Testing and Commissioning of variable

frequency drive control panel of suitable power rating with

direct digital control. The unit is equipped with an automatic

regulator to regulate the operation of the compressor within

the programmable limits. The unit shall be Inbuilt after

cooler. Rate shall be inclusive of Microprocessor / PLC

2

based control panel for automatic operation of

compressors including the scheduling, sequencing, run

time balacing, holiday mode, power supply 415±10%V,

power cables from isolator to equipment, releated

accessories etc with RS 485 connectivity for third party

BMS system. The compressor capacity as follows:

a VFD motor rating: 300 kW

Supply, Erection, Testing and Commissioning of

Nos 1

12400000

Refrigerated Air Drier with Pressure Dew Point of +3 degC

with Environment Friendly Refrigerant R 410a / R 134a

having VSD fan to meet your fluctuating demand and

3

ensuring 100% moisture-free Air. The below mentioned air

flow rate in the required dry air discharge for the dryer. The

vendor shall select the suitable model dryer to get desired

dry air.

2400 m³/hr @ 8.5 bar. Nos 3

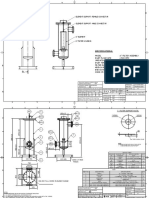

Supply, Erection, Testing and Commissioning of air

receiver of the following capacity, vertically mounted type

of mild steel construction suitable for a working pressure

as mentioned, with safety valve, auto and manual drain

4 valves, siphon pipe with pressure gauge and test

certificate. The shell & dish thickness, test pressure shall

be designed as per IS 2825. Rate shall be inclusive of 2

coats of Epoxy primer and 2 coats of epoxy paint inside

and outside both, supporting arrangements, etc.

10.0 m³ @ 8.5 bar Working pressure and 16 bar Tested

a Nos 2

pressure

Supply of Pre-filter unit capable of removing liquid water

5 and oil aerosol to 0.1 mg/m3 (0.1 ppm) and duct particles

down to 1.0 micron.

a 2400 m³/hr @ 8.5 Bar Nos 3

Supply of After-filter unit capable of removing liquid water

6 and oil aerosol to 0.01 mg/m3 (0.01 ppm) and duct

particles down to 0.1 micron.

a 2400 m³/hr @ 8.5 Bar Nos 3

TOTAL AMOUNT C/O TO SUMMARY

12400000

CLP 30 35 38

GA 55 VSD P 1987719 1391403 1292017 1232386

F 285 592431 414701.7 385080.2 367307.2

DD 215 107476 75233.2 69859.4 66635.12

PD 215 107476 75233.2 69859.4 66635.12

2 M3 70000 70000 70000 70000

2026571 1886816 1803001

40 SK CLP 30 35 40

1192631 1113123 GA 55 VSD FF 2567507 1797254.9 1668880 1540504

355458.6 296215.5 DD 215 107476 75233.2 69859.4 64485.6

64485.6 40000 PD 215 107476 75233.2 69859.4 64485.6

64485.6 40000 2 M3 70000 70000 70000 70000

70000 70000 2017721.3 1878598 1739475

1747061 1559338

1540504

40000

40000

70000

1690504

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Options Trader 0505Document43 pagesOptions Trader 0505mhosszu100% (2)

- Sample Letter of IntentDocument4 pagesSample Letter of IntentKaloyana Georgieva100% (2)

- Date Account & Explanation F Debit CreditDocument7 pagesDate Account & Explanation F Debit CreditCindy Claire Pilapil88% (8)

- Simulation Hybrid Cooling SystemDocument8 pagesSimulation Hybrid Cooling SystemAniruddha Gupta100% (1)

- 1) Cir v. Marubeni Corp-Duya (d2017)Document1 page1) Cir v. Marubeni Corp-Duya (d2017)joyceNo ratings yet

- Large Scale Solar Power System DesignDocument90 pagesLarge Scale Solar Power System Design김동욱No ratings yet

- H940C PartsDocument388 pagesH940C PartsRildo ChavesNo ratings yet

- Full View R1Document1 pageFull View R1Kamalesh KumarNo ratings yet

- Filter AsssemblyDocument2 pagesFilter AsssemblyKamalesh KumarNo ratings yet

- Airnet SteelDocument1 pageAirnet SteelKamalesh KumarNo ratings yet

- SK Assoicates Authorized DealerDocument1 pageSK Assoicates Authorized DealerKamalesh KumarNo ratings yet

- Project Electrical Health Check List: Elcb Cable Specification 3Ɵ Voltage in Volts Current in AmpsDocument5 pagesProject Electrical Health Check List: Elcb Cable Specification 3Ɵ Voltage in Volts Current in AmpsKamalesh KumarNo ratings yet

- GPS System Limitations: Known Geographic & Weather Related LimitationsDocument1 pageGPS System Limitations: Known Geographic & Weather Related LimitationsVaibhav PooniaNo ratings yet

- Cultural Innovation StationDocument5 pagesCultural Innovation StationAriana MuñozNo ratings yet

- Identifying Internal CustomersDocument7 pagesIdentifying Internal CustomersAshenafi AbdurkadirNo ratings yet

- GrihaDocument0 pagesGrihabharath18No ratings yet

- Haramaya Coa Assigment 2022Document16 pagesHaramaya Coa Assigment 2022wubie derebeNo ratings yet

- Electronics and Communication EngineeringDocument552 pagesElectronics and Communication EngineeringShylu SamNo ratings yet

- Corrupted Kingdoms RulesDocument11 pagesCorrupted Kingdoms RulesFathurzzyLaVecchiaSignoraNo ratings yet

- Satanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESDocument140 pagesSatanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESAston WalkerNo ratings yet

- (Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPODocument22 pages(Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPOHaziyah HalimNo ratings yet

- Ashcroft ThermometerDocument2 pagesAshcroft ThermometerjlcegarraNo ratings yet

- Health Economics 1St Edition Bhattacharya Solutions Manual Full Chapter PDFDocument36 pagesHealth Economics 1St Edition Bhattacharya Solutions Manual Full Chapter PDFjames.williams932100% (15)

- Amir Adnan Retain StoreDocument25 pagesAmir Adnan Retain StoreWaqas Mazhar100% (1)

- Blood Glucose Meter PDFDocument10 pagesBlood Glucose Meter PDFsneh1509No ratings yet

- Interrupts in Atmega16Document3 pagesInterrupts in Atmega16Anoop S PillaiNo ratings yet

- SALUDocument1 pageSALUShoaib ali QadriNo ratings yet

- BSBADM409Document27 pagesBSBADM409Diana PulidoNo ratings yet

- Effect of Social MediaDocument14 pagesEffect of Social MediaChaitanya PurohitNo ratings yet

- The EarthDocument12 pagesThe EarthKather ShaNo ratings yet

- New Crypto Lab FileDocument24 pagesNew Crypto Lab FilemyteamalokNo ratings yet

- Proposal NewDocument17 pagesProposal NewbaseNo ratings yet

- Free Movie Streaming Sites: Amazon Prime VideoDocument2 pagesFree Movie Streaming Sites: Amazon Prime VideoZakir AliNo ratings yet

- Real Advice On How To Cheat Turnitin in 2022Document1 pageReal Advice On How To Cheat Turnitin in 2022YandiNo ratings yet

- DEED OF EXTRAJUDICIAL SETTLEMENT AMONG HEIRS Moalboal2Document3 pagesDEED OF EXTRAJUDICIAL SETTLEMENT AMONG HEIRS Moalboal2cliford caballeroNo ratings yet