Professional Documents

Culture Documents

A Caustic Scrubber System For The Control of Phosgene Emissions Design Testing and Performance

Uploaded by

A KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Caustic Scrubber System For The Control of Phosgene Emissions Design Testing and Performance

Uploaded by

A KumarCopyright:

Available Formats

Journal of the Air Pollution Control Association

ISSN: 0002-2470 (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/uawm16

A Caustic Scrubber System for the Control

of Phosgene Emissions: Design, Testing, and

Performance

Stephen Kistner , Daniel Lillian , John Ursillo , Norval Smith , Kenneth

Sexton , Michael Tuggle , George Esposito , George Podolak & Steven Mallen

To cite this article: Stephen Kistner , Daniel Lillian , John Ursillo , Norval Smith , Kenneth Sexton ,

Michael Tuggle , George Esposito , George Podolak & Steven Mallen (1978) A Caustic Scrubber

System for the Control of Phosgene Emissions: Design, Testing, and Performance, Journal of the

Air Pollution Control Association, 28:7, 673-676, DOI: 10.1080/00022470.1978.10470644

To link to this article: https://doi.org/10.1080/00022470.1978.10470644

Published online: 14 Mar 2012.

Submit your article to this journal

Article views: 1288

View related articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=uawm20

A Caustic Scrubber System for the

Control of Phosgene Emissions:

Design, Testing, and Performance

Stephen Kistner, Daniel Lillian, John Ursillo,

Norval Smith, Kenneth Sexton, Michael Tuggle,

George Esposito, George Podolak, Steven Mallen

U. S. Army Environmental Hygiene Agency,

Aberdeen Proving Ground, Maryland

The body of information presented in this paper is directed toward Arsenal (RMA), Colorado, is an illustrative example of a

those individuals involved with handling hazardous materials, whether comprehensive, environmentally conservative, and accord-

in actual use of such chemicals, or in monitoring atmospheric emis- ingly, a successful program to control emissions of a hazardous

sions. Although specifically relating experience in the design and

substance. Many of the principles developed and much of the

technology evaluated in this program should experience wide

testing of phosgene emission control equipment, it attempts to es- application for controlling emissions of hazardous air pollu-

tablish general guidelines for effectively dealing with emissions of tants in general, with specific application to the rapidly

hazardous materials. An approach for handling chemical pollutants growing phosgene industry with a projected 1978 demand of

having no established air quality emission standards is developed. 1.63 billion lb.

The paper presents a technique for establishing process emissions

at acceptably low levels to insure the health and safety of the general

General

population as well as that of the process workers themselves. Phosgene (or carbonyl chloride) was originally purchased

Methods, suitable for measuring phosgene at these low levels, have by the Army as a chemical warfare agent. In the early 1960's

been investigated, and problems associated with such an investigation this chemical was declared an obsolete agent. Approximately

are discussed. While complete theoretical scrubber design criteria

7.7 million lb of phosgene were collected from the demilitar-

ization of munitions at RMA during the period from No-

are beyond the scope of this paper, many of the "real world" problems

vember 1965 to February 1967 and sold to two purchasers.

which affected scrubber performance are presented. Finally, the These two companies shipped approximately 5.7 million lb

practical aspects of process emissions control are illustrated by actual using commercial transportation before shipments were

results from the system test. suspended in 1969 with the enactment of public laws (PL)

91-121 and 91-441 which mandated the detoxification of

chemical warfare agents prior to transport. Accordingly, the

balance of approximately 2 million lb or 1294 ton containers

(TC) of the carbonyl chloride at RMA reverted to government

In its demilitarization program to dispose of obsolete and control. In October 1973, the Department of Defense an-

retrograde chemical agents and munitions, the U. S. Army is nounced that all lethal agents and munitions at RMA would

often faced with unique engineering and environmental undergo disposal action. Subsequently, specific Congressional

challenges. In many instances these problems are unprece- approval was obtained which permitted disposition of the

dented in nature and not specifically covered by State and/or phosgene by sale, providing that stringent requirements were

Federal guidelines and regulations. Similar to industries de- met to insure safety considerations and environmental in-

veloping new technology, processes, and prototypes, the Army tegrity in its transport.

must develop cost-effective air pollution control systems when

the potential exists for emissions of deleterious compounds. For the commercial sale and transportation of the phosgene

In consonance with Army Regulation 200-1 which mandates stored at RMA, the TC's had to be modified and tested to

the overall policy of the Army regarding environmental meet Department of Transportation specification 106A500X,

matters, considerable emphasis is placed on environmental agent R. M. Graziano's Tariff No. 29, ("Hazardous Materials

safeguards, incorporating state of the art technology into the Regulation of the Department of Transportation").1 Such

design of the control systems, the establishment of emission modification and testing required empty containers, and ac-

guidelines, and the development of comprehensive emissions cordingly, a means and system for transferring phosgene from

monitoring programs. The ongoing demilitarization of some

2 million pounds of phosgene stockpiled at Rocky Mountain Copyright 1978-Air Pollution Control Association

July 1978 Volume 28, No. 7 673

donor TC's to modified and tested receiver TC's had to be the calculation resulted in a maximum allowable emission rate

developed. When working with a relatively hazardous com- of 536 mg/sec (with subsequent blower design resulting in a

pound such as phosgene, even a rather simple hydrostatic maximum stack concentration of 114 mg/m3). However, a

transfer from a donor TC to a receiver TC required detailed review of the methodology employed in Regulation No. 8 re-

evaluations of potential emission ranges corresponding to quired that this approach be modified. The nomograph pro-

normal phosgene transfer, emission ranges corresponding to vided to assist in the determination of the allowable emission

maximum credible accident (MCA), and resulting downwind rate is predicated on the assumption that the existing mete-

ground level phosgene concentrations which would be envi- orology is approximately D stability with a wind speed of 4

ronmentally acceptable. And finally, a candidate control m/sec. However, as more severe meteorology is applied to the

system had to be developed which could accommodate, with situation, that is, as wind speeds become less than 4 m/sec

a margin of safety, the projected phosgene challenge and and/or atmospheric conditions become more unstable, ground

provide the required level of control. level concentrations greater than Vsoth of the TLV will result.

Accordingly, to insure that a ground level concentration

Emission Guidelines greater than Vaoth of the TLV is not exceeded during adverse

meteorological conditions, further dispersion modeling was

The initial step in the solution to a problem of this nature conducted using Turner's fumigation model.3 This modeling

is to determine just what degree of control is required to insure established a maximum allowable stack concentration of 50

a completely safe operation. Since it is the Army's policy to mg/m3. Additionally, to afford operational implementation

comply with all applicable air quality standards in conducting of this emission guideline, a tiered control strategy was es-

such operations, Colorado's Regulation No. 8, "Regulation to tablished. Thus for an emission concentration of 20 mg/m3,

Control Emissions of Chemical Substances and Physical remedial action would be initiated; for an emission concen-

Agents,"2 was applicable. Briefly, this regulation uses a value tration of 40 mg/m3, shutdown procedures would commence

of y3oth of the Threshold Limit Value (TLV) as the supposed so that an emission concentration of 50 mg/m3 would never

maximum ground level concentration not to be exceeded be exceeded.

downwind of the emission point. From this value, the esti-

mated plume rise, and predictive modeling techniques, an Analytical Methods

allowable emission rate for the process of interest is calculated.

Using the TLV for phosgene of 0.2 mg/m3 along with the es- One of the major concerns in the establishment of an air

timated effective stack height for the stack to be employed, emission control program for a hazardous substance is the

Table I. Methods comparison.

Specifi- NIOSH- Manual Automated

cation recommended10 colorimetry colorimetry Gas chromatography Infrared spec. Tape monitor

Alarm set for 0.2 ppm none none, but adapt- none none, but adaptable yes

able

Response <90 sec for 30 min (samp./ 10-20 min 3—6 min 30 sec 5—15 sec

time alarm anal.)

Drift <l%fullscalein drift corrected l%/24 hr >l%/24hr <l%/24hr <l%/24 hr

24 hr

Noise <l%fullscale 0.5% 1% 10% at 0.2 ppm F. S. 0.25%

Accuracy ±10% of signal, ±20% ±15% ±15% i ±10% ±15%

0.05 to 0.4

ppm

Precision ±5% fullscale ±15% ±6% ±10% ±4% ±6%

Specificity if interferences, specific specific specific trichloroethylene, specific

known response known

responses

Operating 0—0.4 ppm 0—0.4 ppm 0—0.4 ppm 0—0.4 ppm 0—0.4 ppm 0—0.4 ppm

range

Operation 168 hr contin- 24 hr contin- 8 hr continuous with 168 hr continuous 168 hr continuous

uous uous auto sampling

valve

Explosion safe in explosion yes, with G2- yes, with G2- no yes, with G2- yes

hazard hazard areas approved approved approved

pump pump pump

Detection <0.05 ppm 0.05 ppm 0.001 ppm 0.0001 ppm 0.02 ppm 0.005 ppm

limit

Operating 25 ppm 1 ppm 5 ppm 300 ppm 40 ppm

limit

Calibr. 30 days 24 hr 8hr 7 days 7 days

freq.

Operator every 30 min once daily manual op.: con- once weekly — daily once weekly — daily

attention stant; automated: checks recommended checks recommended

once daily

Downtime none occasional occasional very infrequent very infrequent

Sample 1 1pm 1 lpm 0.5 cc injection 2-5 lpm 0.4 lpm

rate

Operator minimal moderate skilled minimal minimal

expertise

Portability depends on portable — portable portable portable

spectro- 150 1b

photometer

674 Journal of the Air Pollution Control Association

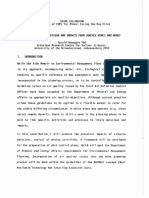

Monitoring Monitoring

po nt sponds to a TLV stack emission concentration which would

Primary l Secondary point

tower

result from an estimated maximum credible accident*

scrubber challenge. A design scenario much more stringent

Transfer

than legally required). However, initial system testing resulted

booths in scrubber efficiencies considerably lower than had been

To anticipated. Actual efficiencies were at least one order of

atmosphere magnitude below the design level.

Additionally, as a test run proceeded, the efficiency de-

Ventilation creased drastically with time. Extensive system testing indi-

cated that both the caustic and sodium carbonate concen-

trations were much more critical than had been determined

from the pilot studies. During the course of a test run, the

Container carbonate concentration would build up gradually as a result

hold of caustic reaction with both phosgene and atmospheric car-

room

bon dioxide. Also, as a test run proceeded the caustic content

was gradually depleted. Both effects tended to lower scrubbing

Scrubbing efficiency.

liquor sump

Based on these results, several process modifications were

Figure 1. Phosgene scrubber system schematic.

made to try to effect an improvement in system performance.

Since the packing height of the towers was fixed and could not

be readily increased, that option was not available. However,

the operating liquid flow rate was increased from 200 to 500

availability of a suitable monitoring technique. The ideal gpm; the caustic makeup was maintained at a level of 4-5%

process in-stack monitor should be sensitive enough to mea- by weight; and the column packing size was increased to 1.5

sure below the established guidelines, real time, relatively in. As a consequence of these rather extensive changes, the

accurate, continuous, simple to operate, and able to withstand design air flow rate had to be reduced from 10,000 cfm to 6000

the conditions which exist in the work area environment. For cfm.

the purposes of monitoring phosgene from the transfer op-

eration, five different methods were investigated.4 Initially, Initial efficiencies, after these modifications, were not sig-

the techniques studied in the laboratory were infrared spec- nificantly improved (i.e., it was still an order of magnitude

troscopy, gas chromatography, automated colorimetry, di- below designed efficiency). However, the drastic decrease in

ethylphthalate (DEP) bubblers, and a colorimetric tape efficiency with time observed in the unmodified system was

monitoring method. Standard phosgene concentrations were much less severe. Nevertheless, because of over design these

obtained from permeation tubes, and potential interferences extended efficiencies were adequate to meet the established

from ammonia, trichloroethylene, water vapor, carbon diox- emission guidelines over the duration of an operational

ide, and hydrogen chloride were examined. Also, to assess day.

these analytical methods under more realistic conditions, they

were evaluated on a common manifold at RMA.5 Tests in- System Testing

cluded mixing phosgene from permeation tubes and/or cyl-

inders with air from a caustic scrubber to simulate an inter- Validation testing was required to select the monitoring

ferent matrix frequently associated with phosgene emission technique which would be used to measure phosgene emis-

control systems. Results of this study indicated that the per- sions under actual process conditions and also to verify

meation devices were well suited for accomplishing routine scrubber performance for controlling phosgene emissions.7

calibration; that all the proposed analytical methods provided Challenge runs were conducted on a wide range of phosgene

acceptable results; also that additional testing would be re- emission rates. These rates were selected to determine the

quired once the actual scrubber system was completed. A lower level of detectability of the monitoring techniques, and

summary of this preliminary field study is contained in Table I. to evaluate the upper level of control provided by the scrubber

Scrubber Design

Concurrent with the evaluation of monitoring methods, a

literature search was conducted and developmental studies

were performed on a pilot packed column. As little data were

available in the literature on packed towers for phosgene

scrubbing, the kinetics and mass transfer data obtained from

the pilot work provided the basis for the design of the columns

at RMA. However, in the pilot studies conducted, there was

no indication of complications which would arise once the

columns had been constructed.

Theoretical design parameters to include a substantial

safety factor resulted in two-counter cur rent packed towers Correlation coefficient=0.93

Phosgene challenge to system = 62.82 g/sec

arranged in series, each 39 ft tall. The initial packed beds x-Tape monitor

consisted of 14.5 ft of 1 in. plastic pall rings. Separate pumps • -Infrared

pulling from a common 4000 gallon sump are used to provide

aqueous sodium hydroxide scrubbing liquor to the tops of the

packed sections at up to 500 gpm per tower. Design liquid flow 0 5 10 15 20 25 30 35 40 45 50 55 60

rate was approximately 200 gpm per tower. Pilot data indi- Time (min)

cated an optimum caustic range of 3 to 8% by weight. The Figure 2. Phosgene concentration (ppm) vs. time (min).

system air flow was to be set at 10,000 cfm to be divided be-

tween the TC holding room and the four transfer booths.6 (See

Figure 1). Solely on theoretical considerations, the scrubber * This corresponds to rupture of a ton container valve, emptying of the container contents

into the transfer booth, and theoretical thermodynamically controlled evaporation of

system was designed for 99.9993% efficiency. (This corre- phosgene into the scrubber («130 g/sec).

July 1978 Volume 28, No. 7 675

Table II. Scrubber efficiencies3

Primary Primary Secondary Total

Challenge Inlet scrubber scrubber scrubber system

rate cone. cone. efficiency cone. efficiency

Date (g/sec) (ppm) (ppm) (%) (ppm) (%)

27 April 2.68 237 0.761 99.68 0.015 99.99+

10.32 911 6.46 99.29 0.050 99.99+

18.93 1671 26.8 98.40 0.470 99.97

28 April 1.00 88 1.17 98.67 0.019 99.98

9.79 864 9.31 98.92 0.132 99.98

29 April 33.11 2922 0.648 99.98

48.07 4242 2.52 99.94

62.83 5545 7.72 99.86

30 April 130.7 11534 6.82 99.94

133.8 11808 10.3 99.91

a

All concentrations and efficiencies are calculated at the end of a challenge run.

system in the event of an unforeseen accident and/or spill. A References

typical test run is illustrated in Figure 2. From these test runs,

along with experience gained in the previous pilot test phase, 1. Draft Environmental Impact Statement, Department of the

it was determined that: Army, subject: Disposition by Sale of Carbonyl Chloride (Pho-

segene)," Jan. 1976.

• The gas chromatography and DEP bubblers suffer 2. "Regulation to Control Emissions of Chemical Substances and

the disadvantage of not providing a continuous phosgene Physical Agents," Regulation No. 8, State of Colorado Depart-

ment of Health, Air Pollution Control Commission, Denver, CO,

measurement. In addition, the bubbler technique does not Adopted 27 Nov. 1973, as amended 5 Dec. 1974.

provide a real time analysis. 3. D. Bruce Turner, Workbook of Atmospheric Dispersion Esti-

• The automated colorimetric method, although very mates, Office of Air Programs, Environmental Protection Agency,

Revised 1970.

sensitive, was slow, and required considerable time and effort 4. "Phosgene Analysis Methods Development," U. S. Army Envi-

for reagent preparation. ronmental Agency, Feb. 1976.

• The infrared technique provided the most accurate 5. "Air Pollution Engineering Special Study No. 99-041-75/76,

Phosgene Measurement, Rocky Mountain Arsenal, Denver,

and reliable results, however, because of the degree of skill Colorado, 22 September-3 October 1975," U. S. Army Environ-

required to operate the instrument, it was not considered mental Hygiene Agency, 29 Apr. 1976.

practical as a routine process monitor. 6. John A. Ursillo, "Caustic Scrubbing of Lethal Chemical Agent

CG (Phosgene) at Rocky Mountain Arsenal, Denver, Colorado,"

• The colorimetric tape monitor would be employed as Demilitarization Directorate, Rocky Mountain Arsenal, CO,

the in-stack method of measuring phosgene emissions. All undated.

indications were that the instrument was continuous, 7. "Air Pollution Engineering Special Study No. 99-041-75/76,

"quasi-real-time," simple to operate, able to withstand the Phosgene Measurement, Rocky Mountain Arsenal, Denver,

Colorado, 19-30 April 1976," U. S. Army Environmental Hygiene

work area environment, and displayed sufficient accuracy and Agency, 5 Aug. 1976.

sensitivity to meet all the monitoring requirements. However, 8. "Estimates of Permissible Concentrations of Pollutants for

it was decided to employ DEP bubblers solely as a backup Continuous Exposure," Office of Research and Development, U.

technique. S. Environmental Protection Agency, Publication No. EPA

600/2-76-155, June 1976.

• And finally, the scrubber system performed satis- 9. W. L. O'Connell, "How to attack air-pollution control problems,"

factorily for the 1 to 2 hour test runs, as illustrated in Table Chemical Engineering Deskbook, 18 Oct. 1976.

II. However, at maximum credible accident challenges, the 10. "Criteria for a Recommended Standard . . . . Occupational Ex-

posure to Phosgene," US Department of Health, Education and

scrubbing efficiency drops off more rapidly than at expected Welfare, National Institute for Occupational Safety and Health,

challenge rates. This effect is attributed to the markedly in- HEW Publication No. (NIOSH) 76-137,1976.

creased temperatures in the scrubbers. The length of time

available to implement corrective action varies from ap-

proximately 45 minutes with a fresh sump condition (i.e., low

carbonate concentration) to about 15 minutes with a high

carbonate concentration in the sump (indicative of scrubber

conditions at the end of a day). Special emergency procedures

have been developed to cope with this type of situation should

it ever occur.

Messrs Kistner, Esposito, Podolak, and Dr. Tuggle are

Summary and Conclusions with the U. S. Army Environmental Hygeine Agency, Aber-

deen Proving Ground, MD 21010. Dr. Lillian's present ad-

dress is U. S. Department of Energy, Washington, D. C. Mr.

As this paper is being written, the transfer operation is Ursillo is now at the Rocky Mountain Arsenal, Denver, CO.

approximately half finished. It is estimated that 3 more Mr. Smith is with the U. S. Environmental Protection Agen-

months will be required to complete the entire project in an cy, Region III. Philadelphia, PA. Mr. Sexton is with the

environmentally responsible manner. School of Public Health, Chapel Hill, NC. Mr. Mallen is at

Tooele Army Depot, Tooele, UT.

As hazardous substances continue to pose serious technical The opinion or assertions contained herein are the private

problems in the areas of control and/or disposal, methodolo- views of the authors and are not to be construed as official or

gies will be required to find solutions to these problems sys- as reflecting the views of the Department of the Army or the

tematically. Many industries and regulatory agencies have Department of Defense. The presentation contains no mate-

already begun to recognize these facts.8-9 It is hoped that the rial that warrants its disapproval for security or policy rea-

sons.

basic procedure presented herein will be of assistance not only This is a revised version of Paper No. 77-19.6 which was

for application to the phosgene industry, but as a more general presented at the 70th Annual Meeting of APCA at Toronto

approach to defining and solving technical problems associ- in June 1977.

ated with many types of hazardous materials.

676 Journal of the Air Pollution Control Association

You might also like

- Booklet For Assignment CHC30113 Subject 1 LG F 2.2Document337 pagesBooklet For Assignment CHC30113 Subject 1 LG F 2.2Kanza Amir100% (2)

- Riswadkar Et Al-1998-Process Safety ProgressDocument6 pagesRiswadkar Et Al-1998-Process Safety Progresszhexiong_zengNo ratings yet

- Air Recirculation in Fume and Dust Extraction SystemsDocument26 pagesAir Recirculation in Fume and Dust Extraction SystemsBülent KabadayiNo ratings yet

- Incineration of Hazardous WasteDocument30 pagesIncineration of Hazardous WasteSai DattaNo ratings yet

- Imppp PDFDocument12 pagesImppp PDFbandayNo ratings yet

- Improve of Air DischaregeDocument27 pagesImprove of Air DischaregeMukti M MuzakkiNo ratings yet

- 025-Air Quality Management (Issues in Environmental Science and Technology) R.E. Hester R HarrisoDocument164 pages025-Air Quality Management (Issues in Environmental Science and Technology) R.E. Hester R HarrisoGiordano BrunoNo ratings yet

- Integrated Pollution Control and Waste MinimizationDocument16 pagesIntegrated Pollution Control and Waste Minimizationapi-3800753No ratings yet

- CRS - 2004 Air Pollution Emission Control Existing Technologies and Mercury CoBenefitsDocument7 pagesCRS - 2004 Air Pollution Emission Control Existing Technologies and Mercury CoBenefitsMercury ExposureNo ratings yet

- Gundersen MOX Limited Appearance Statement To NRC ASLB 9-14-2007Document8 pagesGundersen MOX Limited Appearance Statement To NRC ASLB 9-14-2007Fairewinds Energy EducationNo ratings yet

- Chapter TarunDocument6 pagesChapter TarunDhanya SagarNo ratings yet

- Dust ControlDocument4 pagesDust ControlHendry DrajatNo ratings yet

- Hazardous Waste Control L3Document5 pagesHazardous Waste Control L3Reno Valencia Perez100% (1)

- Sop 1Document19 pagesSop 1herybudiantoNo ratings yet

- NUREG-0683, Vol. 1, PEIS-Decontamination and Disposal of Radioactive Wastes Resulting From TMI-2 (1981-03)Document604 pagesNUREG-0683, Vol. 1, PEIS-Decontamination and Disposal of Radioactive Wastes Resulting From TMI-2 (1981-03)William IvansNo ratings yet

- 1 - Introduction - 2021 - Techniques For Corrosion MonitoringDocument5 pages1 - Introduction - 2021 - Techniques For Corrosion MonitoringKhalil Abdul RazakNo ratings yet

- Guidelines For Selection of Air Pollution Control EquipmentDocument1 pageGuidelines For Selection of Air Pollution Control EquipmentGCB GCBNo ratings yet

- Classification of Hazardous Locations Cox Lees Ang 1691051422Document213 pagesClassification of Hazardous Locations Cox Lees Ang 1691051422tahaNo ratings yet

- Castro, Alan Ishmael - Summative Essay 2Document13 pagesCastro, Alan Ishmael - Summative Essay 2Alan Ishmael Guillermo CastroNo ratings yet

- Envi (Dec.9)Document14 pagesEnvi (Dec.9)michelledugsNo ratings yet

- Republic Act 8749: The Philippine Clean Air Act of 1999Document105 pagesRepublic Act 8749: The Philippine Clean Air Act of 1999Tabs NetNo ratings yet

- American J Industrial Med - 2019 - Doney - Respirable Coal Mine Dust at Surface Mines United States 1982 2017Document8 pagesAmerican J Industrial Med - 2019 - Doney - Respirable Coal Mine Dust at Surface Mines United States 1982 2017dhrutiNo ratings yet

- Articulo Trabajo AtmosferaDocument20 pagesArticulo Trabajo AtmosferaLUZ ANDREA GARCIA CAYCEDONo ratings yet

- EPA Finalizes Amendments to Air Toxics Standards for Ferroalloys ProductionDocument3 pagesEPA Finalizes Amendments to Air Toxics Standards for Ferroalloys Productioneinstein_486No ratings yet

- Air Pollution Control Technology: Research and Development On New and Improved SystemsDocument10 pagesAir Pollution Control Technology: Research and Development On New and Improved SystemsJasthi HarishaNo ratings yet

- NOx_Geophysical Research Letters - 2001 - WildDocument4 pagesNOx_Geophysical Research Letters - 2001 - WildSorry for uploading your docNo ratings yet

- Republic Act 8749Document4 pagesRepublic Act 8749sean PalomaNo ratings yet

- Allen, Hollingsworth Et Al 2018 - The Development and TrialDocument10 pagesAllen, Hollingsworth Et Al 2018 - The Development and TrialZeynep CihanNo ratings yet

- Toxic and Flammable Gases in Research LabDocument7 pagesToxic and Flammable Gases in Research LabjeyalaljNo ratings yet

- Carbon Monoxide Research PaperDocument4 pagesCarbon Monoxide Research Paperfvfmxb2y100% (1)

- 06 Air Pollution (Polusi Udara)Document11 pages06 Air Pollution (Polusi Udara)Ghani Abdul RofieNo ratings yet

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDocument6 pagesU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviNo ratings yet

- Air Quality Management in The United States, Report in BriefDocument4 pagesAir Quality Management in The United States, Report in BriefNational Academies of Science, Engineering, and MedicineNo ratings yet

- Environmental Assessment of Air Pollution in Khartoum North Thermal Power Generation 1. Air PollutionDocument8 pagesEnvironmental Assessment of Air Pollution in Khartoum North Thermal Power Generation 1. Air PollutionLemia ELtyeb ELfadelNo ratings yet

- Technology Update No. 7Document24 pagesTechnology Update No. 7aRiTo!No ratings yet

- Oxygen Reduction SystemDocument38 pagesOxygen Reduction SystemAndrew JacksonNo ratings yet

- Measurement of Air Pollutants: AbbreviationsDocument11 pagesMeasurement of Air Pollutants: AbbreviationsCheenuNo ratings yet

- D 6060 PDFDocument6 pagesD 6060 PDFHossam A.MoneimNo ratings yet

- 15 Air Quality Management ADocument9 pages15 Air Quality Management AEdgarvitNo ratings yet

- Pollution Prevention and Abatement Handbook WORLD BANK GROUP Effective JulyDocument5 pagesPollution Prevention and Abatement Handbook WORLD BANK GROUP Effective JulyEdgarvitNo ratings yet

- Control of Dust Emission and Impacts From Surface Mines and WorksDocument10 pagesControl of Dust Emission and Impacts From Surface Mines and WorksSwastik RathNo ratings yet

- D 3270 - 00 - RdmynzaDocument4 pagesD 3270 - 00 - RdmynzaAnilNo ratings yet

- Pollution Control in Oil, Gas and Chemical PlantsDocument15 pagesPollution Control in Oil, Gas and Chemical PlantsPRAFULKUMAR PARMARNo ratings yet

- Curtin Et Al. - 2016 - Scaling Up The Fabrication of Mechanically-Robust Carbon Nanofiber FoamsDocument14 pagesCurtin Et Al. - 2016 - Scaling Up The Fabrication of Mechanically-Robust Carbon Nanofiber FoamsPedro Jose Arias-MonjeNo ratings yet

- NatRes PPT 04 Brown Laws PDFDocument309 pagesNatRes PPT 04 Brown Laws PDFPatatas SayoteNo ratings yet

- En - EnvStand4 - Emissions To Air From Stationary SourcesDocument13 pagesEn - EnvStand4 - Emissions To Air From Stationary SourcesWellfroNo ratings yet

- Natural Radionuclide Concentrations in MaterialsDocument115 pagesNatural Radionuclide Concentrations in Materialssomu1No ratings yet

- 2009 Sept NIH Effects Reducing Ventilation RatesDocument7 pages2009 Sept NIH Effects Reducing Ventilation RatesJAVIER ARGUEDASNo ratings yet

- Guidelines On Monitoring of Airborne Contaminant For Chemicals Hazardous To HealthDocument47 pagesGuidelines On Monitoring of Airborne Contaminant For Chemicals Hazardous To HealthkelpileNo ratings yet

- Estimation of Public Exposure During Normal Operation of Unit-1 Barakah Nuclear Power Plant Using GALE and HOTSPOT - 1-s2.0-S1026918522000506-MainDocument9 pagesEstimation of Public Exposure During Normal Operation of Unit-1 Barakah Nuclear Power Plant Using GALE and HOTSPOT - 1-s2.0-S1026918522000506-MainMehdiNo ratings yet

- I-4 Definition of TermsDocument5 pagesI-4 Definition of TermspakboyakoNo ratings yet

- ExecSumm NCRP Report No 141Document10 pagesExecSumm NCRP Report No 141Rafa PopocaNo ratings yet

- ATSDR - Landfill Gas Primer - Chapter 5 - Landfill Gas Control MeasuresDocument11 pagesATSDR - Landfill Gas Primer - Chapter 5 - Landfill Gas Control MeasuresCezar FerreiraNo ratings yet

- Modeling The Dioxin EmissionDocument7 pagesModeling The Dioxin EmissionjNo ratings yet

- Flammable A N D Toxic Materials in The Oxygen Atmosphere of Manned SpacecraftDocument32 pagesFlammable A N D Toxic Materials in The Oxygen Atmosphere of Manned SpacecraftJunior MirandaNo ratings yet

- Investigation of Potencial Exposure To Carcinogens and Respiratory Sensitisers During Thermal Processing of PlasticsDocument50 pagesInvestigation of Potencial Exposure To Carcinogens and Respiratory Sensitisers During Thermal Processing of PlasticsGiovani AgostiniNo ratings yet

- National Coal Association v. United States Environmental Protection Agency, 810 F.2d 431, 4th Cir. (1987)Document5 pagesNational Coal Association v. United States Environmental Protection Agency, 810 F.2d 431, 4th Cir. (1987)Scribd Government DocsNo ratings yet

- Bahan AnriskDocument99 pagesBahan AnriskasriNo ratings yet

- Onsite Production of Medical Air - Is Purity A ProblemDocument3 pagesOnsite Production of Medical Air - Is Purity A ProblemViviania BitencourtNo ratings yet

- Construction Risk Assessment Sample ReportDocument9 pagesConstruction Risk Assessment Sample ReportEdgar ChecaNo ratings yet

- Potassium CyanideDocument5 pagesPotassium CyanideDenitaNo ratings yet

- Checkpoint 123Document5 pagesCheckpoint 123carolus ryanNo ratings yet

- Federation of Piling Specialists: Unexploded Explosive Ordnance (UXO)Document3 pagesFederation of Piling Specialists: Unexploded Explosive Ordnance (UXO)BogdanBNo ratings yet

- GOLD INDUSTRIAL MODULE A - PART 1 - Electrical ExamsDocument8 pagesGOLD INDUSTRIAL MODULE A - PART 1 - Electrical ExamsLimuel SapunganNo ratings yet

- Job Posting-Safety Specialist Q Chem 10 2015Document3 pagesJob Posting-Safety Specialist Q Chem 10 2015AF SLIMENo ratings yet

- Standards and References ListDocument6 pagesStandards and References ListAfshadNo ratings yet

- Leuze MLC 520Document63 pagesLeuze MLC 520thiago weniskleyNo ratings yet

- Iocsetra Hot WorkDocument11 pagesIocsetra Hot WorkMohammad AshpakNo ratings yet

- 2021 HR Annual ReportDocument6 pages2021 HR Annual ReportAlex MaugoNo ratings yet

- HSG PDFDocument1 pageHSG PDFIndiren VangheeNo ratings yet

- RFT - Vibration Analysis & Reporting Services - Scope of Work (SOW) PDFDocument15 pagesRFT - Vibration Analysis & Reporting Services - Scope of Work (SOW) PDFShiju100% (1)

- Topic 1 Health and Safety Movement, Then and Now PDFDocument27 pagesTopic 1 Health and Safety Movement, Then and Now PDFJahan Raaz KhanNo ratings yet

- JP-K107, 1107K: Print Date: 08.03.2018 Page 1 of 9Document9 pagesJP-K107, 1107K: Print Date: 08.03.2018 Page 1 of 9Junior BautistaNo ratings yet

- RULADocument4 pagesRULAMichael QuidorNo ratings yet

- Power Presses: Maintenance and Thorough ExaminationDocument50 pagesPower Presses: Maintenance and Thorough ExaminationSathish PSKNo ratings yet

- Safety Data Sheet: SOLO CO Detector TesterDocument7 pagesSafety Data Sheet: SOLO CO Detector TesterMisterrriotNo ratings yet

- 1.school DRRM PlanDocument20 pages1.school DRRM PlanAlexis V. LarosaNo ratings yet

- Steel Door Installation GuideDocument9 pagesSteel Door Installation GuideLloyd MariNo ratings yet

- 6 - Environmental Health PDFDocument8 pages6 - Environmental Health PDFAbo AmgadNo ratings yet

- Nitrogen Gas FillingDocument21 pagesNitrogen Gas Fillingsanjeev kumarNo ratings yet

- Exhibit III - HseDocument12 pagesExhibit III - HseMurtadda MohammedNo ratings yet

- SML Safety ShortDocument17 pagesSML Safety Shortzale barunaNo ratings yet

- Task Analysis and SWMSDocument5 pagesTask Analysis and SWMSg5nbNo ratings yet

- Objectives: Lesson 1: Introduction To Cake MakingDocument18 pagesObjectives: Lesson 1: Introduction To Cake MakingMarj MagalongNo ratings yet

- Professional Diploma in Management Human Resource Management Class Test (15Document10 pagesProfessional Diploma in Management Human Resource Management Class Test (15Arfreden DenNo ratings yet

- Module TwoDocument97 pagesModule TwoJeh UbaldoNo ratings yet

- TN 01 1996Document40 pagesTN 01 1996Tee Klong RungNo ratings yet

- Reaction On The 83RD Post Graduate Course On Occupational Health and SafetyDocument1 pageReaction On The 83RD Post Graduate Course On Occupational Health and SafetyEdcelle SabanalNo ratings yet