Professional Documents

Culture Documents

2020-08-05-Vernier Caliper MSA

Uploaded by

Venkateswaraa InsulationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2020-08-05-Vernier Caliper MSA

Uploaded by

Venkateswaraa InsulationCopyright:

Available Formats

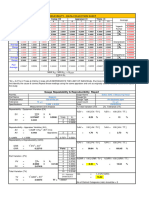

COMPANY NAME

MEASUREMENT SYSTEM ANALYSIS ( VARIABLE )

Customer Name : Stanson Rubbers Characteristics : Thickness Tolerance Range : 1.00

Part No : 20mm x 20mm x 40mm Gage No : VC-01 Specification : mm

Part Name : EPDM Sponge Gage Type : Vernier Caliper Performed By : Ramkumar

Date : 05.08.2020 Least Count : 0.01mm Approved By : PKS

No. of Parts (n) : 10 No. of Appraisers : 3 No. of Trials ( r ) : 3

Appraiser 1 Praveen Kumar Appraiser 2 Rajavel Appraiser 3 Paramasivan

Part Part

Trials Trials Trials

No Avg Range Avg Range Avg Range Average

1 2 3 1 2 3 1 2 3

1 19.58 19.79 19.76 19.710 0.210 19.65 19.77 19.74 19.720 0.120 19.61 19.77 19.77 19.717 0.160 19.716

2 20.63 20.65 20.64 20.640 0.020 20.64 20.65 20.57 20.620 0.080 20.56 20.60 20.61 20.590 0.050 20.617

3 20.76 20.81 20.81 20.793 0.050 20.78 20.82 20.77 20.790 0.050 20.71 20.78 20.82 20.770 0.110 20.784

4 20.38 20.39 20.39 20.387 0.010 20.36 20.45 20.37 20.393 0.090 20.29 20.37 20.37 20.343 0.080 20.374

5 20.96 21.11 21.08 21.050 0.150 20.99 21.09 20.97 21.017 0.120 21.02 20.88 20.91 20.937 0.140 21.001

6 21.04 21.08 20.97 21.030 0.110 21.04 21.02 21.00 21.020 0.040 21.01 20.91 20.78 20.900 0.230 20.983

7 20.61 20.68 20.69 20.660 0.080 20.65 20.71 20.65 20.670 0.060 20.63 20.52 20.63 20.593 0.110 20.641

8 20.56 20.67 20.66 20.630 0.110 20.62 20.71 20.68 20.670 0.090 20.61 20.65 20.65 20.637 0.040 20.646

9 20.52 20.59 20.53 20.547 0.070 20.51 20.61 20.59 20.570 0.100 20.61 20.63 20.55 20.597 0.080 20.571

10 20.71 20.83 20.79 20.777 0.120 20.78 20.88 20.81 20.823 0.100 20.80 20.73 20.79 20.773 0.070 20.791

X1 20.622 X2 20.629 X3 20.586

R1 0.0930 R2 0.0850 R3 0.1070

R= R1 + R2 + R3 / No. Appraisers 0.09500 Trial # D4 D3 Rp

Xdiff = Max. of X1,X2,X3 - Min. of X1,X2,X3 0.04367 2 3.267 0 1.2856

UCL = R x D4 0.24453 D4 = 2.574 3 2.574 0

LCL = R x D3 0.00000 D3 = 0

Measurement Unit Analysis Percentage Analysis

Repeatability - Equipment Variation (EV) % of Total Variation % of Tolerance

EV = R x K1 Where, Trial 2 3 EV = 13.73% 5.6%

= 0.0561 K1 = 0.5908 K1 0.8862 0.5908

Reproducibilty - Appraiser Variation (AV) % of Total Variation % of Tolerance

AV = AV = 4.99% 2.04%

Where, = 0.0204 Appraiser 2 3

K2 = 0.523 n = 10 r= 3 K2 0.7071 0.5231

Part Variation (PV) % of Total Variation % of Tolerance

PV = Rp x K3 PV = 98.93% 40.4%

= 0.4044

Where, Part 5 6 7 8 9 10

K3 = 0.315 K3 0.4030 0.3742 0.3524 0.3375 0.3249 0.3146

Gage Repeatability and Reproducibility (GR&R) % of Total Variation % of Tolerance

GR & R = GR&R = 40.88% 6.0%

= 0.0597

Total Variation (TV) No. of Distinct Data Categories (ndc)

TV = ndc =

= 0.4088 = 9.548

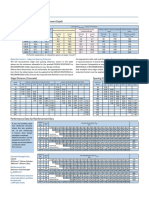

Graphical Analysis

Part Average by Appraiser Range by Appraiser

21.500

0.250

21.000

0.200

20.500

0.150

20.000

0.100

19.500 0.050

19.000 0.000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Appraiser 1 Appraiser 2 Appraiser 3 Appraiser 1 Appraiser 2 Appraiser 3

Result of this Gage R & R : Measurement System is Acceptable and Good Discrimination ability

You might also like

- Particle size analysis of Inicio DSM Tolva materialDocument7 pagesParticle size analysis of Inicio DSM Tolva materialCarlos M. LópezNo ratings yet

- Chapter Two: Measuring Horizontal DistanceDocument18 pagesChapter Two: Measuring Horizontal DistanceWelday Gebremichael100% (2)

- Activity 3.1a Linear Measurement With Metric UnitsDocument4 pagesActivity 3.1a Linear Measurement With Metric Unitsluis quizhpiNo ratings yet

- Manual Alineador Laser TKSA 20Document336 pagesManual Alineador Laser TKSA 20Agustin50% (2)

- Sieve Analysis Test ResultsDocument2 pagesSieve Analysis Test ResultsRajinda BintangNo ratings yet

- Tres Curvas PDFDocument1 pageTres Curvas PDFPaulina SalgadoNo ratings yet

- Curve Superelevation CalculationDocument7 pagesCurve Superelevation CalculationKhan EngrNo ratings yet

- AnalysisDocument3 pagesAnalysisAnnamarie SanDiegoNo ratings yet

- Hasil Hydrometer Dan Sieve AnalysisDocument6 pagesHasil Hydrometer Dan Sieve AnalysisEko NugrohoNo ratings yet

- VC-V15-9AG Particle Size Analysis ReportDocument1 pageVC-V15-9AG Particle Size Analysis ReportPaulina SalgadoNo ratings yet

- Hydrometer - Lot-2, Chancho, 2.70Document1 pageHydrometer - Lot-2, Chancho, 2.70ALEX BNo ratings yet

- Tabla de Impedancia Cables Media TensionDocument7 pagesTabla de Impedancia Cables Media Tensionvcontrerasj72No ratings yet

- Cone Penetration Test Soil DataDocument48 pagesCone Penetration Test Soil Datasmart mediaNo ratings yet

- GRAIN SIZE ANALYSIS RESULTSDocument13 pagesGRAIN SIZE ANALYSIS RESULTSImran KhanNo ratings yet

- 7,-Qad-28sample Inspection Report Mach. 74-100Document1 page7,-Qad-28sample Inspection Report Mach. 74-100azadsingh1No ratings yet

- Sieve Analysis Aashto T 27 - Astm D 421: Item: Hot Mix (Ac. WC) Location: Hot Bin I Date: 18 - 11 - 2008Document43 pagesSieve Analysis Aashto T 27 - Astm D 421: Item: Hot Mix (Ac. WC) Location: Hot Bin I Date: 18 - 11 - 2008Irma Aprillia LubisNo ratings yet

- R&R StudyDocument1 pageR&R StudyDr Rajamani R - PSGCTNo ratings yet

- Hydrometer - Lot-2, Chancho, 1.50Document1 pageHydrometer - Lot-2, Chancho, 1.50ALEX BNo ratings yet

- Tromp Curve Calculations and ResultsDocument3 pagesTromp Curve Calculations and Resultsrecai100% (2)

- GRRDocument2 pagesGRRCarlos Alberto Loredo AguirreNo ratings yet

- Sieve and hydrometer analysis of soil sampleDocument1 pageSieve and hydrometer analysis of soil sampleAkram MuzakkiNo ratings yet

- Universitas Islam Sumatera Utara: Sieve Analysis (ASTM D-422-63 & D-1140-54)Document1 pageUniversitas Islam Sumatera Utara: Sieve Analysis (ASTM D-422-63 & D-1140-54)Akram MuzakkiNo ratings yet

- CALCULO DE LA RED DOMICILIARIA DE AGUA POTABLEDocument13 pagesCALCULO DE LA RED DOMICILIARIA DE AGUA POTABLECarlos Enrique Diaz ReyesNo ratings yet

- National Highways: Quality Control Division, Madurai Benkelman Beam Deflection TestDocument35 pagesNational Highways: Quality Control Division, Madurai Benkelman Beam Deflection Testk.shanmuganathanNo ratings yet

- Fatigue life prediction model for asphalt samplesDocument17 pagesFatigue life prediction model for asphalt samplesthesolomonNo ratings yet

- Specification Data: Performance Data at Standard Embedment DepthDocument1 pageSpecification Data: Performance Data at Standard Embedment DepthatiattiNo ratings yet

- Compacted Conductor Calculation FIX FIXDocument4 pagesCompacted Conductor Calculation FIX FIXGautama Chandra Pradipta100% (1)

- Sondir Box TrafficDocument2 pagesSondir Box Trafficdidiet noer affendiNo ratings yet

- 3.5 Core Al Xlpe ArmdDocument1 page3.5 Core Al Xlpe ArmdRavindra JadhavNo ratings yet

- Perbandingan R15Document1 pagePerbandingan R15labkurniaNo ratings yet

- Ressiduo Cerâmica Vermelha Moido Alan e VanuttiDocument1 pageRessiduo Cerâmica Vermelha Moido Alan e VanuttiAlan SousaNo ratings yet

- METRADO DE MADERA CALCULATIONSDocument2 pagesMETRADO DE MADERA CALCULATIONSDaniella HernándezNo ratings yet

- Syauqi - Nano Silika - Sampel 5 - 1273.nsz Measurement ResultsDocument3 pagesSyauqi - Nano Silika - Sampel 5 - 1273.nsz Measurement ResultsAhmad FarhanNo ratings yet

- Charging and DischargingDocument10 pagesCharging and DischargingIzdihar JohariNo ratings yet

- PLS AlgoritmaDocument107 pagesPLS AlgoritmaJefry AndreanNo ratings yet

- Laxmi R7 90degDocument3 pagesLaxmi R7 90degAamir KhanNo ratings yet

- Costo Hora MaquinasDocument3 pagesCosto Hora MaquinasJulio César Jauregui TolentinoNo ratings yet

- SIEVE ANALYSIS REPORTDocument3 pagesSIEVE ANALYSIS REPORTASHOKKUMARNo ratings yet

- Latihan 5 Frequencies Frequencies: StatisticsDocument19 pagesLatihan 5 Frequencies Frequencies: StatisticsuukumaediNo ratings yet

- Mass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)Document19 pagesMass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)jomari galiasNo ratings yet

- Soil Bearing Capacity ReportDocument1 pageSoil Bearing Capacity ReportAly Arquillano JrNo ratings yet

- Compacted Conductor Calculation FIXDocument2 pagesCompacted Conductor Calculation FIXGautama Chandra PradiptaNo ratings yet

- Sieve Analysis Results for Coarse AggregatesDocument18 pagesSieve Analysis Results for Coarse AggregatesAmmar AliNo ratings yet

- Resilient Modulus Test Results for DISENO CARLOS L SpecimenDocument1 pageResilient Modulus Test Results for DISENO CARLOS L SpecimenJuan Camilo Pérez CantorNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- Btquant1 Sol 2010Document5 pagesBtquant1 Sol 2010ANa TrầnNo ratings yet

- Malvern Instruments Analysis: Measurement Details Measurement DetailsDocument1 pageMalvern Instruments Analysis: Measurement Details Measurement DetailsqhpuongNo ratings yet

- 1 - 2270.nsz Measurement ResultsDocument2 pages1 - 2270.nsz Measurement ResultsBudi SaputraNo ratings yet

- Bar Diameter 10 MM 12 MM: Volume of Concrete Area of FormworksDocument7 pagesBar Diameter 10 MM 12 MM: Volume of Concrete Area of FormworksRey Ivan M. DeinlaNo ratings yet

- A020320013 - Jefry Dwi Putra Tanjung - Uji BatuanDocument1 pageA020320013 - Jefry Dwi Putra Tanjung - Uji BatuanAndreeNo ratings yet

- Addis Ababa University Geotechnical Lab Direct Shear Test ResultsDocument2 pagesAddis Ababa University Geotechnical Lab Direct Shear Test ResultsFrezer AmareNo ratings yet

- Diameter in MM.: Grain Size AnalysisDocument13 pagesDiameter in MM.: Grain Size AnalysisImran KhanNo ratings yet

- Kloter 2Document4 pagesKloter 2Jennifer KhoNo ratings yet

- KCC PQC Mix BlendingDocument2 pagesKCC PQC Mix BlendingQuality JamNo ratings yet

- 1.1 KV 3.5 Core Aluminium Xlpe Insulated Armoured Unarmoured Power CableDocument1 page1.1 KV 3.5 Core Aluminium Xlpe Insulated Armoured Unarmoured Power CableImamul HaqueNo ratings yet

- 1.1 KV 3.5 Core Aluminium Xlpe Insulated Armoured Unarmoured Power CableDocument1 page1.1 KV 3.5 Core Aluminium Xlpe Insulated Armoured Unarmoured Power CableAARK CONSULTANTSNo ratings yet

- Ds InductorsDocument2 pagesDs InductorsOussama MessaoudiNo ratings yet

- Thevenin TheoremDocument9 pagesThevenin TheoremvinothanNo ratings yet

- Pacific Pipe World Class QualityDocument1 pagePacific Pipe World Class QualityDo BuiNo ratings yet

- Pacific Pipe World Class QualityDocument1 pagePacific Pipe World Class QualityDo BuiNo ratings yet

- bs1387 1 PDFDocument1 pagebs1387 1 PDFNarinder SinghNo ratings yet

- Brokerage calculator for NSE and MCXDocument2 pagesBrokerage calculator for NSE and MCXPrasadNo ratings yet

- Microsoft Word - TECHNICAL SPECIFICATIONDocument1 pageMicrosoft Word - TECHNICAL SPECIFICATIONVenkateswaraa InsulationNo ratings yet

- Electricity Consumption-History CardDocument1 pageElectricity Consumption-History CardVenkateswaraa InsulationNo ratings yet

- Stanson Change RecordDocument1 pageStanson Change RecordVenkateswaraa InsulationNo ratings yet

- 2019-04-23-Kaizen-Primer ApplicationDocument2 pages2019-04-23-Kaizen-Primer ApplicationVenkateswaraa InsulationNo ratings yet

- SPC Study Shows Highly Capable ProcessDocument1 pageSPC Study Shows Highly Capable ProcessVenkateswaraa InsulationNo ratings yet

- RBTDocument44 pagesRBTSelvaraj SimiyonNo ratings yet

- What Is Six SigmaDocument4 pagesWhat Is Six SigmaVenkateswaraa InsulationNo ratings yet

- Total Quality Management and Six SigmaDocument306 pagesTotal Quality Management and Six SigmaSohabe MalikNo ratings yet

- ADD-00058819 Six Sigma Learning Guide PDFDocument65 pagesADD-00058819 Six Sigma Learning Guide PDFHéctor NorthmanNo ratings yet

- 7-Wastes: Value Added (VA)Document3 pages7-Wastes: Value Added (VA)Venkateswaraa InsulationNo ratings yet

- Six Sigma ExplainedDocument29 pagesSix Sigma ExplainedVenkateswaraa InsulationNo ratings yet

- GE Six SigmaDocument6 pagesGE Six Sigmaimran27pk100% (2)

- 7-Wastes: Value Added (VA)Document3 pages7-Wastes: Value Added (VA)Venkateswaraa InsulationNo ratings yet

- The Basics of Lean Six Sigma - WWW - goleanSixSigmaDocument15 pagesThe Basics of Lean Six Sigma - WWW - goleanSixSigmagoleansixsigmaNo ratings yet

- Tabla de Conversiones para Ingenieros Quimicos PDFDocument2 pagesTabla de Conversiones para Ingenieros Quimicos PDFElder ReyesNo ratings yet

- Reviewer in PhysicsDocument90 pagesReviewer in PhysicsLouise RonquilloNo ratings yet

- Explainations of General Navigation QuestionsDocument11 pagesExplainations of General Navigation QuestionsZarrar KhanNo ratings yet

- Lat and Long WorksheetDocument1 pageLat and Long WorksheetvinujahNo ratings yet

- Indonesian Geospatial Reference SYSTEM 2013 (SRGI2013)Document22 pagesIndonesian Geospatial Reference SYSTEM 2013 (SRGI2013)Ikhsan LuthfiNo ratings yet

- Https WWW - Suit.edu - PK Uploads Past Papers Instrumentation Measurement - EE2211Document1 pageHttps WWW - Suit.edu - PK Uploads Past Papers Instrumentation Measurement - EE2211GHS Kass Korona MardanNo ratings yet

- Lec 1Document45 pagesLec 1JannoNo ratings yet

- 2 - Motion in One DimensionDocument27 pages2 - Motion in One Dimensionprash_hingeNo ratings yet

- Classify Surveying: Instruments, Methods, Purposes & FieldsDocument53 pagesClassify Surveying: Instruments, Methods, Purposes & FieldsMohammed Ajmalkhan100% (1)

- Projection and Transformation CalculationsDocument38 pagesProjection and Transformation Calculationssrinis4777-1No ratings yet

- 4.1 - Radian Measure: Degrees. There Is Another Unit of Measurement For Angles That Is Frequently Used Because ItDocument4 pages4.1 - Radian Measure: Degrees. There Is Another Unit of Measurement For Angles That Is Frequently Used Because ItBetty WangNo ratings yet

- Tacheometric SurveyDocument15 pagesTacheometric SurveyUsman AfzalNo ratings yet

- Metrology and Calibration of Mechatronic Systems OverviewDocument12 pagesMetrology and Calibration of Mechatronic Systems Overviewaman koundalNo ratings yet

- Experiment 1 (Part 2) : Use of Micropipettor and Analytical BalanceDocument4 pagesExperiment 1 (Part 2) : Use of Micropipettor and Analytical BalanceCara JaenNo ratings yet

- ICPDetection Limits SERA6Document11 pagesICPDetection Limits SERA6homa shaikhghomiNo ratings yet

- CMVA Vibration Math FormulasDocument4 pagesCMVA Vibration Math Formulasyianisr5990No ratings yet

- DREAM Ground Surveys For Buayan Malungon RiverDocument239 pagesDREAM Ground Surveys For Buayan Malungon RivermogsiNo ratings yet

- Engineering Metrology and Measurements Unit 1 2Document82 pagesEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- METCONVDocument195 pagesMETCONVkweevelinNo ratings yet

- Coast Guard Bridge Navigation Refresher Guidebook (August 2011 Edition)Document88 pagesCoast Guard Bridge Navigation Refresher Guidebook (August 2011 Edition)cdnolan100% (8)

- Vernier CallipersDocument21 pagesVernier CallipersazaharNo ratings yet

- 3) Minda Industries (AW2W)Document2 pages3) Minda Industries (AW2W)VikasNo ratings yet

- Lab Report XRF 90: S8 TigerDocument4 pagesLab Report XRF 90: S8 Tigersupendra phuyalNo ratings yet

- M & IDocument70 pagesM & Iccritam100% (1)

- Metrology - Module3-Angular Measurements, Thread Metro Logy, and OpticsDocument122 pagesMetrology - Module3-Angular Measurements, Thread Metro Logy, and OpticsSagar WakankarNo ratings yet

- EURAMET CG 11.01 Temperature IndicatorsDocument21 pagesEURAMET CG 11.01 Temperature IndicatorsMarcos LopesNo ratings yet

- Map Projections Used by UsgsDocument330 pagesMap Projections Used by Usgsloveforyou208No ratings yet