Professional Documents

Culture Documents

Procedure For Cutting and Respooling Fiber Optic Cable: 1. General

Uploaded by

afra09Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Cutting and Respooling Fiber Optic Cable: 1. General

Uploaded by

afra09Copyright:

Available Formats

Procedure for Cutting and

PRETERMINATED SYSTEMS | CABLES | CONNECTORS | CABLE ASSEMBLIES | HARDWARE | TOOL KITS AND ACCESSORIES | TEST EQUIPMENT | SPLICE EQUIPMENT | FAN-OUT KITS | TRAINING

Respooling Fiber Optic

Cable

p/n 005-051, Issue 2

Table of Contents

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Tools and Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Cable Cutting and Respooling: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Appendix A - Minimum Drum Sizes by Measured Cable Outer Diameter (OD). . . . . . . . . . . . . . . 8

Appendix B - Respooling Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. GENERAL

1.1 Improper use of a

Payoff

respooler (Figure 1) can Respooler

cause damage to a cable (take-up)

jacket or result in wavy fiber in

tight buffered cables due to

Counter

cable crossovers or excessive

tensile loading. This document

provides a recommended

procedure for cutting and

respooling Corning Cable

Systems fiber optic cables.

Figure 1

HPA-0477

Traverse

Flange bolt Flange

Tail flanges

(rings)

Drum Drum

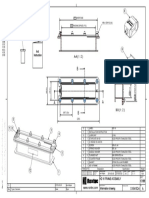

1.2 Figure 2 illustrates the reel and equipment diameter

Drive

terminology used in this procedure. Note that some Arbor hole

hole

features, e.g., tail flanges, are not present on every

reel, and that wooden and steel reels vary in Start

design.. (feed) hole

HPA-0478

Figure 2

1.3 This issue includes an updated format and revised illustrations.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 1 OF 9

2. PRECAUTIONS

2.1 Safety Precautions

CAUTION: Before starting any cable respooling operation, all personnel must be thoroughly

familiar with Occupational Health and Safety Administration (OSHA) regulations and company

safety practices and policies.

CAUTION: To avoid personal injury, observe standard safety precautions. Wear personal

protective equipment (headgear, eyewear, gloves, etc., as specified by your company’s

practices.

2.2 Cable Handling Precautions

NOTE: Care must be taken to avoid cable damage during respooling and handling. Fiber optic cable

is sensitive to excessive pulling, bending, and crushing forces. Consult the cable specification

sheet for the cable you are installing. Do not bend the cable more sharply than the minimum

recommended bend radius. Do not apply more pulling force to the cable than specified. Do not

crush the cable or allow it to kink. Doing so may cause damage that can alter the transmission

characteristics of the cable; the cable may have to be replaced.

2.3 Cable Reel Precautions

NOTE: Inspect and repair all reels prior to use. Check the inside of the reel flanges for objects that could

damage the cable as it pays off. Changes in temperature and humidity can cause the wooden

components of the reel to swell and contract allowing the flange bolts to loosen over time. Loose

flange bolts may cause the cable to become entangled and possibly damage the cable during

respooling–ensure all flange bolts are tight prior to loading the reel.

Tail flange

NOTE: To prevent crushing the cable tail between

the reel and the fork truck, never pick up a reel

from its tail-flange side. Always use proper

reel-carrying procedures when using a forklift.

HPA-0479

3. TOOLS AND MATERIALS

3.1 In addition to the cable being respooled, the following tools and materials are required for this

procedure:

• Respooler • Reel handling equipment (forklift or hand truck)

• Counter • Staples, hammer, cable ties (depending on reels)

• Cable cutter • Hand micrometer or dial calipers

• Reel • Vinyl tape (depending on cable)

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 2 OF 9

4. CABLE CUTTING AND RESPOOLING:

4.1 Locate the cable to be cut and respooled. Verify the part number and length on customer order with

cable reel data sheet. Double check this information before proceeding.

4.2 The take-up reel must have sufficient drum size to maintain cable minimum bend radius and to have

enough capacity for the cable being respooled while also allowing for flange free space (typically 2 inches).

Reels with too small of a drum can cause damage to the cable and result in high attenuation. To determine the

necessary take-up reel size:

a. Measure the outer diameter (OD) of the cable being respooled, using a calibrated measurement

tool such as a band micrometer or dial calipers.

b. Refer to Appendix A which lists the acceptable minimum reel drum size for the measured cable

outer diameter.

c. Select a take-up reel with sufficient drum size to maintain cable minimum bend radius. The drum

diameter should be a minimum of 8 inches or 30 times the cable outer diameter.

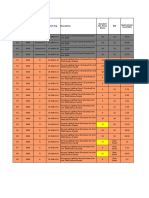

d. Refer to Tables 1 and 2 for general reel sizes and capacities to verify the drum choice.

Reel Sizes Reel Dimensions (Flange x Traverse x Drum)

A 20 in. x 20 in. x 16.5 in.

B 18 in. x 12 in. x 10 in.

C 24 in. x 16 in. x 12 in.

D 6 in. x 28.5 in. x 30 in.

E 41 in. x 28.5 in. x 30 in.

Table 1: Reel sizes

Reel Capacity (in feet)

Cable Outside Reel Size

Diameter (inches)

A B C D E

0.12 8200 1080 20670 – –

0.24 1970 2330 5575 7545 18045

0.36 855 1115 2360 3300 8200

0.48 590 660 1640 2230 5250

0.60 330 460 855 1180 2890

0.72 – 330 720 985 2330

0.84 – – 460 590 1575

0.96 – – 330 525 1150

1.08 – – – 360 855

1.20 – – – – 720

Table 2: General reel capacities

4.3 Move the cable to the payoff using a forklift, hand truck, etc.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 3 OF 9

4.4 To load the reel on payoff:

a. Roll the reel under the payoff so that the cable comes off the top of the reel towards the counter and

respooler (takeup) (see Figure 1).

b. Place the payoff pintles into the reel’s arbor holes.

c. Raise the reel.

4.5 Load the empty reel into the respooler (take-up), making sure that the start hole and tail flanges and

drive holes are on the correct side of the respooler.

Start hole

top view

4.6 Move the respooler reel flange with the feed hole so that it is aligned

with the point where the cable exits the counter (Figure 3). Cable path

Counter

Figure 3

HPA-0480

4.7 Proper traverse travel is critical for the cable to be snug and straight top view

on the take-up reel. Set the traverse travel distance by adjusting left and right

traverse limits so that the traverse travel direction will reverse at the proper

locations to allow for the applicable reel width (Figure 4). Traverse limits

Cable path

Counter

HPA-0481 Figure 4

4.8 Set the respooler speed for the cable based on the cable outer diameter which is determined from either

the cable specification or from measuring the cable.

Excessive take-up speed may cause cable damage due to excessive tensile force being placed on the

cable.

4.9 Before creating a tail, check the length marking on the end of the cable. Using the length marking and

the order length, calculate the length marking at which the cable is to be cut. Record this calculated length

marking.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 4 OF 9

Tail

Respooler

top view

4.10 After resetting (“zeroing”) the counter, pull the top end of the cable

from the payoff through the counter rollers and guides and then through the

start hole in the take-up reel flange (inside to outside)(Figure 5).

Counter

HPA-0482 Payoff

Figure 5

4.11 Pull a ten to fifteen foot length of cable through the start hole to create a tail for subsequent testing of

the cable on the reel.

Special Note for MIC cable only:

If respooling MIC® cable, bend the first inch of cable 180° over itself and

secure the cable end with a tape wrap. This will minimize possible fiber

movement during the respooling process (Figure 6). HPA-0483

Figure 6

Tail

4.12 To secure the tail on reels that are: Strap

Wooden with tail flanges

Route the tail between the tail flanges and secure the

tail with plastic straps (Figure 7). To help keep the Cable

cable snug on the drum during respooling, staple an HPA-0484

open cable tie near the start hole and then use it to

secure the cable (Figure 7, inset).

Cable tie

Figure 7

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 5 OF 9

Wooden with no tail flanges

Apply a cable tie on the cable end and staple the tie to the reel near the

start hole (Figure 8).

HPA-0485

Figure 8

Steel Reels

Secure the tail inside the reel with cable ties (Figure 9).

Figure 9

HPA-0486

NOTE: The respooler take-up and payoff should be powered, or power assisted, and linked by single

control to prevent jerking during startup and to minimize tension spikes on the cable during

respooling.

4.13 To respool a cable:

a) Start the respooler and pay off at a slow speed. Ensure that the cable is snug on the respooler drum

and has no gaps. If any corrections need to be made, stop the units and make the corrections.

Maximum

Tensile

Cable Type

Load (lbf)

900 μm Buffered Fiber 1,4

Interconnect and Fan-out 25

Tubing

OFNR Indoor Distribution 75

b) Monitor the tension on the cable while running. < 12 fibers

Consult Table 3 for guidelines on the maximum OFNR Indoor Distribution 150

tensile load for different cable types. > 24 fibers

OFNP Indoor Distribution 50

< 12 fibers

OFNP Indoor Distribution 75

> 24 fibers

FREEDM® LST < 12 fibers 150

NOTE: Values in this table are based on one- All Other Flame Retardant 300

half the maximum short term tensile Loose Tube

load of the various cables designs to Outdoor Loose Tube 300

allow for a margin of safety. Table 3 Maximum Respooling Tensile Loads

for Various Cable Designs.

.

CAUTION: Do not respool cable at tension levels higher than specified in Table 3. A high tension or

fast take-up speed will result in cable damage.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 6 OF 9

4.14 Use the respooler counter to locate the general area of the cut. At approximately 100m (328 ft.) before

the location of the cut, slow the respooler and visibly observe the cable length markings. When the designated

foot/meter mark is reached, stop the respooler.

NOTE: The counter is for reference only. Rely on the length marking printed on the cable. Remember that

the counter must be reset after each cut of cable that is run through it.

4.15 Double check the length marks to confirm the length of respooled cable before cutting. Do not cut

the cable until you are certain you have respooled the correct length.

Cut the cable and complete the take-up process. When finished, secure the top end of cable to the inside

flange that is closer to the cable end, with tie wrap or a staple for wooden reels.

NOTE: To prevent adhesive residue on the cable, do not use duct tape on the cable.

4.16 To maximize efficiency, cut all orders from a given master reel prior to changing the master reel. Re-

move the reel from the respooler, and if all orders of the cable are complete, also remove the payoff reel.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 7 OF 9

Appendix A - Minimum Drum Sizes by Measured Cable Outer Diameter (OD)

The table below indicates the minimum drum diameter based on the measured cable diameter.

(Cable OD(mm) x (30÷25.4)) = Reel Drum Diameter (in.)

Measured Cable Minimum Drum Measured Cable Minimum Drum Measured Cable Minimum Drum

OD (mm) Diameter (in) OD (mm) Diameter (in) OD (mm) Diameter (in)

≤7.0 16.0 18.9 25.0 29.5

7.5 8.9 16.5 19.5 25.5 30.1

8.0 9.4 17.0 20.1 26.0 30.7

8.5 10.0 17.5 20.7 26.5 31.3

9.0 10.6 18.0 21.3 27.0 31.9

9.5 11.2 18.5 21.9 27.5 32.5

10.0 11.8 19.0 22.4 28.0 33.1

10.5 12.4 19.5 23.0 28.5 33.7

11.0 13.0 20.0 23.6 29.0 34.3

11.5 13.6 20.5 24.2 29.5 34.8

12.0 14.2 21.0 24.8 30.0 35.4

12.5 14.8 21.5 25.4 30.5 36.0

13.0 15.4 22.0 26.0 31.0 36.6

13.5 15.9 22.5 26.6 31.5 37.2

14.0 16.5 23.0 27.2 32.0 37.8

14.5 17.1 23.5 27.8 32.5 38.4

15.0 17.7 24.0 28.3

15.5 18.3 24.5 28.9

NOTES:

• All interconnect cables (e.g., single fiber cable, DIB®, Zipcord, etc.) require an 8.0-inch minimum

drum size.

• Using a reel drum size that is smaller than recommended can cause increased attenuation, and

permanent cable damage.

• When re-spooling cable, use the cable outer diameter to determine the minimum reel drum

diameter.

• If no reel is available of the size listed, use the next larger reel drum that is available.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 8 OF 9

Appendix B - Respooling Checklist

1. Verify the cable part number and cutting length.

2. Determine the take-up reel size.

CAUTION: The drum diameter should be the larger of either 8 inches or 30 times the cable O.D.

3. Load the payoff and take-up reels

4. Set the take-up speed and traverse limits

5. Create the cable tail (typically 10 to 15 feet) and reset the counter.

6. Start the take-up slowly and gradually increase speed.

Monitor respool tension to prevent causing cable damage.

Verify the cable length markings and double check the cut length before cutting the cable.

7. Check the cable length and cut the cable.

8. Secure the cable to the reel flange with tie wraps and staples.

Corning Cable Systems LLC • PO Box 489 • Hickory, NC 28603-0489 USA

1-800-743-2671 • FAX +1-828-325-5060 • International +1-828-901-5000 • http://www.corning.com/cablesystems

Corning Cable Systems reserves the right to improve, enhance, and modify the features and specifications of Corning Cable Systems’ products without prior notification. All

trademarks are the properties of their respective owners. Corning Cable Systems is ISO 9001 certified.

© 2011 Corning Cable Systems. All rights reserved. Published in the USA.

STANDARD RECOMMENDED PROCEDURE 005-051 | ISSUE 2 | NOVEMBER 2011 | PAGE 9 OF 9

You might also like

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (1)

- Network Rail's 12 Principles for Station DesignDocument43 pagesNetwork Rail's 12 Principles for Station DesignLaksmi Pratiwi100% (2)

- Ajuste IAC and TPSDocument17 pagesAjuste IAC and TPSLuis Ignacio SilvaNo ratings yet

- Standards Issued 2017 PDFDocument1 pageStandards Issued 2017 PDFEnrique L BlancoNo ratings yet

- Wire Rope Technical InfoDocument11 pagesWire Rope Technical Infoأزيزى سودينNo ratings yet

- Airbus GlossaryDocument32 pagesAirbus GlossaryLuís Rodrigues100% (2)

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- 2015 - 3 Lennar Concord Proposal PDFDocument148 pages2015 - 3 Lennar Concord Proposal PDFEric LiptonNo ratings yet

- Reference Guide To Fiber Optic Testing: VIAVI SolutionsDocument104 pagesReference Guide To Fiber Optic Testing: VIAVI SolutionsDjnsilva Silva100% (1)

- Samsung WF8800, WF8802, WF8700, WF8714 PDFDocument50 pagesSamsung WF8800, WF8802, WF8700, WF8714 PDFhugotonoli100% (3)

- Module 7 (Maintenance Practices) Sub Module 7.13 (Control Cables) PDFDocument10 pagesModule 7 (Maintenance Practices) Sub Module 7.13 (Control Cables) PDFshareyhouNo ratings yet

- Neca301-16 PDocument42 pagesNeca301-16 PMaxNo ratings yet

- MiG 21Document29 pagesMiG 21Zoran Vulovic100% (2)

- Installation Guide Rev.1.INSTALLATION - GUIDE OFCDocument16 pagesInstallation Guide Rev.1.INSTALLATION - GUIDE OFCSourav RoyNo ratings yet

- Installation Guide Rev.1.INSTALLATION - GUIDE OFCDocument16 pagesInstallation Guide Rev.1.INSTALLATION - GUIDE OFCSourav RoyNo ratings yet

- DRM Wha B PDFDocument31 pagesDRM Wha B PDFzohebNo ratings yet

- Cables de AceroDocument160 pagesCables de AceroAnonymous Hd32bhq100% (1)

- Installation Duct Underground Cable MP 1008 Is 2Document12 pagesInstallation Duct Underground Cable MP 1008 Is 2jebicoreNo ratings yet

- DrakaTechTipNo.1 CompensatingChain PDFDocument2 pagesDrakaTechTipNo.1 CompensatingChain PDFKar Keong LewNo ratings yet

- MCCB Technical InformationDocument106 pagesMCCB Technical InformationsunhuynhNo ratings yet

- Due Amount: We're ListeningDocument2 pagesDue Amount: We're ListeningYogesh PawarNo ratings yet

- Shell Marine Pocketbook For International MarineDocument60 pagesShell Marine Pocketbook For International MarineGage Cendk HNo ratings yet

- Oil & Gas Amine Sweetening Unit ManualDocument56 pagesOil & Gas Amine Sweetening Unit ManualAariz Khan100% (2)

- 2.seismic Coefficient CalculationDocument14 pages2.seismic Coefficient CalculationVenkat PalliNo ratings yet

- MANUAL DE COILED TUBING (Schlumberger) PDFDocument10 pagesMANUAL DE COILED TUBING (Schlumberger) PDFJose Sostenes0% (1)

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385No ratings yet

- DL Throughput Improvement with Aperiodic CQI ReportingDocument10 pagesDL Throughput Improvement with Aperiodic CQI ReportingAqeel HasanNo ratings yet

- Steel Wire RopesDocument18 pagesSteel Wire RopesAwliya TaqwaNo ratings yet

- PN447B PDFDocument17 pagesPN447B PDFBagus TridadiNo ratings yet

- Installation of CORNING Cable System-FODocument17 pagesInstallation of CORNING Cable System-FOdaeng_ifNo ratings yet

- Pendawaian Bawah Tanah PDFDocument14 pagesPendawaian Bawah Tanah PDFHisham AyobNo ratings yet

- Installation PracticeDocument16 pagesInstallation PracticeramsesiNo ratings yet

- MODULE-6-TELECOMDocument29 pagesMODULE-6-TELECOMMADRIAGA, CYRILLE MAE RUMANo ratings yet

- 114-6053 High-Performance Modular Plug ConnectorsDocument10 pages114-6053 High-Performance Modular Plug ConnectorsDiegoNo ratings yet

- Guidance On The Selection Erection and Sagging of OH Line ConductorsDocument22 pagesGuidance On The Selection Erection and Sagging of OH Line ConductorsMahNoorNo ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- Cable Splicing Procedure 005Document6 pagesCable Splicing Procedure 005RenzNo ratings yet

- Philips DVD740VRDocument107 pagesPhilips DVD740VRf17439No ratings yet

- Corning Fan Out Kit - Standard Recommended Procedure 000-084Document6 pagesCorning Fan Out Kit - Standard Recommended Procedure 000-084markNo ratings yet

- Pocket Guide To Cable ManagementDocument24 pagesPocket Guide To Cable ManagementEnbotic AutomatykaNo ratings yet

- Sony Battery Charger BC-M50 Service ManualDocument30 pagesSony Battery Charger BC-M50 Service ManualjorgeluismlimaNo ratings yet

- Hvs-3520S Series 35Kv Class Splice For Extruded Dielectric (Poly/Epr) Power Cables: Metallic Tape, Wire Shield, Unishield or Lead Sheath CablesDocument19 pagesHvs-3520S Series 35Kv Class Splice For Extruded Dielectric (Poly/Epr) Power Cables: Metallic Tape, Wire Shield, Unishield or Lead Sheath CablesJuanes CevallosNo ratings yet

- Kabelstecker Assembly Instruction and Assignment PlanDocument16 pagesKabelstecker Assembly Instruction and Assignment PlanvfernandezNo ratings yet

- 005 038Document11 pages005 038shaicoNo ratings yet

- WP-Circuit-Breaker Terminals and ConnectionDocument28 pagesWP-Circuit-Breaker Terminals and ConnectionfernandoNo ratings yet

- Pinger DatasheetDocument17 pagesPinger Datasheetjose razoNo ratings yet

- Cable Preparation Best Practices For Fiber Optic Indoor/Outdoor Stranded Loose Tube CableDocument14 pagesCable Preparation Best Practices For Fiber Optic Indoor/Outdoor Stranded Loose Tube CableSAMNo ratings yet

- BPG - Wire Cable Marking (Wirecable)Document12 pagesBPG - Wire Cable Marking (Wirecable)Katty CachagoNo ratings yet

- Guide To Connectorization and Polishing Optical Fibers Cable Assembly - Manual Fiber Polishing - Manual Fiber CleavingDocument36 pagesGuide To Connectorization and Polishing Optical Fibers Cable Assembly - Manual Fiber Polishing - Manual Fiber CleavingMauricio Cruz FigueroaNo ratings yet

- BPG - Wire-Cable-Marking (Wirecable)Document12 pagesBPG - Wire-Cable-Marking (Wirecable)Banji EwinNo ratings yet

- 2090 qr001 - en PDocument12 pages2090 qr001 - en PhamdulmoeedNo ratings yet

- Method Statement of LV Cables and Wires InstallationDocument12 pagesMethod Statement of LV Cables and Wires InstallationMohamed AbbasNo ratings yet

- Cable Cleat SpecificationsDocument4 pagesCable Cleat Specificationsferva bashirNo ratings yet

- The Fiber Optic Association, Inc.: Fiber Optic Installers Checklist For Tools, Test Equipment & SuppliesDocument8 pagesThe Fiber Optic Association, Inc.: Fiber Optic Installers Checklist For Tools, Test Equipment & SuppliesZezo MarchettiNo ratings yet

- Subsurface Cable Construction Techniques and Best PracticesDocument13 pagesSubsurface Cable Construction Techniques and Best PracticespahiescorpNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- Technical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant ConfigurationDocument20 pagesTechnical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant Configurationchristophe TrachezNo ratings yet

- Fibre Optic Underground Cable Technical SpecificationDocument7 pagesFibre Optic Underground Cable Technical SpecificationAbhinav SinhaNo ratings yet

- Remote Control Pendant ManualDocument16 pagesRemote Control Pendant ManualRoberto MoctezumaNo ratings yet

- Pioneer Deh-50ubDocument72 pagesPioneer Deh-50ubFazier3548100% (2)

- S-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Document10 pagesS-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Wael AlmassriNo ratings yet

- Service Manual: KEH-1032 KEH-2031Document50 pagesService Manual: KEH-1032 KEH-2031Kyaw San OoNo ratings yet

- Hawke Cable GlandsDocument48 pagesHawke Cable GlandsNicolae VisanNo ratings yet

- Installing Optical Cables For Main-Remote Solutions (2014)Document19 pagesInstalling Optical Cables For Main-Remote Solutions (2014)Denis NonameNo ratings yet

- Toshiba TV 20AF45 - 20AF45C - SVM PDFDocument50 pagesToshiba TV 20AF45 - 20AF45C - SVM PDFcarlos avilaNo ratings yet

- For Global Connection Solutions: Cable GlandsDocument81 pagesFor Global Connection Solutions: Cable GlandsrhomadonaNo ratings yet

- For Global Connection Solutions: Cable GlandsDocument81 pagesFor Global Connection Solutions: Cable GlandsrhomadonaNo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- Installing Optical Cables For Main-Remote Solutions: Installation InstructionsDocument21 pagesInstalling Optical Cables For Main-Remote Solutions: Installation InstructionsLavi KurdmanNo ratings yet

- REA105 OperencDocument24 pagesREA105 Operencluijos1No ratings yet

- BE1!50!51B-244 Instruction ManualDocument64 pagesBE1!50!51B-244 Instruction ManualMina HannaNo ratings yet

- PMCcat WebDocument12 pagesPMCcat Webafra09No ratings yet

- Analogue DIN Panel Meters: Installation InstructionsDocument2 pagesAnalogue DIN Panel Meters: Installation Instructionsafra09No ratings yet

- S-1110HP-SFP Hi-PoE Media ConvertersDocument17 pagesS-1110HP-SFP Hi-PoE Media Convertersafra09No ratings yet

- Upah Berkeadilan Ditinjau Dari Perspektif Islam: Armansyah WaliamDocument28 pagesUpah Berkeadilan Ditinjau Dari Perspektif Islam: Armansyah WaliamAndini DilNo ratings yet

- Cable Gland Catalogue 2012Document22 pagesCable Gland Catalogue 2012afra09No ratings yet

- PMCcat WebDocument12 pagesPMCcat Webafra09No ratings yet

- S 1541524Document1 pageS 1541524afra09No ratings yet

- Lighting and Receptacle Panel Outgoing CircuitsDocument1 pageLighting and Receptacle Panel Outgoing Circuitsafra09No ratings yet

- Integrated IP Solutions For Smarter Railways: Industrial Networking and Computing SolutionsDocument13 pagesIntegrated IP Solutions For Smarter Railways: Industrial Networking and Computing Solutionsafra09No ratings yet

- TON SupportingDocument4 pagesTON Supportingafra09No ratings yet

- 1N4001S THRU 1N4007S: General Purpose Silicon RectifierDocument2 pages1N4001S THRU 1N4007S: General Purpose Silicon RectifierBhadreshkumar SharmaNo ratings yet

- Declaration Letter - Vetagro To GSDocument3 pagesDeclaration Letter - Vetagro To GSVíctor RodríguezNo ratings yet

- Sunningdale School Notes Summer 2022Document12 pagesSunningdale School Notes Summer 2022sunningdaleschoolNo ratings yet

- Build a Homebrew Pre-Amplified MicrophoneDocument3 pagesBuild a Homebrew Pre-Amplified MicrophoneMacario Imbudo BukatotNo ratings yet

- Rift Vally BC N RegularDocument308 pagesRift Vally BC N RegularCabdisacid yasinNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- CompressorsDocument20 pagesCompressorsCarlos Alberto Huamaní GonzalesNo ratings yet

- African Healthcare Setting VHF PDFDocument209 pagesAfrican Healthcare Setting VHF PDFWill TellNo ratings yet

- The Pros and Cons of Reductive Matte Smelting For PGMsDocument4 pagesThe Pros and Cons of Reductive Matte Smelting For PGMsCristian Andres Florez VergaraNo ratings yet

- Service Manual: Mds-Ja20EsDocument84 pagesService Manual: Mds-Ja20Esfoxmulder6161695No ratings yet

- Pol Science ProjectDocument18 pagesPol Science ProjectAnshu SharmaNo ratings yet

- Q's For CONS VivaDocument251 pagesQ's For CONS VivaHanin AbukhiaraNo ratings yet

- Unit 1 Unit 2 Unit 3 DIFFERENTIAL CALCULUS 1 2 3 PDFDocument124 pagesUnit 1 Unit 2 Unit 3 DIFFERENTIAL CALCULUS 1 2 3 PDFjayaram prakash kNo ratings yet

- User Manual For Digital Logic Trainer KitDocument6 pagesUser Manual For Digital Logic Trainer KitHonnura HarijanaNo ratings yet

- Pulsar220S PLANOS PDFDocument32 pagesPulsar220S PLANOS PDFJuan Jose MoralesNo ratings yet

- All ProblemsDocument107 pagesAll ProblemsjoshiabhijeetNo ratings yet

- 85 KW RequestDocument3 pages85 KW Requestاختر بلوچNo ratings yet

- All Questions SLDocument50 pagesAll Questions SLRoberto Javier Vázquez MenchacaNo ratings yet

- Operating - System - Concepts - Essentials8thed - CH 6 SolutionDocument2 pagesOperating - System - Concepts - Essentials8thed - CH 6 SolutionAmirreza Saheb FosoulNo ratings yet

- Feed Water Heater ModellingDocument64 pagesFeed Water Heater ModellingSIVA KAVYANo ratings yet