Professional Documents

Culture Documents

Pneumatic control valve sizing guide

Uploaded by

JOSE MARTIN MORA RIVEROSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pneumatic control valve sizing guide

Uploaded by

JOSE MARTIN MORA RIVEROSCopyright:

Available Formats

Pneumatic Control Valve

Sizing Guide

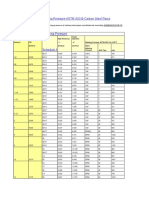

Saving Money and Space by Sizing Your Valves Properly Table 2

This catalog gives you a flow rating (Cv) for each valve Compression Factors and “A” Constants

in the Schrader Belllows line. You can “plug” your

requirements into the following simple formula, and Inlet

“A” Constants for Various

determine the Cv needed to do the job. By not oversizing, Compression Pressure Drop*

Pressure

you’ll save space and money, and you’ll ensure the valve Factor 2 PSI 5 PSI 10 PSI

(PSIG)

you select will do the job. ∆P ∆P ∆P

Converting the Job Requirements Into Cv (Capacity 10 1.6 .155 .102

20 2.3 .129 .083 .066

Co-efficient).

30 3.0 .113 .072 .055

Cylinder Area Cylinder Compression “A” 40 3.7 .097 .064 .048

(Sq. In.) X Stroke X Factor X (Table 2) 50 4.4 .091 .059 .043

(See Table 1) (In.) (Table 2) 60 5.1 .084 .054 .040

Cv =

Stroke Time (sec.) x 28.8 70 5.7 .079 .050 .037

Let’s work through an example: 80 6.4 .075 .048 .035

90 7.1 .071 .045 .033

We want to extend a 3 1/4" bore cylinder which has a 12"

100 7.8 .068 .043 .031

stroke in one second, and we have a supply pressure of 110 8.5 .065 .041 .030

80 PSI to do the work. Here’s what we know: 120 9.2 .062 .039 .029

Cylinder area for a 3 1/4" bore, from Table 1 ....... 8.30 sq. in. 130 9.9 .060 .038 .028

Cylinder stroke .................................................. 12 in. 140 10.6 .058 .037 .027

Stroke time required in seconds ........................ 1 sec. 150 11.2 .056 .036 .026

Compression factor at 80 PSI, from Table 2 ...... 6.4 160 11.9 .055 .035 .026

170 12.6 .054 .034 .025

“A” constant for 80 PSI, from Table 2 ................. .048

180 13.3 .052 .033 .024

Substituting in the formula, we have: 190 14.0 .051 .032 .024

8.30 x 12 x 6.4 x .048 200 14.7 .050 .031 .023

Cv = = 1.06

1 x 28.8 Note: Use “A” constant at 5 PSI ∆P for most applications. On very critical

Any valve, therefore, which has a Cv of at least 1.06, will applications, use “A” at 2 PSI ∆P. You will find in many cases, a 10 PSI ∆P is not

detrimental, and can save money and mounting space.

extend our cylinder the specified distance in the required

time. * Tabulated values are the solution of 1 GT where T is for 68°F

and G =1 for Air. 22.48 (P1 – P2)P2

Choosing the Valve “Series”

Your next step is to choose a basic valve design to do the

job. For a quick guide to valve designs, see Table 3. Table 3

Having selected the basic valve design, consult the Characteristics of the Major Valve Designs

Capacity Co-efficient (Cv) tables which describe the A. Piston Poppet 1. High flow capacities

individual valve capacities. 3-Way and 4-Way 2. Minimum lubrication requirements

Selecting the Valve Model, Options and Accessories 3. Fast response

4. Self-cleaning poppet seats

Having determined Cv, series, port size, flow-path 5. Pressures of 15 to 150 PSIG

configuration (pre-determined by circuit design), and (modifications for vacuum to 250 PSIG)

actuation method, you’re ready to choose the exact valve B. Spool Poppet 1. Medium flow capacities

model number. 3-Way and 4-Way 2. Short stroke and fast response

Read the pertinent catalog pages; note the exact model 3. Inexpensive

numbers, options and accessories you want. Then phone or 4. Wide range of flow-path

write your Schrader Bellows air valve distributor. They will configurations, actuators, accessories

give you prompt, accurate service. 5. Available in direct-operated and

solenoid pilot operated models

Note: Need circuit design help? Contact your local 6. Direct solenoid models are ideal

Schrader Bellows distributor. They are backed up by our for vacuum to 150 PSIG

regional Sales Engineers and offices. Between them, you’ll C. Packed Bore 1. Wide range of flow capacities

find answers to all of your questions. 4-Way 2. Wide range of flow-path configurations

3. Pilot-operated models available

Table 1 4. Pressures of vacuum to 150 PSIG

Effective Square-Inch Areas for D. Rotary Or 1. Inexpensive

Standard-Bore-Size Cylinders Reciprocating Disc 2. Versatility in manual actuation

4-Way, manually

Bore Cylinder Area Bore Cylinder Area operated

Size (Sq. In.) Size (Sq. In.)

3 Cv–Capacity Co-efficients–(sometimes called Flow Factors). Each flow path

/4 " .44 4" 12.57

through the valve has its own Cv value. All Cv ratings for each valve cataloged on

1" .79 41/ 2" 15.90 this page are listed on the front side of this sheet.

1

1 /8" .99 5" 19.64

11 /4" 1.23 6" 28.27 Q = Flow in Standard Cubic Feet per minute (14.7

11 /2" 1.77 7" 38.48 PSIA at 60°F)

Cv = Q GT

13 /4" 2.41 8" 50.27 22.48 (P1 – P2 )P2 P1 = Inlet Absolute Pressure (gauge pressure + 14.7)

2" 3.14 10" 78.54 P2 = Outlet Absolute Pressure (gauge pressure + 14.7)

21 /2" 4.91 12" 113.10 Note: P2 must be greater than .53 x P1

31 /4" 8.30 14" 153.94 G = Specific Gravity of flowing medium (Air, G =1)

35 /8" 10.32 T = Absolute Temperature of Air (460 + °F.)

Cv = Q x “A” (Table 2)

XII

You might also like

- Valve Sizing CalculatorDocument3 pagesValve Sizing CalculatorbrunoNo ratings yet

- Document'S Code Attachment 10.3 Revision 0: ClientDocument4 pagesDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- Preconstruction MeetingDocument32 pagesPreconstruction MeetingMar OlacsNo ratings yet

- Main Pivot Pin Diameter CalculationDocument2 pagesMain Pivot Pin Diameter Calculationjdutia83100% (1)

- Technological Institute of The PhilippinesDocument25 pagesTechnological Institute of The PhilippinesJohn Leonard FazNo ratings yet

- Ace Tut 02 Turbulent BackstepDocument22 pagesAce Tut 02 Turbulent BackstepHilario de JesusNo ratings yet

- Fan Noise EstimateDocument5 pagesFan Noise EstimateBen ClackNo ratings yet

- Depth Gauge PDFDocument9 pagesDepth Gauge PDFRizal IephoNo ratings yet

- BVH2083 GBDocument10 pagesBVH2083 GBsamer salamehNo ratings yet

- DheerajDocument7 pagesDheerajSaksham KakarNo ratings yet

- Pressure DropDocument19 pagesPressure DropGigis Kintan MyarthalunaNo ratings yet

- Rotary Valves ZRSDocument7 pagesRotary Valves ZRSkosmcNo ratings yet

- Sizing a Reciprocating Compressor for Natural Gas ServiceDocument6 pagesSizing a Reciprocating Compressor for Natural Gas ServiceNikhil Ashok Badgu100% (1)

- Self-Cleaning Filters Manual & Automatic GuideDocument4 pagesSelf-Cleaning Filters Manual & Automatic Guidedevang asher100% (1)

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedDocument5 pagesVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerNo ratings yet

- Spray-Type Deaerating Heaters: TABLE 12.2Document2 pagesSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiNo ratings yet

- SN74LVC07Document23 pagesSN74LVC07abcdNo ratings yet

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- Orifice flow calculation sheetDocument2 pagesOrifice flow calculation sheetHeru Tri WNo ratings yet

- Lecture 5 - Power SuppliesDocument48 pagesLecture 5 - Power SuppliesNimsiri AbhayasingheNo ratings yet

- Air Ingress CalculationsDocument5 pagesAir Ingress CalculationsMallinatha PNNo ratings yet

- Conical Base Cylindrical PE Tanks SpecsDocument4 pagesConical Base Cylindrical PE Tanks SpecsAmoolia Ngo0% (1)

- Dimensionless Designator of Pipe Size PDFDocument1 pageDimensionless Designator of Pipe Size PDFleoscbdNo ratings yet

- External Pressure Calculation Results SummaryDocument8 pagesExternal Pressure Calculation Results SummaryAndika DearsonNo ratings yet

- Storage Tank Venting Calculations For Site Tank FarmDocument7 pagesStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinNo ratings yet

- Chibro Press Fit Piping Data SheetDocument5 pagesChibro Press Fit Piping Data SheetBoyd JohnstonNo ratings yet

- Tables and Index Thermodynamics Cengel 7E-2Document118 pagesTables and Index Thermodynamics Cengel 7E-2tomtom9649No ratings yet

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocument1 pageBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNo ratings yet

- Point Load CalculationsDocument3 pagesPoint Load Calculationskedar kavathekarNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- Sop-35 Calibration of Vacuum Pressure TransmitterDocument3 pagesSop-35 Calibration of Vacuum Pressure TransmitterOSAMANo ratings yet

- SmartCEM Continuous Emissions Monitoring System Technical ManualDocument66 pagesSmartCEM Continuous Emissions Monitoring System Technical ManualQuan Nguyen VanNo ratings yet

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerDocument26 pagesIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyNo ratings yet

- Cyclone SeperatorDocument2 pagesCyclone SeperatorVaibhav JainNo ratings yet

- Theory and Experimental Manual For Sensor and Transducer Training KitsDocument37 pagesTheory and Experimental Manual For Sensor and Transducer Training KitsRiady SiswoyoNo ratings yet

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Document16 pages722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611No ratings yet

- Vessel with Large Opening Pressure CalculationsDocument25 pagesVessel with Large Opening Pressure CalculationsRuben Samoel Barros RochaNo ratings yet

- PIPE SIZING CALCULATION SHEETDocument9 pagesPIPE SIZING CALCULATION SHEETmaxmorekNo ratings yet

- VT Program Rotary Screw Compressors 40-75HPDocument6 pagesVT Program Rotary Screw Compressors 40-75HPQco MyNo ratings yet

- Lifting LugsDocument11 pagesLifting LugsISEDAC21No ratings yet

- Blank DIa1Document1 pageBlank DIa1Makrand SakpalNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Derivation of Pressure Loss To Leak Rate Formula From The Ideal Gas LawDocument3 pagesDerivation of Pressure Loss To Leak Rate Formula From The Ideal Gas Lawsatheez3251No ratings yet

- Welcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesDocument10 pagesWelcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesMarcelo MoraisNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Vent Sizing MethodsDocument26 pagesVent Sizing Methodsmieiroluiz12No ratings yet

- Vetrolux Din 11851Document1 pageVetrolux Din 11851uptc1985No ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- Actuator Data SheetsDocument4 pagesActuator Data SheetsCibi SubramaniamNo ratings yet

- Sop-40-Start Up of Loss in Weight Type Schenck UnitDocument2 pagesSop-40-Start Up of Loss in Weight Type Schenck UnitOSAMANo ratings yet

- Sensor Devices Mechanical SensorsDocument41 pagesSensor Devices Mechanical Sensorsdesaivilas60100% (1)

- QuikCal 190 Quick StartDocument12 pagesQuikCal 190 Quick StartsuberecNo ratings yet

- 05 - Test On Linear ActuatorsDocument3 pages05 - Test On Linear ActuatorsShubham SatheNo ratings yet

- TK15 - XLS Sizing - Assignment 2Document187 pagesTK15 - XLS Sizing - Assignment 2Muhammad AzharNo ratings yet

- Lecture No.14 (Pipe)Document8 pagesLecture No.14 (Pipe)Mohsen HassanNo ratings yet

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 pagesAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98No ratings yet

- Pipe Wall Thickness CalculationDocument79 pagesPipe Wall Thickness CalculationRaj Bindas100% (1)

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- ASME Guidance Articles On Repair Strategies - C. RoderyDocument35 pagesASME Guidance Articles On Repair Strategies - C. RoderyGuilherme AlencarNo ratings yet

- JIS Standard For Boiler Water - 1 PDFDocument80 pagesJIS Standard For Boiler Water - 1 PDFCornelius Toni Kuswandi100% (1)

- Break Pressure TankDocument53 pagesBreak Pressure TankParomita Mukherjee Misra100% (11)

- Noise Emissions of Control ValvesDocument2 pagesNoise Emissions of Control ValvesJOSE MARTIN MORA RIVEROSNo ratings yet

- New Standards Updates for Fugitive Emissions ComplianceDocument16 pagesNew Standards Updates for Fugitive Emissions ComplianceJOSE MARTIN MORA RIVEROSNo ratings yet

- 15403-Copes Vulcan MNSD-V (Sd2k) - Multi Nozzle Spray DesuperheatersDocument8 pages15403-Copes Vulcan MNSD-V (Sd2k) - Multi Nozzle Spray DesuperheatersJOSE MARTIN MORA RIVEROSNo ratings yet

- Brochure Noise Attenuation Technologies For Control Valves en 127214Document16 pagesBrochure Noise Attenuation Technologies For Control Valves en 127214JOSE MARTIN MORA RIVEROSNo ratings yet

- Consideraciones de Diseño de CalderasDocument6 pagesConsideraciones de Diseño de CalderasJOSE MARTIN MORA RIVEROSNo ratings yet

- The Flow Noise Characteristics of A Control Valve - OK OK OK TEORIADocument7 pagesThe Flow Noise Characteristics of A Control Valve - OK OK OK TEORIAJOSE MARTIN MORA RIVEROSNo ratings yet

- Control Valve Noise - FlowServeDocument16 pagesControl Valve Noise - FlowServeEstuardo Javier Gan RodríguezNo ratings yet

- TT - Severe Service Trim Brochure - Update OK OK OK CALCULOSDocument20 pagesTT - Severe Service Trim Brochure - Update OK OK OK CALCULOSJOSE MARTIN MORA RIVEROSNo ratings yet

- Super Duplex Valve PDFDocument87 pagesSuper Duplex Valve PDFMohamed YousufNo ratings yet

- Ag 4915158Document4 pagesAg 4915158Kishore SinghNo ratings yet

- Predicting Valve Noise with IEC StandardDocument4 pagesPredicting Valve Noise with IEC StandardJOSE MARTIN MORA RIVEROSNo ratings yet

- The Silent Treatment: Fisher Solutions To Noise ProblemsDocument16 pagesThe Silent Treatment: Fisher Solutions To Noise ProblemsJOSE MARTIN MORA RIVEROSNo ratings yet

- 1081ch6 14 PDFDocument21 pages1081ch6 14 PDFNguyễn Thống NhấtNo ratings yet

- Welker Jet® Control ValveDocument30 pagesWelker Jet® Control ValveJOSE MARTIN MORA RIVEROSNo ratings yet

- Predicting Valve Noise with IEC StandardDocument4 pagesPredicting Valve Noise with IEC StandardJOSE MARTIN MORA RIVEROSNo ratings yet

- Welker In-Line Diffuser: Welker ... When Excellence Counts!Document2 pagesWelker In-Line Diffuser: Welker ... When Excellence Counts!JOSE MARTIN MORA RIVEROSNo ratings yet

- Ag 4915158Document4 pagesAg 4915158Kishore SinghNo ratings yet

- Pipe NoiseDocument10 pagesPipe NoiseRoshin99No ratings yet

- Severe Service Guide OK OK OK CALCULOS Trim Servicio SeveroDocument8 pagesSevere Service Guide OK OK OK CALCULOS Trim Servicio SeveroJOSE MARTIN MORA RIVEROSNo ratings yet

- SRV NoiseDocument7 pagesSRV NoisebbmokshNo ratings yet

- NoiseMan PDFDocument30 pagesNoiseMan PDFshan07011984No ratings yet

- Sizing & Selection: Control Valve Noise PredictionDocument5 pagesSizing & Selection: Control Valve Noise PredictionsnamprogNo ratings yet

- Typical F Valve Style Modifier Values Catalog 12: (From IEC534) Page 1-1 June 2014Document352 pagesTypical F Valve Style Modifier Values Catalog 12: (From IEC534) Page 1-1 June 2014CarlosIkedaNo ratings yet

- IEC - 60534 - 8 - 4 - 2015 - The Impact of Lee 534-8-3Document11 pagesIEC - 60534 - 8 - 4 - 2015 - The Impact of Lee 534-8-3JOSE MARTIN MORA RIVEROSNo ratings yet

- Control Valve Noise Control Manual - DresserDocument24 pagesControl Valve Noise Control Manual - DresserTrevor KanodeNo ratings yet

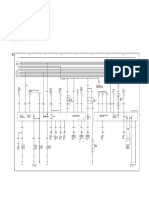

- Wiring DiagramDocument1 pageWiring DiagramAlexgavgray GNo ratings yet

- FORCED INDUCTION BASICS - Engine Professional PDFDocument84 pagesFORCED INDUCTION BASICS - Engine Professional PDFjoop1231177No ratings yet

- VW Gearbox RatiosDocument2 pagesVW Gearbox RatiosAndrei MarchisNo ratings yet

- Cat Forklift V60e V70e V80e Service Manuals PDF enDocument23 pagesCat Forklift V60e V70e V80e Service Manuals PDF enashleymcneil190382yko100% (115)

- 0CV10-M86900EN: Last Update Mar., 2013Document26 pages0CV10-M86900EN: Last Update Mar., 2013Linzaw OoNo ratings yet

- FORScan Codes For 2017 Focus ST PDFDocument5 pagesFORScan Codes For 2017 Focus ST PDFIsmael ArenasNo ratings yet

- ISUZU N-SERIES 5.2L 2007-2010 ECM Wire DiagramDocument15 pagesISUZU N-SERIES 5.2L 2007-2010 ECM Wire Diagramrusadi100% (4)

- Peugeot Obd CodesDocument4 pagesPeugeot Obd Codesmrx200No ratings yet

- hx500 QRDocument46 pageshx500 QRChristopher LougeeNo ratings yet

- General Technical Data 1006 - 6tDocument4 pagesGeneral Technical Data 1006 - 6tsengoNo ratings yet

- John Deere 329D Skid Steer Loader (Manual Controls) Service Repair Manual (TM11431)Document15 pagesJohn Deere 329D Skid Steer Loader (Manual Controls) Service Repair Manual (TM11431)laopaodun100% (1)

- Lycoming PlugsDocument5 pagesLycoming PlugsrapidshotNo ratings yet

- Magna: Mining & EarthmoverDocument1 pageMagna: Mining & EarthmoverWilliams NiñoNo ratings yet

- Viewer Zmags PDFDocument78 pagesViewer Zmags PDFMichelle SmithNo ratings yet

- Sentron Oem-ApprovalsDocument2 pagesSentron Oem-ApprovalsMudabbir Shan AhmedNo ratings yet

- 2W Cables MRP List with New and Highlighted ItemsDocument29 pages2W Cables MRP List with New and Highlighted ItemsManish ChandNo ratings yet

- Toyota 8FBDocument6 pagesToyota 8FBtomy112No ratings yet

- Pit Viper 351Document6 pagesPit Viper 351Sebastian Robles100% (2)

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- TM 9-1765a Bomb Service Truck M6Document128 pagesTM 9-1765a Bomb Service Truck M6AdvocateNo ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Secondary Air Injection System - MIL "ON" P2440 And/or P2442Document8 pagesSecondary Air Injection System - MIL "ON" P2440 And/or P2442David BlevingsNo ratings yet

- PM-CLINIC DATA SHEET InsightsDocument3 pagesPM-CLINIC DATA SHEET InsightsGiancarlo Calderon JuradoNo ratings yet

- L36GSI: VGF Series Gas EngineDocument2 pagesL36GSI: VGF Series Gas EngineferyNo ratings yet

- Ae - MTRLDocument30 pagesAe - MTRLHemanth KumarNo ratings yet

- Parts Manual: Kawasai I T1A SeriesDocument11 pagesParts Manual: Kawasai I T1A SeriesJustin_Elam_9833No ratings yet

- An overview of the ECU and sensors for the Mitsubishi 4G93 engineDocument6 pagesAn overview of the ECU and sensors for the Mitsubishi 4G93 engineSyahiratul Nadiah MoktarNo ratings yet

- Loc GovDocument45 pagesLoc GovCarl Joshua SaraynoNo ratings yet

- Manuel Skyteam MonkeyGorilla Mini4tempsDocument27 pagesManuel Skyteam MonkeyGorilla Mini4tempshugo kasprzakNo ratings yet

- STIHL 009, 010, 011 Service Manual GuideDocument52 pagesSTIHL 009, 010, 011 Service Manual Guidehey_hop50% (4)