Professional Documents

Culture Documents

Review Paper - TRM Vs FRP

Uploaded by

Manisha ShewaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review Paper - TRM Vs FRP

Uploaded by

Manisha ShewaleCopyright:

Available Formats

REVIEW PAPER

A REVIEW ON TEXTILE REINFORCED MORTAR AND FIBER

REINFORCED POLYMER COMPOSITES FOR

STRUCTURAL APPLICATIONS

By

H. R. PRIYANKA * MADHAVI K. **

*-** Department of Civil Engineering, RV College of Engineering, Bengaluru, India.

Date Received: 07/06/2020 Date Revised: 26/06/2020 Date Accepted: 13/07/2020

ABSTRACT

Fibre reinforced composites are being used to strengthen the structural components. Fibre Reinforced Polymer which

consists of organic matrices are widely used for structural retrofitting due to its high strength to weight ratio. The use of

fibre reinforced cementitious mortar (FRCM) is gaining popularity due to their ability to evade the problems associated

with fibre reinforced polymer (FRP) systems. The advantages of FRCM are (i) mortar used in FRCM system is more

compatible with the concrete and masonry substrate compared to epoxy; (ii) high thermal conductivity; (iii) fire

resistance and (iv) can be applied on wet surfaces. Recycled materials can be incorporated in FRCM systems leading to

a sustainable product with less impact on the environment. Therefore, the use of FRCM is becoming attractive for

retrofitting of structures than FRP which are being widely used. This paper addresses the application of textile reinforced

mortar (TRM) composites over FRP in strengthening of structural members.

Keywords: Textile Reinforced Mortar, Fiber Reinforced Polymer, Fibre, Composite.

INTRODUCTION

The deterioration of reinforced concrete structural

members occurs due to several causes such as exposure

to severe environmental conditions. Several techniques

have been proposed in the past to mitigate these effects

and increase service life of structure (Chen & Teng, 2003).

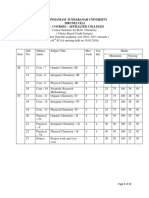

Fiber reinforced composites as shown in Figure 1. are

budding to be better option to retrofit reinforced structures

due to its high strength, light weight, higher stiffness and also

does not interfere the regular function of the building. These

include Fiber Reinforced Polymer (FRP) system and

Figure 1. Fiber Reinforced Composite (Jawaid et al., 2018)

ferrocement. A number of studies have been carried out by

many researchers worldwide regarding fibre reinforced strengthen RC structures have been studied and widely

composites to strengthen the structures (Achudhan et al., accepted (Balachandar et al., 2019; Das et al., 2019).

2019; Arpitha & Yogesha, 2017; Cheon et al., 2020; Despite the added advantage and effectiveness, the FRP

Holčapek et al., 2017; Pani et al., 2019; Pohoryles & strengthening systems have major drawbacks such as i)

Bournas, 2020). Upgrading the members is one among the handling and application of epoxy resin ii) lack of

simplest technique. Addition or installation of formwork compatibility iii) high cost. To replace the drawbacks of FRP

adds weight to the members and is labour intensive. The a new system was introduced called as textile reinforced

usage of Fiber Reinforced Polymer (FRP) systems to mortars. The organic matrices consisting of epoxy is

34 i-manager’s Journal on Civil Engineering, Vol. 10 l

No. 2 l

March - May 2020

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Construction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeDocument9 pagesConstruction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeManisha ShewaleNo ratings yet

- Research Progress On The Flexural Behaviour ofDocument22 pagesResearch Progress On The Flexural Behaviour ofManisha ShewaleNo ratings yet

- Fabric-Reinforced Cementitious Matrix A Promising StrengtheningDocument18 pagesFabric-Reinforced Cementitious Matrix A Promising StrengtheningManisha ShewaleNo ratings yet

- Mechanical Properties of TRM Inorganic MatrixDocument36 pagesMechanical Properties of TRM Inorganic MatrixManisha ShewaleNo ratings yet

- Construction and Building Materials: Saad M. Raoof, Lampros N. Koutas, Dionysios A. BournasDocument13 pagesConstruction and Building Materials: Saad M. Raoof, Lampros N. Koutas, Dionysios A. BournasManisha ShewaleNo ratings yet

- Flexural Behavior of Reinforced Concrete Beams Strengthened With TextileDocument32 pagesFlexural Behavior of Reinforced Concrete Beams Strengthened With TextileManisha ShewaleNo ratings yet

- Shrinkage Losses - 2 PDFDocument5 pagesShrinkage Losses - 2 PDFManisha ShewaleNo ratings yet

- Analysis & Design of Statically Indeterminate StructuresDocument20 pagesAnalysis & Design of Statically Indeterminate StructuresManisha Shewale50% (2)

- Concept of Prestressed PDFDocument10 pagesConcept of Prestressed PDFManisha ShewaleNo ratings yet

- Unit VI: Plastic Analysis of StructuresDocument56 pagesUnit VI: Plastic Analysis of StructuresManisha ShewaleNo ratings yet

- SRI VIDYA COLLEGE OF ENGINEERING & TECHNOLOGY STRUCTURAL ANALYSIS-II QUESTION BANKDocument21 pagesSRI VIDYA COLLEGE OF ENGINEERING & TECHNOLOGY STRUCTURAL ANALYSIS-II QUESTION BANKManisha ShewaleNo ratings yet

- QB Ps Research Methodology PDFDocument18 pagesQB Ps Research Methodology PDFmohit4physicsNo ratings yet

- Plastic Analysis PDFDocument69 pagesPlastic Analysis PDFShakeelNo ratings yet

- Questions With SolutionsDocument6 pagesQuestions With SolutionsManisha ShewaleNo ratings yet

- PHDDocument15 pagesPHDManisha ShewaleNo ratings yet

- QB Ps Research Methodology PDFDocument18 pagesQB Ps Research Methodology PDFmohit4physicsNo ratings yet

- Structural Design and Drawing Iii: SDIII: Session On PracticalDocument17 pagesStructural Design and Drawing Iii: SDIII: Session On PracticalManisha ShewaleNo ratings yet

- SDIII Practical SessionDocument1 pageSDIII Practical SessionManisha ShewaleNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lake Fred Watershed ProposalDocument6 pagesLake Fred Watershed ProposalCailinBaderNo ratings yet

- High Productivity Methanol Carbonylation Catalysis Using Iridium The CativaTM Process For The Manufacture of Acetic AcidDocument15 pagesHigh Productivity Methanol Carbonylation Catalysis Using Iridium The CativaTM Process For The Manufacture of Acetic AcidPragadeeshNo ratings yet

- ISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HDocument7 pagesISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HBrijesh GajjarNo ratings yet

- Non-Evaluative Portion - ChemistryDocument3 pagesNon-Evaluative Portion - ChemistrySwastik PatilNo ratings yet

- 13 - OGV Inner ShroudDocument4 pages13 - OGV Inner ShroudVALDEMIRNo ratings yet

- Lec 1 Hydrocarbon TypesDocument17 pagesLec 1 Hydrocarbon TypesSagar JaisiNo ratings yet

- Chapter 8 - Elimination ReactionsDocument68 pagesChapter 8 - Elimination ReactionsBianca-Rebeca PetreNo ratings yet

- Aerosol-OT Surfactant Forms Stable Reverse MicelleDocument33 pagesAerosol-OT Surfactant Forms Stable Reverse MicelleSantiago LopezNo ratings yet

- Water Treatment Plant With RO For Mineral Water Rahul VKDocument13 pagesWater Treatment Plant With RO For Mineral Water Rahul VKRahul Khedkar100% (1)

- Name: Tati Elfrida Samosir NIM: 1951170 Class: Pharmacy 1-A Chemistry Number Symbol Name NotesDocument2 pagesName: Tati Elfrida Samosir NIM: 1951170 Class: Pharmacy 1-A Chemistry Number Symbol Name NotesTaty Ai Elfrida SamosirNo ratings yet

- Pom 90Document2 pagesPom 90busyNo ratings yet

- Protocol - Serum CholesterolDocument2 pagesProtocol - Serum CholesterolBianca Chellyne AguilarNo ratings yet

- 706 Aed 831676438Document27 pages706 Aed 831676438Online JobNo ratings yet

- 2 Ralf NeumannDocument10 pages2 Ralf Neumannbhagavathi KatamNo ratings yet

- AU Instructions For Use Creatine Kinase (CK NAC)Document8 pagesAU Instructions For Use Creatine Kinase (CK NAC)Anas TjNo ratings yet

- Part ІІ Microscopic World I: Ans: ADocument7 pagesPart ІІ Microscopic World I: Ans: AGabriel FungNo ratings yet

- Chemistry HYDocument8 pagesChemistry HYHarini DasNo ratings yet

- Perspective in Pharmacy SlidesDocument37 pagesPerspective in Pharmacy SlideschinNo ratings yet

- 555 Tech Data SheetDocument1 page555 Tech Data SheetAhmed OusamaNo ratings yet

- Project Details: Synthetic Organic Chemicals 5 (F) For Terms of Reference (Tor) New ProjectDocument14 pagesProject Details: Synthetic Organic Chemicals 5 (F) For Terms of Reference (Tor) New Projectrajesh kothariNo ratings yet

- Up 1755 WFDocument1 pageUp 1755 WFMena TharwatNo ratings yet

- BIORESONANCE REPORT DECODEDDocument32 pagesBIORESONANCE REPORT DECODEDJuan Pablo RosasNo ratings yet

- Biological Treatment of Hazardous WasteDocument47 pagesBiological Treatment of Hazardous Wastesamson meseretNo ratings yet

- The Impact of Antiozonants On Rubber-to-Metal Adhesion, Part 2 - LORD CorpDocument18 pagesThe Impact of Antiozonants On Rubber-to-Metal Adhesion, Part 2 - LORD CorpMarcos ROSSINo ratings yet

- Characteristics of Mareme Leaf Simplicia and ExtractsDocument6 pagesCharacteristics of Mareme Leaf Simplicia and ExtractsgunturNo ratings yet

- 1 Romania Catalog 2023 _compressedDocument141 pages1 Romania Catalog 2023 _compressedbazarulonline.roNo ratings yet

- Pressure Vessel Plates, Carbon Steel, Manganese-Titanium For Glass or Diffused Metallic CoatingsDocument2 pagesPressure Vessel Plates, Carbon Steel, Manganese-Titanium For Glass or Diffused Metallic CoatingsNagendra KumarNo ratings yet

- Diesel SDS V2Document14 pagesDiesel SDS V2francisNo ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- Refinery and Petrochemical Equipment: Distillation ColumnDocument48 pagesRefinery and Petrochemical Equipment: Distillation ColumnFikrie MuhdNo ratings yet