Professional Documents

Culture Documents

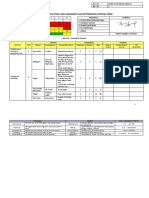

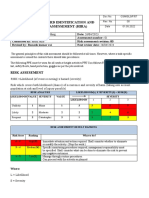

Risk Assessment Form: Risk Analysis Additional Control Risk Analysis With Controls Evaluation

Uploaded by

amr soud0 ratings0% found this document useful (0 votes)

13 views8 pages1. The risk assessment form identifies 10 potential hazards at a work site including misunderstanding job plans, lack of familiarity with escape routes, dropped objects from cranes, swinging loads, working at heights, and manual handling of heavy tools.

2. For each hazard, the form evaluates the existing controls and consequences, and provides recommendations to reduce the level of risk such as safety meetings, inspections, permits, PPE, and mechanical assistance.

3. The overall goal is to minimize safety risks at the work site through proper planning, communication of hazards, use of protective equipment, and addressing issues like housekeeping, access, and load handling procedures.

Original Description:

Original Title

Risk Assesment

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The risk assessment form identifies 10 potential hazards at a work site including misunderstanding job plans, lack of familiarity with escape routes, dropped objects from cranes, swinging loads, working at heights, and manual handling of heavy tools.

2. For each hazard, the form evaluates the existing controls and consequences, and provides recommendations to reduce the level of risk such as safety meetings, inspections, permits, PPE, and mechanical assistance.

3. The overall goal is to minimize safety risks at the work site through proper planning, communication of hazards, use of protective equipment, and addressing issues like housekeeping, access, and load handling procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views8 pagesRisk Assessment Form: Risk Analysis Additional Control Risk Analysis With Controls Evaluation

Uploaded by

amr soud1. The risk assessment form identifies 10 potential hazards at a work site including misunderstanding job plans, lack of familiarity with escape routes, dropped objects from cranes, swinging loads, working at heights, and manual handling of heavy tools.

2. For each hazard, the form evaluates the existing controls and consequences, and provides recommendations to reduce the level of risk such as safety meetings, inspections, permits, PPE, and mechanical assistance.

3. The overall goal is to minimize safety risks at the work site through proper planning, communication of hazards, use of protective equipment, and addressing issues like housekeeping, access, and load handling procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

RISK ASSESSMENT FORM

Risk

Risk Analysis

Analysis Additional with Evaluation

No Hazard Consequences Existing Control controls

control

S L R S L R

Make sure the

whole crew

On arriving to the The crew Review the attended the

1 site, personnel aren’t doesn’t know escape routes in 3 B 3B safety induction 2 B 2B

familiar with the the escape pre-job safety course and each

location layout routes at meeting by the know the safety

emergency case job supervisor requirements

and good

sticking to it

*Issue PTW

and update JRA

should be

*Misunderstanding discussed

2 the plan of the job Confusion lead *Conduct pre- 2 B 2B

to mistakes job meeting

*Hazards of the job with crew

aren’t clearly known discussing all

by the operators hazards

*Use clear

language

*Identify

roles&

responsibilities

*Slippery if

there is oil spill

*Verification

*Preparation for t the *Tripping and

work area Falling. for the position

of isolation

3 *Housekeeping the *Injuries. and/or blind 2 B 2B

work area ones

*Fire *Use FBH to

reach elevated

areas

*H2S Gas

monitoring

*Delay in

Malfunction for starting the job Visual inspection

4 equipment back to resulting in after equipment 2 A 2A

been hit during lay downtime laydown for

checking

down *Company

reputation

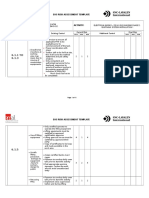

*Only use *Confirm

certified Slings preventative

*Injuries for *Inspect Pad maintenance of

people or eyes certificates crane before

5 Dropped objects fatality *Ensure the 3 C 3C lifting 1 C C

during Rig Up crane CMPI and *Ensure one

*Damage to the crane banksman

equipment operator have *Ensure the job

valid is supervised

certificates. *Issuing PTW

*Ensure load *Insure full PPE

test certificate is *Staying away

valid from the radius

*Safety meeting of the crane

with all people carrying the

involved in the load

operation

*All people

have to be away

from outriggers

*Check the

weather

*People injuries conditions

*Use tag lines

*Pinching or *Check the load

crushing limits

6 Swinging Loads *Tool box 2 B 2B

*Back Injuries meeting about

the hazards and

*Objects hit in the injuries

eyes *Obligatory to

wear the full

PPE

* Project HSE, * Protection of

Ops HSE and any adjacent

*Falling PA to reviewed utilities

*Working at height the installed * Designated

7 *Injuries scaffold to be 3 C 3C access/egress 3 A 3A

*Dropped objects sure the erected routes to be

scaffold used at all

*Equipment

contained the times.

damages working area * Good

and has safe housekeeping

access and standards to be

egress, smooth maintained at

platforms to all times

avoid tripping *Use full body

and good harness

fixation of *Install

wooden plates barricaded tape

and tie boards around the

* Green tag for working area.

scaffold *Avoid/control

inspection to be enter this area

installed and by unauthorized

signed by persons and

scaffold entrance to

inspector before controlled by

use the scaffold assigned area

* Keep the authority.

scaffold free * Any manual

from loose handling to be

materials done by rope to

equipment and avoid dropping

descending any objects and

unused under

materials/hand supervision of

tools to a assigned area

dedicated

authority and be

location on the

sure no one

ground

* Minimize the underneath

number of during this

persons to the handling

task on-going

only and people

waiting to be

away from the

working

Downtime Apply function

affecting the test as its

8 Delay in execution of cost and the operational 2 B 2B

the job reputation of safety standards

the company to check the

equipment’s.

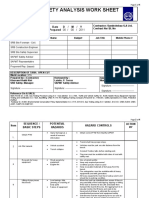

*Surround the

*Property location with Inform the

damage caution tap or client HSE to

9 Vehicle Access barrier 3 B 3B direct the 2 B 2B

*Injury *Designate vehicles to

other road for another way

vehicles

*Pre-job tool

box about the

hazards

including in the

job

*Back injuries *If the tool

10 Manual handling exceeds 10 Kg 2 B 2B

hand tools *Pinching has to be

fingers carried by more

than one

* If the tool is

heavier than

been carried by

human, use a

mechanical tool

(ex. Forklift)

*Use proper

gloves

*Competent

crew

Wear full PPE (

SCBA)

*Watcher *Confirm there

outside the is a connection

vessel between the

*Full body worker inside

*Suffocation harness and the vessel and

11 Working in confined anchor point in 2 C 2C the supervisor 2 B 2B

space *Asphyxiation working at outside the

height in the vessel

vessel *Competent

*Presence of person only

backup SCBAs, authorized to

stretcher and enter the vessel

tripod at

emergency case

*Wear an *There has to

Work at top of the anchored full be gauges

vessel operating the *Falling body harness watcher

12 rotating part if the *Use mask to 3 B 3B *Barrier has to 2 B 2B

hose inside the vessel *Suffocation avoid dust be put to keep

harms people away

*Wear full PPE from this area

*Material *Housekeeping

deterioration for hoses

*Inadequate use *Periodic check *Replacement

of hoses for hoses for any worn

13 High pressure hose *Detachment *Confirm hoses one or with no

2 C 2C 2 B 2B

from any of service pressure certificate

both ends and temperature *Confirm

attached to the *Use whip service fluid

asset check to keep it

attached

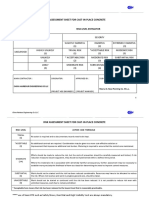

*Presence of

spill kit

*Control of fire

*Chemical source

14 Chemical handling spills *Fire

extinguishers 2 B 2B

*People injuries must be

available

*Handling tool

box talk by the

supervisor

15 Motor sparks Fire There has to be 2 B 2B

spark arrestor

Bad communication Good handover

in closing the work *Injury to the location

16 permit with the client, 2 B 2B

(Bad handling the *Fatality with the last

client the location situation.

with the last status)

Check all vents

This line has to are opened

17 Pressurized line Harm people or be vented 2 C 2C before starting 2 B 2B

asset before leaving the process

flowing

You might also like

- Allison 1000 y 2000Document672 pagesAllison 1000 y 2000Mauricio Gomez Gomez100% (10)

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Step by Step TroubleshootingDocument9 pagesStep by Step TroubleshootingKenny CreechNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- JHA - Handrails and GratingsDocument10 pagesJHA - Handrails and GratingsVidyesh Nair67% (3)

- Risk Assessment Work at HeightDocument3 pagesRisk Assessment Work at HeightSathi sh0% (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- JSA 06 (Rebar Assembly Work)Document8 pagesJSA 06 (Rebar Assembly Work)abdulthahseen007100% (1)

- RMDJV Pj74 Hiradc Sube 01 (Equipment Delivery)Document2 pagesRMDJV Pj74 Hiradc Sube 01 (Equipment Delivery)myn maliQueNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Job Safety Analysis (JSA) Stringing WorkDocument4 pagesJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar50% (4)

- Blasting and Painting - BUHPDocument6 pagesBlasting and Painting - BUHPMuhammed yahiyaNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Cast-In Place Concrete - Risk Assessment SheetDocument3 pagesCast-In Place Concrete - Risk Assessment SheetYash SharmaNo ratings yet

- RA HSE 12 001 Process Rev03Document3 pagesRA HSE 12 001 Process Rev03zarni77No ratings yet

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentMohammed Shiful0% (1)

- RoofWaterProofing - Risk Assessment SheetDocument7 pagesRoofWaterProofing - Risk Assessment SheetYash Sharma100% (2)

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- Manual de Servicio Rayos X INNOVETDocument113 pagesManual de Servicio Rayos X INNOVETTeresa Rosas Guzmán100% (1)

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Job Hazard Analysis For Cementitious GroutingDocument8 pagesJob Hazard Analysis For Cementitious Groutingaloysius akpanNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Neutral Ground Resistor Calculation For TransformerDocument2 pagesNeutral Ground Resistor Calculation For TransformerJeya Kannan89% (9)

- IEC 60071 Insulation Coordination Abb LiteratureDocument8 pagesIEC 60071 Insulation Coordination Abb Literaturereza515hei100% (2)

- BMK 1250-6.1 enDocument116 pagesBMK 1250-6.1 enEdilson100% (1)

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Document1 pageJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007No ratings yet

- EdSim51 - Notes On The 8051Document16 pagesEdSim51 - Notes On The 8051Pawan KaswanNo ratings yet

- Forecourt Risk AssessmentDocument8 pagesForecourt Risk AssessmentsalesNo ratings yet

- C063 JSA For Installaiton of I Beam at Laundry AreaDocument7 pagesC063 JSA For Installaiton of I Beam at Laundry Areaiftikhar ahmadNo ratings yet

- Hira Fan & Components Lifting ShiftingDocument4 pagesHira Fan & Components Lifting ShiftingBilal QureshiNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- Jha EpoxyDocument4 pagesJha Epoxyaloysius akpanNo ratings yet

- HSE Risk AssessmentDocument4 pagesHSE Risk Assessmentwhtez0neNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 BahhierNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Job Hazard Analysis For Corrosion Control On Gto 5Document14 pagesJob Hazard Analysis For Corrosion Control On Gto 5aloysius akpanNo ratings yet

- Revised-JSA On WTG InstallationDocument16 pagesRevised-JSA On WTG InstallationRaza Muhammad SoomroNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Parvez Taslim OfficialNo ratings yet

- HIRAC - Soil ProtectionDocument7 pagesHIRAC - Soil ProtectionAugust Caezar LagatNo ratings yet

- Adjusment DEHYDRATORSDocument3 pagesAdjusment DEHYDRATORSferielvpkNo ratings yet

- Daqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS record No. 22Document2 pagesDaqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS record No. 22khurramNo ratings yet

- BS SB OPSRA 038 Heavy Lift Crane Operation - GenericDocument4 pagesBS SB OPSRA 038 Heavy Lift Crane Operation - GenericФуад АзимовNo ratings yet

- Doc5.hirard PilingDocument3 pagesDoc5.hirard PilingJames JoviNo ratings yet

- RA Air Gas FillingDocument17 pagesRA Air Gas FillingsantoshNo ratings yet

- 3.ceiling Installation JSA ADocument2 pages3.ceiling Installation JSA APijah AhmadNo ratings yet

- Risk Assessement For AAES ProductsDocument4 pagesRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- MF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Document11 pagesMF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Bhanu Pratap ChoudhuryNo ratings yet

- MGEL JSA Steel Yard-Excavation-Steel WorksDocument7 pagesMGEL JSA Steel Yard-Excavation-Steel WorksengrtofiNo ratings yet

- Brochure 550Document2 pagesBrochure 550serge.pungweNo ratings yet

- COntoh Upload ShopeeDocument106 pagesCOntoh Upload ShopeeBurhanudinUrcNo ratings yet

- Split Air Water Heat Pump Bwl-1 S Installation and Operating InstructionsDocument120 pagesSplit Air Water Heat Pump Bwl-1 S Installation and Operating InstructionsDarek MNo ratings yet

- Design of An Automated Solar-Powered Light Trap For Monitoring and Mass Trapping of Major Date Palm Pests By: Maged E.A. MohammedDocument8 pagesDesign of An Automated Solar-Powered Light Trap For Monitoring and Mass Trapping of Major Date Palm Pests By: Maged E.A. MohammedGino NungayNo ratings yet

- Boom Cylinder Assembly (Right Hand) PDFDocument4 pagesBoom Cylinder Assembly (Right Hand) PDFReyes VargasNo ratings yet

- IR Job No. VI-052-0181 Premier Oil Review01 Rev.Document21 pagesIR Job No. VI-052-0181 Premier Oil Review01 Rev.Salman Syafar RamzyNo ratings yet

- Catalog-Mmc 2014 Web (LD)Document184 pagesCatalog-Mmc 2014 Web (LD)carlosNo ratings yet

- Chapter 5. The Service MenuDocument5 pagesChapter 5. The Service MenuMiquiztli SpillingNo ratings yet

- Ptat Current SourcesDocument16 pagesPtat Current SourcesqqqbobqqqNo ratings yet

- SABER PRO - PART 5 (II) - Revisión Del IntentoDocument3 pagesSABER PRO - PART 5 (II) - Revisión Del IntentoOscar Leandro Gaitan VasquezNo ratings yet

- KategoriDocument218 pagesKategoriIlham KurniaNo ratings yet

- Programmer ENDocument1 pageProgrammer ENDaniel IliescuNo ratings yet

- Spare Parts List Cori Puno C32019008 Ver20191120Document5 pagesSpare Parts List Cori Puno C32019008 Ver20191120Elmer LizanaNo ratings yet

- DRV8312 C2 KIT HWGuideDocument12 pagesDRV8312 C2 KIT HWGuideYang ElvisQUNo ratings yet

- SER SER SER SER Servo Amplifier Vo Amplifier Vo Amplifier Vo Amplifier Vo AmplifierDocument28 pagesSER SER SER SER Servo Amplifier Vo Amplifier Vo Amplifier Vo Amplifier Vo AmplifierjeevanNo ratings yet

- 5.6 Execution 5.4 5.5: Ball ValvesDocument2 pages5.6 Execution 5.4 5.5: Ball ValvesMajid DixonNo ratings yet

- CellularRam-External Memory InterfaceDocument21 pagesCellularRam-External Memory InterfaceManuel MaruccoNo ratings yet

- Candy Evogt12701d SM PDFDocument23 pagesCandy Evogt12701d SM PDFgolg1de1994No ratings yet

- Skytop Brewster Brake Blocks For DrawworksDocument3 pagesSkytop Brewster Brake Blocks For DrawworksMuhamad zainiNo ratings yet

- C109 Cut SHDocument1 pageC109 Cut SHDufourNo ratings yet

- 6 FMX 190 (Regular)Document2 pages6 FMX 190 (Regular)Daniel PieriniNo ratings yet

- Bombas Wilden P.025Document24 pagesBombas Wilden P.025Antony CarbajalNo ratings yet

- Caterpillar 9194600610 - Kit de Reparación Cilindro de FrenoDocument3 pagesCaterpillar 9194600610 - Kit de Reparación Cilindro de FrenoFernando PadillaNo ratings yet