Professional Documents

Culture Documents

Material Comparision r1

Uploaded by

senthil prakashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Comparision r1

Uploaded by

senthil prakashCopyright:

Available Formats

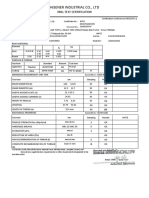

Chemical Composition

Grade

Quality C Mn S P

Designation

A 0.23 1.5 0.045 0.045

BR 0.22 1.5 0.045 0.045

E 250

B0 0.22 1.5 0.045 0.045

C 0.2 1.5 0.04 0.04

Mechanical Properties

Tensile

Yield Stress

Grade Strength

Quality ReH, Min

Designation Rm , Min

MPa

MPa

<20 20-40 >40

A

BR

E 250 410 250 240 230

B0

C

ical Composition

Carbon

Mode of

Si Equivalent

deoxidation

(CE), max

0.4 0.42 Semi-killed/killed For semi-killed steel, silicon shall be less than 0.10

0.04 0.41 Semi-killed/killed

0.04 0.41 Semi-killed/killed

0.04 0.39 Killed

Mechanical Properties

Percentage

Internal

Elongation

Bend Charpy

A, Min

Diameter Impact Test

at Gauge

Min (See Note 3)

Length,

(See Note 2)

Lo=5.65

<=25 >25 Temp OC Min J

RT 27 3) For sub-quality BR, impact

23 2t 3t

0 27 1MPa = 1N/mm2 = 1MN/m2

(-) 20 27

silicon shall be less than 0.10 percent.

3) For sub-quality BR, impact test is optional; if required, at room temperature (25 ± 2°C).

1MPa = 1N/mm2 = 1MN/m2 = 0.102 kgf/mm2 = 144.4 psi.

You might also like

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Document1 pageC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용No ratings yet

- JIS G3131 Hot JIS G3131 Hot - Rolled Steel Rolled Steel: Remark: All Values Are Only For ReferenceDocument1 pageJIS G3131 Hot JIS G3131 Hot - Rolled Steel Rolled Steel: Remark: All Values Are Only For ReferenceKenvi AlarconNo ratings yet

- Din 1630 PDFDocument3 pagesDin 1630 PDFv53100% (1)

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Chemical Composition: IS: 2062 Specification of Structural Steel For FabricationDocument2 pagesChemical Composition: IS: 2062 Specification of Structural Steel For FabricationppglNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- 316 PDFDocument1 page316 PDFViswanathan SrkNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship Buildingnpankaj1No ratings yet

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- Siau DIN W.N. Afnor BS Aisi/Sae: Comparable StandardsDocument1 pageSiau DIN W.N. Afnor BS Aisi/Sae: Comparable StandardsYana Jarang OlNo ratings yet

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFDocument1 pageAisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFfeltofsnakeNo ratings yet

- CC401Document1 pageCC401Aditya maulana NurjamanNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- C86200 Manganese BronzeDocument1 pageC86200 Manganese BronzeDeepak KumarNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- SA 283 Grade CDocument1 pageSA 283 Grade CHandri YantoNo ratings yet

- CNX ArmaduraDocument3 pagesCNX ArmaduraDaniel RosalesNo ratings yet

- Astm A242-04Document1 pageAstm A242-04truongdinhbkNo ratings yet

- R315A Oscilator DatasheetDocument5 pagesR315A Oscilator DatasheetrenampNo ratings yet

- Esparrago Astm 193 B7 1.1.4 - 7 X 3.60 Mt.Document1 pageEsparrago Astm 193 B7 1.1.4 - 7 X 3.60 Mt.Cristian Xavier Avendaño BelloNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship BuildingAnkit MauryaNo ratings yet

- C63020 Nickel Aluminum Bronze - ConcastDocument3 pagesC63020 Nickel Aluminum Bronze - ConcastBruno FaveroNo ratings yet

- Test Report & Inspection CertificateDocument1 pageTest Report & Inspection CertificateAji HatmantoNo ratings yet

- Inspection Certificate: Fevziçakmak Mah. 10801 Sok. No:1B Karatay/KONYA +90 332 502 86 53Document1 pageInspection Certificate: Fevziçakmak Mah. 10801 Sok. No:1B Karatay/KONYA +90 332 502 86 53Murat CelikNo ratings yet

- Excel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)Document16 pagesExcel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)SOURAV RANJAN KHANRANo ratings yet

- Alcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyDocument2 pagesAlcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyChristina Christina ChristinaNo ratings yet

- DIN 1628 ST 52.4Document2 pagesDIN 1628 ST 52.4Anonymous m1cSnEavoNo ratings yet

- Polyethylene Terephthalate Key Properties: Chemical ResistanceDocument1 pagePolyethylene Terephthalate Key Properties: Chemical ResistancerajaNo ratings yet

- MarchDocument1 pageMarchImran HussainNo ratings yet

- Perno Hex Unc AstmDocument1 pagePerno Hex Unc AstmEsther CVNo ratings yet

- Perno Hex Unc AstmDocument1 pagePerno Hex Unc AstmEsther CVNo ratings yet

- Velvex - 296 Ut: Transformer Oil Product Data SheetDocument9 pagesVelvex - 296 Ut: Transformer Oil Product Data SheetVaradrajan jothiNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- Carbono Equivalente chapter-2-material-2023-JAN-2Document21 pagesCarbono Equivalente chapter-2-material-2023-JAN-2viyfNo ratings yet

- Kapitel 01 DINO Techn TeilDocument12 pagesKapitel 01 DINO Techn TeilLê Đức BảoNo ratings yet

- Extracts of ASTM A 106Document4 pagesExtracts of ASTM A 106RAGHVENDRA PRATAP SINGHNo ratings yet

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- ITP Aluminum DCM Rev 00Document1 pageITP Aluminum DCM Rev 00maheshpanditNo ratings yet

- MAWP Calculation SpreadsheetDocument9 pagesMAWP Calculation SpreadsheetLawrence Osuvwe OfuokuNo ratings yet

- R433M 433.92MHz 3.0x3.0 6PINDocument5 pagesR433M 433.92MHz 3.0x3.0 6PINAnselmo LimaNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- Astm A572 Steel, Grade 50 DurezaDocument1 pageAstm A572 Steel, Grade 50 DurezaMaikol Chino100% (1)

- COMPARISON TABLE OF Rock Revetment 0-1600kg Rocks: Supplie R M/S Alamara Crusher LLCDocument5 pagesCOMPARISON TABLE OF Rock Revetment 0-1600kg Rocks: Supplie R M/S Alamara Crusher LLCSajidNaeemNo ratings yet

- Technical Evaluation Sheet: Kishan Forge, RajkotDocument3 pagesTechnical Evaluation Sheet: Kishan Forge, RajkotRajoo PrajapatiNo ratings yet

- Material Data Sheet: Ref: HIL826M40 Issue: 1.0 Title: 826M40 - 2.5% Nickel-Chromium-Molybdenum Through Hardening SteelDocument1 pageMaterial Data Sheet: Ref: HIL826M40 Issue: 1.0 Title: 826M40 - 2.5% Nickel-Chromium-Molybdenum Through Hardening SteelRaghav GoelNo ratings yet

- Asme2b SB 446Document8 pagesAsme2b SB 446Marjan SubanNo ratings yet

- ETABS 18.0.2-Design DetailsDocument2 pagesETABS 18.0.2-Design DetailsFabian Villegas MendizabalNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Asphalt RC - 250 Specification QS-PL 119 Laboratories & Quality Control DepartmentDocument1 pageJordan Petroleum Refinery Co. Ltd. Asphalt RC - 250 Specification QS-PL 119 Laboratories & Quality Control Departmenthz135874No ratings yet

- Technical Delivery Condition: LBST Specification Code: LB 304Document2 pagesTechnical Delivery Condition: LBST Specification Code: LB 304Prasenjit PuriNo ratings yet

- 203 Super S Inhibited Transformer OilDocument2 pages203 Super S Inhibited Transformer OilHanderson PanjaitanNo ratings yet

- 106 QiplDocument1 page106 QiplPRITESHNo ratings yet

- Structural Steel Framing - BLDG2034 Class Assignment: Tension Stay - Sports Stadium RoofDocument12 pagesStructural Steel Framing - BLDG2034 Class Assignment: Tension Stay - Sports Stadium RoofNatalie BryanNo ratings yet

- Trouble Shooting Dewatering PumpDocument136 pagesTrouble Shooting Dewatering PumpMuhammad NoorNo ratings yet

- UNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmDocument2 pagesUNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmArjun BhargavaNo ratings yet

- Company Names and Number UAEDocument35 pagesCompany Names and Number UAESoju Suresh100% (1)

- 9365Document69 pages9365Kivanc NEROGLUNo ratings yet

- Fastner and Tooling Components. Fertrading Group Venezuela.Document4 pagesFastner and Tooling Components. Fertrading Group Venezuela.Renso PiovesanNo ratings yet

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 pagesProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranNo ratings yet

- Matrix APDDocument1 pageMatrix APDQHSE BTGNo ratings yet

- Dielectric HeatingDocument2 pagesDielectric HeatingPallavi JainNo ratings yet

- Vibration Diagnosis and CorrectionDocument54 pagesVibration Diagnosis and Correctionbhanuka2009No ratings yet

- TransformerDocument14 pagesTransformerNegrea Cristian0% (3)

- Torre Sauter 0 - 5 - 320 - 025 - 4 PDFDocument27 pagesTorre Sauter 0 - 5 - 320 - 025 - 4 PDFGuiNo ratings yet

- What We Offer.: RemunerationDocument8 pagesWhat We Offer.: Remunerationsurabhi mandalNo ratings yet

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Document441 pagesComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzNo ratings yet

- Tally Erp 9.0 Material Control Centre in Tally Erp 9.0Document27 pagesTally Erp 9.0 Material Control Centre in Tally Erp 9.0Raghavendra yadav KMNo ratings yet

- Argus Dual System Pi enDocument2 pagesArgus Dual System Pi enfahmi1987No ratings yet

- Recondition BatteryDocument46 pagesRecondition Batteryafic219473100% (1)

- RE14092021Document2 pagesRE14092021francis puthuserilNo ratings yet

- Power Tool Switches: Catalog 1308650 Issued 1-01Document18 pagesPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNo ratings yet

- V33500 TVDocument2 pagesV33500 TVgoriath-fxNo ratings yet

- FP CLOCK - csproj.FileListAbsoluteDocument14 pagesFP CLOCK - csproj.FileListAbsolutePhi Huỳnh NgôNo ratings yet

- Craftsman 73754 ManualDocument24 pagesCraftsman 73754 Manualjkchromy945No ratings yet

- Shrinkage Strip Method Statment and Ther PDFDocument4 pagesShrinkage Strip Method Statment and Ther PDFhakim2020No ratings yet

- K 1020189523hfjfjDocument3 pagesK 1020189523hfjfjCarlos Angel Vilcapaza CaceresNo ratings yet

- 2014 - Solved Problems in Facility PlanningDocument135 pages2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- Modulation Reviewer For ECEDocument171 pagesModulation Reviewer For ECEianneanNo ratings yet

- PQP FormatDocument10 pagesPQP FormatMichael TeoNo ratings yet

- (52621001078) DM - DM Half Inch Flex Jumper Spec SheetDocument2 pages(52621001078) DM - DM Half Inch Flex Jumper Spec SheetmicroqualNo ratings yet

- FRP Fish TanksDocument33 pagesFRP Fish TanksA.Subin DasNo ratings yet

- DASApplicationForm PDFDocument3 pagesDASApplicationForm PDFEngr.Hamid Ismail CheemaNo ratings yet

- StoichiotryDocument57 pagesStoichiotryJezriel Theana SisonNo ratings yet