Professional Documents

Culture Documents

Technical Information: Limiting Speed For Spindle Bearings

Uploaded by

penOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information: Limiting Speed For Spindle Bearings

Uploaded by

penCopyright:

Available Formats

Technical Information

High Precision Ball Bearings

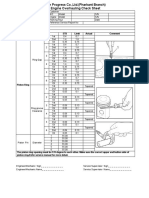

Limiting speed for spindle bearings

The stable operation condition of a bearing is endangered as The friction generated in the bearing depends essentially on:

soon as the limiting speed is attained or exceeded. Within the · Speed

range of the contacting areas between the balls and the rings · Bearing load

friction and temperature increase progressively. · Viscosity of the lubricant

· Amount of lubricant

Limiting speed for spindle bearings

The speeds listed in the table are attainable speeds for a single If the operating conditions deviate from the conditions menti-

spring-preloaded bearing operating under normal conditions oned these must be taken into account by correction factors.

such as:

· Good heat dissipation Correction factors and speed values are only for guidance.

· Low external load

· Rotating inner ring

· Oil-mist or oil-air lubrication

· Good form accuracy of associated components

· Alignment of associated components

Permissible speed = speed value · fn1 · fn2 · fn3 · fn4

Correction factors Preload

F L M S

fn1: Lubrication Grease lubrication 0.75

(note n x dm factor of grease)

oil-air or oil-mist lubrication 1.0

fn2: Bearing arrange- Single bearing with spring preload 1.0

ment

Bearing pairs

Rigid 0.8 0.7 0.5

0.75 0.6 0.4

0.7 0.6 0.4

0.6 0.5 0.3

0.65 0.5 0.3

fn3: Kinematics Rotating inner ring 1.0

Rotating outer ring 0.6

fn4: Ball material Steel 1.0

Ceramic Si3N4 1.25

GMN Paul Müller Industrie GmbH & Co. KG Phone: +49 911-5691-225, 229, 217, 326 vertrieb.kula@gmn.de

Äußere Bayreuther Straße 230 · D-90411 Nürnberg Fax: +49 911-5691-587 www.gmn.de

You might also like

- Journal Bearing EditedDocument15 pagesJournal Bearing EditedAzri ZaidiNo ratings yet

- Maintenance Manual For HW19710T Transmission: China National Heavy Duty Truck Group Datong Gear Co.,Ltd. (CNHTC)Document24 pagesMaintenance Manual For HW19710T Transmission: China National Heavy Duty Truck Group Datong Gear Co.,Ltd. (CNHTC)Ayane DejeneNo ratings yet

- SM HM400-1 Pretelan 1Document4 pagesSM HM400-1 Pretelan 1faisalandriansyahtspNo ratings yet

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- Group 3 Track and Work EquipmentDocument6 pagesGroup 3 Track and Work EquipmentDavidNo ratings yet

- SKF - 10000 EN - Page(s) 0116 To 0129 - SpeedsDocument14 pagesSKF - 10000 EN - Page(s) 0116 To 0129 - SpeedsSergio OrtizNo ratings yet

- Investigation On Vibration Characteristic On Ball Bearing Operated With Hexagonal Boron Nitride (HBN) NanoparticlesDocument13 pagesInvestigation On Vibration Characteristic On Ball Bearing Operated With Hexagonal Boron Nitride (HBN) NanoparticlesshakinaNo ratings yet

- Wa0006.Document62 pagesWa0006.Abraham Cruz PérezNo ratings yet

- Cuscinetti Progetto: SKF Bearing Select v1.2-40Document10 pagesCuscinetti Progetto: SKF Bearing Select v1.2-40AlbertoNo ratings yet

- Belt ChainDocument95 pagesBelt ChainLuis BalducciNo ratings yet

- Technical Details: Standard Unitized PistonDocument2 pagesTechnical Details: Standard Unitized PistonRPINILLA (EICO S.A.)No ratings yet

- 7311 BECBY: Angular Contact Ball Bearings, Single RowDocument4 pages7311 BECBY: Angular Contact Ball Bearings, Single RowWildan PriatnaNo ratings yet

- The SKF Model For Calculating The Frictional MovementDocument15 pagesThe SKF Model For Calculating The Frictional Movementdaviqperez100% (1)

- 0901d1968065e9e7 The SKF Model For Calculating The Frictional Movement - TCM - 12 299767 PDFDocument15 pages0901d1968065e9e7 The SKF Model For Calculating The Frictional Movement - TCM - 12 299767 PDFKengg dglNo ratings yet

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- SKF Sphericl Roller BRNGSDocument2 pagesSKF Sphericl Roller BRNGSkv123No ratings yet

- 7214 BECBM: Angular Contact Ball Bearings, Single RowDocument4 pages7214 BECBM: Angular Contact Ball Bearings, Single RowarieprachmanNo ratings yet

- The SKF Model For Calculating The Frictional Moment: Diagram 1 Shows How Friction Changes, As ADocument15 pagesThe SKF Model For Calculating The Frictional Moment: Diagram 1 Shows How Friction Changes, As AkiranmittisilaNo ratings yet

- SKF Bearing SelectDocument7 pagesSKF Bearing SelectJaimeNo ratings yet

- The SKF Model For Calculating The Frictional Moment - TCM - 12 299767Document15 pagesThe SKF Model For Calculating The Frictional Moment - TCM - 12 299767MikaelNo ratings yet

- Technical Principles Rolling Bearings Friction and Increases in TemperatureDocument6 pagesTechnical Principles Rolling Bearings Friction and Increases in TemperatureGunjan PatelNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- Angular Contact Ball Bearings, Single Row: DimensionsDocument4 pagesAngular Contact Ball Bearings, Single Row: DimensionsJaganathan KrishnanNo ratings yet

- SLIDING CONTACT BEARINGS W ProblemsDocument28 pagesSLIDING CONTACT BEARINGS W ProblemsRex OabelNo ratings yet

- Ccja - W33va405 - 20200422Document4 pagesCcja - W33va405 - 20200422adhyNo ratings yet

- RTA-01-02 Crosshead Bearing Vertical Bearing Clearance Frteas2Document4 pagesRTA-01-02 Crosshead Bearing Vertical Bearing Clearance Frteas2Catalin CataNo ratings yet

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- Proyect G 23Document3 pagesProyect G 23adamNo ratings yet

- Rodamientos de Cinta de RodillosDocument5 pagesRodamientos de Cinta de RodillosAlejandro Enriquez SalazarNo ratings yet

- 18 Engine Lubrication - Unimog 435 Workshop ManualDocument30 pages18 Engine Lubrication - Unimog 435 Workshop ManualJuan JapNo ratings yet

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

- 28 GBDocument40 pages28 GBjahzooneNo ratings yet

- Reporte SKFDocument2 pagesReporte SKFJaimeNo ratings yet

- Wellhead Fittings & Valve Components - PGI-WFDocument28 pagesWellhead Fittings & Valve Components - PGI-WFIan KevinNo ratings yet

- Omm Ex1200-6 PDFDocument22 pagesOmm Ex1200-6 PDFdayatNo ratings yet

- VibrationSeverityGuidelines PDFDocument2 pagesVibrationSeverityGuidelines PDFPuchit SpkNo ratings yet

- VibrationSeverityGuidelines PDFDocument2 pagesVibrationSeverityGuidelines PDFEng MBNo ratings yet

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDocument2 pagesMechanical Seals - Mechanical Seals For Pumps - Pusher SealsimtiyazNo ratings yet

- 566 563D TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialDocument5 pages566 563D TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialFAVIONo ratings yet

- Cylindrical Roller Bearings, Four-Row: DesignDocument3 pagesCylindrical Roller Bearings, Four-Row: Designmanoj_doshi_1No ratings yet

- SKF - Bearing - Select Oil CoolerDocument7 pagesSKF - Bearing - Select Oil CoolerSơn Quốc CầuNo ratings yet

- 127-152 КлапанаDocument26 pages127-152 Клапанаalieks.klim1611No ratings yet

- Angular Contact Ball Bearings, Double Row: DimensionsDocument4 pagesAngular Contact Ball Bearings, Double Row: DimensionsIsmael Duvan Pabon LeonNo ratings yet

- MMME1024 Engineering Design and Design Project Bearings 1: DR Mike JohnsonDocument26 pagesMMME1024 Engineering Design and Design Project Bearings 1: DR Mike JohnsonRishNo ratings yet

- Z5 Parker-Praedifa GBDocument2 pagesZ5 Parker-Praedifa GBArun51092No ratings yet

- Formato Arial G23par2Document3 pagesFormato Arial G23par2adamNo ratings yet

- Technical Details: Piston SealsDocument2 pagesTechnical Details: Piston SealsRPINILLA (EICO S.A.)No ratings yet

- Timken 22219EJW33-SphericalRollerBearings-SteelCageDocument4 pagesTimken 22219EJW33-SphericalRollerBearings-SteelCageArief sitompulNo ratings yet

- PreLoad in BearingsDocument7 pagesPreLoad in BearingsRaghavendra NagarajNo ratings yet

- T 50 PG 65-66 PDFDocument2 pagesT 50 PG 65-66 PDFJossimar PerezNo ratings yet

- SBPT Catalogue DC CouplingDocument11 pagesSBPT Catalogue DC CouplingEserNo ratings yet

- Angrenaj MelcatDocument4 pagesAngrenaj MelcatDiana Maria CozmaNo ratings yet

- Calculation / Installation Proposal: Bearing AnalysisDocument2 pagesCalculation / Installation Proposal: Bearing AnalysisDaniel Andrés ReigNo ratings yet

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument17 pagesFord Worldwide Fastener Standard: Printed Copies Are UncontrolledRico MalibiranNo ratings yet

- 7340 BCBM: Angular Contact Ball Bearings, Single RowDocument4 pages7340 BCBM: Angular Contact Ball Bearings, Single RowMohamed AliNo ratings yet

- AGITATORDocument75 pagesAGITATORRidwansyah HelmiNo ratings yet

- Specifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosDocument6 pagesSpecifications 7.1: Table 7-1. Transmission Data Table 7-2. Internal Gear RatiosMarcelo Ramos SaldanhaNo ratings yet

- 5 6336639141853267248Document3 pages5 6336639141853267248penNo ratings yet

- Is 3624 1987 PDFDocument56 pagesIs 3624 1987 PDFpanduranganraghuramaNo ratings yet

- Is 4711 2008Document9 pagesIs 4711 2008Rishab TanejaNo ratings yet

- Disclosure To Promote The Right To InformationDocument7 pagesDisclosure To Promote The Right To InformationSriram SubramanianNo ratings yet

- Is 2693 1989Document12 pagesIs 2693 1989devang asherNo ratings yet

- Is 3624 1987 PDFDocument56 pagesIs 3624 1987 PDFpanduranganraghuramaNo ratings yet

- Holiday List For 2022Document2 pagesHoliday List For 2022penNo ratings yet

- SS Case Process Pressure Gauge: FeaturesDocument4 pagesSS Case Process Pressure Gauge: FeaturespenNo ratings yet

- Key Way SpecifyDocument1 pageKey Way SpecifyMichaelNo ratings yet

- Is 1239 BookDocument34 pagesIs 1239 Booknagaraj108No ratings yet

- Is 3624 1987 PDFDocument56 pagesIs 3624 1987 PDFpanduranganraghuramaNo ratings yet

- Disclosure To Promote The Right To InformationDocument6 pagesDisclosure To Promote The Right To InformationpenNo ratings yet

- Is 8805 2002 PDFDocument18 pagesIs 8805 2002 PDFShamik ChowdhuryNo ratings yet

- Is.7651.1997 Wire Reinforced Rubber Covered Hydraulic HoseDocument14 pagesIs.7651.1997 Wire Reinforced Rubber Covered Hydraulic HosepenNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationAtendra SinghNo ratings yet

- IS 7906-3 - Helical Compression SpringsDocument6 pagesIS 7906-3 - Helical Compression SpringsVishal MistryNo ratings yet

- Trochoid Pump Products GuideDocument2 pagesTrochoid Pump Products GuidepenNo ratings yet

- Anti Micropitting Gear Oil: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationDocument1 pageAnti Micropitting Gear Oil: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationpenNo ratings yet

- Circulating and Hydraulic Oils (Anti-Wear Type)Document1 pageCirculating and Hydraulic Oils (Anti-Wear Type)penNo ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationpenNo ratings yet

- Is 7907 1 2004 PDFDocument30 pagesIs 7907 1 2004 PDFAnisVisuNo ratings yet

- Trochoid Pump Products GuideDocument2 pagesTrochoid Pump Products GuidepenNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationpenNo ratings yet

- Circulating and Hydraulic Oils (R&O Type)Document1 pageCirculating and Hydraulic Oils (R&O Type)penNo ratings yet

- Synthetic Gear OilsDocument1 pageSynthetic Gear OilsPawan ChaturvediNo ratings yet

- Fire Resistant Hydraulic Fluids (Water Free)Document1 pageFire Resistant Hydraulic Fluids (Water Free)penNo ratings yet

- Control Valve Hydraulic FluidDocument1 pageControl Valve Hydraulic FluidmanilakumariNo ratings yet

- Circulating Oils (Anti-Wear Type) : Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationDocument1 pageCirculating Oils (Anti-Wear Type) : Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationpenNo ratings yet

- Spindle Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationDocument1 pageSpindle Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Description / ApplicationpenNo ratings yet

- Fire Resistant Hydraulic Fluids (Water Glycol Type)Document1 pageFire Resistant Hydraulic Fluids (Water Glycol Type)penNo ratings yet

- 2019 New Product From WintomDocument6 pages2019 New Product From WintomVictorNo ratings yet

- Dolphins in The Water!: Add OnDocument21 pagesDolphins in The Water!: Add Ongeorgika_85No ratings yet

- Phys Ed Semester PlanDocument4 pagesPhys Ed Semester Planapi-200845891100% (1)

- TB016Document1 pageTB016frank rodriguezNo ratings yet

- La Llamada de CthulhuDocument10 pagesLa Llamada de CthulhuHer Kaky0% (1)

- A Week in AlicanteDocument1 pageA Week in AlicanteAlexandruOpreanNo ratings yet

- Alphaex Capital Candlestick Pattern Cheat Sheet InfographDocument1 pageAlphaex Capital Candlestick Pattern Cheat Sheet InfographRizal MahendraNo ratings yet

- Pattern - Amigurumi Cat Doll: Created by Havva ÜnlüDocument30 pagesPattern - Amigurumi Cat Doll: Created by Havva ÜnlüRamos MontseNo ratings yet

- Create A Poster of Your Favourite Band or SingerDocument2 pagesCreate A Poster of Your Favourite Band or SingerGerardo E. GonzálezNo ratings yet

- Johnson OE (2012) - Therapeutic Exercises in The Management of Non-Specific Low Back PainDocument23 pagesJohnson OE (2012) - Therapeutic Exercises in The Management of Non-Specific Low Back PainApollwn100% (1)

- Livrogustavo78 3 330 74332 8Document94 pagesLivrogustavo78 3 330 74332 8claudiiNo ratings yet

- Clinical Observation Score SheetDocument5 pagesClinical Observation Score Sheetdominiquejonker05No ratings yet

- Opaheke SchoolDocument4 pagesOpaheke SchoolmikebcappNo ratings yet

- Pathophysiology of DiabetesDocument3 pagesPathophysiology of DiabetesJeffrey Ramos GironNo ratings yet

- Belt DrivesDocument10 pagesBelt DrivesJyoti ChoudharyNo ratings yet

- Honeywell Rookie Safety ShoeDocument2 pagesHoneywell Rookie Safety ShoeAbdul Quddus Mat IsaNo ratings yet

- First Step Poker (William T. Love) PDFDocument0 pagesFirst Step Poker (William T. Love) PDFIrina ConstantinescuNo ratings yet

- List of Experts On GST 0Document9 pagesList of Experts On GST 0Rahul SharmaNo ratings yet

- BW172D-2 NO 109520120xxx Parts BookDocument278 pagesBW172D-2 NO 109520120xxx Parts BookOecox Cah Djadoel100% (7)

- Doc559863158 662202728Document22 pagesDoc559863158 662202728babibel19100% (2)

- Republic of The Philippines Department of EducationDocument3 pagesRepublic of The Philippines Department of EducationSherwin Basan CelestialNo ratings yet

- Sinag Pep Squad: Adversities Behind Victories: Deped Beefs Up Digital Education ThroughDocument8 pagesSinag Pep Squad: Adversities Behind Victories: Deped Beefs Up Digital Education ThroughBilly Grant Ponayo BalonaNo ratings yet

- Spyder Victor 2012Document36 pagesSpyder Victor 2012William HernándezNo ratings yet

- The Vault of DribbleDocument49 pagesThe Vault of Dribbleabdul haadi75% (4)

- Starting Out in Backgammon (Paul Lamford)Document128 pagesStarting Out in Backgammon (Paul Lamford)Spiros Tramountanas100% (2)

- Dark of The Matinée (The) TAB+SHEETDocument3 pagesDark of The Matinée (The) TAB+SHEETCésarMendozaBajecaNo ratings yet

- Ice Hockey Officials' Signals: (Women's Only)Document1 pageIce Hockey Officials' Signals: (Women's Only)Edelmar EspedillonNo ratings yet

- Assignment 01 DS Solutions Math 2401 2018Document2 pagesAssignment 01 DS Solutions Math 2401 2018Marvin McLeodNo ratings yet

- SOCKS Product Catalogue UpdateDocument6 pagesSOCKS Product Catalogue UpdateKazi Abdullah All MamunNo ratings yet

- Exercise Effect On The Respiratory SystemDocument18 pagesExercise Effect On The Respiratory SystemSunitha100% (4)